Masonry fireplaces, which are installed to create a cozy atmosphere in country houses, restaurants and a favorable environment for communication, relaxation and as an additional source of heating for premises, are popular services in the construction market.

And their original designs are associated with real works of art. Performing such work is available to real masters.

Their skillful hands are able to build strong, reliable structures that will be distinguished by safety, long service life without repair work, functionality, and attractive appearance.

Heat-resistant glue for stoves and fireplaces

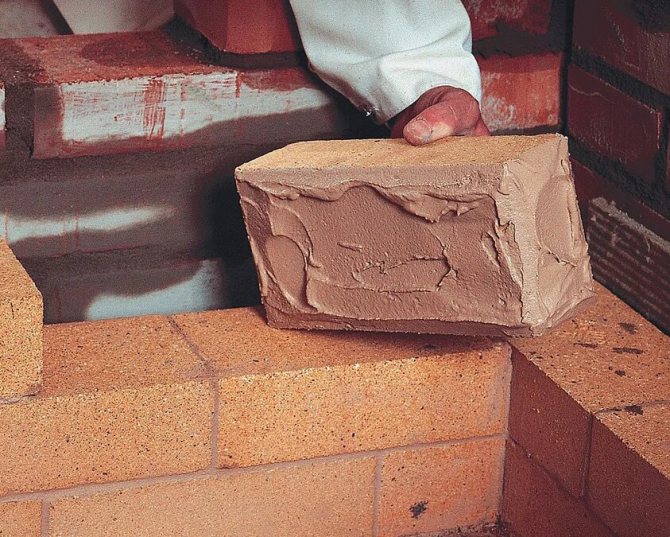

For laying work, tilers use a special glue for laying ovens based on clay, however, for facing work, the solution is inconvenient, it spreads over the surface, and the hardening process takes longer. Therefore, for this purpose, furnace adhesives with a different composition were created. They are a viscous substance that ensures fast and reliable fixation of the veneer. It can be sold ready-made, or in the form of a dry mixture, which requires dilution before use.

The first option has several drawbacks: you need to work with it quickly, otherwise it will dry out, and its price is also higher.

For laying work, tilers use a special glue for laying ovens, based on clay.

What components should be included

Manufacturers are trying to create heat-resistant tile adhesive for ovens with universal properties, but more attention is paid to improving a number of properties necessary for these structures:

- Heat resistant resistance;

- Water resistance;

- Plastic structure;

- Heat exchange capacity;

- Linear expansion;

- Environmental friendliness.

To obtain these characteristics, various fillers are added to the main elements. These include:

- Cement mixture;

- Sand;

- Fireclay fibers;

- Mineral supplements;

- Synthetic elements.

Manufacturers try to create heat-resistant tile adhesive for ovens with universal properties.

Distinctive operational features

Heat-resistant glue for stoves and fireplaces has the following features and advantages over other adhesion mixtures:

| Features of the | Detailed description |

| Affordable cost

| The price for this adhesive is affordable and low in comparison with similar solutions based on clay, chamotte powder and cement. The cost of the glue can vary and vary depending on the manufacturer, properties and qualities of the composition, as well as the mass of dry matter in the bag or box. |

| Ease of use

| Heat resistant glue for fireplaces and stoves is easy to use. In order to dilute and use such a composition, there is no need to follow a certain technology, to procure and check the quality of each component in advance (this is necessary exclusively for clay homemade compositions). An already finished product can be cooked within 30-40 minutes, unlike clay, it may take several hours to obtain a composition from which, and about 2-3 days to prepare. |

| Versatility and durability

| It has a high degree of adhesion and allows the facing material to lay down efficiently and evenly. The clutch is very reliable and durable. Such glue is perfect for both stoves and fireplaces, it allows you to adhere any material to a previously prepared installation surface. |

| Fast drying

| Refractory glue for stoves and fireplaces dries quickly. However, the drying time depends on the thickness of the applied layer, the consistency of the product, as well as the type of veneer and its weight. |

Important:

heat resistant fireplace adhesivesuitable exclusively for facing work. Due to its unique characteristics, it may well be used for the assembly of decorative portals, as well as heat technological furnaces.

High temperature resistant adhesives

Varieties of oven adhesives are distinguished according to two main criteria: by purpose, at what stage the composition is applied; according to the form of release, the choice is determined by the conditions and volume of work, the experience of the master.

By appointment

You can always find universal remedies on sale, but you can get a more reliable and high-quality effect by choosing a composition for a specific purpose and conditions.

An important guideline is the type of material that will be glued. Adhesive for metal will not work so well with glass. Heat-resistant glue for a fireplace has its own characteristics and in other situations it can affect the quality.

An important guideline is the type of material that will be glued.

By release form

When an inexperienced stove-maker is going to work, it is better for him to choose ready-made types of adhesives, it will be easier for him to work with them. After all, you do not have to dilute the composition with water, of course, manufacturers attach instructions for preparation, but still the process can cause difficulties.

It is important to take into account that ready-made mixtures cannot be stored for a long time, they can solidify during laying, so you need to work with them faster. You should not buy any type of adhesives in large quantities, the shelf life of the formulations does not exceed 1 year.

Dry mix is usually used when working with uneven surfaces. During production, the mixture is subjected to heat treatment, changing its structure.

The disadvantages are: the need to have a number of skills, the narrowness of the scope of use.

Ready-made adhesives on the market are presented in large quantities, they differ from each other in purpose. Therefore, a suitable solution can be selected for each purpose. It is more convenient to work with them, they are often produced in tubes.

Dry mixes are usually used when work is carried out on an uneven surface.

What the main parameters say

Many novice craftsmen mistakenly believe that indicators such as heat resistance, thermal strength, heat resistance and fire resistance are synonymous with one parameter. Then, in the case of using a universal tool, in which all these characteristics are expressed to a high degree, they may simply be lucky and the hot melt glue will cope with all the functions. Professional craftsmen distinguish between these terms and manipulate these parameters, choosing the composition for various types of work.

- Heat-resistant glue is capable of maintaining technical properties for several hours at temperatures above 140 ° C.

- A heat-resistant material must retain its qualities for a long time.

- The heat-resistant material increases the temperature bar of the heat-resistant adhesive by 10 times.

- Heat resistance - the ability to maintain qualities under prolonged exposure to temperatures above 1000 ° C degrees.

- The flame retardant compound is in direct contact (open contact) with the flame itself for several hours.

- The refractory adhesive is adapted to lasting contact with fire.

Good to know: What should be the dimensions of the fireplace for normal operation

In the event that only certain characteristics are pronounced in the adhesive composition, then such a material is suitable for performing a narrow interval of work.

Mix under the brand name Terracotta

Heat-resistant and refractory mixtures are used when laying fireclay bricks in the firebox itself.They form a strong mortar that, when dry, has high adhesion and withstands critical temperatures without cracking. Heat-resistant compounds are often used for laying stoves in places of heat exchange or in the labyrinths of a brick chimney.

From inexperienced craftsmen, offers are often received to use heat-resistant glue in all types of work, since it has the highest performance. Such a thought can be formulated from a misunderstanding of the basic processes that occur in a stove or fireplace during their operation.

Some of the contact surfaces (fireplace walls and their cladding) have different expansion coefficients. Only an elastic material, which is not a heat-resistant adhesive, can act as a connecting link. After drying, heat-resistant mixtures are able to deform without destruction under the influence of external forces. Such glue is suitable for facing the fireplace frame, as a tile mortar or in places where the temperature does not exceed 140 ° C degrees.

How to choose the right one, the most important criteria

To make the right choice of fireplace glue, you need to consider some criteria. These include:

- The location of the stove, whether it will be on the street or in the house. The threshold for maintaining temperatures can reach +1200 degrees, but the minimum temperatures that the solution can withstand may differ, therefore, if the structure is to stand outside, then frost-resistant properties of the composition are required;

- You should carefully read the instructions to buy exactly the heat-resistant look;

- One glue cannot be used for different types of materials, it is worth knowing in advance which facing material will be used;

- The application of the adhesive solution should be carried out in a thin layer, therefore, if the surface has strong irregularities, then the choice should fall on compositions with high viscosity indicators;

- It is worth paying attention to the indicator of moisture and vapor permeability, they are most important for stoves in saunas;

- The safety of the formulations for human health is important, the level of toxicity of solutions must be taken into account, toxic substances can be released under the influence of high temperatures, therefore, on the packaging you need to read about the environmental friendliness of the solution.

You should carefully read the instructions to buy exactly the heat-resistant look.

Preparation of the composition at home

To prepare a composition that can cope with fixing tiled materials on the stove with a thickness not exceeding the thickness of the tile, you should prepare:

- 1 part cement;

- 1 part clay;

- 3 pieces of sand;

- Edible salt 1 glass.

Clay must be refractory, in order to test its stability, you need:

- Twist the material with your hands into a tourniquet.

- Wrap it around the object in the shape of a cylinder.

- Next, they look at the appearance of cracks in the material, if they appear only in the upper layer, then sand should be added. Normally, the cracks should be distributed over the entire surface of the bundle evenly, while their depth should not exceed a third or a quarter of the mass, if the flaws are thicker, then a grease must be used.

The clay must be refractory.

To prepare the grease, the following steps are carried out:

- Finely ground clay is poured into the container.

- Add water, mix the components well.

- Waiting for the appearance of a precipitate.

- Half of the liquid is drained off the sediment.

- Next, the mixture should be infused, the grease is ready.

First, sand, clay, cement are mixed, then water is added. It must be added gradually, checking the resulting viscosity. Then salt is added. Mix everything again thoroughly.

First, sand, clay, cement are mixed, then water is added.

Heat-resistant glue for stoves and fireplaces must withstand special operating conditions, therefore special requirements are imposed on it. You need to choose the composition, carefully studying the instructions.For beginners, it is preferable to stop the choice on ready-made solutions.

Pop stamps

Products of domestic and foreign manufacturers are presented on the building materials market. Many firms producing building ceramics (bricks, facing tiles) also produce related products: heat-resistant glue for ovens, heat-resistant plasters, grouting and other building mixtures. For the convenience of the reader, we have summarized in the table the most popular brands of adhesives and mixtures for stoves and fireplaces.

| Brand | Appointment | Temperature оС | Weight, kg) | Price, rub) |

| TERRACOT | Facing | 200 | 25 | 500 |

| PLITONIT | Masonry | 400 | 20 | 450 |

| Bohr Ross | Mix (clay, sand) | 1750 | 25 | 250 |

| KV glue - 1250 | For ceramic insulation | 1250 | — | — |

| PROFIX | Finishing and gluing | 300 | — | — |

| Ivsil Termix | Facing | 250 | 25 | 355 |

| Hercules GM-215 | Masonry | 1200 | 25 | — |

| Belife silicone | Adhesive sealant | 300 | — | — |

| Dow corning | thermosealant | 275 | — | — |

| K-77 heat-resistant | Facing | 800 | — | — |