Do-it-yourself long-burning stove from a gas cylinder

Stove stoves, made from improvised means, do not lose their popularity, especially in the winter period. A potbelly stove can be made from a gas cylinder in two ways. The vertical oven is most often installed in small utility rooms and country houses. A horizontal potbelly stove is usually built for heating and cooking.

Stove heating is considered to be quite in demand, and most often it is created in such structures in which it is simply impossible to bring another heating system. If you wish and have time, you can carry out all the work on the formation of the structure with your own hands. It can run on wood or another type of fuel.

The very shape of the balloon ensures the formation of an optimal and interesting stove with a spherical firebox. The result is a long burning design. It is suitable both for a private house and for a bath. If you need to do it yourself, then it is advisable to study the instructions well and watch the training video.

Kebab oven

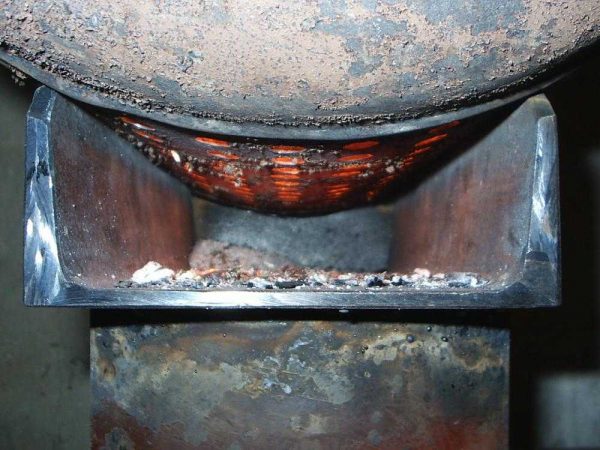

This wonderful device is made of two disks from the wheels of passenger cars. Although, if someone wants a bigger stove, then there are no restrictions: you can use wheels from UAZ or GAZ-53. In one of them, the bottom is carefully cut and then the rims are welded together.

We offer you to familiarize yourself with the bathhouse with a garage under one roof

In order for the unit to be reliably installed on any surface, legs are attached to the lower section by welding, as shown in the photo.By the way, the hole for the hub must also be plugged, but the side holes can be left, through them air will enter the firebox. For ease of portability, handles are welded to the outside of the body, and an opening for the door is cut in the side part.

The latter is made from the same piece, planted on hinges. That's it, the oven from car drives for barbecue and cooking is ready. As practice shows, 5 skewers with meat fit on it.

Small stove from a small cylinder

For a small steam room with a volume of 8-10 cubic meters, it will be enough to make a stove from a small gas cylinder. Usually 27 liter cylinders are used. The wall thickness at the bottom is remarkable - 6 mm. Without a crane, their height is 500 mm, diameter is 300 mm. It turns out to be a wonderful little stove.

First, the remaining gas must be removed from the cylinder. For this, water is poured into it. Water gradually displaces all residual gases. After the cylinder is filled, you can cut off the tap and start making the furnace.

First, with a grinder, carefully, at the end where the tap was, cut a hole for the firebox door. On one of the sides, which turned out to be under the long side of the cut-out hole for the door, we arrange a kind of grate. We take a drill and cut 10 mm, drill holes every 20 mm. There are 5 rows in total.

Ash pan holes should be at the bottom

Weld a piece of channel over the holes. In our case, its width is 140 mm. We weld the back wall to the front flood and attach a door. You get an ash box. Its minus is that in this version it is not retractable. If desired, the design can be improved by making a separate box.

Welded channel

As a support, a protective structure was welded to the channel, which closed the tap. Economical and completely reliable.

The stand is made of protective construction

The doors were fixed to the ash pan and to the firebox, a chimney pipe was welded closer to the rear of the firebox (first it was welded, then the metal was cut out inside by welding).

Doors are installed in place

We carried out a test kindling. In the presence of a high pipe - more than 2.5 meters, the thrust is excellent.

Trial kindling

As tests have shown, a 2.5 * 2.5 * 2.3 m steam room from 3 ° C to 25 ° C was heated in less than half an hour (almost without insulation, since the bath was not completed yet). Then they stopped drowning, it is necessary to improve: too hard heat is emitted.

Read how to make a sheet metal sauna stove here.

Content

- Choosing a cylinder

- Improvised means, materials and tools

- Creation options Create a vertical oven

- Horizontal potbelly stove device

A stove-stove is very often used for heating premises such as a garage, utility room, basement, country house, etc. For occasional heating, it is impractical to buy a boiler and install a heating system. For these purposes, many purchase stove stoves. However, there is another, more budgetary option - to make a potbelly stove with your own hands from a gas cylinder.

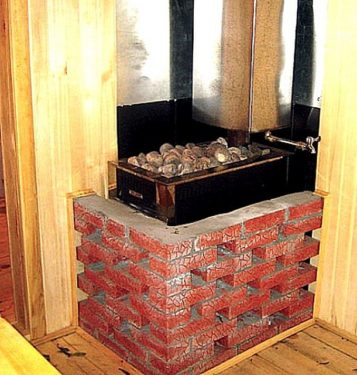

An example of a handmade potbelly stove. Such a heater is often installed in summer cottages, garages and utility rooms.

Choosing a cylinder

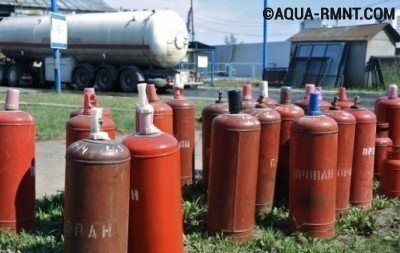

An old and unnecessary gas cylinder is a suitable body for a future oven. But in order for the potbelly stove to effectively heat the room, you need to choose the right size of the container. Five-liter cylinders are very small, their volume is not enough to create heat even in a small room. Cylinders of 12 and 27 liters can be used for heating small rooms, but such stoves will be low-powered. The most suitable option is a 50 liter gas (propane) cylinder.

Important! The dimensions of a cylinder with a volume of 50 liters have standard dimensions: diameter - 30 cm, height - 85 cm.

If a forty-liter industrial gas tank is at hand, then it can also be used as a case for a stove. However, it should be borne in mind that the walls of such a cylinder are thicker, and the diameter is smaller.

Important! Freon cylinders for the manufacture of a potbelly stove are not suitable, since they have a large mass and size.

The power and heating rate of the furnace directly depend on the size and thickness of the walls of the cylinder. The optimal volume of the tank for a potbelly stove is 50 liters.

Before using a gas cylinder, it is prepared for work, for this you need:

- unscrew the tank valve;

- leave the cylinder overnight and let the remaining gas come out;

- turn the balloon upside down;

- drain the condensate and collect it in an unnecessary container;

- fill the container with water to the very top;

- turn over and drain the water.

↓ Be sure to study the recommended material on the topic ↓

DIY mini-stove stove: on wood and working off

Important! Failure to dispose of the remaining gas in the cylinder increases the risk of explosion when welding or cutting the container. Be careful.

Before starting work on the creation of a potbelly stove, the gas cylinder is cleaned of gas residues. Otherwise, an explosion and unpleasant consequences may occur.

How to install a cast-iron door on a metal cylinder

When making a stove for a bath from a gas cylinder with your own hands, it is easier to attach a ready-made casting than to cook the door yourself. Only now it is not clear how to dock two different metals. In reality, everything is simple. Buy a cast-iron door you like or suitable in size. It comes with a frame. The same frame is cooked from a metal corner of a suitable size. It is welded to the cylinder, and the cast iron door is bolted to it.

How to attach a cast-iron door to a gas cylinder

For sealing between the frames, you can lay a layer of asbestos or mineral wool cardboard (just watch that the temperatures withstand high - up to 1200 ° C minimum). You can do it differently - weld a small side 1-2 cm on the metal frame, which will cover the gap.

Improvised means, materials and tools

In order to make a potbelly stove from a gas cylinder, you will need the following materials:

- pipe for creating a chimney;

- metal (sheets with a thickness of at least 3 mm);

- fittings;

- metal corners.

The principle of operation of a potbelly stove from a cylinder is very similar to the example of an ordinary potbelly stove in the drawing

From tools and equipment you need to prepare:

- hammer, chisel, pliers;

- welding machine;

- marker;

- grinder;

- drill and drills of the correct size.

We recommend that you study the material on how to increase the efficiency of a stove and find answers to your questions.

Advice! The stove-stove must have doors and a grate. Curtains can be made by hand from sheet metal. As a grate, you can use the bottom of the cylinder with drilled holes or fittings. If it is not possible to do it yourself, you can buy ready-made parts in the store.

For the construction of a potbelly stove from a gas cylinder, you will need metal sheets, corners, reinforcing mesh and a pipe. Many have such materials lying around in the garage or utility room idle.

Preparatory work

For work, it is better to use a propane cylinder. It is most suitable for this design because of its size. You can buy a cylinder at any scrap metal collection point, as long as it is intact, without holes and large dents.

It does not matter when the cylinder was produced and the period of its testing. Do not pay attention to the uniformity of coating the walls of the container with paint, it will still burn out immediately during the first tests of the oven. The main thing is that the walls are not eaten by rust, it is better if the tap is removed before you and the gas is released from the cylinder.

We offer you to familiarize yourself with the boiler in the oven with your own hands schemes

It is difficult to indicate the exact amount of materials. Much depends on the size of the water tank or the size of the stone compartment. Here is a list of the necessary materials, and how many you need, it's up to you:

- gas cylinder;

- metal sheet, 2-3 mm thick;

- if after construction there are pieces of reinforcement or rods from them, you can make a grate and handles for doors;

- for the legs, you can use a corner or a profile pipe. If the farm has a large-diameter pipe segment, you can cut off a piece 60-70 mm wide, cut it in half and weld it to the cylinder;

- pipe, section 120 mm, length 400 mm for chimney outlet;

- a bar or reinforcement, for the manufacture of a mesh in which we lay stones;

- bricks for the basement of the sauna stove.

Instruments

- welding machine with hand and eye protection;

- workbench with a vice;

- clothing with long sleeves made of dense material;

- electrodes for welding structural steels. An inexpensive option - ANO-21 or MP-3, with a diameter of 3-4 mm;

- Bulgarian;

- cutting and stripping discs;

- locksmith's tool;

- sandpaper, metal brush.

Tips & Tricks

Experienced craftsmen advise making a potbelly stove from a gas cylinder, taking into account the following nuances:

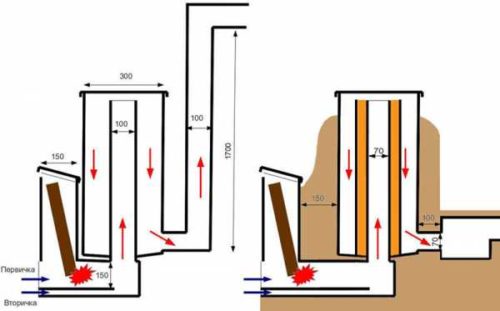

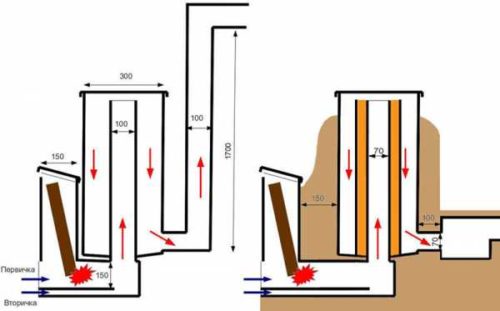

- The chimney must not follow the shortest route. In this case, the heat will go away along with the combustion products. The best type of chimney is a broken pipe.

The chimney is made of a broken shape so that heat does not escape from the stove along with the smoke. The curved pipe prevents heat energy from escaping. It is only important that the pipe is not made of aluminum!

- Any type of fuel can be used as fuel - coal, wood. If necessary, household waste and carpentry waste can be burned in the stove.

- You can increase heat transfer and make a stove with high efficiency by increasing the length of the chimney. Parts with straight sections or with a downward slope should be avoided.

- If an additional one (in the form of a vertical pipe) is attached to the main body cylinder, then the heat can be used doubly. Such a potbelly stove from two cylinders creates good traction, combustion products and smoke will not get into the room / garage / utility room. In addition, the heat transfer of the heater will increase.

Positive and negative parameters

The use of a gas cylinder to form this structure has certain advantages, which include:

- you can get a long burning stove with minimal costs. since you will need standard and inexpensive elements and materials;

- you can do all the processes with your own hands. therefore, you do not need to resort to the help of specialists;

- you can use the resulting equipment for a house, a bath or other structures;

- on the Internet you can find video instructions for creating a structure. therefore, you can avoid any problems during work;

- it is quite easy and convenient to use such stoves. and also there is no danger for users;

- completely different types of ovens can be made from a gas cylinder. which can have various parameters and features.

The disadvantages of this equipment include the fact that there must be competent and high-quality drawings, according to which all work will be performed. Without them, you can violate the basic principles of furnace design and make serious mistakes.

Typical designs of gas heaters

For heating and heating a bath, several basic types of boiler equipment are used:

- Brick stoves-heaters with a gas-fired burner built into the firebox;

- Combined gas bath boilers;

- Low-power metal gas stoves with a bulk stove.

For your information! All of them are united by a similar device of the burner and control equipment, otherwise all of the listed devices have significant differences.

Therefore, the selection of the most suitable model of a gas boiler is carried out in each specific case according to the individual parameters of the steam room and the bath itself.

Why is such a boiler needed and how does it work?

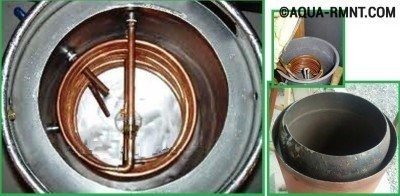

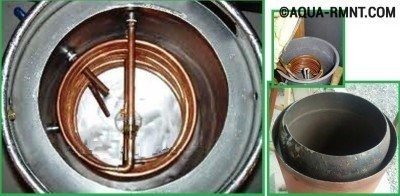

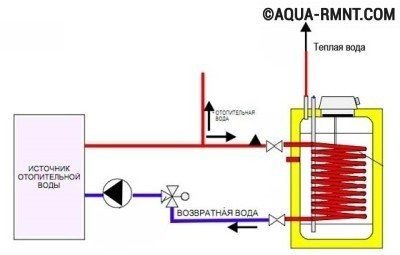

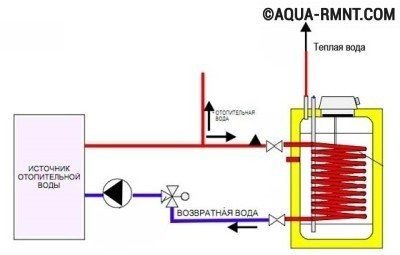

To understand how an ordinary indirect heating boiler works, it is enough to study the device of this device. It is a tank in which pipes are installed. A coolant circulates through the pipes, for example, used to heat a house. Cold water is supplied to the tank, it gradually heats up to a certain temperature and can be used for household needs.

The diagram clearly shows the device of an indirect heating boiler, which consists of a water tank and pipes with a coolant inserted inside

Owners of gas water heaters and electric flow heaters are well aware of the problems associated with their operation. After the water is open, you need to wait for a while until it warms up to the desired temperature. It also happens that the temperature of the water in the shower suddenly drops if at that moment a tap in the kitchen is turned on, etc. But the indirect heating boiler eliminates these shortcomings, since the water in the device maintains a constant temperature.

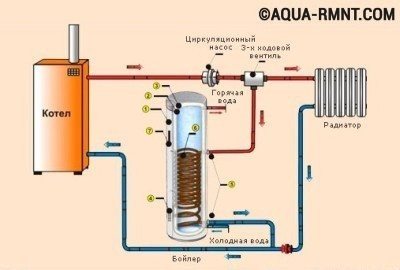

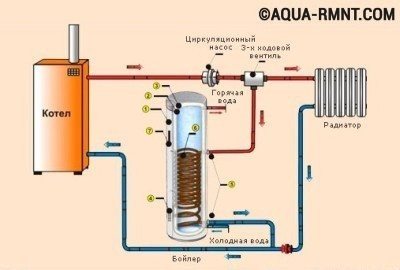

There are several types of device for a self-made indirect heating boiler:

- The most popular option is a coil made of metal pipe. The coil is placed in a tank and a coolant is passed through it. Cold water is poured into the tank, which heats up on contact with the coil.

- The pipes with the coolant can be placed not in the center of the tank, but along its walls, if it is more convenient. In this case, there are no other fundamental differences from the first version of the indirect heating boiler.

- You can do without pipes at all, and use two containers of different diameters. They are inserted into one another, water is supplied to the smaller tank for heating, and the coolant circulates in the space between the walls of the tanks.

Since the principle of operation of an indirect heating boiler is quite simple, you can come up with your own version of this design.

To create a long-burning oven with your own hands, you must choose only suitable and high-quality materials. Therefore, you need to choose an all-metal cylinder. Explosion-proof elements that are not resistant to high temperatures are not suitable.A household balloon is also not suitable, since usually such elements are too small in size.

The best solution is considered to be cylinders with a volume of 12 or 27 liters. However, for a full-fledged design of long burning, the most ideal choice is a 50-liter cylinder, the diameter of which is 300 mm. It can burn absolutely any type of fuel, and its cost is considered affordable.

Types of Iron Furnace Construction

There are 2 types of metal heating devices for a bath:

- Hot. Such structures heat up quickly. Experts recommend installing them in rooms of inconstant use, for example, in a country house. In other rooms, it will be impossible to control the heating temperature, which will lead to overheating of the air.

- Cold. The units are equipped with a temperature control system. The walls of such devices do not heat up above 50 C.

By the type of construction, heating devices are divided into cold and hot

There are 3 types of heating device design:

- Closed apparatus. Compact equipment is installed in small baths. From the inside, the device is lined with a refractory material to increase the heat resistance. Also place a grate for stones.

- Open type units. Appliances are often equipped with a water container and an open heater.

- Combined devices.

Ovens of open, closed and combined types are distinguished.

By the type of fuel, sauna stoves are distinguished:

- on coal;

- wood-burning;

- electrical;

- gas ovens.

3 types of fuel: wood, electricity and gas

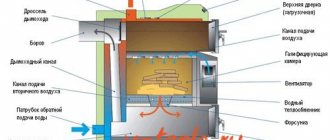

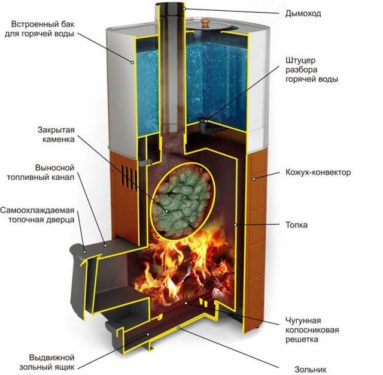

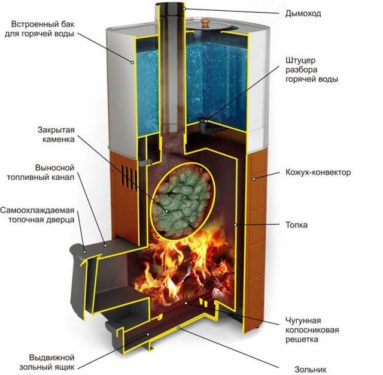

Before starting to describe the principle of operation of gas-fired furnace equipment, you need to understand its device. Structural elements:

- gas burner for the oven in the bath;

- fuel source;

- gas combustion chamber;

- chimney for removing vapors;

- container for stones;

- convector for thermoregulation;

- Control Panel;

- metal case;

- protective screen between the stove, the combustion chamber.

We offer you to familiarize yourself with a frame bath with your own hands: how to build efficiently

A man needs to open the gas supply, light a fire. After that, set the gas supply power, wait until the stones in the heater are completely warmed up.

Furnace design

Technologies for the formation of different types of furnaces

To create a long-burning furnace using a gas cylinder with your own hands, it is important to determine initially what purpose it will have, what fuel will be used to heat it up, and what other parameters it will have.

The simplest option would be to make a standard stove a potbelly stove from a cylinder. which can be intended for a home or a bath. Firewood is used as fuel for it. A cylinder with a volume of 12 or 27 liters is suitable for these purposes, but you can also choose a 50-liter element if necessary.

The operating principle of the resulting equipment will be very simple. It is important to use correct drawings during work. It is enough only to purchase a furnace door, which is installed in a cylinder, but different partitions or a grate are not needed for this design. Additionally, you will have to form a chimney elbow.

If you need to make a cooking oven, then cylinders are suitable materials for this purpose. From them you can get a grill or barbecue or even a smokehouse.

Another option is considered to be an oil stove, which is most often installed in garages. It is much more difficult to form such a structure with your own hands than an element on wood. The principle of operation of this equipment is as follows:

- The oil burns in a special fuel compartment. moreover, oxygen is supplied here in small portions with a special air throttle.

- As a result of combustion, vapors are generated, which rise into a unique reactor with re-formed walls.

- Air from the outside enters through the existing holes, which intensifies the already existing combustion of oil vapors.This leads to an increase in temperature, as a result of which the pyrolysis process begins. therefore the temperature rises even faster. This leads to the formation of nitrogen oxides, which prevents the oven from overheating.

- The gases from the reactor enter the afterburner chamber, which has two sections, separated from each other by a partition. Pyrolysis gases burn out in front of the partition, which leads to the maintenance of a high temperature. After the baffle, all the oxygen is consumed, but the temperature is still very high.

- A chimney is connected to the afterburner, through which combustion products are removed.

As a rule, such furnaces are created from sufficiently large cylinders, which are sawn into three parts. each of which has its own purpose. It is believed that this design has high efficiency and durability. A video of its creation on its own can be found on the Internet, but in order to obtain an ideal result, it is important to take into account all the nuances so as not to violate the principle of operation.

Another unique option is considered to be long-acting ovens, which are formed from 50-liter cylinders. They use wood fuel for their work. During long-term burning of wood, the pyrolysis process begins, which affects the fuel, which leads to a significant increase in efficiency, and also increases the heat transfer of the entire structure as a whole.

The bubafon stove is considered quite unusual. whose drawings differ in specific nuances. It is a long-lasting construction with a distinctive feature being separate combustion. It has a special oppression, under which the fuel is rammed, and the pyrolysis process is performed.

Thus, a gas cylinder can be used to form completely different types of furnaces, differing in purpose, appearance and principle of operation. The use of this element has many positive parameters, and you can cope with all the stages and technologies on your own. The resulting structures can be used for absolutely any structures.

What are the features of installing gas equipment in a bath

A do-it-yourself gas stove for a bath is an extremely complex idea, requiring accurate calculations, performing checks, and having practical knowledge in working with gas equipment. In addition to this, you must obtain permission to install it.

Before building a gas oven for a bath, a permit is required. The optimal material for construction is brick.

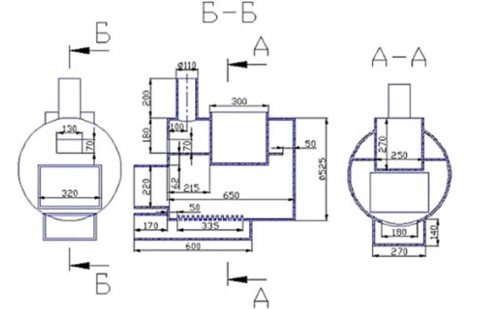

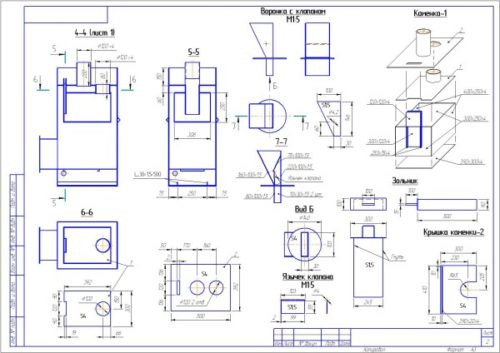

There are a number of devices that stand out for their constructiveness and principle of operation. Before proceeding with the assembly of a metal heating device for a bath with your own hands, draw up a drawing of the device. The principle of operation of the units is practically the same.

The first step is to equip the firebox. The dimensions of the structure are determined by the area of the room. Stoves are advised to make the unit height and width the same. Many professionals, when drawing up a drawing, assume that they will use ready-made elements.

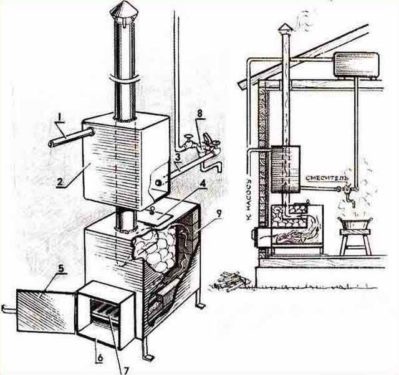

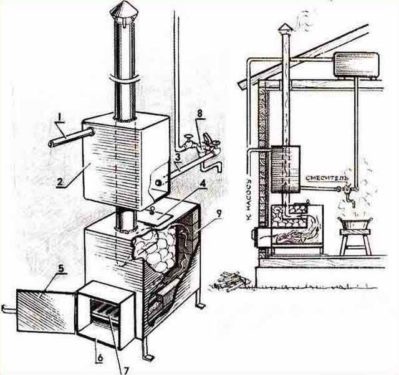

The device and principle of operation of a metal stove for a bath

The furnace is divided into 2 sections. Fuel is burned in 1, and ash is collected in 2. A grate is installed between the sections and separate doors are made. The ash pan can be used as a blower to create traction.

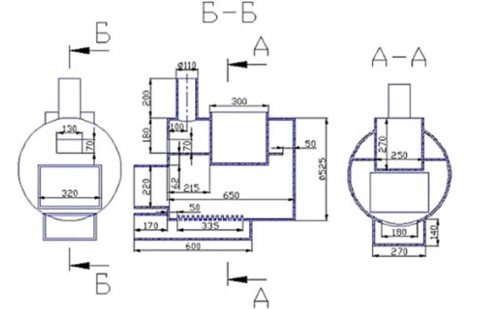

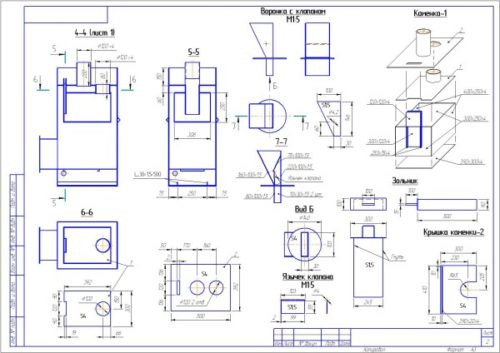

The simplest heating drawing for a small, rarely used bath

The upper part of the structure is made of a lattice for arranging a heater. This section is also separated by a door.

Attention! To create a furnace, experts recommend using 5-8mm thick metal. This design does not deform when heated, and the device will give off more heat.

Heating device for a metal bath, indicating the exact dimensions of the elements

The upper compartment of the unit is filled with stones to maintain the high temperature in the steam room for a longer time. The most common is the steam locomotive sauna stove, the drawing of which is presented below.

Steam locomotive device drawing

The top of the stove is equipped with a chimney. A water tank is built around it. As the smoke passes through the pipe, the liquid will heat up.

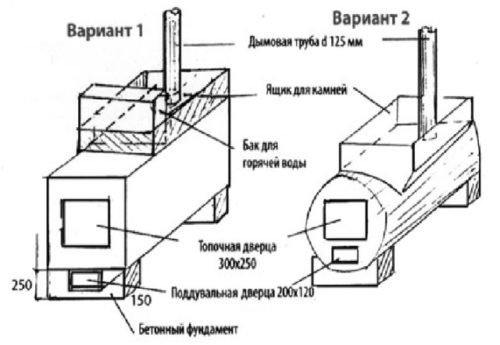

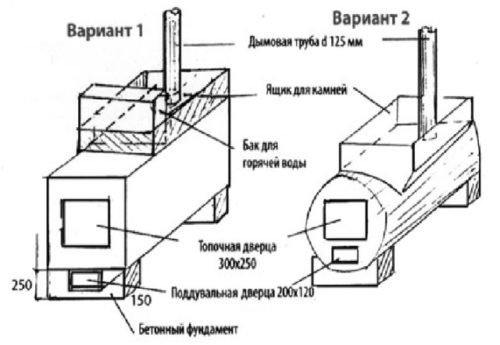

Two design options for horizontal pipe and sheet metal devices

The pipe in the water heating tank is installed strictly in the center. A tap is mounted from the bottom of the tank for ease of dialing. The water container is made from a thick pipe.

Drawing of a heating device for a metal bath with a detailed description of parts

At the design stage, it is important to know exactly where the chimney will come out on the roof in order to additionally equip the opening with a heat insulator and prevent a fire. To create thrust, the pipe must be positioned at a height of at least 4 m.

Heater project with a hot water tank

Stove-makers advise purchasing ready-made elements for arranging a chimney. So the unit will last longer, since the segments are made of durable material that is resistant to combustion.

Correct organization of the chimney

A protective screen is installed over the chimney to prevent hot air from acting on the walls and roof of the bath.

Factory products for the chimney have an attractive appearance and cope with the tasks

The pipe and the protective shield are made of reflective materials.

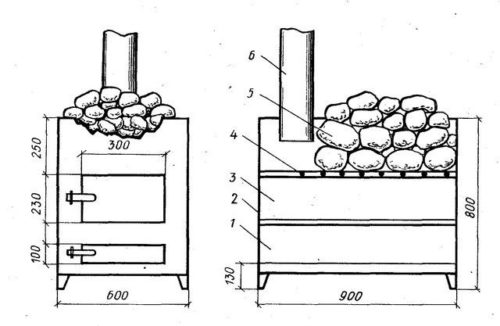

To make a stove for a metal bath with your own hands, you need to draw a drawing or pick up a ready-made one. The figure below shows the simplest version of a heating unit for a bath. Legend:

- Retractable ash pan with blower door.

- Metal body.

- Firebox.

- Lattice.

- Kamenka.

- Trumpet.

The easiest hot oven drawing to make

They build a stove for a bath made of stainless steel, sheet metal or pipes.

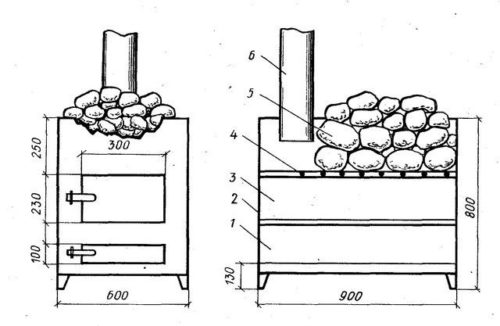

For manufacturing, you need a sheet of St3 steel with a thickness of 5-6 mm. Product width 60 cm, length 90 cm, height 80 cm. It can easily fit even in the smallest bath.

The pipe will require a pipe with a cross section of 11.5 cm. The length depends on the preferences of the owner. If you plan to install a water heating tank, then the length is taken longer.

Experts recommend seams to be welded on a metal profile 30 * 30 * 3 mm. It is suitable for laying the grate and grate under the heater.

Welding furnace

The ash pan door has dimensions 2-2.5 times smaller than the furnace opening. Cast iron grates are installed between the ash pan and the furnace compartment.

Cast iron grates are installed between the ash pan and the firebox

If there are no ready-made grates, they can be welded from reinforcement with a section of 10-12 mm according to the size of the ash pan hole at a distance of 10 mm between the rods

Welded grate made of a 10 mm reinforcement rod

The uppermost sector is the heater. A branch pipe fits to it, through which the combustion products are discharged from the furnace.

Hinges for ashpit and firebox doors are attached to the body. Latches are also welded on.

In the stove, 1/3 of the back is welded with a 30 * 60 cm metal sheet, in the center of which there is a hole for the pipe. It is welded to the compartment and lowered 12 cm.

Attention! The stove cover is not shown in the drawing. It must be made for the removal of combustion products into the chimney.

A lid is made of metal 1 mm thick, with which it is necessary to cover the heating device during the furnace. The lid should completely overlap the stove and extend 0.5-1 cm over the edges of the stove. It will not let the stones cool down quickly, and the heat in the steam room will stay longer. The lid is removed during bathing procedures.

After all the elements are welded, the seams are thoroughly cleaned from burrs. Outside, the metal is coated with heat-resistant paint or varnish for stoves and fireplaces.

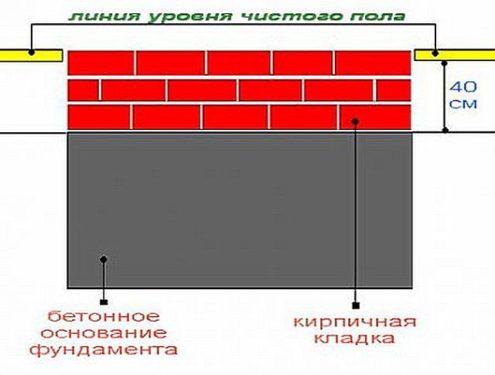

Under a metal heater, it is not required to equip a solid foundation like a brick counterpart. It is enough to build any base made of heat-resistant material:

- reinforced concrete slab;

- refractory bricks;

- Metal sheet.

In the place reserved for the heating device, a deepening of 50 cm is made. Sand and crushed stone 10 cm high are poured onto the bottom. Lay the roofing material waterproofing. Pour the base with concrete or lay a reinforced concrete floor.

Arrangement of a base for a metal stove for a bath

A second layer of roofing material is laid on top of the concrete base and the masonry is made of refractory bricks in 3 rows. The prepared base for the stove should be equal to the finished floor in the bath.

We suggest that you familiarize yourself with How to fold a brick oven for a brick bath with your own hands: ordering, drawings, oven diagram

Experts do not recommend installing the unit on a concrete base, since it will crack and lose strength from the temperature drop and constant humidity. The unit is erected from the walls at a distance of 20 cm. Heat-resistant material is attached to the wall:

- stainless steel shield;

- foil heat insulator based on mineral wool;

- lined with heat-resistant bricks.

The finished structure is installed on a prepared base. Mount the branch pipe. The chimney is brought in.

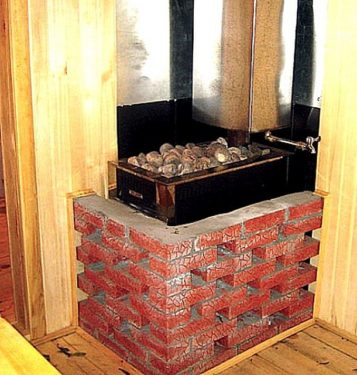

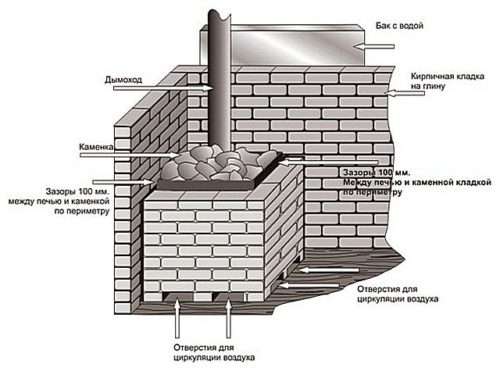

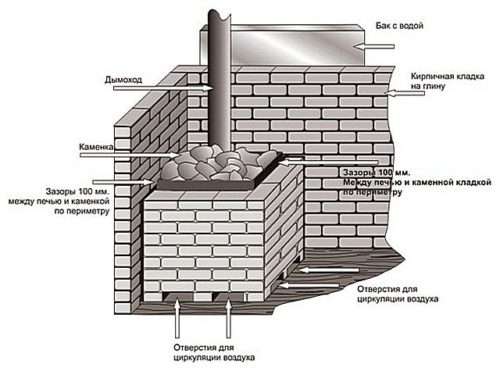

To maintain the temperature in the bath for a longer time, the metal structure is lined with bricks with clay mortar. Also, this technique will allow you to burn less against the walls of the furnace.

Option of lining a metal stove for a bath with a brick

A distance of 10 cm is left between the heater and the brickwork for air circulation. This technique will create a convection flow for quick heating of the steam room. In brickwork, windows are provided so that the metal does not corrode.

Scheme of lining a metal stove with a brick

Attention! The brick is laid on a clay-sand mortar, since cement mixtures do not tolerate moisture and temperature and will quickly lose strength.

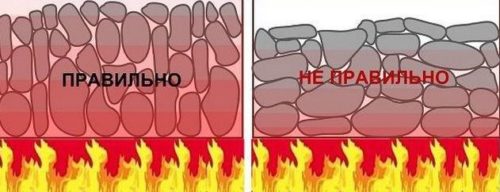

At the final stage, stones are placed in the stove. For an average stove, 50-80 kg will be required, with a fraction of 5-15 cm. Natural rounded cobblestones of different sizes will provide better thermal conductivity.

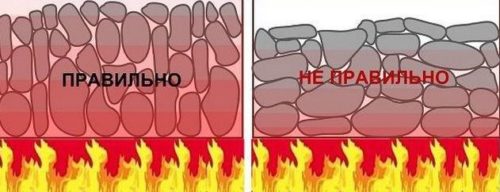

The scheme of the correct laying of stones

The best stones for a bath are jadeite, basalt and talcum chloride.

You can make a grate for a furnace with your own hands from a rod of reinforcement with a cross section of 10 mm. According to the size of the hole for the grate, parts are cut out: 2 longitudinal and 10-15 transverse beams. With a step of 2 cm, the crossbars are welded to the shared rods to form a lattice.