In systems with a closed tank, water pumps for heating a house are an integral element that must accelerate the coolant to a certain speed, maintain a stable pressure in the system and create a head sufficient to overcome the resistance created by pipes and fittings.

But the pump will also be useful in open systems. Although they can only function by gravity, the appliance will significantly increase the heating efficiency.

In order for the unit to perform its functions, it is necessary to correctly calculate the circulation pump for the heating system. How to do this will be described below.

What is the calculation of the heating system pump for?

Most modern autonomous heating systems used to maintain a certain temperature in living quarters are equipped with centrifugal pumps that ensure uninterrupted circulation of liquid in the heating circuit.

By increasing the pressure in the system, it is possible to reduce the temperature of the water at the outlet of the heating boiler, thereby reducing the daily consumption of gas consumed by it.

The correct choice of the circulating pump model allows an order of magnitude to increase the level of efficiency of the equipment during the heating season and to provide a comfortable temperature in rooms of any area.

What are the types

The pump for heating is in modern systems one of the decisive factors that ensure uniform movement of the coolant and, therefore, all heat-generating elements are heated in the same way.

Such units are endowed with a set of advantages, defined as:

- Contribute to maintaining a constant temperature of the coolant.

- Low level of electricity consumption.

- High operational reliability.

- Ease of use.

Their main functional task is to level the resistance of the piping to the heating agent flow.

There are two main designs of circular pumps:

- with dry rotor;

- with a wet rotor.

The working chamber of the device with a dry rotor is separated from the electric motor by a sealed partition. Such units usually have higher power and performance, but they make noise during operation, therefore their use is limited to installation in isolated rooms or buildings.

Glandless pumps operate in a coolant environment, which increases their service life. For the same reason, they are low-noise, which allows their use inside serviced buildings.

A significant disadvantage of such units is their low efficiency, which limits their use in large heating systems, however, in small private houses they are used very widely because of the above-mentioned low noise and durability.

It should be noted that the selection criteria are not limited to taking into account their positive and negative qualities. The choice of a circulation pump for heating necessarily includes its calculation according to several criteria.

Selection of a pump according to its main characteristics

The main technical characteristics of any pump for heating are:

These parameters must ensure sufficient circulation of the coolant for efficient transfer of thermal energy from the boiler to the radiators, so they must correspond to both the power of the system itself and the hydraulic resistance in it during the circulation of the coolant. Therefore, in order to make the correct selection of a pump for a heating system, it is necessary to know both of these values.

Their exact calculations, which are used by specialists, are rather cumbersome and complicated. Therefore, with self-selection, you can use simplified calculations using the below simple formulas and recommended average indicators that will allow you to select the optimal characteristics of the circulation pump. Moreover, almost everyone can do such calculations.

Three options for calculating thermal power

Difficulties may arise with the determination of the thermal power indicator (R), therefore it is better to focus on generally accepted standards.

Option 1... In European countries, it is customary to take into account the following indicators:

- 100 W / sq. - for private houses of small area;

- 70 W / sq. M. - for high-rise buildings;

- 30-50 W / sq. - for industrial and well-insulated living quarters.

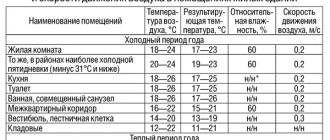

Option 2... European standards are well suited for regions with mild climates. However, in the northern regions, where there are severe frosts, it is better to focus on the norms of SNiP 2.04.07-86 "Heating networks", which take into account the outside temperature up to -30 degrees Celsius:

- 173-177 W / m2 - for small buildings, the number of storeys of which does not exceed two;

- 97-101 W / m2 - for houses from 3-4 floors.

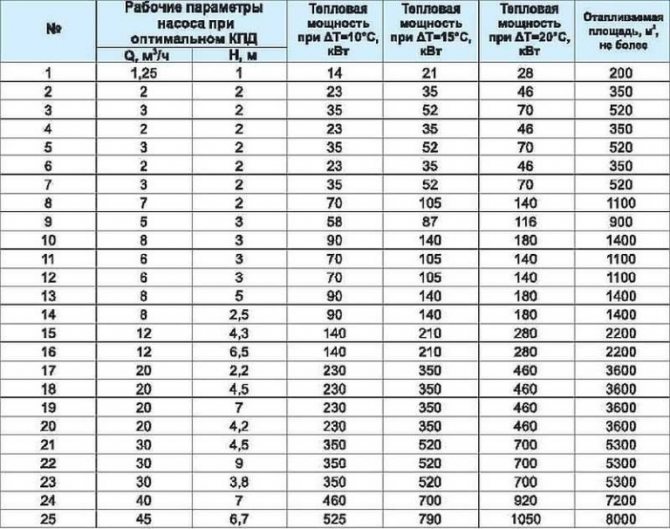

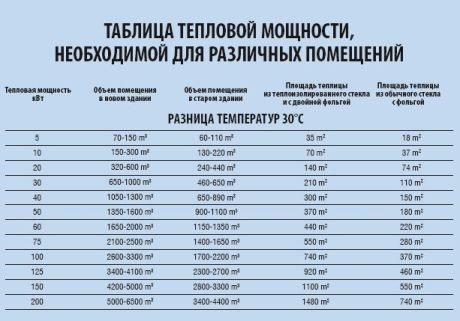

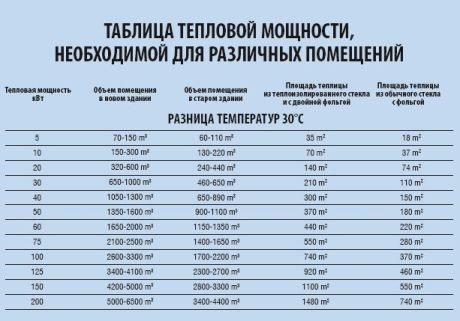

Option 3... Below is a table by which you can independently determine the required thermal power, taking into account the purpose, degree of wear and tear and thermal insulation of the building.

Table: how to determine the required heat output

How to determine the power of the heating system and the required pump flow

The required thermal power of the heating system depends on the amount of heat that is required for comfortable heating of the house and is in direct proportion to its size and the thermal insulation properties of the materials from which its walls, roof, ceiling, floor, windows, doors are made. It is not difficult to calculate the size of a house or part of it heated. A tape measure and a calculator are enough here.

It is more difficult to calculate accurately the heat loss through external structures, since here their material, thickness and design features must be taken into account. Therefore, for a simplified calculation, you can use the recommended average values of 1-1.5 kW of thermal power per 10 m2 of a heated room with a ceiling height of up to 3 m.If the room is well insulated, then you can use a lower value, and if it is not insulated or not enough, then it is better use a larger value.

For example, for a well-insulated house with an area of 120 m2, approximately 12 kW of thermal power will be needed. If the selection of a circulation pump is carried out for an existing natural circulation heating system, then the power of the installed boiler can be taken into account.

Calculation of the required pump capacity

Having decided on the thermal power of heating, you can start calculating the flow (capacity) of the circulation pump. To do this, you can use two simple formulas. The first of them: P = Q / (1.16 x ΔT), (kg / h or l / h) Where:

- Q– previously calculated heating power (W);

- ΔT is the difference between the temperature of the supply pipe and the "return", which for conventional systems, as a rule, is within 20 ° C, and for underfloor heating - about 5 °;

- 1.16 - coefficient taking into account the specific heat of water, W × h / kg × о С (for other coolants (antifreeze, oil) it will be somewhat different and, if necessary, can be found in reference books or on the Internet).

Another formula: P = 3.6 x Q / (s × ΔT), (l / h) Where: s is the heat capacity of the heat carrier (for water 4.2 kJ / kg × ° С). Using any of these formulas, it is possible to determine that, for example, for a two-pipe system with a thermal power of 12 kW, a pump with the following capacity (supply) will be required: P = 12000 / (1.16 × 20) = 517 l / h or 0.5 m3 / h

Calculation of the required head to overcome hydraulic resistance

In order to select a circulation pump for a heating system, in addition to capacity, it is necessary to determine its head (pressure), which it must create in order to overcome the existing hydraulic resistance. But first you need to know the magnitude of this resistance. For a simplified calculation, you can use the formula: J = (F + R × L) / p × g (m) Where:

- L is the length of the pipe line to the most distant radiator (m);

- R is the specific hydraulic resistance of the straight pipe section (Pa / m);

- p is the density of the coolant (for water - 1000 kg / m3);

- F - increase in resistance in connecting and shut-off valves (Pa);

- g - 9.8 m / s 2 (acceleration of gravity).

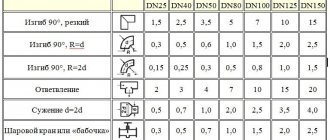

The exact values of R and F for different pipes, connecting and shut-off valves of different types can be found in the reference literature. For our simplified calculation, you can use the average data of these values obtained experimentally: R - 100-150 Pa / m (the larger the diameter of the pipes and the smoother their inner surface, the less resistance); F can be taken depending on the type of fittings:

- additionally up to 30% of losses in a straight pipe - for each connecting fitting in this section;

- up to 20% - for a three-way mixer or similar devices;

- up to 70% - for the regulator.

You can also use the formula proposed by the specialists of the well-known pump manufacturer Wilo for the calculation: J = R × L × k, m Where: k is the coefficient that takes into account the increase in resistance in the control and shut-off valves:

- 1.3 - simple heating systems with a minimum number of fittings;

- 2.2 - in the presence of control valves;

- 2.6 - for complex systems.

It should be borne in mind that if circulation in a system with two or more wiring circuits (branches) will be provided by only one pump, then their total resistance should be taken into account to select its pressure. If each circuit is provided with a separate pump, then the calculation of the thermal power and resistance of each of them must be performed separately. The number of storeys of a building, when calculating the pressure, does not play a big role. Because in a closed heating system, the liquid column of the supply line is balanced by the “return” column.

Number of speeds of the circulation pump

Most modern models of circulation pumps are equipped with the ability to adjust the speed of the device. Most often these are three-speed models, with which you can adjust the amount of heat entering the room. So, with a sharp cold snap, the pump speed is increased, and in case of warming, it is reduced so that the air temperature in the rooms remains comfortable for living.

For gear shifting, there is a special lever located on the device body. Models of circulation pumps equipped with an automatic speed control system for the operation of the device, depending on the change in the outside air temperature, are very popular.

It should be noted that this is just one of the options for this kind of calculations. Some manufacturers use a slightly different calculation method when selecting a pump. You can ask a qualified specialist to perform all the calculations, informing him of the details of the device of a specific heating system and describing the conditions for its operation. Typically, the maximum load indicators at which the system will operate are calculated. In real conditions, the load on the equipment will be lower, so you can safely purchase a circulation pump, the characteristics of which are slightly lower than the calculated indicators. The purchase of a more powerful pump is not advisable, as this will lead to unnecessary costs, but will not improve the performance of the system.

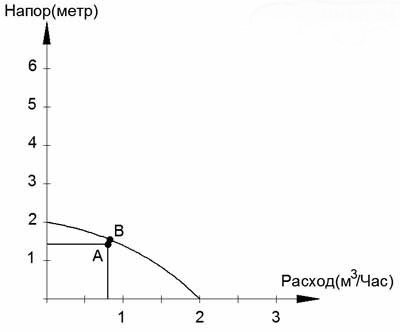

After all the necessary data has been obtained, the pressure-flow characteristics of each model should be studied, taking into account different operating speeds. These characteristics can be presented in the form of a graph. Below is an example of such a graph, in which the calculated characteristics of the device are also marked.

Using this graph, you can select a suitable model of a circulation pump for heating according to the indicators calculated for the system of a particular private house

Point A corresponds to the required indicators, and point B indicates the real data of a specific pump model, as close as possible to theoretical calculations. The smaller the distance between points A and B, the better the pump model is suitable for the specific operating conditions.

How to calculate the heating circulation pump from the boiler power

It often happens that the boiler was purchased in advance, and the rest of the system elements are selected later, focusing on the power indicators of the heater declared by the manufacturer. Often, a circulation pump is bought to modernize natural circulation heating systems in order to provide the possibility of accelerating the movement of the coolant.

If the power of the boiler is known, use the formula: Q = N / (t2-t1)

Q - pump flow rate in cubic meters / h;

N is the boiler power in W;

t2 - water temperature in degrees Celsius at the outlet from the boiler (inlet to the system);

t1 - on the return line.

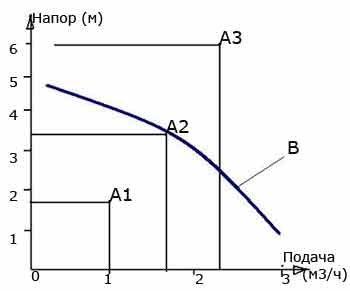

How to choose a circulation pump according to the data obtained

After completing the calculations and determining the main parameters (flow and pressure), we will proceed to the selection of a suitable circulation pump. To do this, we use graphs of their technical characteristics (B), which can be found in the passport or operating instructions. Such a graph should have two axes with the values of head (usually in m) and flow (capacity) in m3 / h, l / h or l / s. On this graph we plot the data obtained during the calculation, in the appropriate dimension and at their intersection we find the point (A). If it is above the pump characteristic curve (A3), then this model does not suit us. If the point falls on the chart (A2) or is below it (A1), then this is a suitable option. But it must be borne in mind that if the point is significantly lower than the graph (A1), then this means that the pump will have an excessive power reserve, which is also impractical, since it will consume more electricity and its cost will also be higher than the model, the characteristic graph which will be as close as possible to our point.

There are models of pumps that have not one, but 2-3 speeds. The graphs of their characteristics will have not one, but, respectively, 2 or 3 lines. In this case, the selection of the pump must be done according to the schedule of the speed that will be used or taking into account all lines if all speeds are used.

Number of speeds of the circulation pump

Pump speeds are the ability of the instrument to vary performance. It is easy to find out about the availability of modes - not one power will be indicated in the description, but several (usually three).

In the same way, the rotation speed and productivity are indicated in three versions. For example: 70/50/35 W (power), 2200/1900/1450 rpm (rotation speed), head 4/3/2 m.

There are models that automatically change the speed of work (and hence the performance), depending on the ambient temperature.

There is a special switch on the pump body to change the mode. Manual models are advised to set to the maximum power mode and turn it down if necessary. In automatic devices, you just need to remove the regulator from the lock.

The presence of speed modes is not only for increasing comfort. It is also economically justified. Up to 40% of energy can be saved by a mode device versus a conventional one.

Empirical pump selection table

| Heated area (m2) | Productivity (m3 / hour) | Stamps |

| 80 – 240 | 0.5 to 2.5 | 25 – 40 |

| 100 – 265 | Is the same | 32 – 40 |

| 140 – 270 | 0.5 to 2.7 | 25 – 60 |

| 165 – 310 | Is the same | 32 – 60 |

Note: in the third column, the first number is the diameter of the nozzles, the second is the lift height.

Using the given data, you can easily select the right device for stable and long-term operation without much hassle.

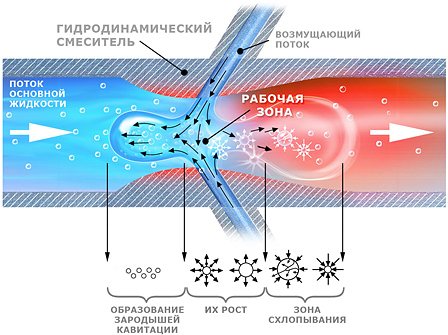

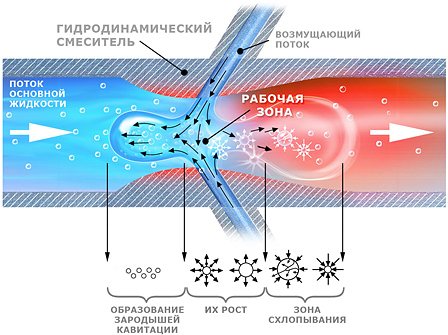

Cavitation in the heating system and in the water supply system

Cavitation is a process during which steam molecules are formed in the heating system due to the decrease in pressure. This process takes place if the fluid flow rate decreases or increases in the pipes.

Heating system cavitation

If the heating system is characterized by too low or too high temperatures, then this phenomenon can have a negative effect. The steam that forms collects in bubbles, and if they burst, then, thereby, damage the material from which pipes or other components of the heating system are made.

A correctly selected device and a correctly carried out calculation of the power of the heating circulation pump will guarantee that the operation of the heating system and the water supply system will be most efficient.

If you cannot independently carry out such operations as calculating a pump for heating, or you doubt their correctness, then it is better to entrust this matter to a professional in this field. The specialist will not only help with choosing a pump or making calculations, but will also deal directly with the installation of the pump.

Other factors influencing the choice

The selection of a circulation pump for a heating system, in addition to those considered above, its main parameters, characteristics are influenced by other factors, such as: reliability, workmanship, temperature mode of operation, cost, method of connection, etc.

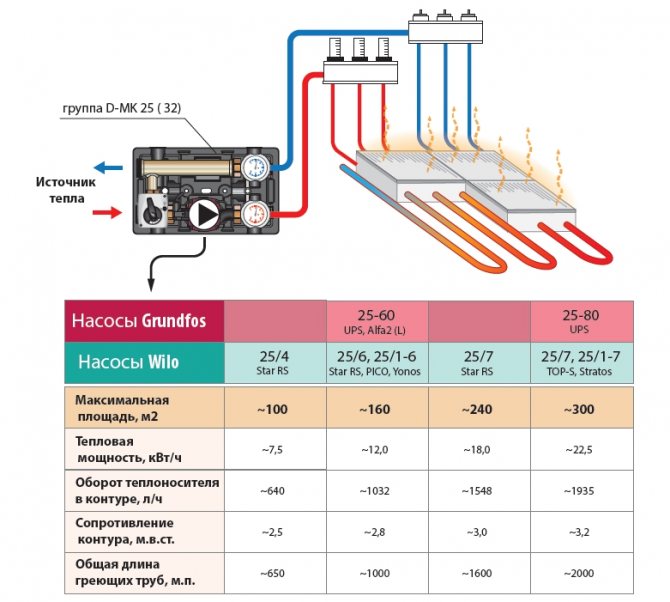

Workmanship, reliability and durability are usually directly related to cost. Manufacturers who offer reliable and quality models, for example: "Grundfos" (Denmark), "Wilo" (Germany), "DAB", "Lowara", "Ebara" and "Pedrollo" (Italy), respectively, and evaluate their products.

Circulation pump wilo in the heating system

Domestic or Chinese models are cheaper, but the guarantee of their quality, respectively, is lower. Here, everyone must make a choice himself, choose a quality product for a higher price or buy a cheaper circulation pump, with the knowledge that it may soon have to be changed.

If you want to save money, you can also buy used Grundfos or Wilo, they can often work normally longer than new Chinese ones, but it is better to buy them from trusted specialists who know them and give them a certain guarantee.

In addition, when choosing, it is necessary to pay attention to the type and diameter of the connection between the pump and the pipes of the system. Some models are equipped with connecting elements of the "American" type, and some will have to be selected independently. Another parameter that you need to pay attention to is the temperature mode of operation of the circulation pump, which should be in the passport. This is especially important if it will be installed on the supply pipe in a system with a solid fuel boiler. In this case, the maximum allowable temperature must be at least 110 ° C. If, however, the pump will be installed on the "return", then this is not so important, since the temperature at the boiler inlet rarely exceeds 80 ° C.