Complete set and principle of operation

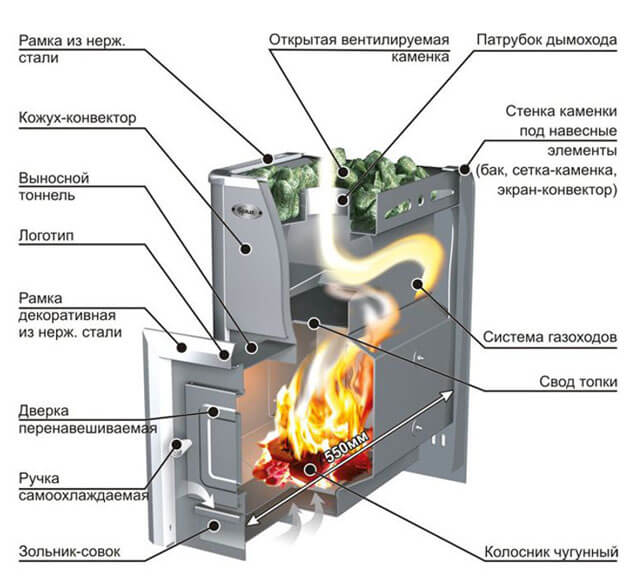

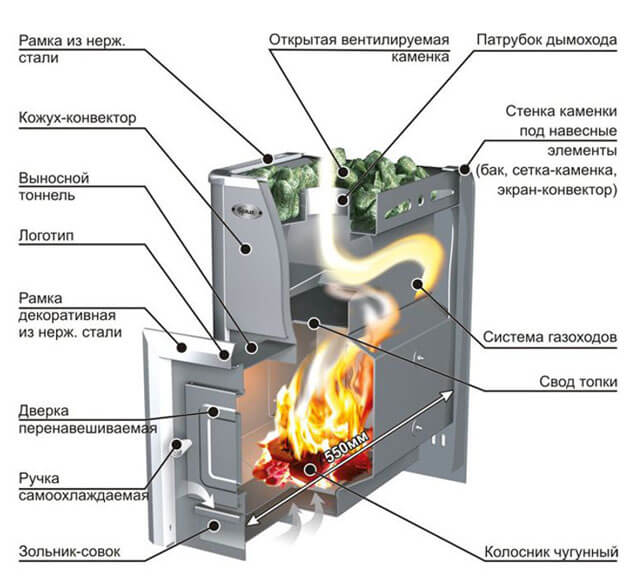

Before thinking about making your own stove equipment or buying a ready-made model, you need to figure out the difference between a stove for a Finnish bath and equipment for a Russian one. To do this, you need to study the main structural elements:

- Fuel chamber, in which firewood will be burned.

- Chimney for evacuating evolved gases.

- Stove for heat-resistant minerals.

- A convector is a detail that distinguishes a sauna stove from equipment for a classic bath. This part provides quick heating of the steam room and the creation of dry steam.

- Ash box.

- Metal body.

In addition to the converter, steam generators can be installed on new models of furnace equipment to create steam.

Finnish modifications - heaters

Finnish electric heater

In a Finnish sauna, the air heats up less than in a Russian bath, and the air is more humid. If you intend to purchase a Finnish model for a Russian bath, then closed versions are suitable for you - heaters.

In a domestic bath, the air reaches 70 ° C, and a lot of moisture is concentrated in the steam. Not many metal ovens can provide the necessary conditions. The specified Finnish stove is convenient in that the stones in it do not come into direct contact with fire. And to create steam, a special device is used - a water dispenser. The funnel here is fastened with capillary technology, which directs water into the closed stones by a drip method.

There is a transformation of the liquid into steam. And this steam is very active. He enters the room through special channels. When steam is generated, a very high pressure is generated. And for this reason, this unit was named "steam cannon".

Many electric Finnish metal stoves, with an insulated heater, can be switched to sauna mode. In fact, they are versatile and optimal for use in conditions of heating dry air, where high temperatures and a huge percentage of humidity are formed.

Varieties

Furnace equipment is classified according to various factors. By fuel type:

- Electric models. There is no need to buy firewood for the equipment, you can accurately set the temperature regime. Among the shortcomings, one can single out the need to connect to the power supply network. Powerful designs operate from 380 volts, which requires the installation of an expensive transformer.

- Wood-burning models. Popular oven equipment that works from different types of wood, compressed sawdust briquettes. The pluses include autonomy. The main disadvantage is that it is necessary to constantly clean the chimney, combustion chamber, ash box.

A separate group includes gas equipment. It is less popular due to the complexity of installation, explosion hazard.

The equipment can be with a built-in water tank, a portable tank or without it at all.

It is also customary to classify equipment by material: brick, metal.

Choosing a metal sauna stove

Among the wide variety of products from various manufacturers of Finnish wood-burning stoves, it is sometimes difficult to decide which one is better to opt for (read: "Which wood-burning stove for a sauna is best for a steam room").

There are two types of baths:

- Russian wet steam room;

- dry Finnish sauna.

As it is clear from the classification, the Finnish dry steam room has a maximum humidity threshold of 15% and rather high temperatures, and 90-100 ºС is not the maximum. With such high rates, excess moisture would lead to unpleasant consequences - fainting, for example.

And, conversely, in a Russian steam room, very humid air (up to 50-60%) heats up to not very high temperatures, no more than 50-60 ºС. It is not advisable to increase the temperature more strongly, since not everyone can withstand such a load.

Depending on which type you prefer, it is worth choosing one or another type of Finnish boiler for a bath in order to create an optimal microclimate.

Selection principles

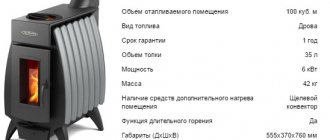

When choosing a purchased model of a Finnish stove, you need to pay attention to a number of characteristics:

- Rated power. For every 1 m3 of the room, you need to take 1 kW of furnace equipment power. There is no point in spending money on high power models for small steam rooms.

- The volume of the water tank. 15 liters of water is enough for one person.

- To the manufacturer. The more famous the company, the more expensive the oven will be.

- The location of the firebox. For small steam rooms, a remote firebox would be the best option. It can be taken to the dressing room.

You also need to pay attention to the material from which the oven is made.

Advantages and disadvantages

Benefits:

- Not everyone likes the high humidity in the steam room. Finnish stoves are deprived of this.

- Since the humidity level is low, the wood in the steam room decays more slowly. Reduces the risk of fungus, mold.

- Manufacturers pay increased attention to the materials from which the furnaces are made. Thanks to this, they do not emit harmful substances when heated strongly.

Among the shortcomings, one can single out the fact that not all bath visitors love dry steam, and universal models cost a lot of money.

Models and prices

Many Finnish oven manufacturers are known. Based on the opinion of buyers, several popular models can be distinguished:

- Harvia 20 SL BOILER. The peculiarity of this stove is that an additional water tank can be connected to it, operating on the principle of a boiler. The stove holds 40 kg of stones. Suitable for heating steam rooms up to 20 m3.

- Harvia 20 Duo. A model of furnace equipment, which stands out for its modern design, a remote combustion chamber, a door made of heat-resistant glass. Suitable for heating steam rooms up to 20 m3. The stove can hold no more than 40 kg of stones.

- Narvi Kota Inari. A true Finnish stove that matches the interior of a classic sauna. The stove is located above the combustion chamber. Designed for heating rooms with a volume of up to 13 m3.

- Narvi Stony 18 tunnel. Furnace equipment with a remote firebox, which has a vertical heater located along the chimney. Designed for steam rooms up to 18 m3.

- HELO ROCHER WOOD L SL. An unusual stove, which is suitable for saunas, Russian baths. The firebox is located under the stove. The heater itself is stretched high up, fenced off with twigs. It can hold up to 140 kg of stones. Suitable for steam rooms up to 20 m3.

The average price for Finnish stoves in stores is 40-50 thousand rubles.

Pros and cons of Finnish stoves

A lot of heat, developed by the combustible material, is lost from a bad device: a) A firebox, disproportionate neither to the amount of fuel, nor to the heating planes of the furnace. b) Chimneys, closed and inaccessible to room air. If little firewood is put into the firebox, as it should be in warm weather, then heat does not penetrate through the thick walls of the stove to its outer planes. A large amount of firewood, imposed above and on the sides of the furnace doors, does not light up at the same time and gives different products, of different temperatures, some of which light up earlier, others later, and some do not ignite with everything. Under such combustion conditions, small particles of carbon, not combining with oxygen, are carried away from the firebox into the chimney, sitting on its walls and smoke circulation in the form of soot and giving the smoke a thick and black color, which proves a clear loss of combustible material. At the end of the firebox, when the furnace doors are left open to burn out the embers, room air, flowing through the furnace in large quantities, cools the internal, just heated surfaces. Turnover takes away little heat from the smoke, this is proved by its high temperature in the view (from 182 to 267 ° С). Here, sometimes, sparks are shown, igniting at a temperature of 300 °, and this is almost half of the temperature that occurs in a firebox.Among the inconveniences is the fact that Finnish stoves take up space in the room. This is not yet noticeable in two or three of them heated by a single oven, but in large homes that require a significant number of ovens it is really difficult to place them. On the other hand, such ovens offer the possibility of monitoring their firebox and ducts.

DIY making

You can make a Finnish sauna stove, but you will have to face many difficulties:

- calculating the dimensions of the structure to ensure proper heating for the steam room;

- calculating the volume of the heater;

- taking into account fire safety rules;

- placement of the main elements of the furnace;

- creating a solid foundation;

- checking the tightness of welded seams.

If you have experience with a welding machine, grinder, you can try to assemble the structure yourself.

Finnish manufacturers of wood-burning sauna stoves

For many decades, Finnish companies have been creating furnace equipment and selling it on the Russian market. Thanks to many years of experience, the technologies are perfected to the smallest detail, and the materials are checked and tested more than once.

Basically, these stoves are suitable for heating dry air, which is typical for Finnish saunas. But recently, the Finns have taken care of creating the atmosphere of a Russian bath, starting the production of new furnace equipment. It is surprising that few domestic companies are engaged in the production of heating units for Russian baths.

Tulikivi

This is a well-known Finnish concern and a recognized world leader that produces stoves and fireplaces from natural stone.

Finnish bath devices Tulikivi are made from a material called talcomagnesite... This is a unique stone of volcanic origin. Products obtained from it are distinguished by their massiveness and long heating. But the big advantage is that the heat emanating from this material is very soft and lasts a long time.

The advantages of talc magnesite for the manufacture of sauna stoves:

- Environmentally friendly material.

- Absence of radiation background.

- Heat capacity and thermal conductivity.

In addition, not every stone goes into production: first, they must all undergo a serious selection.

Tulikivi has a wide range of products, with more than 250 models of stoves and fireplaces. Thanks to the material used, they all have an impressive weight - from 207 to 4000 kg. To the listed advantages of the products, an attractive appearance with two options for the surface of the stone should be added: polished and chipped.

Harvia wood-fired heating units

Furnace equipment from this manufacturer is reliable and durable. All metal elements are coated with a special fireproof paint. The firebox is made of heat-resistant steel with a thickness of about 10 mm, and the cast-iron grate is designed to serve for more than one decade. Thanks to this serious approach from the manufacturer, Harvia ovens can work day and night.

Almost all models have a glass door, which opens the view for fans to watch the fire and allows you to control the process of burning wood.

The main advantage of the Finnish Harvia sauna stove is the presence of two fuel combustion channels, which are absolutely independent of each other. This reduces the heating time of the sauna room to the desired temperature, which contributes to fuel savings.

Installation

When installing the oven, you need to adhere to some rules:

- In places where the chimney passes through the roof, the ceiling must be installed with special sleeves made of non-combustible materials.

- Surrounding surfaces should be protected with metal sheets that will reflect heat radiation. Under them you need to place asbestos slabs.

- The base for the furnace should be laid out of fireclay bricks. Check it by level so that there are no distortions.

After completing the installation work, you need to check the oven.To do this, a trial kindling is carried out in a gentle mode. Chips, straw are used.

Excellent quality steam

For more than half a century, the Finnish company Harvia has been producing first-class sauna appliances: electric and wood-burning. At the same time, electric heaters are no less popular than the classic wood-fired models, because electric heaters are convenient to use, they are very beautiful and reliable. Made of modern high-quality materials, Harvia electric sauna stoves look like new even after many years of continuous use thanks to a special coating. A wide range of electric models for a sauna allows everyone to choose the best, in terms of price / class ratio, option for everyone. At the same time, you can buy both a powerful heater for a large public sauna, and a compact model.

Exploitation

The rules for operating the furnace are simple:

- do not load a lot of firewood into the firebox at one time;

- regularly clean the chimney, ash box;

- check the integrity of the stones once a month, throw out minerals that have split from the heat;

- lay a sheet of stainless steel in front of the stove so that the floor does not catch fire from sparks flying out of the firebox.

You need to heat a wood-burning stove only with high-quality wood. It is forbidden to burn garbage in the combustion chamber.

Finnish stoves are needed for saunas. They allow you to get dry steam, low air humidity. They differ from the stove equipment for Russian baths, they have certain features in the device.

Finnish oven device

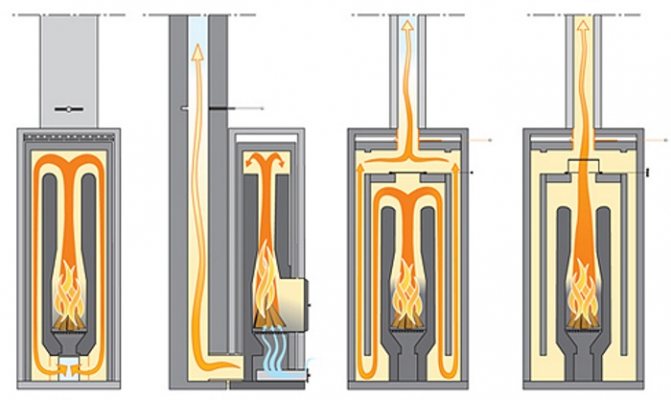

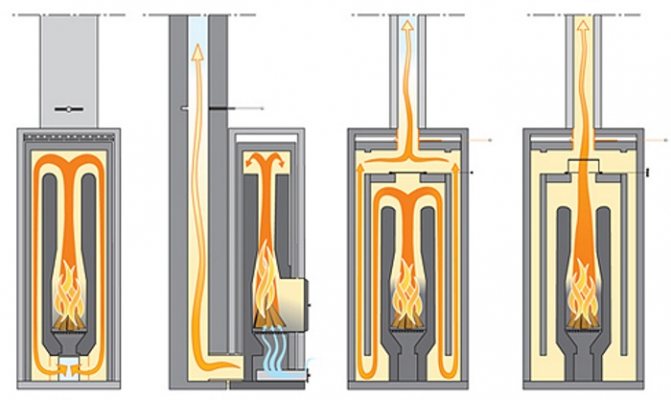

An ordinary Finnish stove, as you know, consists of a large firebox, its entire length between the outer walls of the stove area, closed by a vault, with an opening in the back of it, called a hail. Through it, the combustion products pass from the firebox into the chimneys (wells), arranged above the vault in numbers from 4 to 8, according to the size of the furnace. In the furnace, the heat is retained by a view placed at the top of the last turn in front of the chimney. The details of the arrangement of ordinary Finnish stoves are more or less known to every stove-maker.

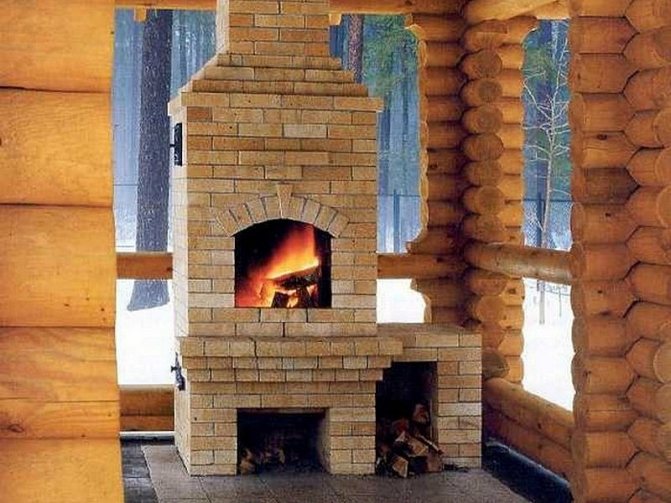

Heat-intensive oven. A symbiosis of Russian and Finnish technologies.

E. Doctors

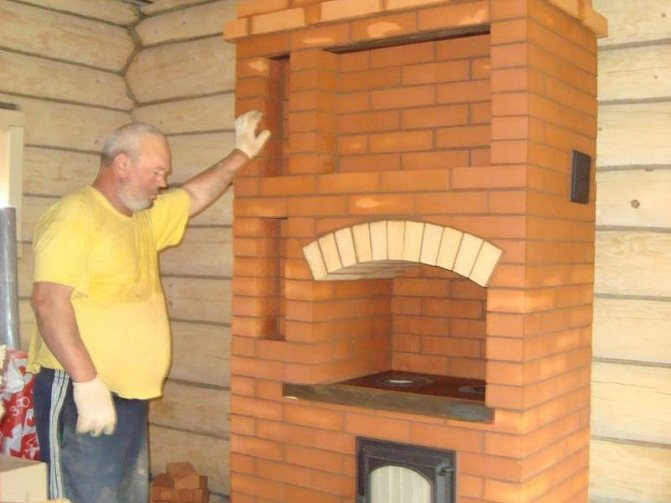

I have long wanted to try to combine the gas movement system used in Finnish fireplace stoves with the bell system used by the famous furnace designer I.V. Kuznetsov. However, all hands did not reach the development of such a project. But in September 2006, an order appeared, which made it possible to implement old ideas.

I had to fold the stove in a chopped house with dimensions of 8 × 6 m. Considering the area of the heated room, I asked the builders to make a foundation for the stove measuring 130 × 95 cm and bring it 15 cm below the level of the finished floor. This part of the foundation of two rows of bricks I reported later myself.

The room in which I put the stove is, according to the plan, divided into three parts: two small equal bedrooms and a living room. The front wall of the stove had to be positioned flush with the partition that separates the living room from the bedrooms (Fig. 1).

At the request of the customer, I designed the oven in such a way that the front wall becomes the hottest part of it. In addition, the facade was decorated with shelves, like the front of the fireplace, which required strict symmetry in the masonry.

In Finnish fireplaces, as you know, gases from the firebox are fed through the central channel into the large smoke chamber of the 2nd tier, where the gases are efficiently burned. In my furnace, I wanted to combine the advantages of this design with the advantages of bottom heating in bell-type furnaces, where the firebox and the first bell (according to the recommendation of I.V. Kuznetsov) should form a single whole.

Fig. 1. House plan: 1 - living room; 2 ... 3 - bedrooms; 4 - oven.

Using my previous positive experience, I also abandoned the separate summer (ignition) stroke with a valve. The fact is that with the valve closed, part of this stroke always remained cold. In my oven, this drawback is eliminated.And to prevent smoke from the cold stove, I connected the firebox with the hoods of the 2nd tier with firing holes. At the same time, the thermal characteristics of the furnace did not deteriorate.

Of course, when developing the design of the furnace, we had to proceed from the fact that in Moscow, and even more so in the "outback", there are no component materials used in Finnish furnaces, for example, floor slabs for gas chambers. (In this regard, one can envy the stove-makers of Karelia - the head of their guild, S.I. Seregin, managed to organize the production of such slabs from heat-resistant concrete in Petrozavodsk.)

When designing the stove, I decided to increase its heat capacity by increasing the thickness of the side walls of the firebox to 25 cm. For this, the side walls made of red stove bricks were overlaid with fireclay bricks placed on a die. A thermal gap of 5 ... 6 mm was left between the fireclay and red bricks. The same gap was left between the front wall of the furnace and the lining of fireclay bricks placed on the edge. By doing this, I "untied" the laying of the firebox and the outer walls of the stove, reducing the risk of cracking the latter at the seams.

I made the ascending channel from the chambers of the first tier to the bell chambers of the 2nd tier in a quarter of a brick, thereby increasing the length of the furnace. The caps of the 1st tier were blocked on 17-18 rows, which is 2/3 of the furnace height. This position of overlap, according to I.V. Kuznetsov, is the most optimal.

Holes for ignition of the furnace with dimensions of 6 × 6 cm on each side in the side inner walls are located on 21 rows. This is two rows above the bottom of the tier 2 caps. This arrangement, in my opinion, prevents them from clogging when cleaning the channels.

In addition, in my stove, in contrast to Finnish projects, the uppermost part of the gas chamber, located above the firebox, can also be considered a bell, which, in my opinion, is an advantage. Cold air passing after the end of the furnace through the loosely closed blower and furnace doors enters through the firing holes into the pipe, without affecting the hot gases in the upper part of this chamber, as well as the hoods of the 1st and 2nd tiers.

The furnace is made with fire-prevention cutting on the sides and on the rear side (it is not shown in the orders) in those places where partitions are planned. The openings at the bottom and top of the fire protection section will be covered with ventilation grilles through which air will circulate throughout the premises.

Summing up, I want to note that the oven is strictly symmetrical in terms of the location of the bells of both tiers. This ensured uniform heating of all surfaces of the furnace, including the front one.

According to I.V. Kuznetsov, the heat transfer per square meter of the furnace surface with a two-time firebox is approximately 500 W. Knowing this, it is easy to calculate the heat output of my oven.

Heat dissipation of the front and rear walls: (1.25mx2.1m) x (500W / m2) x2 = 2625W.

Heat dissipation of the side walls: (0.9 mx 2.1 m) x (500 W / m2) x2 = 1890 W. Total: 4515 watts.

Thus, the heat transfer of the stove with two fireboxes per day averages 4.5 kW. With a one-time firebox, the heat transfer of the furnaces (according to the same calculations by IV Kuznetsov) can be taken with a coefficient of 0.6 ... 0.7.

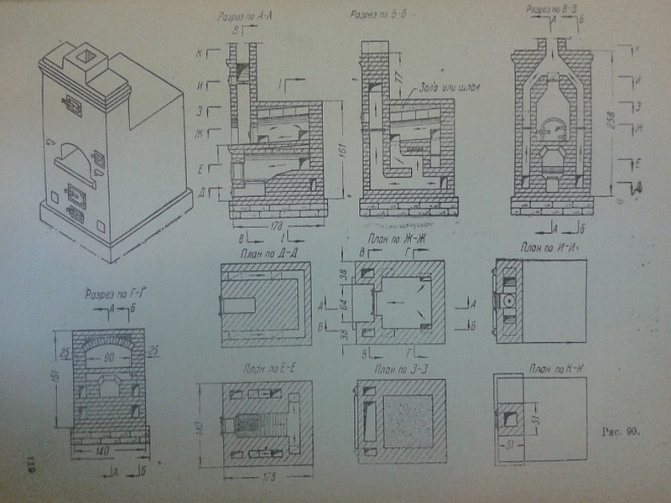

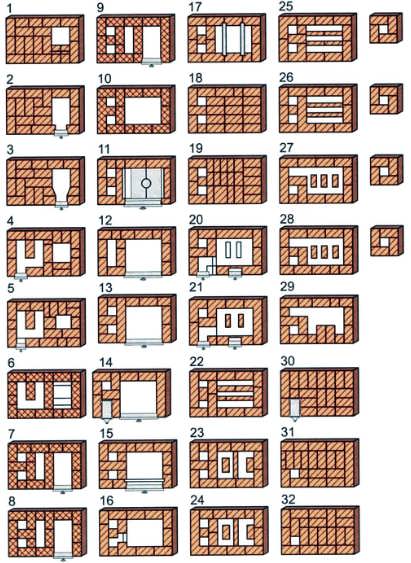

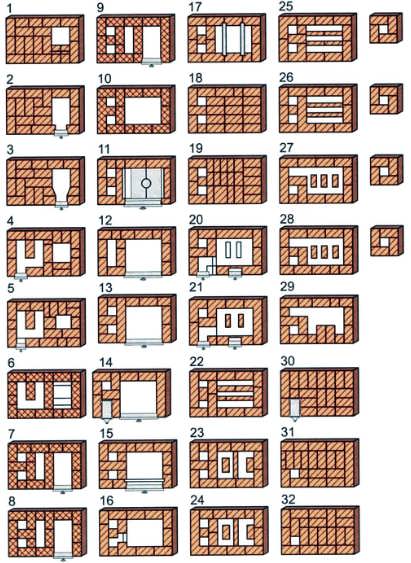

Fig. 2. Ordering the oven

Fig. 2. Ordering the oven (continued).

List of materials (excluding pipe and fire cut)

Kiln brick M-200 (Vitebsk) - 753 pcs. Fireclay bricks SHA-8 - 65 pcs. Fireclay clay - 120 kg. Sand - 500 kg. Doors: blower - 1 pc., Furnace - 1 pc. Grate - 1 pc. Small valve (250 × 130 mm) - 1 pc. Corner 40 × 40 х350 mm - 2 pcs. Knitting wire 03 mm - 4.8 m.

A selection of articles on the topic of stoves and fireplaces. Previous page :: Next page >>

Our site is regularly updated with interesting and unique materials and articles on the subject of ovens, barbecues, grills and barbecues. If you would like to receive information about this, subscribe to the newsletter of our website. It is guaranteed that your address will not be passed on to third parties.

Do-it-yourself Swedish stove: masonry, drawings, ordering

Photo: Do-it-yourself Swedish oven masonry drawings ordering

Before you start laying, you need to familiarize yourself with the order. You need to decide where the firebox will be located: from the end or in the back. The Swedes are heated with wood, they can be installed for a frame house on two floors, since the height is large. You can make a mini oven by reducing its size, but then you have to find a suitable surface for the stove.

The work consists of the following stages:

- Choosing a place. Decide on the placement not only from an aesthetic point of view, but also from the point of view of the location of the chimney.

- Foundation. Assumes a deepening of up to 80 cm: a surface is marked on the floor and cuts are made using a grinder. Next, dig a hole with a shovel, tamp the sand with gravel.

- Reinforcement of the foundation. Use formwork and iron reinforcement, which is filled with mortar.

- Layout. You can use a 3 by 4 brick scheme, you can use Kuznetsov's scheme. You can make a bell-type oven with your own hands: the order in this case will be different. The first two rows are laid out in full, then the ash chamber is built, the doors are installed. From the fifth row, the wind section is mounted, the combustion chamber is laid out with refractory material. At the end, an ash pan is made.

You can install the product in a wooden house, you can make it for a wood-fired sauna. Do not forget about the formation of the chimney according to the planned scheme.

Device maintenance

During operation, some questions about the use and maintenance of the Swede may arise:

- a wood-burning Swede may require repair of the firebox: the replacement of the firebox door occurs by dismantling the old one and installing a new one;

- how to cover cracks: for this, use a mixture of clay and sand on a primed surface;

- how to establish draft in a cold stove: check the chimney for soot, clean it, provide a good air flow;

- how to heat properly - when firing up the main pipe valve must be open.

Advice! The design has independent fireboxes, therefore, when the fireplace is in operation, the stove itself may not work, and vice versa.

Compliance with all the nuances will lead to the longevity of the Swede, made by yourself.

Don't Miss: Working Furnace - How It Works, Drawings, Pros and Cons