Protective shroud to keep warm

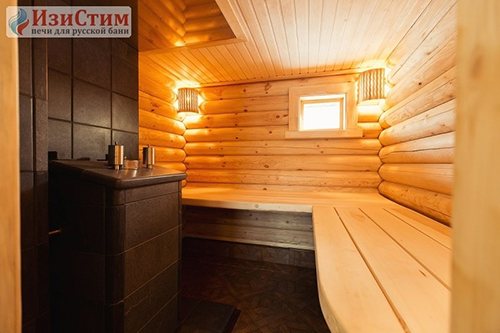

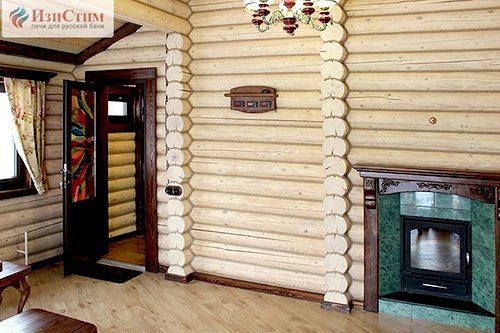

The lining of sauna stoves with natural stone slabs is not only very beautiful, but also has a beneficial effect on the microclimate in the steam room. The fact is that direct contact of air with a red-hot metal contributes to the burnout of oxygen, and the harsh heat radiation from it is not beneficial for the body. Stone, unlike steel, accumulates a lot of heat and slowly releases it. Therefore, the radiation from the stone is perceived as soft and similar to the sun, and the required air temperature in the steam room is maintained for a long time.

For cladding of EasyStim stoves, polished stone slabs made of a coil, soapstone or pyroxenite 40 mm thick are used.

Tubular steam generator

"Enjoy Your Bath!" - everyone has heard this wish at least once. But is the steam in the bath really light? And what does it depend on?

Light steam does not burn the body and does not hinder breathing, but pleasantly warms and causes a feeling of comfort. But such steam can be obtained only in one case - by supplying water to hot, and not slightly warmed up stones.

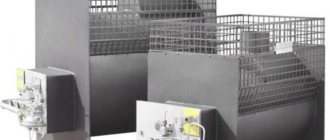

Such conditions can be provided either by a large mass of stones, which needs to be heated for a very long time, or by a special design of the sauna heater. EasySteam engineers chose the second way, placing a tubular steam generator in the closed heater of their stoves. Water enters it through a dispenser with a check valve, heats up in pipes and is distributed in the lower layer of stones. It is here that a high temperature is constantly maintained, due to which finely dispersed light steam is formed.

In commercial versions of EasySteam sauna stoves (with high power and increased weight of stones), a two-level steam generator is used. It provides enough quality steam for a spacious steam room.

Hot water system

The manufacturer offers two options for additional equipment for heating water:

- tanks for a pipe with a capacity of 48 and 64 liters, made of stainless steel. To heat water, they use the energy of flue gases, and at the same time soften the infrared radiation coming from the chimney;

- rectangular wall tanks with a powder-polymer coating with a volume of 50, 80 and 100 liters.

Our services

Our company has extensive experience in the installation of sauna stoves, as well as a staff of specialists who will install the equipment in compliance with all rules and regulations. And that's not all - we offer our clients!

- Isistim ovens in our online store

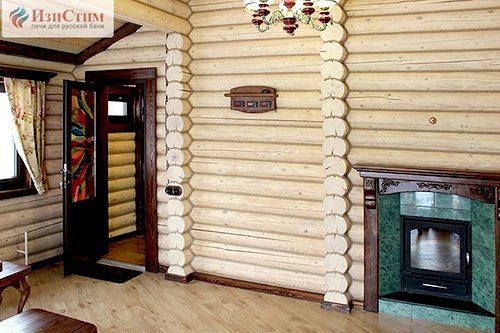

- Bath, steam room decoration

Closed stove with thermoseal

In EasySteam stoves, the heater is located directly above the firebox, so the maximum amount of heat is transferred to the stones. It has a complex geometrical shape with a semicircular bottom, which ensures an even distribution of the load. The weight of the loaded stones depends on the model of the sauna stove.

The stoves of the Yalta series also have an external open heater - a layer of stones laid behind an openwork steel casing around the firebox and internal heater.

All models of EasyStim ovens are equipped with a thermostatic valve. By opening or closing it, you can accelerate the transfer of heat to the steam room or increase the heating of the stones.

Multilayer weld

Why was this method chosen for joining parts? In multi-layer welding, relatively low amperage values are used, and the steel at the seam does not melt significantly. Therefore, the chemical composition of the metal in the weld zone hardly changes and there is no need to fear accelerated corrosion of the metal in this place, which is inevitable in conventional welding.

In addition, with the execution of each subsequent layer, the heat treatment of the previous one takes place.As a result, the weld and the heat-affected zone acquire a fine-grained structure, increased toughness, ductility and the ability to withstand thermal deformation.

Heat resistant stainless steel

For the manufacture of EasySteam sauna stoves, thick-sheet stainless steel AISI 430 is used. Due to its low carbon content and rather high chromium content, it is plastic and corrosion-resistant not only under natural conditions, but also at temperatures from 500 to 800 ° C.

AISI 430 steel is also characterized by:

- low coefficient of thermal expansion, due to which the products from it are not afraid of temperature extremes;

- low thermal inertia, which allows the stove to warm up in a short time with moderate fuel consumption.

DIY making

The easiest way is to assemble a metal stove. It is much more difficult to make a brick structure, since you need to think over the location of the channels for supplying and removing air, making air spaces to improve heat transfer.

Preparation and design

Before you start assembling a metal oven, you need to prepare a place for it. The equipment must not touch surrounding surfaces.

If the combustion channel is remote, it must be indicated on the drawing that the heater will be inside the steam room, and the furnace door in the adjacent room will be the dressing room.

Materials and tools

To assemble the furnace, erect the base, you need to prepare:

- sheets of stainless or heat-resistant alloy steel with a thickness of 5 mm;

- welding machine;

- metal corners;

- grinder with discs;

- a set of files;

- metal brush;

- shovels, boards, bars;

- fireclay brick;

- chimney pipes;

- grate fittings;

- doors for ash pan, combustion chamber.

Separately, you will need metal sheets, plates of non-combustible material to protect the surrounding surfaces from heat.

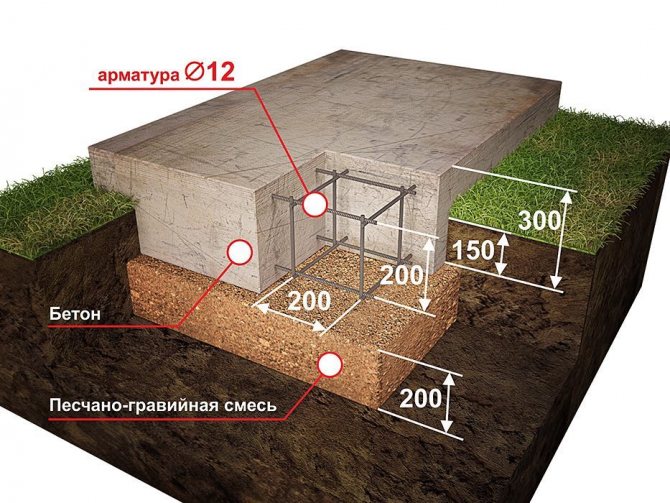

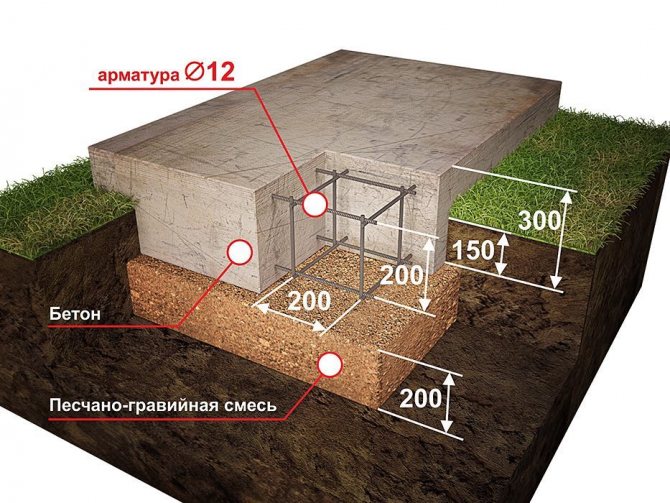

Site preparation and foundation construction

It is necessary to erect a base for furnace equipment at the first stages of building a building. Features of preparation, construction of the foundation:

- the depth of the pit for the base under the stove is from 50 to 80 cm;

- the base should be 15 cm larger than the oven on each side;

- at the bottom of the pit, you need to lay a sand pillow 15 cm thick.

Furnace foundation diagram

Base construction

Stages of construction of the base:

- Dig a hole under the foundation with shovels.

- Fill up with a layer of sand 15 cm thick, tamp it.

- Knock off the formwork from boards, bars. Its height should reach the floor surface in the bath.

- Tie the reinforcing frame from the reinforcement, place it in the formwork.

- Mix the cement mortar. Fill the formwork with them.

After 3-4 weeks, you can start further work. It is necessary to dismantle the formwork, fill the vacated space with expanded clay or sand. The concrete should be covered with 1-2 layers of roofing material. On top it is necessary to lay out two layers of fireclay bricks on which the furnace will be installed.

Stages of self-assembly of a stove with a sauna heater:

- Mark the metal sheets, cut them with a grinder to the required dimensions.

- Weld the oven body.

- Close the seams with metal corners, weld them.

- Cut holes for the furnace door, ash pan.

- Divide the interior into 2 parts using a grate.

- Make a hole in the upper part of the body for fixing the chimney.

Weld 4 rectangular metal plates on the top of the case. They will act as walls for the heater.

If consumables remain, a hinged water tank can be welded from metal sheets. It can be fixed to the chimney or leaned against one of the walls of the stove.