What do you need to assemble a stove?

The steel from which the pipe is made should not be alloyed and high-carbon. This material has a negative effect on the weld seams. After their welding and subsequent cooling, cracks may appear, which will lead to deformation of the furnace. The most suitable steel grade option is St10 and St20.

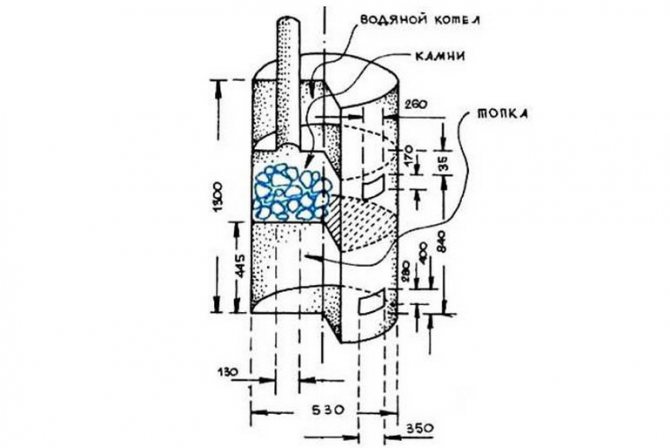

It is necessary to determine the exact dimensions of a vertical stove for a bath from a pipe with your own hands, based on the size of the room itself. Ideal dimensions of a pipe for a bath:

- diameter - 50-55 cm;

- thickness - 0.8-1.2 cm.

Required material:

- steel pipe with a diameter of 50-65 cm, a length of 120-150 cm and a wall thickness of 0.8-1.6 cm, for a water tank and a firebox;

- another, 35 cm in diameter with a wall thickness of 0.5-0.8 cm for laying stones;

- one more, with a diameter of 12-15 cm and a wall thickness of 0.2-0.4 cm, for the chimney;

- cut reinforcement made of low-carbon steel for grates with a diameter of 1.2-2.0 cm and a length of 50 cm;

- asbestos cord - needed to seal the doors;

- metal sheet for doors, 0.4 cm thick;

- door handles;

Required tools:

- electric welding machine;

- locksmith tools;

- drill and grinder.

Why is it important to make a vertical bath stove with your own hands from a 530 mm pipe with a wall 0.6 cm thick? The pipe of this diameter has passed the hydro-pressure test. This will help create a stove without holes and burnouts.

Preparatory stage - the choice of drawing, materials, tools

If the farm has several large sheets of rolled steel, a rectangular structure can be welded. However, such units have a number of significant disadvantages:

- Rectangular systems have a large number of welded joints. Considering that this is a sauna stove located in a small enclosed space, the quality of such seams should be very high. The services of a professional welder are quite expensive. As a result, a home-made rectangular unit can surpass the purchased one in terms of costs. The distribution of heat from the combustion of firewood in the volume of an angular shape is much worse and requires more firewood for heating a bath.

- The round shape of the fuel chamber ensures better circulation of flue gases. The absence of corners in round furnaces facilitates the removal of combustion residues from the ash chamber. In rectangular systems between the blower door and the bottom of the ash pan, there is always a small threshold in which ash accumulates. In a furnace made from a cylinder, this transition is rounded due to the natural shape of the casing.

When choosing a specific heater project, you need to take into account the size and layout of the steam room, as well as personal preferences. For a small steam room, it is usually recommended to install a vertical stove from a pipe. This is a more compact option that does not take up much space in the room. The design of such an installation assumes the presence of not only a combustion chamber, but also an additional area for laying stones, as well as a water tank for heating. Externally, the stove resembles a classic potbelly stove.

If the choice fell on this variety, then it should be remembered that the presented option has lower thermal qualities, and its furnace doors and blowers are placed in a pair room.

If space permits, then more preference should be given to the horizontal variety. There are also areas for laying stones and a container for heating water, but the doors and ash pan are located at the end of the installation, and therefore they can be placed outside the steam room, for example, in the dressing room or outside the bath, which greatly simplifies the kindling process.

The heating area of the stones is much increased due to the longer length of this option; the natural convection of warm air increases in the steam room.

Among the main advantages of steel pipes used for a sauna stove, it is worth highlighting the following:

- the stability of the coating under mechanical stress;

- reliable heat dissipation;

- low coefficient of expansion when heated;

- the ability to retain heat even after burning firewood;

- the ability to use any type of fuel;

- minimum of welding seams;

- quick warm-up of the steam room.

A couple of disadvantages of metal structures cannot be ignored:

- the metal heats up quickly, but it cools down just as quickly, that is, you need to add fuel quite often to maintain the required air temperature;

- heat is distributed unevenly throughout the room.

If we compare a metal and brick stove for a bath, then the latter loses in such criteria as the heating rate, the likelihood of carbon monoxide poisoning, and ease of manufacture.

When choosing a metal pipe for heating a bath, pay attention to the following points:

- check the strength of the structure;

- make sure there is no damage or corrosion on the surface;

- if defects are found, reinforcement with welded metal patches must be performed;

- functional holes can be made in corrosive areas.

We offer you to familiarize yourself with the Design of the relaxation room in the bath 50 photos of examples of the interior

Do not use high carbon steel or alloy steel. They are not suitable for making a furnace. It is preferable to choose steel with a carbon content of up to 2%. You can calculate a high-carbon material by the state of sparks when the surface is rubbed against sandpaper. It has white sparks in the form of stars scattering in different directions, while the sparks of mild steel are yellowish and straight. Alloyed steel will have red, orange, or bright white sparks in the same test.

Sauna stoves are made not only from metal pipes, but also from sheet steel. Most often, a rectangular shape comes out of this material.

Compared to such an installation, a round pipe has the following advantages:

- a metal pipe is much easier in terms of manufacturing - in fact, it is already a ready-made firebox, unlike sheets that should be cut, cut, assembled and welded;

- pipes are the most economical option;

- the process of heat exchange with the surrounding air in the presence of a round bath stove is more efficient;

- from the point of view of the movement of flue gases, the finished round pipe is also more selective;

- the service life of the round furnace is longer, even when comparing rectangular and cylindrical pipes made of the same material.

The unit perfectly solves the problem of lack of space in the steam room, since its vertical body contains 3 chambers - a fuel chamber, a heater and a water heating tank. True, the capacity of the combustion chamber is small and in the process of heating the bath, you will have to do several loads, but this is the price to pay for saving usable space. Again, if desired, the size of the firebox can be increased by removing the water boiler or making its volume smaller.

Advice. The total height of the stove for the bath and each chamber separately can be selected by yourself, the main thing is to maximize the capacity of the firebox. Then the duration of burning from one bookmark of firewood will become longer.

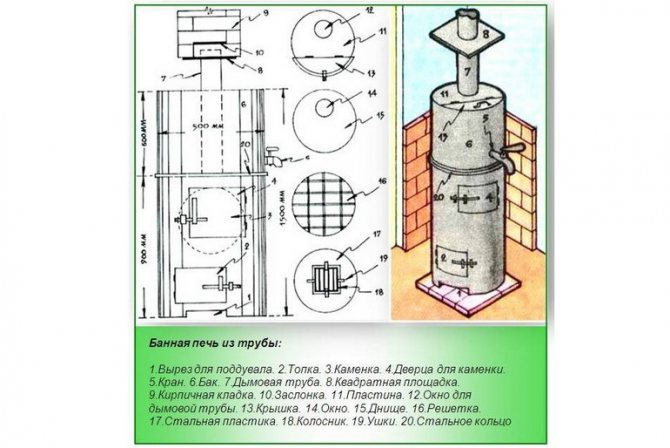

The procedure for carrying out work on the manufacture of a vertical heater is as follows:

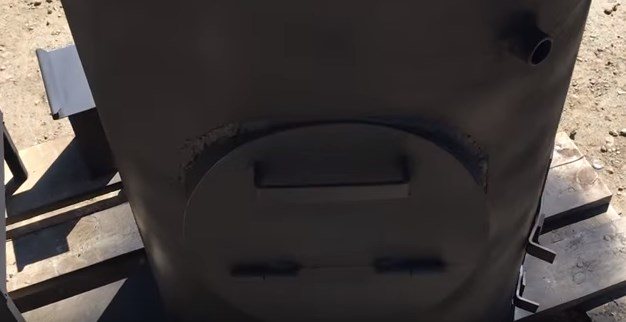

- Cutting and processing of pipe ends DN500, cutting openings for doors.

- Preparation of round metal blanks 5-10 mm thick for partitions, bottom and lid.

- Processing of cut parts and making oven doors from them.

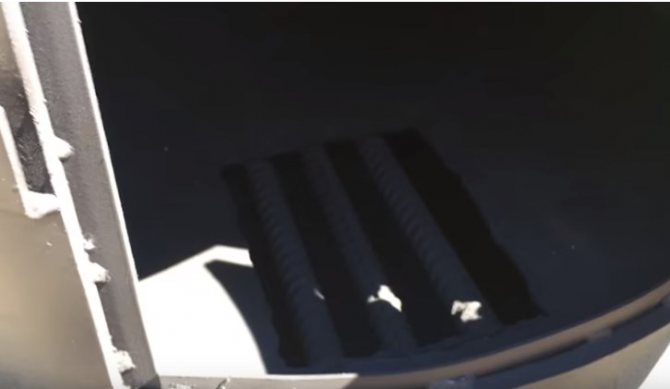

- Welding of a grate from reinforcement.

- Assembling a metal bath stove.

The round unit can be positioned either horizontally or vertically. Vertical placement has one significant plus - space saving. However, such an arrangement reduces the efficiency for heating and increases the number of firewood bookmarks.

This is due to the fact that the combustion chamber is very small. In fact, its dimensions are about 50 cm.at the base. In a firebox of this shape, the fire covers the entire volume of the laying of firewood, which leads to rapid burnout and the release of heat. The heat from combustion rises up and rushes into the chimney. The heating of the side walls decreases, and most of the heat escapes into the pipe.

The horizontal arrangement eliminates all these disadvantages. The side walls are heated evenly. The combustion chamber along the entire length of the boiler ensures gradual combustion of firewood and greater heat transfer from one bookmark.

The location and parameters of the grates are of great importance for the efficient operation of a horizontal furnace. If you make them too wide, the thrust will decrease. The grate width should not be larger than 12 mm. They should be positioned along the entire length of the combustion chamber.

Choosing between steel and cast iron grates, you should give preference to the latter. Such elements will last much longer. To avoid clogging of the ash suction, the ash pan is welded in the form of a separate box. It is connected from below.

Often the window for loading fuel is made in the form of a box tunnel. Thanks to this, it turns out to bring the doors of the firebox and the basement into the utility room. This eliminates the appearance of dirt and cinders from the washing room.

The heater box is installed on top of the structure, closer to the chimney. The front of the case is always colder. Often it serves only to heat the air in the room. In some horizontal ovens, the chimney outlet is bent. This increases the contact area with rocks and the water tank.

- the main dimensions of the products;

- mode of production;

- type of steel;

- production standard.

When choosing a suitable pipe, two parameters must be taken into account: the inner section and the wall thickness. For example, marking 400 * 7, where 400 mm is the diameter, 7 mm is the thickness of the steel.

An efficient pipe sauna stove should heat up quickly with a small amount of fuel. To achieve similar results, it is recommended to use pipes:

- diameter from 50 to 60 cm;

- with wall thickness from 7 to 13 mm.

- High mechanical strength of the material, capable of withstanding sudden changes in temperature conditions.

- Low thermal expansion and high heat output.

- Good heat capacity to store heat energy after long burning of fuel material.

- Resistance of thick-walled metal to corrosion, destruction and deformation under excessive exposure to high temperatures.

- Efficient distribution of energy throughout the entire volume of the room and the creation of natural draft within the structure.

- Reliability, practicality and long service life of the finished product.

- Affordable material cost, ease of manufacture and installation.

It is difficult to assemble a structure without drawing documentation, since there is a high probability of making mistakes at any production stage, which can lead to inefficient equipment operation.

To make a stove with your own hands, you need to prepare:

- a section of a thick-walled pipe with a diameter of 500 to 550 mm, a thickness of 8 to 15 mm, a length of up to 150 cm (for a combustion chamber and a water reservoir);

- a cut of a steel pipe with a diameter of 310 to 340 mm, a thickness of up to 8 mm (for a heater);

- a cut of a pipe with a diameter of up to 150 mm, a thickness of 2 to 5 mm (for a chimney);

- sheet metal up to 12 mm thick;

- ready-made grate or metal rod (for self-production);

- doors for the main cameras or metal (for a homemade model);

- heavy hinges for garage doors (for homemade doors);

- welding equipment (manual or semi-automatic);

- grinder with circles for cutting and stripping;

- electric drill;

- locksmith tool.

- Vertical sauna stove with 530 pipes. The design is similar to an ordinary stove, but, in addition to the compartment for the firebox, it also has a water tank for heating water and a container for laying stones. This is a fairly compact model that takes up little space, so it is suitable for small steam rooms.At the same time, its main disadvantage is that the blowers and firebox doors are located in the steam room, and it also has a lower thermal efficiency.

- Horizontal heater. The design also includes a water tank and a stone container, but at the same time the doors of the firebox and blower can be taken out into the next room or outside. A horizontal stove from a pipe takes up more space, however, due to the longer length of the firebox and its low location, the heating area of the stones increases and the heat exchange of air in the steam room improves.

- firebox;

- a container for stones, which can be located both inside and outside the case;

- chimney;

- ash collection chamber;

- a water heating tank, which can be part of the body or located above the chamber with stones.

Assembly instructions

The entire assembly must be carried out in accordance with the drawings so that there are no difficulties and errors. This design can cause slight difficulties during assembly, since there will be a section for laying stones in the firebox compartment.

- The bottom of the pipe is welded with a blank or sheet metal.

- At a distance of 1-2 cm from the bottom, a rectangular 24 × 8 window is cut out for the blower. This will give oxygen access to the combustion chamber and where the ash is extracted.

- At a distance of 15-20 cm from the upper part of the blower, another hole is cut to lay the fuel. Its size will be 20-24 cm. Special thin discs are used.

- On top of the firebox there is a chamber in which stones are placed. A round hole is cut out at a distance of 12-18 cm from the top of the combustion compartment. Note: the round hole must be 35 cm in diameter, the offset around the pipe circumference is 900.

- The other, 35 cm in diameter, is cut to a length that is equal to the outer diameter of the larger pipe. The upper segment is cut ¾ in the form of a "shoulder", to the border of the anterior edge.

- A blank wall is cooked to the rear end, and a plug with a door at the bottom to the front. Stones will be laid through it and water will be poured to create steam.

- The cut-out "spatula" is inserted into the opening of the main pipe. Its outer protrusion should be 2-3 cm. A gap should remain inside along the entire perimeter, which is completely welded. To enhance the stability of the structure, rods are welded to the body.

- Based on the diameter of the main pipe, a round piece is cut out of the sheet steel. To fix the grate, rectangular holes are cut in the cut out round piece of steel;

- The firebox is welded into the main pipe, parallel to the floor, 2 cm above the upper edge of the blower hole.

- The base of the blower is cut out of metal based on the outer diameter of the main pipe. Legs are welded under the stove to hold it. Then weld to the bottom.

- The main pipe is the wall for the water heating tank.

- In the cut out bottom of the tank, a compartment for the chimney is made from the edge by 3-5 cm.

- A piece of chimney pipe is welded into the hole, protruding at a distance of 10-12 cm.

- The bottom of the tank is installed on the main pipe. Then it is welded 10-12 cm above the stone compartment. The chimney should be on the side of the "blade".

- The bottom of the tank is completely scalded. A hole is drilled at the bottom for a water pipe inlet.

- To make a double tank lid, 2 semicircular parts are cut out. One is fully welded, and the other serves to open the tank and is attached to the hinges.

- As a result, you should get this kind of oven:

Chimney arrangement

The chimney is an important component for the removal of combustion products.

They are of three types:

- Ceramic. The ceramic chimney has the longest shelf life. Maximum resistance to high temperatures.

- Brick. Due to the rough surface, the brick chimney quickly accumulates soot and slows down the draft of air.

- Steel.Steel chimney, the most suitable for a bath in connection with an affordable price. Also, due to the rapid heating of the metal, they put a tank, after which they are used for procedures. The stainless steel chimney is the most relevant. This material is not afraid of water, high temperatures, is not susceptible to corrosion, lightweight, durable and cheap.

Build process:

- Before installation, you need to designate a place for making a hole.

- A galvanized steel casing is installed on the pipe, then rings are put on, which are fixed on the ceiling. The lower pipe is secured with self-tapping screws. Clamps securely fix the chimney.

- The second part is installed on the roof. The openings between the roof and the chimney are filled with expanded clay, clay or asbestos.

Description of typical schemes of pipe furnaces

The stove from the pipe is a metal cylinder with holes made for the firebox and ash pan and a chimney welded on top. There are two main options for pipe ovens:

- horizontal;

- vertical.

Horizontal models are suitable for baths and industrial premises, since their design provides for the installation of a tank for heating water and other accessories.

On the "recumbent" ovens, barbecue grills and grills are installed, which makes them the best option for a personal plot or summer cottage.

Vertical ovens occupy a small area and are suitable for heating change houses and cooking in small country kitchens.

Reference. In a vertically located stove, firewood burns faster and gives more heat, and horizontal structures melt more slowly, but they allow you to keep heat longer with less fuel consumed.

Advantages and disadvantages

A significant advantage of a vertical oven over a horizontal one is its compactness, which allows it to occupy a minimum space in the bath. Suitable for small spaces.

Other benefits include:

- saving money investments;

- metal, as a reliable material, has excellent mechanical strength, withstands temperature surges that do not affect this property;

- sufficiently thick walls of the material provide high heat transfer. After the fuel has completely burned out, further retention of heat occurs;

- a rounded cut of the pipe gives a powerful heat distribution and the formation of the necessary traction;

- fast warming up of the room in less than 1 hour;

- a metal stove will last more than 10 years if you skillfully approach its manufacture;

- the cylindrical shape of the pipe will eliminate unnecessary right angles and long welds. The main reason for the appearance of corrosion and holes through which the leakage of carbon monoxide will go is precisely the welds.

The main and common disadvantage of a metal structure is that it is more susceptible to corrosion.

Types and characteristics

By location in the space, furnaces made of pipes are divided into the following types:

- vertical;

- horizontal.

The vertical stove looks like a potbelly stove, but it has differences - an additional container for stones and a container for water.

A vertical home-made stove takes up less space, which is of great importance for the small dimensions of the steam room, but for the same reason it is inferior to a horizontal stove in terms of burning time and heat transfer intensity. In the process of fuel combustion, heat goes up, the side walls do not have time to warm up very much.

In a horizontal furnace, the process goes differently - since the heated air on the way to the chimney simultaneously heats the vault of the body. Based on this, it is clear that the efficiency of a horizontal furnace will be higher than that of a vertical one. The main disadvantage of this design is considered to be the location of the blower and firebox doors directly in the steam room.

Fuel in a vertical pipe will burn faster if the ash pan door is not closed, thereby stopping the access of oxygen to the fire.In such a pipe, the fire interacts at once with the entire volume of firewood, while in a horizontal pipe, fuel is consumed gradually, which is more logical for the heating of a bath. Also, in the horizontal form of the stove, the coverage of heating stones is greater and the convection of hot air is higher, in addition, the doors of the blower and furnace, which are located at the very end of the pipe, make it possible to take them out of the steam room. Both the first and the second type can be made by hand.

Important Tips

- To prevent heat from leaving the furnace, an opening valve is installed on the edge of the chimney.

- A fire can be caused by a huge accumulation of soot. For this, two holes are drilled in the pipe. Steel tubes are inserted into them with a turn towards the pipe. This prevents the appearance of soot. The fuel will be completely burned out, and the accumulation of soot will be minimal.

- After completing the manufacture of the structure, it must be checked for holes, gaps and cracks.

- There should be no objects around the stove that are susceptible to fire: synthetics, wood and fabric.

- All cut edges of pipes and metal sheets must be cleaned from sharp edges to avoid cuts. If there is no experience in the correct installation of the chimney, then it is better to contact a specialist.

- The installation of this furnace should be done on a ready-made concrete foundation, its height is 250-300 mm. Brickwork with clay mortar is laid on it in one or two rows. The brick screen protects the walls from overheating.

Installation and operation of pipe furnaces

The main requirements for the safety of the bathhouse are fire safety and protection from burns. A very serious mistake is the absence of a non-combustible base under the body and the lack of wall insulation - this is a direct road to fire.

Do not install shelves close to the body, and even more so so that the wood is in contact with hot metal.

- The stove is installed on a previously prepared foundation, with a 20-cm indent from the wall.

- In the place where the pipe will go out, a thickening of about 120 mm is made.

- All wooden elements are covered with insulating material (this can be, for example, asbestos or felt) with a layer of clay applied to it.

- The chimney section between the ceiling and the roof is plastered and covered with lime mortar.

- The height of the pipe section protruding above the roof must be at least 50 cm.

- The shelf should be placed next to the wall where the oven is located. When installing the shelf, you need to take care that the person sitting there does not touch the ceiling with his head.

- Install above floor level on a concrete or brick foundation with a height of 20 cm or more.

- Place a metal sheet in front of the ashtray and firebox doors.

- The distance from the wooden walls of the bath to the hot surfaces of the stove should be at least 1 meter.

We suggest that you familiarize yourself with How to make a chimney for a bath with your own hands

After watching the video instructions and having dealt with the drawings, you can make a stove for a bath from a pipe with your own hands. This task will turn out to be really simple. The design will be highly efficient and, if properly installed and operated, is completely safe. The main thing is to carry out all stages of work strictly according to the instructions, without violating the technology.

Trial furnace

- Before using the furnace, a test furnace must be carried out, which will test the entire structure for the tightness of the welded seams.

- The damper opens and the blower is opened. After that, a small bookmark is made of firewood and set on fire. The door is closed and oxygen is supplied to the upper compartment.

- Complete heating, the presence of traction and a check of the tightness of the seams are traced.

This is how this sauna stove is made cheaply and practically. Anyone can afford such a simple luxury.