Why do we make warm floors? For what purpose? When choosing a heating system, we naturally think about the efficiency of heating first. However, in the case of underfloor heating, in addition to efficiency, comfort comes first. The warm water floor was originally invented in order to increase the level of comfort in the living space, not as the main heating system. Accordingly, homeowners always had a question. What kind of covering for a warm water floor should be in order to have effective heating and ensure the aesthetics of the interior.

Already from time on, consumers have appreciated all the advantages of this method of heating interior spaces. The practical use of underfloor heating in a variety of options gives an idea of how different floor coverings behave in a given situation. Thanks to modern technologies, today the consumer has at his disposal a fairly wide selection of materials that can be used as a coating for a water floor. What types of coatings can be used in this case, what are their technological parameters and operational capabilities? In this article we will try to provide answers to these and other questions.

Underfloor heating characteristics

Since the underfloor heating system is a low-temperature heating system, it means that the finish coating must be able to quickly pass the low temperature through it. This is called heat transfer. Also, the finishing coating should be as natural as possible, which also affects heat transfer.

Another property that should have a final underfloor heating Is density. The denser the material, the better the thermal conductivity. This, of course, does not apply to artificial materials and materials of thermal insulation.

You can list the properties of the finishing material for underfloor heating systems for a long time. But for the first time, those three properties that I have listed above are enough to understand.

Now I want to analyze these main characteristics in detail and select the ideal coating for underfloor heating systems for them.

So, the first characteristic is good thermal conductivity. The best thermal conductivity will naturally be with the stone.

Now is the time to list those natural materials that we can use when finishing the final floor covering for underfloor heating systems.

Preferences given

The choice between underfloor heating systems is always better to start with the study of the water type. He shows one of the longest paths. But it implies great opportunities.

Not to mention the simplicity of design, long service life, a huge number of methods used, and a variety of materials for the final coating.

Installation in buildings / apartments with neighbors from below will become a challenge. Even one incorrectly positioned element will lead to flooding.

Electrical options have their own advantages. But they are used according to a certain algorithm. If, in the case of the cable, there is still a concrete screed, then the IR radiation does not have such protection.

But it heats up / cools down quickly. Easy to repair. Of course, it is better to give preference based on personal interests.

- Similar posts

- What are the advantages of Thermo underfloor heating?

- How much does a warm floor cost?

- What is a mobile floor heating?

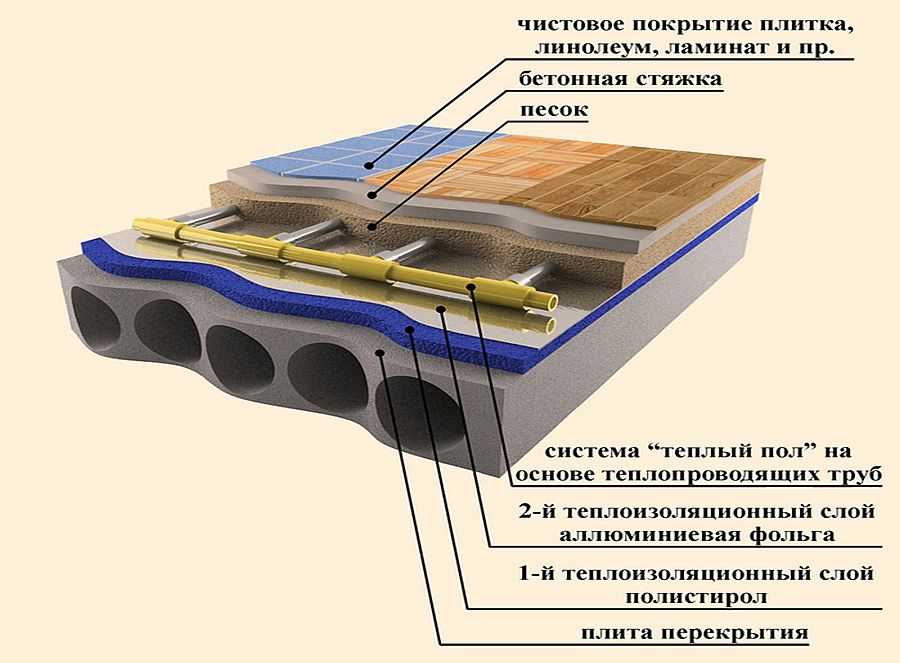

- What is included in the underfloor heating cake?

- How to install underfloor heating under the cork?

- Pros and cons of underfloor heating

Warm floor coverings made of natural materials

Such coatings include marble, granite, porcelain stoneware, ceramic tiles, tiles etc.That is, any material with similar properties and characteristics will do.

Porcelain stoneware floor

Therefore, warm under the tiles is the most ideal and compromise option. Also, tiles or natural stone have additional advantages. This coating transfers heat quickly. Many people are familiar with this feeling of filling the whole body with warmth when you stand with your bare feet on marble with a warm floor system.

A fine finish of natural stone or tiles is easy to clean. He took a rag, brushed off the dust and that's it. It is very comfortable and looks beautiful and rich.

Tile floor

There is also such an important property of the floor heating as density. If we take, for example, natural dense marble and ordinary clay tiles, then the thermal conductivity of marble will be better.

The same applies, for example, to coatings such as parquet and laminate. If the parquet is made of dense types of wood, such as elm, then its thermal conductivity is lower.

At the same time, laminate is an artificially made material using natural materials. Consequently, the thermal conductivity of the parquet is better.

Now let's summarize a little. If you plan to install underfloor heating systems in your home, be it electric or water, then make sure that the finishing coating is made of natural stone, ceramic tiles or tiles to the maximum.

Infrared equipment

This type of underfloor heating is radically different from the water subspecies. Installation takes no more than one day. Moreover, most of the time is devoted to the competent distribution of zones that require increased attention.

The rest is done in a few hours. Simplicity of design does not mean availability of materials. Only suitable for IR heating:

- linoleum;

- carpet;

- wood;

- laminate;

- tile;

- parquet.

Of course, each has its own advantages. We all have something in common. Versatility due to the original production of quality materials with high thermal conductivity. The temperature of the warm floor rarely even reaches 21 degrees Celsius.

Usually everyone sets the standard 20. Correct setting will exclude heat loss. The insulating layer prevents moisture from entering, directs the radiation flow straight up.

Rapid warming up / cooling down implies temperature differences. Therefore, the material must initially be resistant to such things.

The room must be carefully insulated with appropriate substances. Then it heats up effectively by eliminating losses.

Of all the available coatings, only ceramic tiles are demanding to install. Preference should be given to models with self-adjusting rods.

Such mats are used even in places of high humidity. Some are successfully combined with porcelain stoneware. But you have to think about the heat-reflecting substrate. The total thickness of the warm floor remains at the level of 2-6 cm.

Features of soft flooring, laminate, parquet

The infrared warm floor, unlike the water one, is quickly repaired. Installation of a non-hard final coating excludes serious fixation. The only difficulty will be to ensure the required rigidity. The parameter is achieved by installing a protective layer. Even plywood or chipboard is suitable.

Then children / adults can even jump without fear of breaking the structure. After all, the material itself has some rigidity. And do not forget about the presence of a waterproofing layer. Hard polyethylene will eliminate even the smallest moisture from the carbon heater.

We recommend: How is the underfloor heating damper tape installed?

The permissible thickness is 5-8 mm. This is quite sufficient with adequate protection. The mechanical impact is also extinguished by a special stacking device. That is, nothing is attached to the panels themselves.The additional layer has pivot points at the desired intervals.

Nuances are taken into account even at the planning stage. They are marked on the graph for the concentration of heat in specific places.

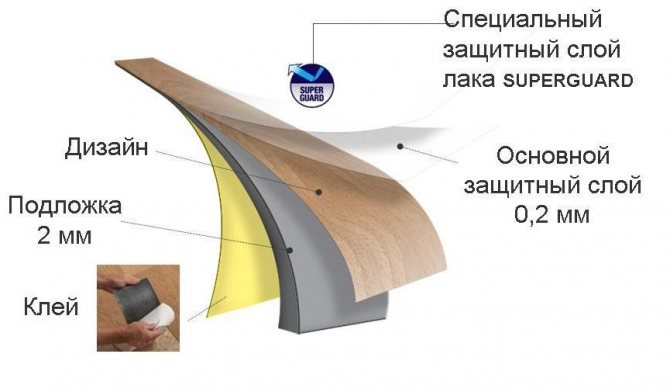

Laminate

It is a type of wood-based panel with fibers, which is distinguished by its high density. The main layer is a decorative protective film.

Before starting the calculations, all the details are clarified. In addition to the main coating material, cement mortar is considered, as well as insulation.

If the area of the room is 50 m², then the thickness of the insulation, laminate and mortar is 4/1 / 0.2 cm.

The layers under the pipes will also be of three types: concrete and two insulation. The thickness of the elements under the pipe is 22, 2 and 4 cm.

After choosing the average temperature of the heating medium, for example 40 ° C, then the values of the upward flow will be 72 W / m², and the maximum floor temperature will be 26 ° C. These calculations allow you to determine which coating is best suited.

Carpet

This is a type of floor covering that differs from other types in its softness. It is sold in rolls, where a drawing or a beautiful ornament may be present on each version.

The difference between installing carpet and laminate is already noticeable at first when it comes to changes above the pipe. In this case, only the flooring and cement mortar remain. Thickness - 4 and 1 cm.

The layers under the pipes remain unchanged because they are not affected by changes in the coating. The thickness of the concrete and two insulation materials is 22, 2 and 4 cm.

When calculating, set the same temperature as in the first option (40 ° C). After calculation, the upward flow has noticeably decreased - 60.1 W / m², and the maximum room temperature is 25 ° С.

Cork covering

The material itself is warm. But in interaction with underfloor heating, it is not quite "oil oil", as some will think. To some extent, this is true.

Pros:

Cork flooring

1.) Better heat retention. If, after switching off the heating of the tiles, the cooling of the coating occurs after 10 minutes, then the cork coating confidently keeps heat for about an hour. "The thickness of the cork coating, taking into account the substrate, should not exceed 15 mm, and on the manufacturer's packaging we are also looking for the corresponding pictogram (" permissive "icon)."

2.) Compared to the rest, in the warm season, as well as in case of impossibility to use heating, the tactile sensation ("high" from the contact of bare heels with the floor) is the most pleasant. "The cork, after being introduced into the room, should stand for 2-3 days in order to" absorb "the surrounding microclimate."

Minuses:

1.) Restriction on surface heating temperature. The same + 28 ° С as for the laminate. And the problems are correspondingly similar. If frost hits, then above the recommended, no, no;

2.) Low heat transfer. Cork itself is the best insulating material. Take, for example, Termokork (this is not a floor covering), which is successfully used in a bath. Therefore, in comparison with the same tiles and even laminate, it takes much longer to heat up.

Parquet board

This type of flooring is made from different types of trees. Depending on the type of manufacture, it differs in different types. According to the established generally accepted rules, it is necessary to install additional insulation under this coating. Therefore, there are now three layers on top of the underfloor heating pipe, together with insulation, mortar and the main parquet, 4, 2 and 0.2 cm thick.

The layers under the pipe do not change (concrete and two insulation materials).

Parquet boards, like carpet, differ from laminate in their less effective thermal conductivity. Therefore, when the temperature is set to 40 ° C, the upward flow is 59.6, and the floor temperature is 25.6.

Ceramic tile

This is a type of plate that is made of baked clay, which takes different shapes. Flat and rectangular views are popular. With the help of these squares, patterns are created on the flooring.This material does not require additional insulation, therefore, only mortar and tiles are used, in a thickness ratio of 4 to 0.8 cm, where the coating belongs to a lesser value.

The layers located under the underfloor heating pipe do not change, there remains concrete and two insulation (22, 2, 4 cm). If you set the average temperature of the heat carrier to 40 ° C, then the air flow will increase significantly to 107 W / m². The maximum room temperature rises to 29 ° C.

PVC for water floor

We all know polyvinyl chloride well, however, not many are familiar with the fact that it is used as a floor covering for a water floor. PVC tiles are made up of almost the same materials as linoleum.

The material goes well with different types of flooring - concrete, laminate, wood floor and others. PVC tiles fit better on a flat floor.

Advantages:

- Relatively low prices - 400-600 rubles / m²;

- Simple installation procedure;

Pvc floor tile laying technology - The PVC surface is not at all prone to slipping, so you can safely move on the tiles in any shoes or barefoot;

- Large assortment, which allows you to better choose the necessary color scheme or pattern for the interior;

- The material has an average margin of strength and elasticity. Under experimental conditions, it was proved that PVC tiles are able to withstand the fall of a metal object weighing 0.7 kg from a height of 1.5 m;

- Underfloor heating under PVC tiles is a guarantee of sound insulation of the coolant circulating through the pipes;

- Damaged areas are easy to replace.

Disadvantages:

- Experts cannot call the PVC coating completely safe for human health, since when heated, polyvinyl chloride begins to emit harmful substances;

PVC tile structure - Relatively short service life. On average, a PVC coating lasts no more than 10 years. Therefore, if you plan to change the floor covering in the near future, then it is better to buy inexpensive tiles made of artificial materials;

- The structure of the tile does not withstand the action of solvents, acetones and other strong substances.

Linoleum

This type of coating is made of polymer materials. In this case, no insulation is installed above the pipes of the warm floor, but only the cement-concrete mixture and the main coating, in a ratio of 4 to 0.2 cm.

For layers under the pipe, reinforced concrete and expanded polystyrene (22, 2 and 4 cm) are used.

When the temperature of the heating medium is set at 40 ° C, the heat flux also increases to 102. The maximum floor temperature is 29.2. This is a significantly increased value than in previous versions, except for ceramic tiles.

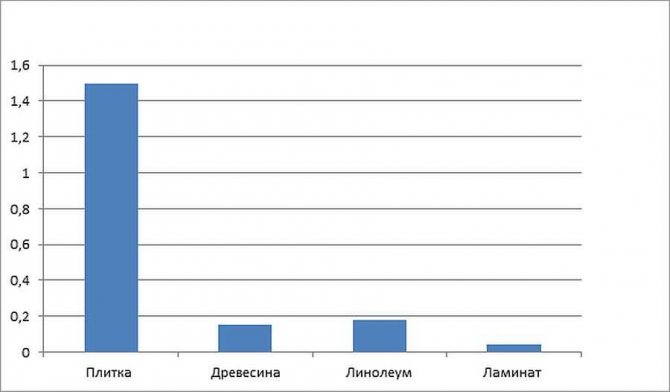

If we compare all coatings with each other, then at the same temperature in all rooms, the upward heat flux will be less for parquet boards and carpet, which is explained by the poor thermal conductivity of these carriers. Linoleum and ceramic tiles have the highest flux and good thermal conductivity.

If the floor temperature is taken into account, the rating remains unchanged. Parquet and carpet are heated up to 25 ° С, and linoleum and tiles up to 29 ° С.

The golden mean of this rating is laminate. The flow and temperature of the floor are closer in values to parquet and laminate (73 W / m² and 26.8 ° C. In general, it is most often used with a combination of water floor heating.

Opposite values are obtained for heat loss, when carriers with better thermal conductivity lose more heat than less conductive coatings.

Unfortunately, linoleum and tiles heat the floor above the allowed limit (26 ° C), so a larger installation step can be taken to eliminate this problem. Also, for this it is not necessary to set huge temperatures of the coolant, it is enough to reduce the values and the norms will be met.

The best coating option for an underfloor heating system is linoleum and tiles.After all, they are the most effective material, because the energy expended for heating will be much less if you lower the temperature and bring the values back to normal.

Such conclusions help to save more on electricity if you install linoleum and tiles.

Selection features

Laminate is a good choice for finishing coat on warm floors

In this regard, ceramic tiles and porcelain stoneware are the most popular, and their peculiarity lies in the fact that they require more powerful heating. Another important characteristic is the coefficient of linear expansion. Given this parameter, it is required to abandon the use of vinyl or PVC tiles, since when used when arranging a warm water floor, they can swell when heated.

Laminate has proven itself well as a topcoat on a warm floor. It is a fairly dense structure with a high level of thermal conductivity. For a long and fruitful operation of this material as a floor covering, careful preparation of the floor surface will be required.

Everything must be done to ensure that the base of the floor is absolutely dry, otherwise, after a short time, cracks will appear on the surface, the lamellas will begin to "walk" and the coating will have to be dismantled and the components changed.

The maximum floor heating will differ for different types of flooring.

When deciding which coating to choose for underfloor heating and how to install it, you should take into account the maximum heating temperature. So, for example, for laminate it is 27 ° С, for linoleum - 30 ° С, and for porcelain stoneware - 45-50 ° С.

Speaking of linoleum, it is worth noting its high thermal conductivity and the ability to soften and lose its original shape when heated.

Because of this, such coverage is considered not the best solution to the problem, and experts recommend choosing it only in the most extreme cases.

Before covering warm floors with one or another finishing material, it is necessary to study the markings, which will indicate both thermal conductivity, and resistance to damage, and installation features.