The device and principle of operation of the circulation pump

If you do not know what the principle of operation of the circulation pump is, then it will be difficult for you to both make repairs and engage in maintenance.

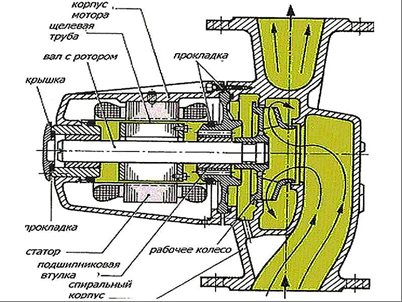

The circulation pump is constructed from the following elements:

- a body made of stainless steel or non-ferrous alloys;

- an electric motor, the shaft of which is connected to the rotor;

- a rotor on which a wheel with blades is mounted - an impeller (its blades are in constant contact with the pumped medium, they are made of metal or polymer materials).

There are two types of circulating pumps:

- wet rotor;

- with dry rotor.

The types of circulation pumps are described in this article.

For units with a wet rotor, this part is always placed in a liquid medium. These pumps are usually supplied to domestic heating systems. Due to the fact that the rotor is located in the liquid, all moving parts are not only lubricated, but also effectively cooled.

The main advantages of this type of circulation pump:

- During operation, they practically do not emit noise, since the water in which all the parts of the device are located absorbs vibrations well.

- They are simple to install, it is enough to cut them into the pipeline, and repair and maintenance will not take much time and effort.

The disadvantages of pumps with a wet rotor include low capacity, they should be mounted exclusively in a horizontal position. Also, if there is no liquid in the heating system, then such devices may malfunction.

Circulation pump and pump

The drive motor for dry rotor pumps is a separate group. Rotation from the motor shaft is transmitted to the impeller using a special coupling. Compared with the previous type, this one has a higher performance, the efficiency reaches 80%. Also, the design of units with a dry rotor is more complex, in this regard, it is also somewhat more difficult to maintain and repair.

When is noise normal

If the contractor has set you dry pump, where the rotor does not have contact with the coolant, the presence of noise during its operation is not a sign of a malfunction. Such products are rarely used in private homes due to the above reason and the need for regular maintenance. You have two choices: install soundproofing in the room or buy a wet-type product. The second method involves a decrease in efficiency. (For a detailed description of the differences between wet and dry pumps, see here)

Manufacturers in the instructions for the device warn the buyer that the heating pump is noisy. There you can also find recommendations on how best to proceed to reduce their impact to a minimum. There is an option to purchase a special casing. It will significantly reduce noise, but will not completely eliminate it. You can also move the pump to another room, from which sounds will not reach the living rooms.

The most common malfunctions, their causes and remedies

There are situations when the circulation pump for heating does not work. You can fix many of the problems yourself. You can find out faults by a number of characteristics that are distinctive for them.

The circulation pump hums, but the impeller does not rotate

Users often ask the question: why is the heating circulation pump humming and what to do in this situation? Often, pump noise and complete immobility of the impeller occur due to oxidation of the drive motor shaft.

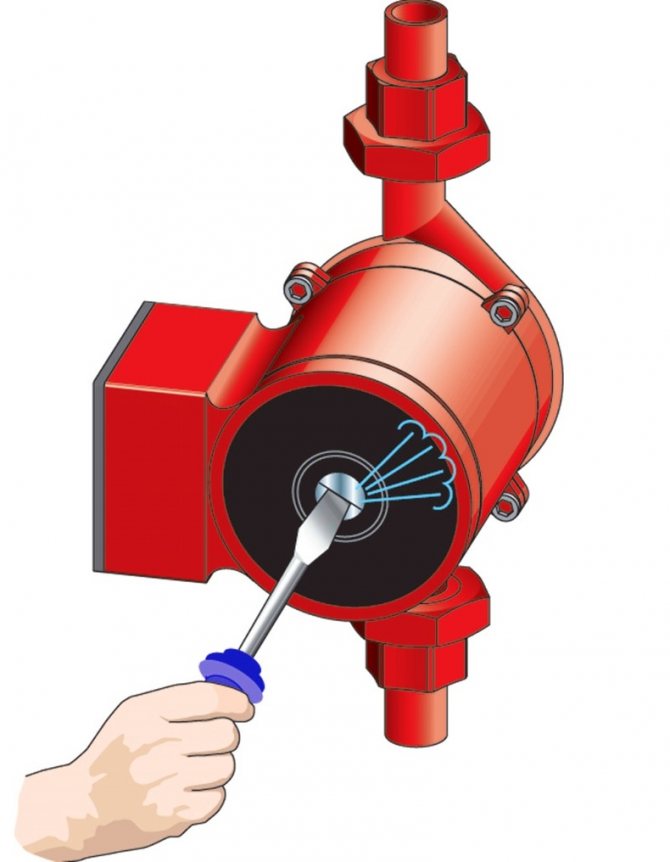

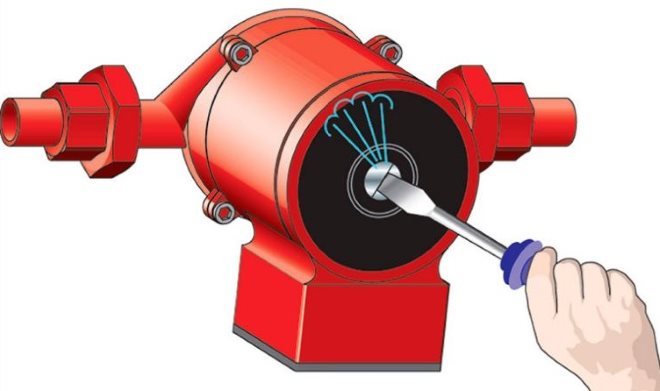

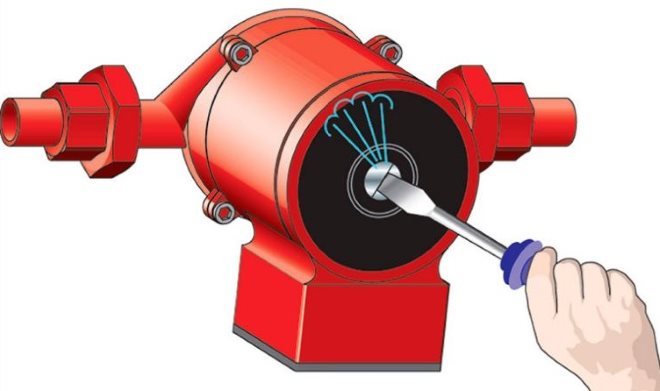

This situation can happen due to the fact that the hydraulic machine has not functioned for a long time. In order to repair the pump with your own hands, you need to follow the sequence of steps:

- initially you must turn off the power supply;

- then it is necessary to drain all the liquid from the pump and the adjacent pipeline;

- after that it is necessary to unscrew the screws and dismantle the drive motor together with the rotor;

- and the last thing you have to do is to move the pump off the dead center, for this you need to rest your hand or a screwdriver against the working notch of the rotor.

Components of the circulation pump

The pump will make noise, but it will not function even if some foreign object gets inside the structure, which will be an obstacle to the rotation of the wheel. Here you need to check the heating circulation pump, find an extra part and resort to repairing the circulation pump:

- the power supply is initially cut off;

- then the water is drained from the pump and pipeline,

- then you need to disassemble the circulation pump as shown in the diagram in the figure;

- then you need to remove the foreign object;

- and at the final stage - a mesh filter is installed on the inlet pipe.

The circulation pump is heating

It is important that the temperature regime of the device is identical to the temperature regime of the coolant pipes. If it has increased, then it means that there were some mistakes in the installation process, or you are simply using it incorrectly. The reasons why the device may warm up are as follows:

- The installation was done incorrectly. It is easy to identify the problem: if the pump heats up immediately after installation, then the reason clearly lies in this.

- Clogged system. During long-term operation, various deposits accumulate in the pipes and rust forms, which makes it difficult for the liquid to pass. Consequently, the pump is overloaded in order to ensure normal circulation of the heating medium. This causes the engine to overheat, but unscheduled maintenance can solve the problem.

- Foreign object. When there is too much slag in the communications from pipes and radiators, pieces of rust or plaque begin to flake off. If they enter the device, the electric motor will jam. If you do not disassemble and clean the device in time, there will be a high probability of a breakdown of the electric motor coil and you will face the problem that the circulation pump for heating will not turn on at all.

- Bearings lack lubrication. When there is not enough lubricant, the bearings begin to wear out very quickly, which negatively affects the service life of the device as a whole.

- Low voltage in the network. At a voltage below 220 V, the electric motor overheats very quickly, which leads to a failure.

The switched on pump does not hum and does not work

If the pump is turned on, it does not make any noise, but does not function either, then there may be some problems with the electrical supply. It is important to know how to check the heating circulation pump in this case.

To do this, it is not necessary to resort to disassembling the unit. You need to take a tester and check the level and presence of voltage at the terminals of the device. Most often, to solve this problem, it is enough just to make the correct connection of the pump to the power supply.

If there is a fuse in the design of the circulating pump, then it could simply burn out during the transfer of voltage to the electrical network.

In order to start the pump, it is necessary to replace the blown fuse.

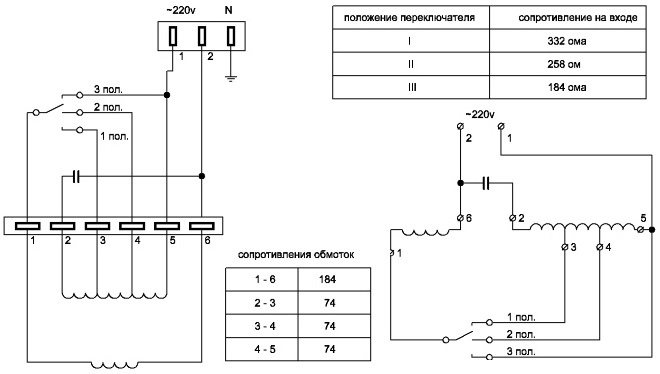

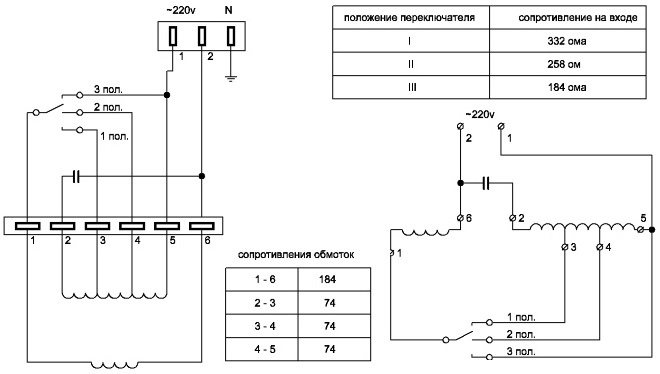

Circulation pump power supply diagram

How to repair a heating circulation pump if it turns off by itself

If you are faced with a situation when a layer of lime deposits has appeared on the inner walls of the device and a functioning pump is periodically turned off, then you need to urgently solve this problem.

You need to disassemble the device and clean all of its internal parts. The procedure should be carried out as soon as possible. Delay is fraught with the final failure of the circulation pump.

Why does the heating circulation pump make noise?

Bleeding circulation pump

Often, a lot of noise occurs due to too much air in the pipeline. In order to solve the problem, you need to know how to bleed the air from the heating circulation pump.

To solve this problem once and for all, you can install a special unit in the upper section of the heating system circuit, which will independently produce air from the pipeline.

Knocking noise in the heating circulation pump or strong vibration

Most likely the problem is bearing wear. All you have to do is replace this part.

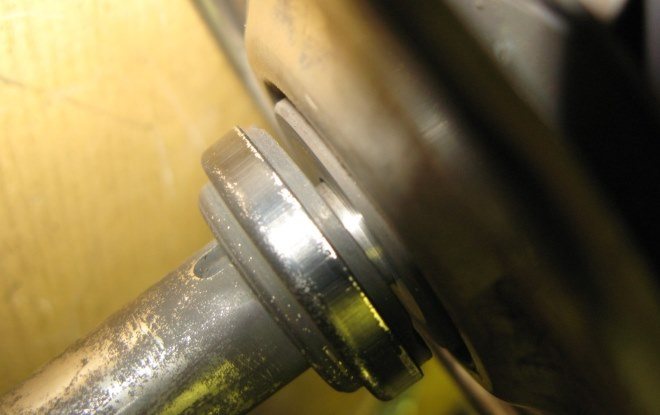

Circulation pump bearing

How does the sound from the basement reach the apartment?

Constant complaints from residents of apartment buildings forced specialists to come to grips with the study of the causes of noise from pumping equipment in basements. According to the results of numerous examinations, it was found that the sound level is less dependent on the power and type of the pump, as well as on the manufacturer. The size of the equipment does not have a special effect, because even a very small pump can produce a serious hum.

It was determined that the sound reaches the living quarters from the basement in several ways: through the air, structurally and through the water through the water supply:

- If the noise is heard outside, then it means that it is transmitted through the air. The main reason for its appearance is a poor-quality soundproofing layer in the room where the pumps are located. The most affected are the residents of the first floors, under whose apartments the technical premises are directly located. Also, noise in apartments is often amplified after their illegal redevelopment.

- Structure-borne noise propagates through the building structure. This can happen for various reasons: illiterate installation of pumps, contact of pipes with the walls of the house, the presence of acoustic bridges (metal elements, racks, etc.), the absence of sleeves (they must be installed in the places where pipes pass through structures). Experts note that when metal bridges are removed, the sound level decreases by 5-6 dB.

- The noise that is transmitted from the pump in the basement through the water is often due to the formation of vortices inside the pump housing. In addition, the absence of special shock absorbers will contribute to the propagation of sound.

The causes of noise can be very different. Only specialists can understand them. If you are constantly bothered by sounds coming from the basement of the house, you should immediately contact the housing office or another governing body. The specialists who came at your request must assess the causes of the noise, as well as carry out work to completely eliminate it (within the limits of the current standards for apartment buildings).

How to disassemble a heating circulation pump with your own hands

In order to repair the circulation pump, it is necessary to dismantle it and disassemble it properly.

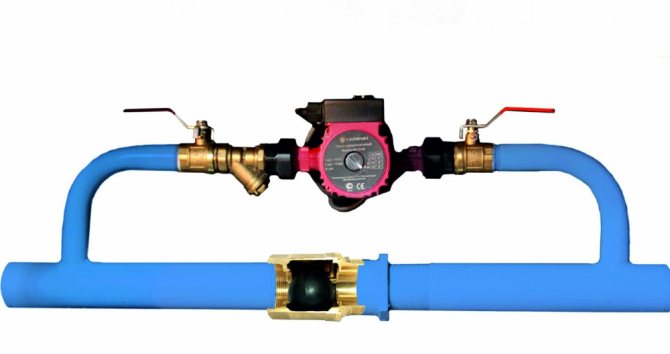

Initially, the device must be disconnected from the electrical network. To disconnect the cable from the terminal box, it is necessary to remove the case from the power supply unit of the device. Then you need to shut off the water supply by means of the side valves and drain the remainder in the system. Next, the pump must be unscrewed with a hex screwdriver.

You may run into a problem when the bolts are stuck. They need to be moistened with WD-40 liquid and after 20-30 minutes try to unscrew again.

After the dismantling is completed, it is necessary to remove the cover of the device. Under it is a rotor with a wheel and blades. You need to remove the rotor, which is usually secured with bolts. This gives you easy access to the internal parts of the pump. Then you should carefully inspect the device and troubleshoot.

Summing up all of the above, it is worth noting once again that the circulation pump is a very important element of the heating system, which is entrusted with serious functions. That is why it is very important to monitor its work and carry out regular maintenance. In case of malfunctions and malfunctions, you need to immediately take the necessary measures, otherwise you can start and your unit will simply fail.

When the source of sounds is the heating system

Often, an unpleasant hum occurs in the case of poor-quality design or installation of hydraulic systems, as well as illegal changes in the standardized designs of existing pipelines in the house. There are cases when, after unauthorized redevelopment and replacement of the heating system in the apartment, installation of warm floors or new plumbing, there is a lot of noise throughout the house. Often the reason is that after the repair, pipes of a larger diameter than required by the project standards were installed. In this case, vibration occurs, which leads to the formation of noise.

Noise can also be generated by replacing old pumping systems with new ones. This is because the technical characteristics of the installed equipment do not match the characteristics of the hydraulic system operating in the house. In addition, a small hum can also appear because the hydraulic system damper is not tightly closed, due to which there is additional resistance and an increase in the speed of water movement through the pipes.

Abnormal movement of water through pipes (faster or slower), as well as an incorrect diameter of recently installed pipes, very often become the reasons for the appearance of a powerful hum, which can be eliminated only by installing a new pipeline. That is why, before any repair work related to the replacement of water supply and pumping equipment, it is necessary to consult with specialists.

What to do to prevent noise

It is possible to prevent the occurrence of extraneous sounds in the heating system even at the project stage:

Modern circular pumps are very powerful. The productivity of the simplest silent unit is enough to maintain a comfortable temperature in a low-rise building. Competent installation, carried out according to the manufacturer's instructions, will significantly improve the operation of the pump

It is important to remember that the rotor of the wet model is installed horizontally only. The error will lead to noise and quick wear of parts. A coarse filter in front of the pump will keep out sand and fine debris. If you are uncertain about the parameters of the system's functioning, it is worth choosing a model with the ability to change the operating mode.

The permissible heating temperature of the heat carrier is 65 ° C. The circulating pump is mounted on a pipe that delivers cooled water to the boiler.

The main causes of pump overheating

Under ideal conditions, the temperature of the coolant in the hot water supply system should be exactly the same as in the pump. Overheating of the pumping equipment can occur for the following reasons:

- Incorrect installation of the appliance.In this case, the pump overheats at the start of operation.

- The presence of blockages in the circuit. Here, the unit works in an intensive mode in order to push the coolant through the narrow holes, which leads to an increase in pressure and heating of the rotor. The way out of this situation will be to flush the heating system under pressure.

- The ingress of a foreign body under the impeller can be diagnosed by extraneous unpleasant noises or wedging, engine overheating. In this case, it is necessary to disassemble the pump and remove a piece of scale or rust.

- Another reason for overheating is considered to be voltage drops in the network. The device must be taken for diagnostics.

The reasons for the overheating of the unit can be very diverse, but do not rush to remove the device from the pipeline or replace it. First flush out the heating with caustic soda solution. If this does not help, leave a request on the website to call the master or call

Examples of completed work

Installation of water heated floors (Novorizhskoe highway, Yakunino village)

Installation of a turnkey water underfloor heating (Volokolamskoe highway, Dedovsk, SNT Prodmontazh)

Moscow region, Krasnogorsk district, der. Timoshkino. September 2015 Completed work on the turnkey engineering communications of the cottage

In heating systems, circulation pumps are used for uniform circulation of the coolant. The pumps pump the working fluid from the boiler to the heating devices, and when the fluid cools down - back to the boiler. All modern boilers are equipped with circulation pumps, which ensure the smooth operation of the heating system. This equipment is quite reliable, designed for a long service life and, if used correctly, will work normally, without failures. If used incorrectly, various problems can arise, the most common of which is that the circulation pump heats up.

Replacing the mains pump repair kit

Most major manufacturers sell ready-made repair kits for the repair of centrifugal units. For example, such a set for a network pump u4814 pumping up 5200 l / h and operating with a voltage of 12/24 V costs 950 rubles. Purchasing a similar kit significantly reduces repair costs. It is possible to carry out repair work on the pump on its own only after the end of the warranty period or the absence of service centers in the area of residence.

Stages of pump repair with the installation of a repair kit:

- Disassemble the pumping part of the device;

- carry out troubleshooting of the internal components of the unit;

- replace rejected parts;

- assembling the unit;

- installed in the workplace and perform post-repair service and performance check.

The principle of operation of network centrifugal pumps

After the power is supplied to the device, the rotor begins to rotate, and with it the impeller, located with it on the same shaft. According to the principle of centrifugal force generated by the impeller, water is drawn from the suction pipe.

At the outlet of the impeller, the coolant enters a spiral-shaped channel in the form of a confuser, in which the kinetic energy received by the liquid from the impeller is transformed into potential energy, thereby increasing the pressure in the heating network.