Kuznetsov's stoves are popularly called "Russian teplushki". The heating stove has been in use for half a century and is one of the most efficient in operation. Models designed by Igor Kuznetsov are in demand even in foreign countries. Using special simple drawings and diagrams at home, you can easily fold brick Kuznetsov ovens, which will not only give warmth to the room, but will also help in preparing meals for the whole family.

Features of the Kuznetsov furnace

Engineer Kuznetsov's stoves have been known not only at home, but all over the world since the 60s of the last century.

Moreover, the relevance of the developments half a century ago has not diminished in the least, but on the contrary - Kuznetsov's furnaces are becoming more and more popular.

The purpose of modernizing the old design of the Russian stove with a not so significant change in its internal structure was to create a heating unit with a higher efficiency while saving fuel.

Bell-type furnaces are one of the most common and in terms of characteristics are in no way inferior to channel furnaces.

This stove is the latest development in the conservative field: the installation and design of stoves. This stove features a fundamentally new method of using hot gas.

In a standard type design, the movement of cold and hot gas occurs due to the draft of air, which flows through the ash pan.

The bell-type furnace is very similar in principle to the operation of rocket furnaces, where hot gases move not under the influence of the chimney draft, but due to the gravity of the gases themselves.

About the author-inventor

KUZNETSOV IGOR VIKTOROVICH is the author of many inventions concerning the construction of household brick bell-type stoves for various purposes and different powers: heating, heating and cooking, Russian heat-insulating stoves, stoves for baths with regulation of water heating and regulation of temperature and humidity in the steam room of a bath. He has patented these structures, combined with fireplaces, while the walls of the fireplace are heated and are part of the stove. IV Kuznetsov has developed furnaces for various functional purposes with built-in water boilers for use as a backup in systems with water heating. Now he is the chairman of the socially oriented NP "Development of Kuznetsov Furnace Systems"

Oven advantages and disadvantages

Benefits:

- high rate of efficiency of 75-85% (efficiency);

- fuel burns at high temperatures;

- the furnace runs on all types of solid fuels - wood, coal and brown coal, briquettes, etc.;

- ease of maintenance, there is no need to clean long channels (low soot formation);

- durability of the furnace;

- aesthetic, original appearance;

- high efficiency, versatility;

- profitability;

- long-term preservation of heat;

- the shape and design of the stoves may vary depending on the purpose;

- with the frequency of fuel inserts in the blacksmithing room only twice a day, you can have a thermal regime in the house, which compares favorably even with the regime of apartments with central heating.

An apartment in a high-rise building has more frequent temperature fluctuations than a private house heated by a Kuznetsov stove, which gives a uniform heat output between the fireboxes;

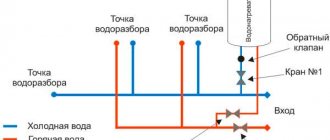

- combining a Kuznetsov oven and water heating at home is not difficult and is often used in practice.

A tubular heat exchanger is installed inside the firebox and connected to the heating circuit pipeline.The main plus is that the heat engineering and heat transfer of the furnace during modernization remain unchanged, without the slightest decrease in efficiency;

- the design of the blacksmithing allows you to arrange low chimneys, and there is no reduction in draft at the same time. This fact is somewhat surprising to those who first get acquainted with the design and operation of these furnaces;

- the features of the internal design of Kuznetsov furnaces allow the unit to be installed in almost any room of any size, regardless of what the room is intended for.

Both in kitchens and in common rooms, the stove looks solid and aesthetically pleasing, and organically fits into many interiors;

- the most interesting and unusual feature of blacksmithing in the context of a home oven: you do not need to close the view. This most important part of the furnace and one of the conditions for safe daily operation is needed for the Kuznetsov furnace only if an emergency situation arises.

The fact is that when the process of fuel combustion comes to an end and cooling begins, the thrust in the channels of the furnace is redistributed spontaneously, “automatically”.

It was the bell-type stoves that became the basis for the creation of many household, heating and cooking stoves of a new type, which give a significantly better effect with less fuel consumption.

What can be said about the disadvantages of the oven.

Technically, there are none, but you still need to take into account something.

The Kuznetsov furnace cannot have massive walls - this would negate many of its advantages. But at the same time, it is exposed to rather high thermal loads.

Therefore, this unit must be carefully calculated and verified at the development stage and built just as carefully, with scrupulous observance of all technology requirements. With the slightest deviations from the technical regulations, the "blacksmithing" will turn out to be very short-lived.

The principle of operation of the furnace

It is based on the principle of free movement of gases. For the circulation of air in a conventional furnace, the influence of external energy is necessary, that is, the creation of forced draft in the pipe.

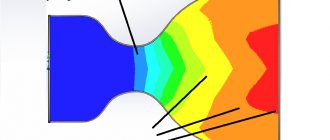

When gases are in a confined space, in the presence of a constant source of heat, they separate under their own weight - the cold ones settle down, the hot ones rise up. At the same time, in the area of high temperatures, the pressure increases, and where it is cold, it drops and energy is generated.

It turns out that turbulent motion arises automatically due to the laws of physics. This means that if convection flows are correctly directed, then thermal energy will be carried by the masses of gas themselves.

No draft tube is required for electrical heat supply. If the stove is heated with wood, then the combustion product must invariably come out.

Thanks to the clever design, it accumulates at the last stage of its path, as if under a hood. There it burns out again, giving up its heat to the end, and then, in the form of useless gas, is taken out into the street without cooling the system. Such ovens are also called bell-type ovens.

The fundamental feature of gas filling of cavities is that, no matter how many compartments the furnace has, they are all filled with gas evenly and the same physical processes take place in all. It is impossible to create something similar using traction, the principle of counterflow (widely used in Europe) or other convective methods.

That is why such stoves are an innovation in the stove heating system.

They regulate themselves and, no matter what configuration they give them, they always work according to a natural principle.

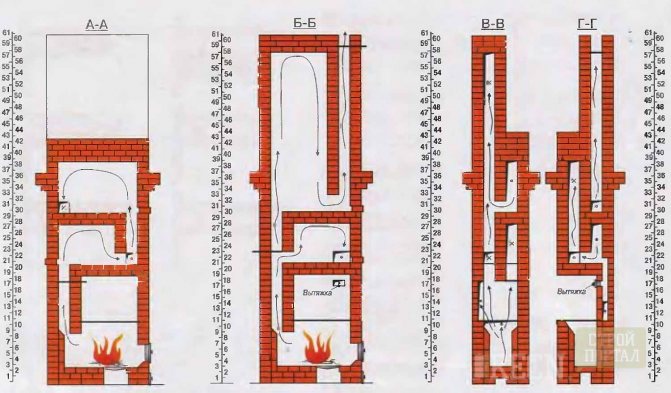

The principle of the furnace is quite simple: the lower tier and the firebox (also called the hearth) are combined into a single space - a bell, inside which the free movement of hot gases occurs.

The hottest, lighter gases move to the upper part of the bell, while the "heavy" cold gases are located in the lower part.And between them, gases circulate with an intermediate temperature.

The heated air is held in the furnace for a long time, transferring heat to the walls of the bell, and the cooled air is discharged into the chimney through a special passage. The combustion temperature in the bell is very high. The efficiency of such a furnace is three times higher than that of a traditional Russian one.

Characteristics

Kuznetsov's bell-type stoves have a number of distinctive characteristics and advantages that distinguish them from the main competitors in the market for heating equipment for home and baths.

The principle of operation of such a device is quite simple: the lower level (tier) and the firebox are a single structure - a hood, which is designed to efficiently move gases generated during fuel combustion. In this case, the accumulation of light gases is at the top of the bell, and heavy gases - at the bottom. In the middle are concentrated gases with an average heating temperature.

"Kuznetsovka" made of bricks provides for a long-term retention of heated air inside the bell for effective heat accumulation inside the room, and then the rapid removal of combustion waste through the chimney.

A feature of the furnace is the maintenance of the maximum combustion temperature. In addition, the Kuznetsov furnace has a high efficiency, which is several times higher than that of the classic Russian furnace.

The specific advantages of such ovens are as follows:

- High efficiency - up to 94%.

- High temperature mode of combustion of fuel material.

- Fast accumulation and long-term maintenance of heat.

- Low soot deposition.

- Easy to care for and unpretentious.

- Insignificant material consumption with high heat output.

- Possibility of additional integration of a circuit for hot water supply.

- Increased draft with small chimney dimensions.

- Attractive design and a wide range of designs. An improved version is Kuznetsov's two-bell furnace, which can be designed for any type of room.

- Fast distribution of thrust between channels in automatic mode.

Varieties of Kuznetsov furnaces

According to the functions performed, Kuznetsov's brick ovens can be divided into several main groups:

- Heating.

Their main task is to heat the premises.

- Cooking.

They are used for cooking. This group also includes bread ovens and stoves adapted for a cauldron.

- Bathrooms.

The principle of operation of Kuznetsov's sauna stoves remains unchanged - the natural movement of gases through two hoods. Another thing is that there is a heater here, which needs to be thoroughly warmed up to obtain high-quality steam.

The developer has proposed and is still using the optimal technical solution, where the stone filling is located in a heat-resistant steel oven. The oven is located directly above the firebox.

The heat energy accumulated in the lower and upper bells is used to heat water and heat not only the steam room, but also all adjacent rooms. The water coil is installed under the first hood so that it can be easily repaired or replaced.

The installation location can be determined by examining the drawings of the stoves.

- Fireplaces.

- Grills and barbecues.

- Combined structures, complexes.

- Perhaps the most popular are Kuznetsov's heating and cooking stoves. They will warm the house and will not leave hungry.

The heating and cooking option is most in demand both by summer residents and residents of rural areas. There is a simple practicality here: if there is already a fire, why not use it additionally for cooking.

Kuznetsov also has such projects.

Before you start building, make sure that this is exactly the option that you want to see at home.

Such stoves imply a convenient protrusion with a cast iron surface, with the possibility of partially opening the holes to increase the temperature. It is also possible to make a door for a cauldron, similar to the old Russian stoves.

Layout of heating and cooking stoves requires its own approach and individual drawings.

Bell-type furnaces can be erected in almost any room. This can be an apartment, a residential building, an outbuilding, or a bathhouse. For example, for a bathhouse, a bell-type stove will be an ideal replacement for a conventional standard stove.

By building this stove for a bath, you can solve several problems at once. This design is capable of heating several rooms: a sink and a steam room, as well as a relaxation room. In addition, it is very convenient to heat up the water on the stove, simultaneously creating steam in the required amount.

The house can be equipped with two-bell heating with a stove, this installation is very functional. Before erecting such a structure, it is necessary to carefully study the project.

The system that burns raw fuel must be organized in the most optimal way. The oven must always be kept at the correct temperature, otherwise the gases that form after combustion can be transformed into harmful wastes of soot and tar.

Views

By purpose and design features, "blacksmithing" can be divided into several types:

- Heating. The devices are designed for efficient and safe space heating.

- Cooking. Used to prepare food. These include ovens for baking bread and bakery products.

- Bathrooms. Kuznetsov's stove for a bath is designed for simultaneous heating of the main bath rooms. Such devices have high heat dissipation with minimal fuel consumption.

- Street. A stove complex consisting of a grill or barbecue for outdoor cooking.

- Fireplaces. The equipment is used as a decorative element of the interior or as an additional heating option. Some fireplace stoves are equipped with special loungers for a pleasant pastime.

The most popular are complex devices that are distinguished by their multitasking. A striking example is the Kuznetsov heating and cooking stove, which is intended both for heating living quarters and for cooking food.

Despite their functional features, all stoves work according to the same principle - efficient distribution of heated gases in the bell into separate streams.

It is noteworthy that the stove hoods can be equipped with additional equipment - electric heaters, hot water tanks, steam generators, an oven and a stove.

A well-designed and built Kuznetsov sauna stove will provide reliable heating in all functional rooms: a steam room, a washing room, a dressing room, a rest room. In addition, it will allow you to quickly heat up water, accumulate hot steam and purify the air.

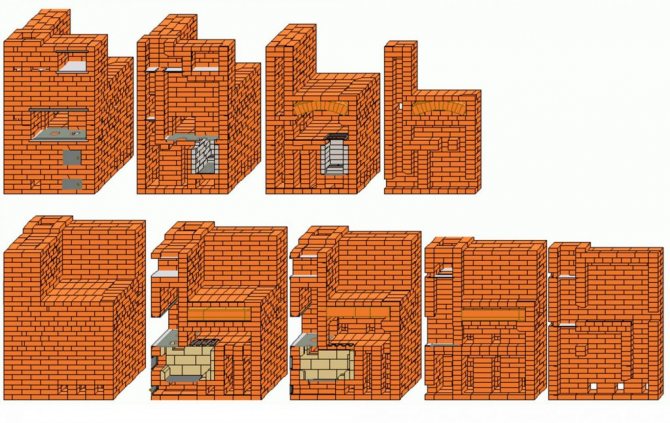

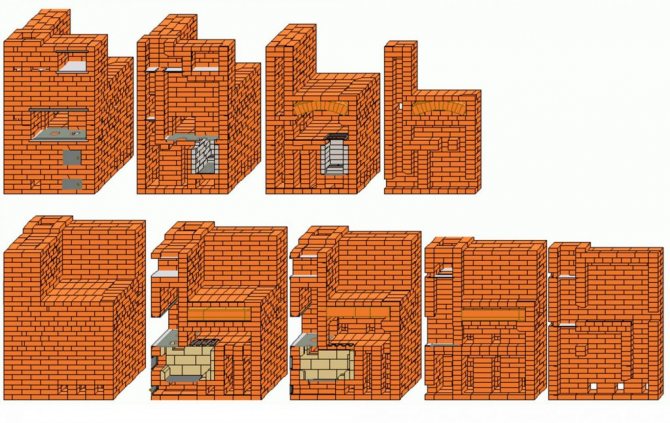

Do-it-yourself Kuznetsov stove

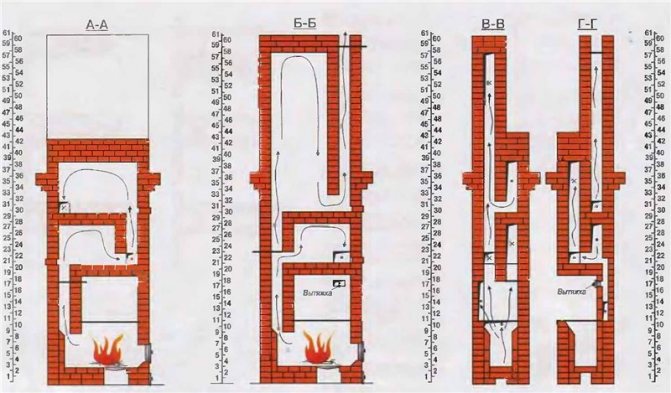

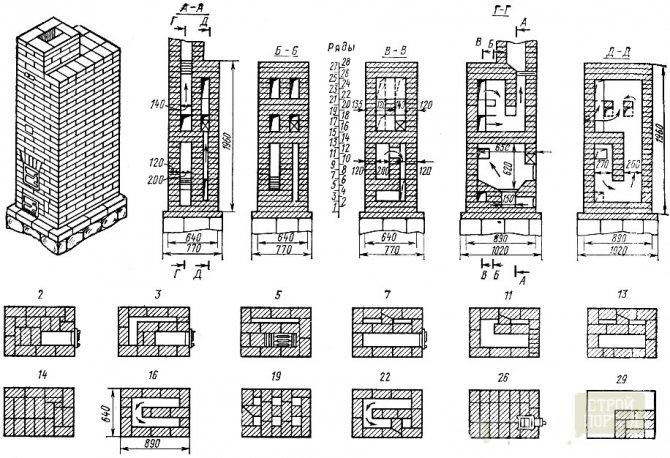

Building a blacksmithing requires not so much skill as having good diagrams and blueprints, as well as utmost care. Not even a stove-maker, but a skilled householder can master this task.

It will be easier for those who already have precious experience in brickwork, then the only thing you will need to quietly and peacefully lay the rows, observing the scheme.

Having decided to build a furnace according to one of Kuznetsov's orders with your own hands, get ready for careful and scrupulous work.

On the diagrams that can be easily found on the Internet, you will see a graphic image of each row, however, before starting laying, you need to get acquainted with the features of the technique, in particular:

- selection and preliminary processing of bricks;

- purchase of metal parts (plates, dampers, doors, latches);

- determining the most suitable place;

- preparation of the base and foundation;

- the possibility of equipping a chimney, etc.

Fireclay refractory bricks (Ш-5, ШБ-8) were recognized as the best material for the internal masonry of "blacksmiths", and ceramics (М-150) for external decoration.

To strengthen the brick walls, metal elements (reinforcement, wire) are used.

In order for the stove to function with maximum heat transfer, experienced craftsmen hone not only their skills, but also every brick - in the literal sense. They polish every detail, which is why projects made by professionals look flawless.

The main purpose of any stove is heating; its location should be chosen to provide heat in the most efficient way.

Kuznetsov's stoves are infrared heaters that provide the most heat through direct radiation.

Thus, maximum power is achieved when positioned correctly.

Therefore, the center of the room is always the right choice. A wise decision is to place as a separator of functional spaces such as kitchen and living room or living room and bedroom.

Try to avoid placing the stove masonry next to an outside wall, or worse, place it in a niche in the outside wall (typical for conventional fireplaces) if you want to keep warm indoors.

The choice of a stove of one type or another and its location in the house, in addition to the owner's preferences, depends on the intended purpose of the stove, the size of the house and the level of its thermal insulation, the number and size of windows.

In addition, for normal operation and repair, access to the stove must be free from all sides, that is, none of the sides of the stove should simultaneously enter any of the outer walls of the house.

To complete the construction process, you need to stock up on a bayonet and shovel, as well as the following materials:

- sand (3 parts), cement (1 part) and water for solution preparation;

- reinforcing rod of medium section;

- plastic wrap;

- board for the construction of formwork.

Construction stages:

- It all starts with the foundation. It should be unconnected with the main foundation of the bath. Its size is 10-15 cm larger than the estimated dimensions of the oven. The height of the foundation for the stove is selected based on the height of the bath's foundation: they must end at the same level.

On top of the finished base for the furnace, waterproofing (roofing felt, roofing material) is laid in two layers. The floor around the future stove must have a fireproof covering. There are options: these are metal sheets, ceramic or ceramic tiles, natural or artificial stone, brick, etc.

- To determine the required number of bricks for building a furnace, we count the number of bricks in the first row of the order, multiply by 0.8 (the average fill factor of the rows) and by the number of rows.

This amount of bricks is enough for the oven for sure, even taking into account broken and rejected bricks. For a brick pipe, add 4-6 bricks per row.

- After the concrete foundation has completely solidified, you can proceed to the brickwork. Kuznetsov's stove is built correctly only if the order proposed by the inventor is observed.

- Before starting laying, it is worth considering the location of the chimney inside the room and outside on the roof, which must meet certain requirements. Recall that any Kuznetsov furnace has ready-made drawings, in accordance with which construction work is carried out.

- For the laying of the first two rows, fireclay fire-resistant bricks are used.To connect the bricks, a special masonry mortar is prepared. It is not recommended to use a mixture prepared for arranging the foundation.

- After completing the masonry of the 1st row, the corners are checked, each of which should be 90 degrees. Arrangement of chimney ducts begins from the 2nd row.

- To improve the heat transfer of the device, it is recommended to install 4 duct cleaners - in the back, in the blower and on the sides. The sizes of the cleanings are selected on an individual basis. At this stage, the horizontalness of all surfaces is checked using a corner.

- From the 2nd row, an ash pan and a blower are formed. These working chambers are designed to clean ash and create the necessary combustion draft. Brickwork is staggered with a 6 mm seam. A mortar based on refractory clay is used to fix the bricks.

- Further, partitions for the internal compartments are installed, a wall is formed between the blower and the working part of the furnace.

- When laying the 5th row, the grate is installed, the thickness of which is determined by the degree of loading the chamber with fuel.

- When installing the grate, the technological gaps of 7 mm are observed between the grate for the grate and the outer wall of the stove. The grille is installed at a slight angle in relation to the door.

The door for the firebox is also installed here. When arranging the combustion chamber, it is additionally lined with fireclay bricks, which are laid with an edge. This ensures reliable protection of the outer walls of the furnace against high temperatures.

- Up to the 16th row, laying is carried out similarly to the previous rows.

- A cap is installed from the 17th row, after which you can start arranging the second chamber located above the first. It will be the second cap. At this stage, the hood is overlapped, and on the 21st row, passages are arranged, which are directed along the inner walls on both sides.

- The work is carried out in accordance with the proposed order up to the 26th row, after the completion of which the upper part of the hood is reliably closed with brickwork.

After making the foundation, you need to attend to the preparation of the mortar for laying the furnace. For the construction of a brick kiln, not cement is used, but clay. And not any, but only the one that lies at a depth of at least 2 meters. The clay is sieved and washed out, preparing a solution of the desired viscosity.

- 24 hours after completion of laying, a test run of the furnace can be carried out with the addition of a small amount of fuel material. This will allow you to check the finished structure for leaks and the absence of gaps between the bricks.

- If even minor flaws are found, they should be eliminated immediately.

- The furnace is made of fireclay bricks, and the body of the furnace is made of ceramic, which means that they behave differently when heated and cooled. Therefore, the firebox itself must be floating; for this purpose, a special dry seam is made around it.

This is done so that fireclay and ceramic bricks, different in physical characteristics, do not break during operation. "Dry joint": between the fireclay and ceramic bricks, the masonry mortar must be removed, and mineral cardboard must be inserted into the resulting void.

- One more rule must be strictly observed - the projections from the fireclay masonry should not enter the recesses of the ceramic masonry, and vice versa. Thus, we get an absolutely independent firebox.