Even a solid assortment of ready-made sauna stoves made of metal could not diminish the popularity traditional heatersbuilt of bricks.

Lovers of bath procedures, having experience in using both brick stoves and their metal counterparts, unanimously claim that it is a brick that can create in a steam room comfortable atmosphere.

The steam is intense, but not scalding, breathing easily, and in the entire space of the bath, pleasant and soft warmth. The owners of a brick sauna stove are attracted by the opportunity, choosing a design to their liking, to create a unique interior with its help. However, for a brick heater, not only its magnificent appearance is important.

The first priority of this facility is heating the room and water and obtaining high-quality steam. For this, the sauna stove must be built in accordance with all the rules, using the most suitable high quality materials. Only in this case, its characteristics will meet the requirements of a brick oven for a bath.

Preparing the foundation for a brick bath stove

A brick oven made in a bathhouse with your own hands weighs several tons. Taking up a small area, it exerts a large specific pressure on the base with its weight. Therefore, stone sauna stoves are installed on their own foundations.

To select the location of the foundation, we lower the plumb line strictly in the middle of the hole in the roof for the chimney. The plumb line will indicate on the ground the place of the projection of the center of the smoke channel. Starting from this point, with an allowance of 10 cm in each direction, we mark the plan of the pit for the foundation.

The depth of the hole should be below the freezing point of the soil. The foundation for a stove in a brick bath should not be associated with the foundation of the building itself. Sand is poured at the bottom of the pit and on top of it - small stones, gravel and concrete chips. All this is carefully compacted. Then the welded frame of the foundation is laid and the cement mortar is poured.

Preparation of the foundation of the furnace for a brick bath, photo

The upper cut of the foundation for a brick bath stove should be perfectly horizontal. Any deviation from the horizon is fraught with the deviation of the stove to the side, both during construction and during its use.

The top of the foundation should be a few centimeters below the floor. Then, for waterproofing, two layers of roofing material are laid, on top of which one layer of brick is laid, and on top of it is a metal sheet that serves to protect the wooden floor from fire.

How to fold the sauna portal

As with any large-scale structure, a preliminary construction plan is required here.

For an exact match between the expected and the resulting result, it is necessary to measure all sides and observe the planned dimensions when laying the walls.

Solution preparation

Proportions for preparing a mortar based on sand and clay.

- Clay - 2 parts.

- Sand - 1 part.

- Water - 0.5 parts.

Operating procedure

When performing work, the following sequence must be observed.

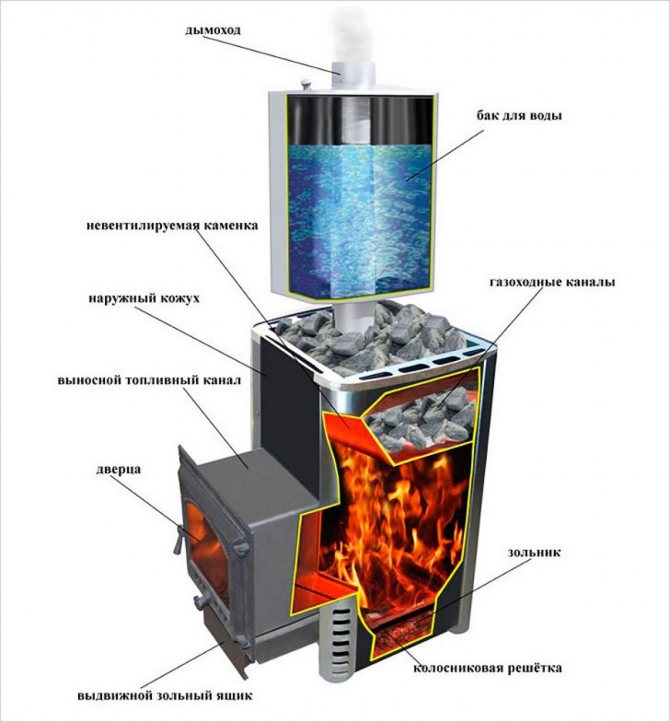

Sauna stove design

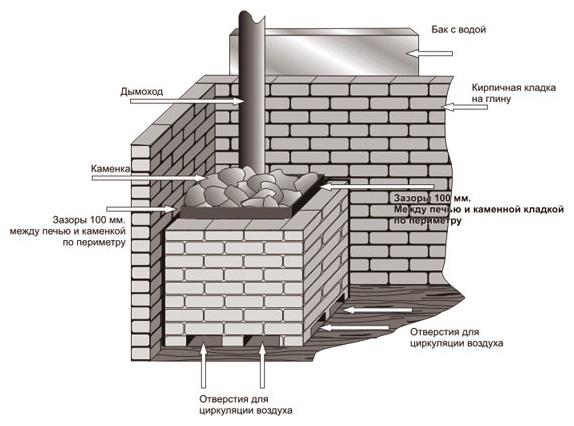

To build sauna stoves from bricks - the experience of a bricklayer alone is not enough! Significant local heating of the combustion chamber and the associated thermal expansion of the stone can easily destroy the brickwork after several good warming ups. Therefore, for self-construction, it is better to focus on the design with a "floating firebox". In this case, the combustion chamber is laid out from fireclay bricks, which lays down on a special furnace solution.

Fireclay refractory brick for the combustion chamber of the furnace for a bath

Around it, already from ordinary ceramic bricks, the outer walls of the furnace are erected. The combustion chamber and the outer walls are not rigidly connected to each other. Therefore, linear expansion of the combustion chamber will not cause destruction of the outer masonry.

In addition, under the influence of the high combustion temperature of the fuel, reaching 1100-1400 degrees, fireclay bricks are sintered into a single monolith with clay mortar and smoke does not penetrate outside, even if the seam between the bricks of the outer masonry crumbles over time.

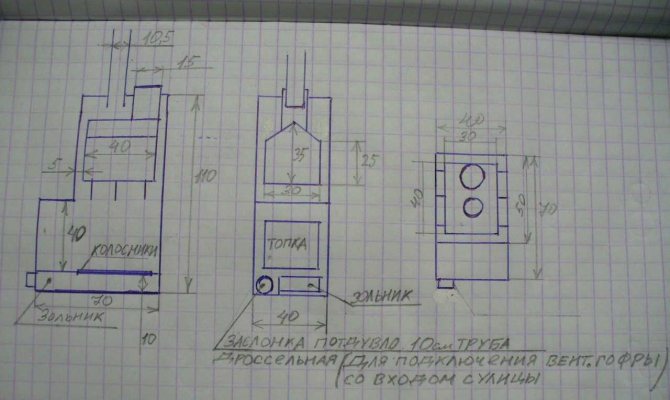

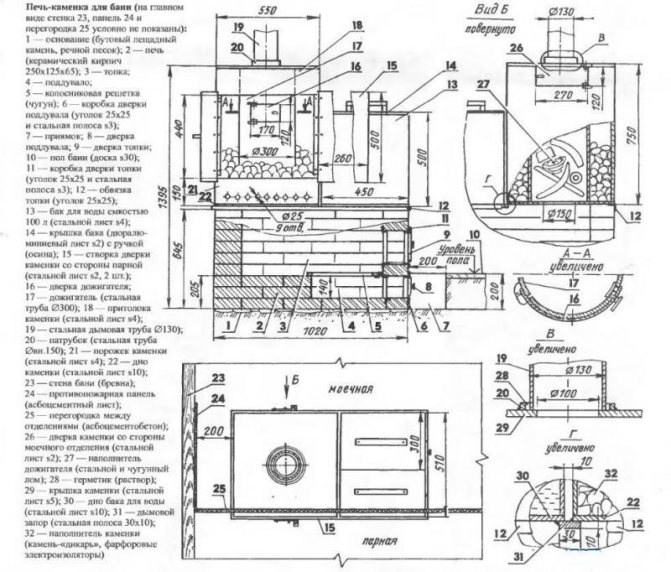

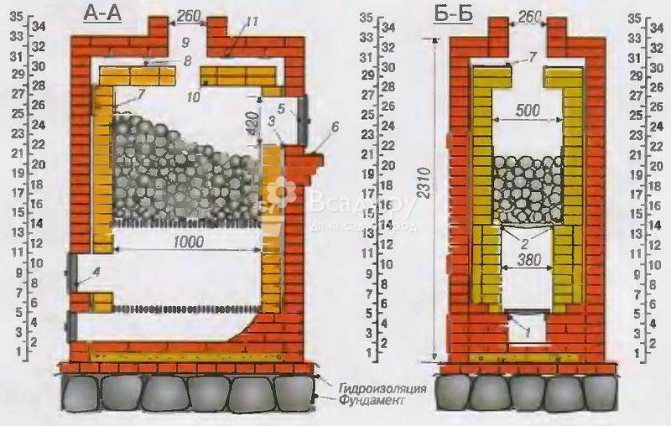

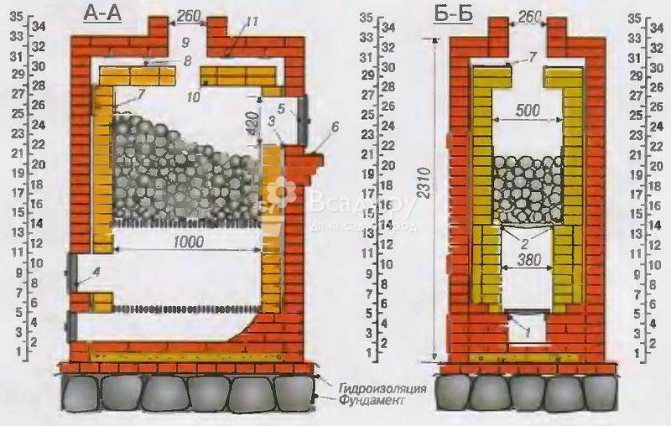

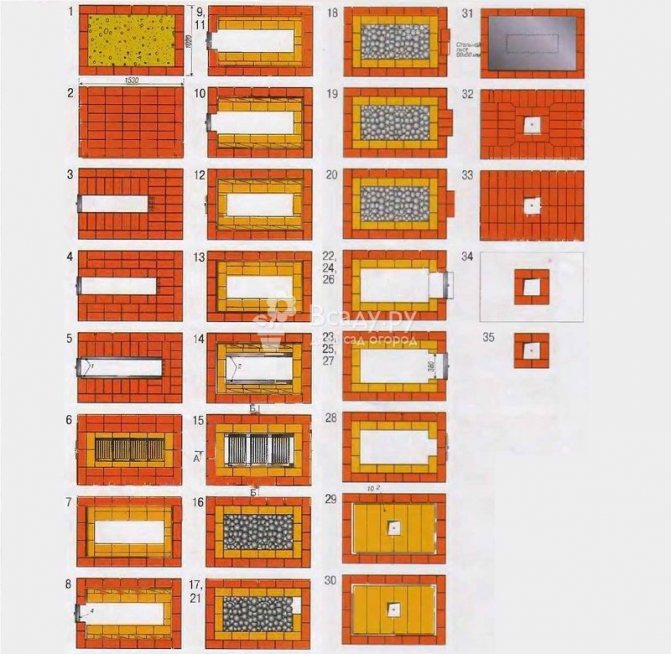

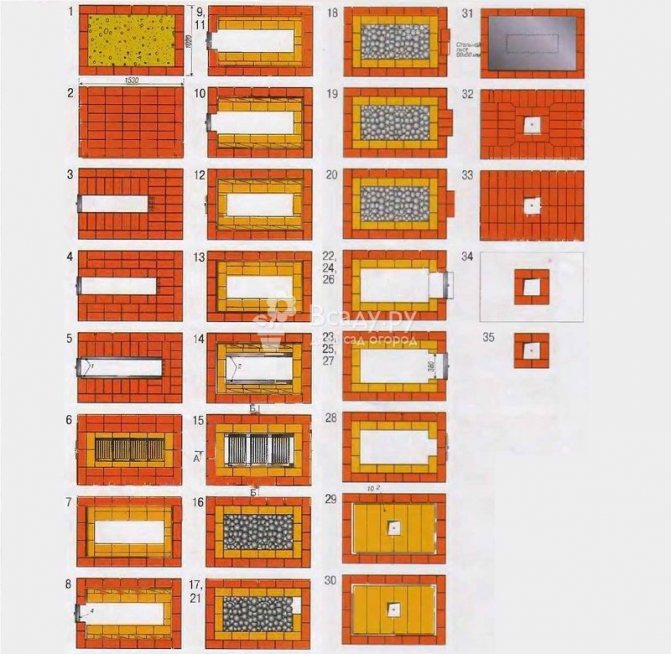

Brick oven for a bath with your own hands, drawings

The figure shows a plan of the structure of the furnace. Numbers marked:

- steel corners - cast iron grates of the furnace are superimposed on them;

- corners for grates on which cobblestones are laid to accumulate heat;

- clearance to compensate for thermal expansion;

- door for the combustion chamber;

- steam outlet to increase air humidity in the bath;

- metal facing of the shelf-stand;

- heat-reflecting steel screen;

- upper temperature gap (30-50 mm);

- chimney;

- overlapping the firebox;

- steel corners for laying the arch of the furnace.

How to fill the chamber?

In this case, it should be remembered that there are special bath stones. They are specially treated. You also need to take precautions to avoid carbon monoxide poisoning. It is required to separate the backfill from the chimney and combustion chamber. It is best to choose heavy, dense and whole stones. In addition, natural options should be preferred. In this case, the only exception is sandstone. This stone can clog the steam passages. Moreover, it becomes unusable very quickly. The recommended diameter of stones is not less than 10 cm. After the first firebox has been carried out, they must be checked. They should not expand or crack when exposed to temperature. It is best if the selected stones have a round shape and a smooth surface. It is not recommended to give preference to spicy options. When water gets on them, they can start "shooting". It is recommended to choose pebbles, boulders or granite.

Before placing stones in the oven, they must be thoroughly rinsed. Thus, the dirt that has accumulated on their surface will not end up in the steam room. The bottom layer should be made up of larger stones. Accordingly, small ones remain at the top. The strongest stones should be laid out on the sides. In some cases it is necessary to increase the heating rate. For this, the cast iron ingots must be stacked vertically. The recommended diameter of stones placed in the bottom row is at least 15 cm. They must be placed directly on the grate. In the case of a heat storage stove, the masonry should cover the holes of the latter to a minimum. All items that are cracked within one year of use must be replaced with new ones.

Do-it-yourself brick masonry oven for a bath

If, during the construction of a house, the joints between bricks can reach 10 mm, then for a furnace their thickness of more than 4 mm is already a disaster. From periodic heating, such seams crumble very quickly, and smoke and carbon monoxide begin to flow into the room. Therefore, brick ovens for a bath must be erected from the same one-size brick with an even bed and side walls.

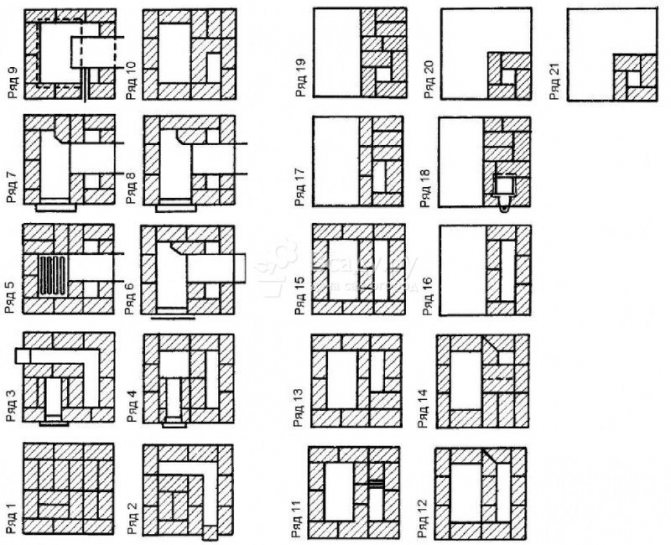

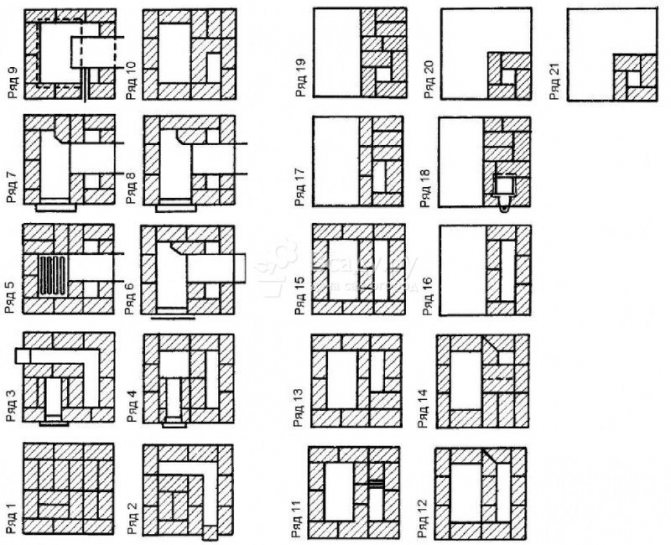

Brick ovens for a bath - drawings with orders

Sauna stove ordering

Experienced craftsmen spare no time for preliminary erection of the lower part of the furnace dry - without mortar. This makes it possible to select the necessary bricks, number them, assess possible problems, make cuts and prepare pieces of the required size and shape. Then the "dry masonry" is disassembled and repeated with the mortar.

Brick stove for a bath - masonry photo

The first row should be laid out very carefully.It should be perfectly horizontal, and the dimensions of the diagonals of the resulting rectangle should be equal to each other.

Ordering a brick sauna stove

On the bricks of the first row, using a plumb line, the vertical of the furnace walls is further checked. The horizontal is checked with a long level (the length of the level should be greater than the diagonals), and the sameness of the diagonals - with a lace. In addition, right angles and a straight line of the sidewalls of this row are checked. Subsequently, each row is also level controlled and checked for vertical.

Laying the wall of the stove for a bath with your own hands from bricks

For attaching the blower door on the 3rd row, use galvanized steel wire or a strip of mild steel. So that the door fasteners do not interfere with the masonry, grooves are selected in the brick with a grinder, where the wire is recessed.

Fastening the oven door for a bath with your own hands from brick

Under the steel corners on the 5th row, platforms are also selected with a grinder so that the metal is flush with the brick plane. The grates are freely placed on the corners and, if they burn out, they can also freely change to new ones. In addition, by their expansion, the grates do not destroy the brickwork.

Grates for a brick sauna stove

Next, you should start building the combustion chamber, and after it, continue to raise the outer walls. In this way, it is much more convenient to maintain the required dimensions of the high-temperature furnace and adjust the dimensions of the thermal gaps between it and the outer wall.

We lay out the firebox of the sauna stove

The furnace masonry is made of fireclay oven bricks and refractory clay. It is impractical to make the entire furnace out of fireclay bricks, since it has a low heat capacity and cools quickly. On the other hand, the use of ordinary red bricks in the firebox, even ceramic, leads to its rapid destruction from high temperature, and the stove in a brick bath with your own hands simply fails.

Bricklaying of the furnace chamber for a brick bath

The firebox doors, as well as the heater chamber doors, are fastened with wire or metal strips, as mentioned above. The perimeter of the door frames should be wrapped with an oven basalt cord, which compensates for thermal fluctuations in size. Similar compensation is done on the guide frames of the chimney valves.

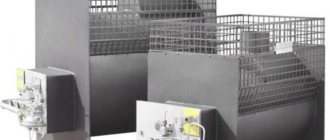

We select grates and stones for the bath

Particular attention should also be paid to the selection of grates. They operate in very aggressive temperature conditions and therefore can burn out quickly. Therefore, grates are usually made of heat-resistant thick cast iron, but in no case from reinforcement, construction wire rod, no matter how thick it is. Beautiful do-it-yourself brick sauna stoves are obtained from scrap rails or rail linings. The service life of such grates exceeds the service life of the stone furnace itself.

Homemade grate bars for a brick bath

The stones for the stove must be round and sized so that they can be loaded and unloaded without problems through their chamber door. The role of cobblestones can be played by medium-sized pieces of broken insulators of high-voltage lines. They are made of heat resistant glass and are resistant to rapid temperature changes. But the heat capacity of glass is worse than stone, such a furnace will cool down faster.

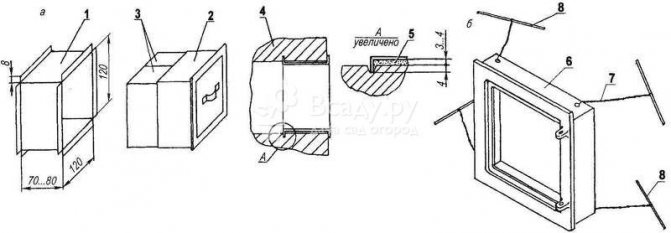

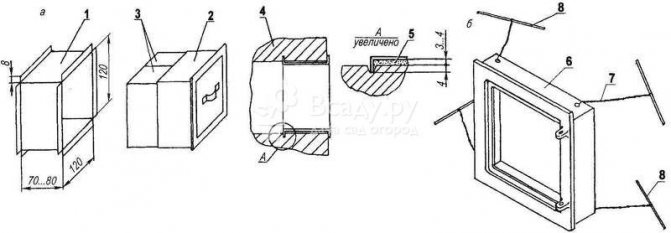

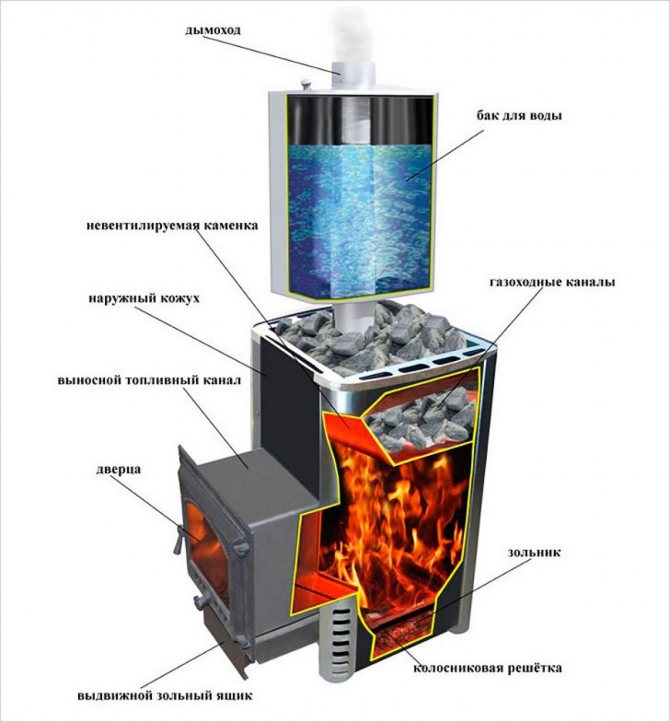

Installing the stove in a bath with a remote firebox

A modern sauna stove is equipped with systems for blowing a glass furnace door, as a result of which the heating of the dressing room will not be intense. For good heating, the firebox doors will have to be slightly opened, and this is taken into account when choosing a place to place the stove. The door in a slightly open position should not interfere with walking in the dressing room, and should not create a risk - if the area of the room is small, then it is better to take the firebox to the next room or to the street.If it is possible to install a firebox in the dressing room, this should be done, especially when the dressing room is combined with a relaxation and tea room. Modern stoves have panoramic heat-resistant glass in the furnace doors, and the spectacle of a living flame under the glass will add a special flavor to the bath room. Blowing glass performs the task of cooling and cleaning the inner surfaces of the firebox doors, so the glasses are transparent, and soot accumulation is impossible. Aesthetics and warmth, a great addition to the interior - a remote firebox can serve as a fireplace for rest rooms. Remote fuel channels near stoves can be rectangular and narrowed to the fire doors, and an impromptu fireplace can look different - this is taken into account when choosing a stove and plans for its placement.

On the street, there are fuel channels for bath stoves, usually when it is impossible to place a firebox in a dressing room or a rest room:

- If the areas of the premises of the steam rooms and dressing rooms are too small and do not allow placing a firebox in them;

- If coal is planned as fuel, when burning it you cannot get away from pollution and toxic combustion products;

- In commercial baths, where the stoker should not be present during bath procedures.

The operation of a sauna with a firebox on the street becomes difficult, and in winter it turns into a complicated process or requires the appointment of a "duty stoker", since it is not always pleasant to jump out of the steam room to add firewood to the stove.

The only real plus of installing a stove firebox in the outer wall of the bathhouse with access to the street is cleanliness in the bathhouse, because there will be no firewood or coal inside the bathhouse building.

Fire safety during the installation and operation of sauna stoves must be ensured properly. One of the primary tasks is to equip a reliable foundation for the sauna stove, adjacent to the wall or partition. The edge of the foundation is insulated with heat-resistant materials, and a metal sheet is laid on top. Asbestos board as heat-resistant insulation has no drawbacks, but from the point of view of ecology, asbestos materials are questionable. The modern market offers pressed mineral wool, foam glass, mica-plastic materials - safe for human health and resistant to high temperatures.

- In front of the fire doors, a metal coating is provided with a size of at least 0.4 * 0.8 m. A sheet of metal on the floor will make it easier to clean the stove and become a barrier to sparks and fire. The floors in dressing rooms are usually wooden, less often tiled, and this measure is necessary.

- The nodes of the passage of the fuel channel in the partitions and walls from the steam room and the rest room, as well as the outer wall when the firebox is removed outside, are strictly standardized. Wood-based materials are separated from the channel by brick linings or stone. The minimum clearance from the kiln wall to a wooden wall or cladding is 0.45 m.

- The minimum distance from the ceiling of the bath to the surface of the stove is 1.20 m.

- The minimum distance from the edges of the furnace doors to the doors is 1.25 m.

The unit for the passage of the fuel remote channel, as a rule, is equipped with a thermal insulator - cement fiber sheet, mineral basalt wool. The insulation is installed along the entire end frame of the passage. With a thermal insulation thickness of up to 5 cm, it is allowed to reduce the size from the outer wall of the stove to the wooden wall cladding to 25 cm.When the thickness of the thermal insulation is increased, the safe clearance can be further reduced - up to 12.5 cm. Often the opening is laid with bricks.

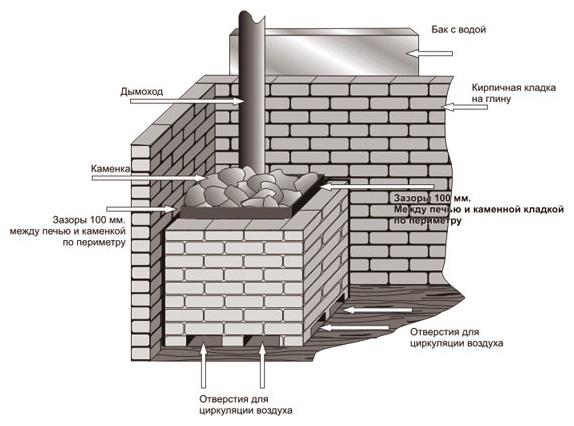

The installation of a factory stove is easier, since its design, as a rule, has a double casing with a thermal insulation layer or with convection channels. Homemade stoves are simpler, usually made of sheet steel. Lining the stove with a brick in this case is not just a fire safety measure, but also protection for those taking bath procedures from injury.

Installation and insulation of metal stoves in wooden baths should be carried out according to the calculation, without simplifications and in accordance with the norms, since the safety of people depends on this.

The sequence of works on the lining of the furnace

The brick structure must have a solid foundation under it, therefore, the process of lining the furnace begins with the arrangement of a solid or columnar foundation. Having a wooden floor in the bath, you should also take care of fire safety. To do this, in the area of the firebox door, a metal sheet is laid, covering it from above with asbestos material. Further work is carried out in the following order:

- perform a base, which is one or two-row masonry;

- a furnace is mounted on the base;

- lay the first row of bricks, along which the entire structure is being installed;

- gradually lay out the following rows of the screen, leaving special holes for air circulation below and above, additional elements are mounted along the way;

- make a brick chimney or install a metal pipe.

When performing work, one should not forget about such nuances:

- for lining the furnace, use a brick that has been pre-soaked for 30 - 40 minutes in water;

- joints between bricks should not exceed 5 mm.

Otherwise, everything is the same as in ordinary masonry: checking the angles with a plumb line, and the evenness of each row with a level. Strict adherence to technology is a guarantee of the quality of the future design.

A few final words

Labor costs and money spent on lining the sauna stove justify themselves with interest. The brick casing increases the safety of the metal stove operation, the heat is distributed evenly, since the artificial stone first accumulates heat, and then gives it off. And the heat remains much longer, you can comfortably steam in the bathhouse for several hours in a row. The benefits are obvious.

stroikadialog.ru