The fireplace is considered an important element of the interior of a country house. The flame contributes to the creation of a cozy atmosphere in which to relax and unwind. Modern opportunities allow you to make a fireplace with your own hands, but certain rules must be followed when carrying out work.

Many people like to spend time by the fire or at home, looking at the fire in the fireplace, basking in its warmth.

Types and sizes of false fireplaces

All existing fake fireplaces can be divided according to several criteria.

From the point of view of practicality, three types of fireplaces can be distinguished:

- decorative. These models are made only to decorate the room, and cannot perform any other functions. When creating them, inexpensive and not particularly durable materials are usually used, for example, cardboard or foam;

- semi-functional. For this variety, more durable materials are used: MDF, drywall, etc. In this case, the fireplace can be used as an additional shelf for storing decorative trifles, or a secret niche for built-in cabinets, a bar or a safe;

- functional. Durable materials (brick, wood, etc.) used in their manufacture allow not only using a false fireplace as a full-fledged shelf, but also using it to heat a room.

Of course, it is impossible to light logs in it, but it is quite possible to place a heater or a heating radiator inside.

You can also consider fireplaces, only from an aesthetic point of view. In this case, their classification will look somewhat different:

- conditional. There is no fireplace as such, there is an image of it on the wall, or a nominal designation of the boundaries of the hearth, for example, with the help of decorative moldings;

- standard. The most popular variety. In this case, all the necessary components are present: a mantelpiece, a niche for firewood, protruding side walls. The decor can be varied: painting, wood trim, wallpaper, or brick-like;

- as realistic as possible. In this case, preference is given to natural materials. At the same time, the real proportions and sizes are respected so that the finished fireplace looks extremely real.

A conventional fireplace is unlikely to be functional, but a standard or realistic one can be used in any way.

In addition, false fireplaces can be subdivided based on their shape and size:

- minicamines. This type is very rarely a separate independent decoration. Usually they are made part of a decorative composition, for example, a Christmas one;

- corner. Suitable for small spaces as they take up less space. At the same time, due to attachment to two walls at once, they are more stable and reliable;

- straight lines. They can occupy up to a third of the wall (dimensions and proportions are close to real fireplaces). Great for organizing photo sessions and decorating rooms.

It should also be understood that all types of fireplace portals must also be considered from the point of view of durability. In this case, they can be:

- disposable. Most often, this decor is made for the New Year holidays and Christmas. This form of fireplace is made of short-lived and inexpensive materials (paper, cardboard, boxes, etc.). After the end of the festive events, the craft is sent to the scrap;

- foldable or portable. They can be made from cardboard, boards or MDF. Installed if necessary;

- stationary. They are permanently attached to the wall and floor. They are an integral part of the interior of the living room, bedroom or nursery.

Before you start making a dummy fireplace, you need to clearly think over the end result. The construction of some types of false fireplaces requires a serious investment of finance and time.

- To avoid mistakes, you must first create a detailed sketch with dimensions.

- For clarity, you can make a "pattern" from old newspapers or wallpaper.

- This approach will help you "see" how the finished structure will fit into the interior. At this stage, it will be easier to adjust the dimensions and appearance of the craft.

Features and advantages of fireplaces in a private house

The hearth is indispensable in a house or in a small cottage when cold weather sets in. A large firebox, a direct chimney allows large air flows to pass through, which allows you to get rid of unpleasant odors and dampness. Heat begins to spread throughout the house immediately after kindling, the air warms up well only during combustion. Fireplaces are installed in country houses and summer cottages, only electric models are installed in the apartment.

Today, fireplaces have gained popularity not only as an element for heating, but also as a fashionable note in a modern interior.

The advantages of fireplaces:

- heating speed, they are indispensable if necessary to quickly warm up;

- excellent ventilation;

- comfortable atmosphere;

- therapeutic effect, positive emotions;

- ease of use;

- status - a fireplace in the house is considered one of the attributes of a successful person.

As a result of research, it was found that there are no harmful microorganisms in houses with fireplaces, which is achieved due to excellent air circulation. The possibility of contracting ARVI in this case is minimal. Fire dries the air, which is useful for people with diseases of the bronchi and respiratory tract.

In order for a fireplace to appear in your home, it is absolutely not necessary to contact a specialist.

False fireplace made of cardboard boxes

Having a large amount of cardboard or small cardboard boxes for shoes or small appliances, it is very easy to "build" a real fireplace. In addition to cardboard, you will need:

- a lot of wood glue;

- masking tape;

- roulette;

- scissors or utility knife;

- something heavy in the quality of the press;

- writing something.

The beauty of this method lies not only in its ridiculous cost, but in the fact that the creation process can be carried out in a playful way, in which your children will gladly take part.

Moreover, you do not need to drill anything, and there is nothing to spoil. So, let's begin.

For the first time, we recommend using simpler forms for making a portal. Moreover, such a false fireplace can be used as a disposable one. For example, make it for the new year and hold a small family photo session against it.

You will get a lot of positive and memorable moments, surprise your friends and loved ones and make the most unusual jewelry from the most ordinary materials.

If you have a large box of large equipment, then you need to carefully unfold it and make a pattern. To do this, draw the dimensions of the back and side walls on its surface. You should have a rectangle that needs to be folded with the letter P.

The sides must be made voluminous. To do this, they must be folded as shown in the figure.

If one box is missing, don't despair. Glue small boxes together, forming a frame. Place a press in place of the joint, if necessary. All edges and joints at the end must be glued with masking tape and secured with glue. After the structure has completely dried, it can be painted with spray paints, pasted over with foam bricks or decorated in any other way.

Remember that this is a decorative, very fragile structure.

Choosing a place to build a fireplace

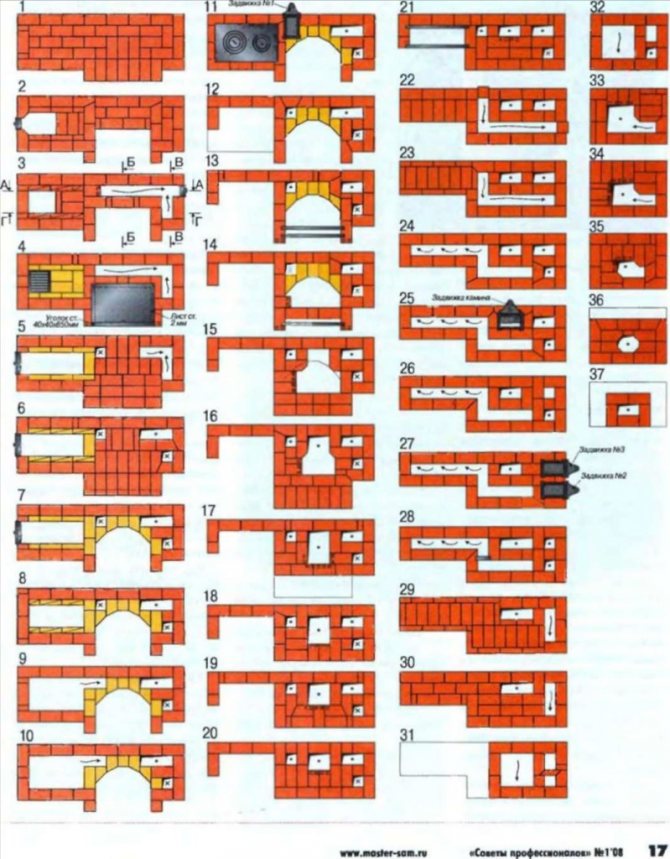

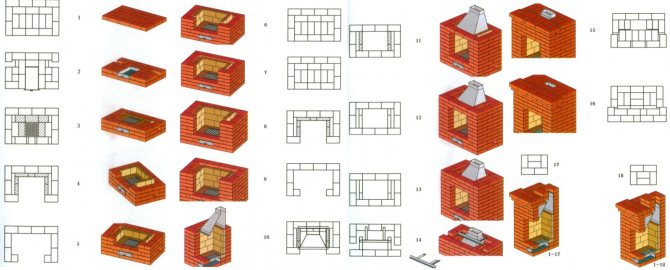

The dimensions of this type of stove are tied to the volume of the rooms in which they are arranged.For example, the area of a fireplace insert for rooms with a volume of up to 70 cubic meters should be 1:50 or 1:70, i.e. from 0.2 to 0.4 m2. The parameters of the firebox opening are determined as follows: the ratio of height and width should be 2: 3, i.e. with an area of 0.2, 0.3 or 0.4 m2, the furnace hole (portal) will have the following dimensions - in the first case 36x45 cm, in the second - 44x67 cm and in the third - 52x77 cm.The ratio of the depth of the furnace to its height should be in the range from 1: 2 to 2: 3, these parameters are very important, because non-observance of these proportions in the direction of increasing the depth of the firebox will reduce heat transfer, and if it decreases, the fireplace will begin to smoke the room. The size of the depth of the fuel chamber must be maintained in the following proportions: with a total area of the firebox equal to 0.2 m2 - the depth should be from 18 to 24 cm, equal to 0.3 m2 - from 22 to 30 cm and equal to 0.4 m2 - from 26 up to 35 cm.

False plasterboard fireplace

Of course, the cost of the finished composition also plays an important role. Let's start with the most affordable material, apart from cardboard, - drywall. It is a pleasure to work with it due to the fact that details of any configuration are very easily cut out of it.

And the installation of such elements is very simple.

For the construction of a medium-sized fireplace, one sheet of gypsum board is quite enough for you, because its dimensions are 1200 × 2500 mm. Better to use a wall look that is 12.5mm thick. To work you will need:

- sheet or scraps of gypsum board;

- profile or wooden planks;

- roulette;

- level;

- stationery knife;

- putty knife;

- finishing putty;

- primer;

- perforated corner,

- painting net;

- screwdriver and self-tapping screws for drywall.

In order to most accurately represent how much space the fireplace, which you have depicted in the drawing, will take, mark the installation location on the wall and transfer the outer dimensions to it. Move to the opposite wall and evaluate the result.

You may need to decrease or increase the size, or change the location a little.

At this stage, you can still make all sorts of amendments. Only after you are completely satisfied with the dimensions and place, start cutting out the parts and fastening the frame, taking into account the changes, if any.

The basis for the frame can be the remnants of a special profile for drywall or even wooden planks.

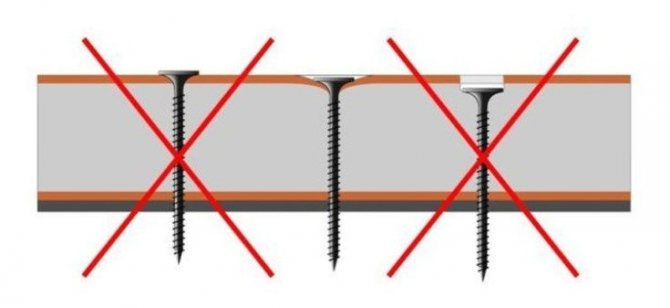

According to the markings, screw the first elements to the wall with self-tapping screws. It is not recommended to use nails - threaded connections are much more reliable. If the dimensions of the fireplace are quite large, for its stability and reliability, make additional mounting points on the floor. Use horizontal lintels to stiffen the structure. In the case of fixing the profiles to a concrete base, first simply attach it to the wall and drill a hole with it.

Then insert the dowel and secure with self-tapping screws. Be sure to control the evenness of each element with a building level.

After the frame is ready, transfer the dimensions of all the walls to the gypsum board sheet, trying to place them as close as possible so that there is less waste. For cutting, you can use both a regular stationery knife and a jigsaw.

True, from the latter there will be a lot of dust and cardboard around the edges can wrinkle and tear if you move too fast.

All details must first be tried on and the edges must be finished with sandpaper if necessary. When you are sure that all the elements fit perfectly in size to the frame, you can start securing them.

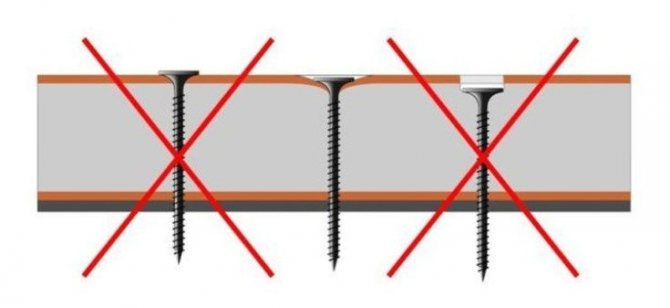

Be careful when tightening the screws. With proper installation, their cap should sink into the surface of the drywall to a depth of about 1 mm. This will greatly facilitate the cladding process in the future.

The recommended distance between fasteners is 10-15 cm.

After sheathing, it is necessary to hide all joints and irregularities. For this, a finishing putty is best suited. The surfaces must first be primed. If the wall does not consist of a single piece, then the joints between the fragments must be glued with masking tape.

All corners should be leveled with perforated corners and then the first layer of mortar should be applied.

The putty should be spread evenly in a thin layer. After it dries, irregularities and sagging must be cleaned with sandpaper or a special metal mesh. Prime again to remove dust and apply a finishing coat of putty again.

At this stage, the construction of a false fireplace made of plasterboard is considered complete. Further, there is little left to do - the decor of its surface, which we will talk about a little later.

Fireplace technical requirements

- The foundation is made so that it can withstand the load from a brick fireplace. Small foci weigh about 0.5 tons, and large ones give a load commensurate with a ton or more.

- The base is arranged with a concrete strip type or made of bricks on a construction cement mortar. In any case, it plays the role of an independent structure, which is not tied to the supporting base of the house itself.

- The average height of the foundation for the fireplace is taken at 30-40 cm and does not reach the level of the finished floor to a height of 10 cm.

- The volume of the furnace space in the fireplace depends on the volume of the room and makes up its fiftieth part. Its depth depends on the accepted height and is calculated as a third or half of this size. The smaller the fireplace, the more heat it will give into the room. But the volumetric indicators must be respected.

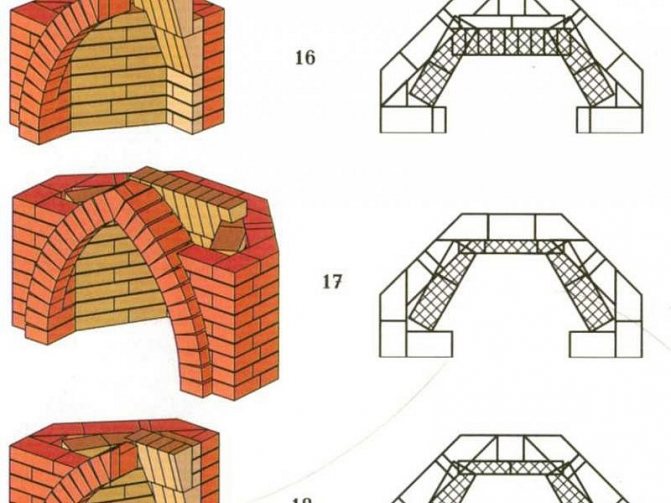

- In order for the heat rays to be better reflected and enter the room, the side walls of the furnace are turned at a small angle outward, and the back wall is tilted starting from one third of the height.

- Fire safety requirements regulate the height of the base of the firebox, which should not be lower than 30 cm from the floor. The same requirements provide for fixing a stainless steel sheet in front of the fireplace on the floor. Its width is 15 cm larger than the front dimension of the combustion chamber.

- In the smoke chamber, a ledge, called a pass, is necessarily laid out, which prevents soot and sparks from entering the chimney cavity and returning smoke to the room.

The combustion chamber includes the following elements

- Base for laying firewood.

- Two side and one back walls.

- Smoke collection chamber.

- The grate of the grate.

- Door according to the project.

- Gate damper.

- Ash pan at the bottom of the firebox.

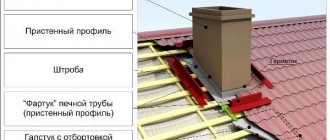

Chimney requirements

- To improve traction, the pipe is made of circular cross-section. The area of its opening depends on the area of the lower base of the furnace and is 1 / 10–1 / 15 of this size.

- When leading to an external wall, the duct should not have more than three changes in direction.

- The pipe installed above the combustion chamber is made strictly vertical, without bends, its height is set from 5 m and above. The verticality is checked along the entire length, the violation of which may lead to smoke pollution of the living space in the future.

False fireplace made of polystyrene

Another quick and easy way to make a false fireplace is to use foam sheets. They can be purchased at any hardware store. Better to buy sheets with a thickness of 100 mm.

You can also use the shipping foam left over from the purchased refrigerator, TV, washing machine or other equipment.

If you do not plan to move, then it is hardly useful to you, but in terms of density, it is much superior to the finishing option. Draw a drawing and estimate if the available amount of material is enough for you. In addition, you must have:

- adhesive solution;

- mixing container;

- putty knife;

- level;

- hacksaw;

- painting net;

- priming;

- finishing putty.

To avoid crumbling and jagged edges when cutting parts, use a fine metal hacksaw. Due to the large thickness and density, it is unlikely that it will be possible to simply cut off a fragment with a knife accurately. It is also not worth breaking off the half-cut elements, in case of a crack, such a piece can no longer be used.

We will glue the elements to the wall and to each other using a special foam solution.

It is very important to buy a mixture specifically for the installation of this material. Due to the very slippery surface, which is practically devoid of absorbent properties, another type of composition may simply not glue the elements together. The wall, floor and ends of the foam, which will come into contact with them, must first be primed and allowed to dry.

Knead the mixture strictly following the instructions.

Begin the installation from the side pieces. The solution is applied to the wall and floor, focusing on the previously made markings. After leaning against the foam. Until the solution has set, use a level to check whether it is level and correct its position if necessary.

So all the details are gradually connected.

After the frame is dry, it is necessary to plaster its surface and prepare it for subsequent decoration. You don't need to do this if you plan to glue decorative styrofoam bricks.

The foam surface is very hard to putty. To facilitate this process and ensure the required level of adhesion, it is necessary to cover the entire surface with a masking net. If the edges come out uneven and torn, use a corner.

The putty application process is similar to that described in the previous version.

After complete drying, the foam fireplace is ready for decorative cladding. If you liked this manufacturing option, then keep in mind that in the future, the construction of this material should not be used as a location for pots with house plants, various equipment and other heavy objects. Decorative items only.

Correct selection and calculation of materials

Kiln brick is divided into types

- Fireclay bricks are made of clay, which are able to withstand a persistent rise in temperature to critical states, do not crack during heat drops, and do not undergo chemical reactions.

- Quartz brick is made from quartz sintering, has high strength, but is exposed to active acids.

- Ordinary clay brick is used for laying sections of the fireplace that are not exposed to very strong heating during operation.

- Hollow ceramic bricks are used to insulate the fireplace from the walls of the house. It can be cement-sandy, poorly heat transferring, or made of foamed dolomite.

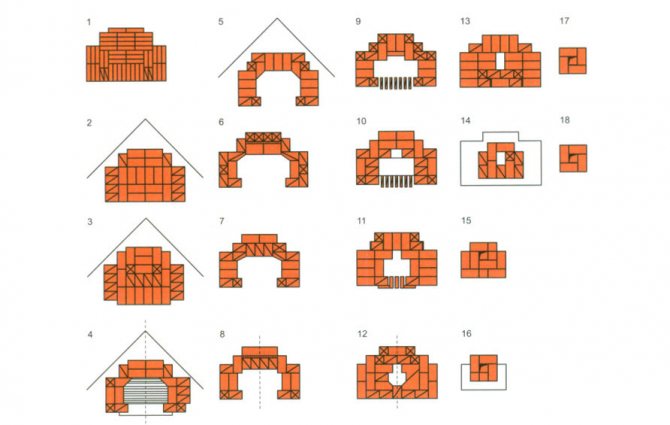

For the device of the vault, a special wedge-shaped brick is used. but it can be cut into shape from ordinary ceramic bricks.

Burnt and unburned bricks of dark brown and pale yellow colors are not used when laying fireplaces. Due to its increased moisture saturation, silicate brick is not used when laying fireplaces.

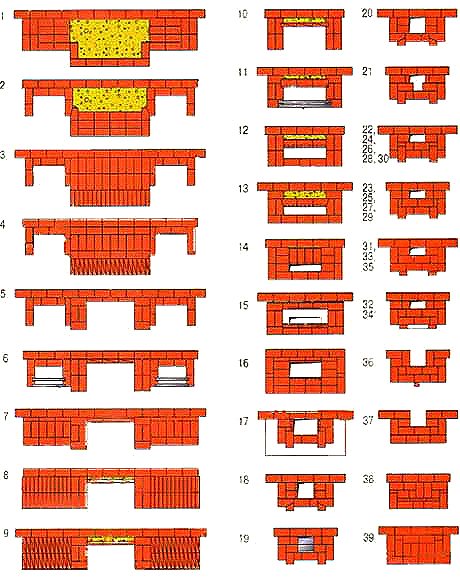

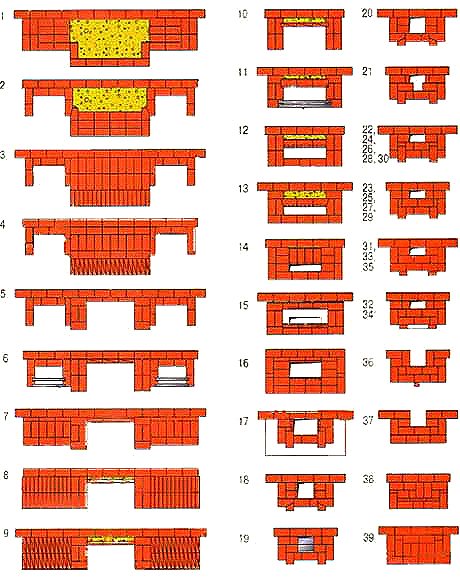

The calculation of bricks for the construction of a fireplace is carried out in strict accordance with the order drawings. Those elements that are indicated in the orders of halves or incomplete bricks are considered as whole. To account for various marriage and battle, a coefficient of 1.15 is used, by which the number of bricks obtained when calculating according to the ordering schemes is multiplied.

If you adhere to the experience of the stove-makers and make masonry seams of 3 mm, then to calculate the finished mortar, you need to count a bucket of mortar for every hundred bricks.

Type and preparation of sand

For the construction of the base, masonry of the side walls and the upper part of the chimney, any type of sand is used in the solution.The preparation of clay solution for areas of high temperatures is carried out only with quarry or ravine sand.

In river and marine species, grains of sand are smooth due to the constant action of water and have poor adhesion to natural clay.

Before using any kind of sand, it must be sifted from large debris through a mesh and washed with a stream of water through a sieve made of burlap until clean water flows.

The furnace heat-resistant part, the smoke collection chamber and the lower part of the pipe are laid out on a clay solution. It is mixed with quarry sand to reduce the fat content.

To prepare the solution, the clay is pre-soaked for a time equal to 7-10 days. During this time, it must be thoroughly mixed every day, after which sand is added in the right amount.

If there is no time for such a long preparation of the solution, then dry refractory mixtures are bought on the construction market. They are packed in sealed bags, have a balanced composition and only need to be mixed with water with construction beaters.

For other parts of the fireplace that are not exposed to strong heat, use a solution of clay, sand and cement.

Raised fireplace made of chipboard or old furniture

Another very suitable type of material for creating an artificial hearth is particle board. You can use both ordinary sanded chipboard and laminated chipboard. The choice is based on how the finished product will look.

If you want to imitate a wooden fireplace, then, of course, it is better to give preference to chipboard.

The start of work should be done, as in the first option, from a drawing. In this case, it is necessary not only in order to more realistically represent the dimensions, but also so that in the place where you will purchase a chipboard sheet, you can immediately saw it into the necessary fragments. It is very convenient both in terms of easy transportation and assembly.

At home, you just have to fasten all the elements together with self-tapping screws.

The main difference between a chipboard raised fireplace and a drywall construction is its mobility. It is not necessary to firmly fasten it to the wall in order to achieve stability. By equipping it with a small base-stand, you will make a completely independent structure, which can be easily repositioned.

And if you wish, you can even equip it with small wheels.

With the right skills, you can cut the sheet yourself. In the case of using chipboard, you must also purchase a decorative edge that will hide the ends and make them more accurate. By the way, you can use old shelves or cabinets to make a "wooden" fireplace. And small doors can even serve as side walls. It will be much cheaper.

The finished product must be removed from dust and sawdust and rubbed with furniture polish. A fireplace made of ordinary chipboard must be further decorated.

Finishing the unit

Consider finishing issues in advance. If desired, the fireplace can not be finished at all, but it is better to decorate the structure with tiles, or at least treat it with plaster.

The design made with the use of decorative bricks looks beautiful. However, for the device of such a cladding, certain skills and experience are required, therefore, beginners are not recommended to undertake its implementation. Even the slightest mistakes can lead to damage to the decor and simply a waste of money.

Tiles

Tiles decoration is very beautiful and simple in its execution. It is not recommended to use tiles for facing the fireplace. Temperature changes will gradually destroy even the highest quality glue. It is recommended to pay attention to this option only if you are ready to periodically carry out repairs and restoration of the finish.

The chimney is traditionally 1.5x1 brick in size.To improve and stabilize traction, it is recommended to use additional devices. For example, with the help of weather vans and deflectors, the chimney can be protected from precipitation and all sorts of debris.

Forged chimney on the chimney

Thus, self-laying of the fireplace is possible. Take the time to study the theoretical part, be patient and follow the recommendations received at each stage. Your efforts will be rewarded with a reliable, beautiful, efficient and durable fireplace, in front of which you can gather with your family, friends or relax alone.

Happy work!

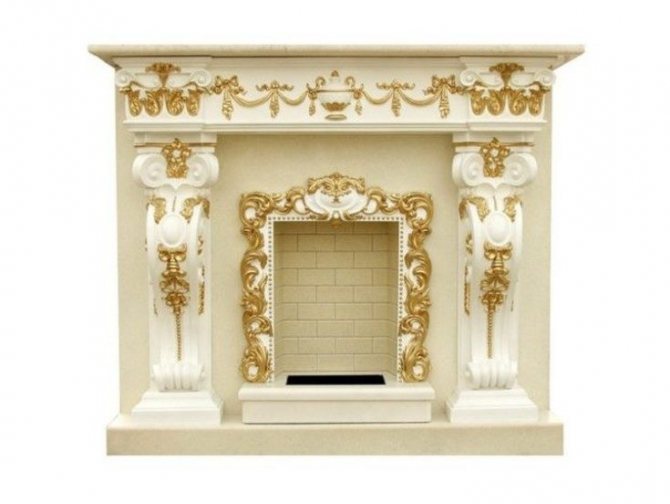

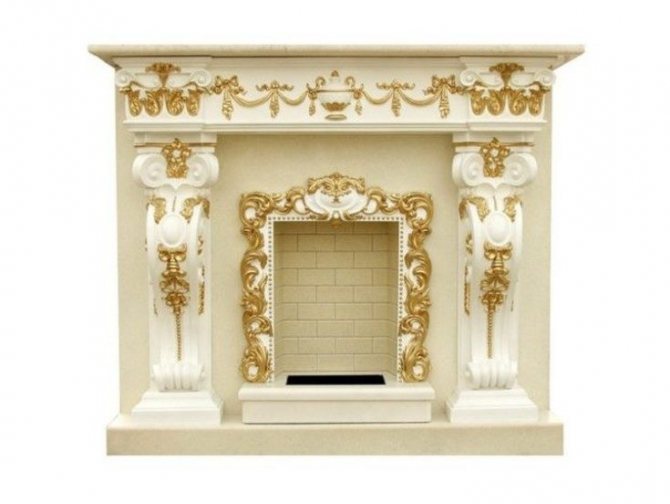

Polyurethane false fireplace

This modern material has won the acclaim of many designers and consumers alike. This is not surprising, because in addition to its attractive appearance, it can bend and take on various forms.

You can easily find in stores or on the Internet many offers for the sale of ready-made polyurethane portals.

Moreover, their variety will allow you not only to choose the required size, but also the style of performance. The models are presented both in the form of strict, straight lines, and with a richer finish, which imitates stucco elements and even wood carvings.

In general, you will not have any difficulty with the choice. Its installation is also not difficult. You just need to glue it to the wall with a special adhesive solution in the desired place. Then you can paint the surface of the portal or add extra luxury to individual elements by applying gold, bronze or silver powder.

In addition to a solid portal, you can imitate it with the help of various moldings or half-columns from the same material, as if marking the hearth zone, but not so clearly. Of course, this option is less realistic, but in some interiors it will be quite appropriate.

Especially in rooms with limited free space that you want to diversify a little.

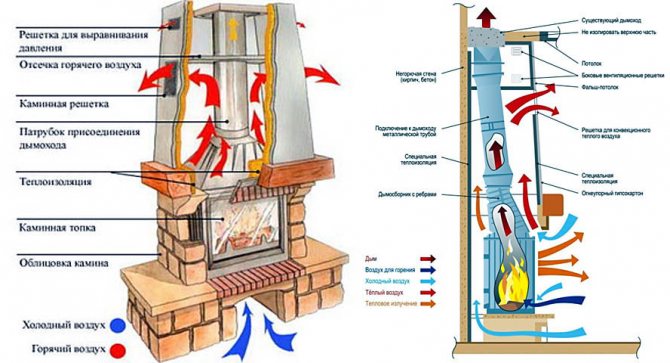

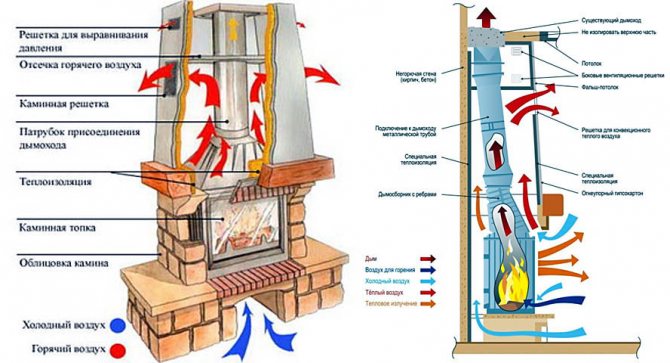

How the fireplace works

The fireplace is inferior in efficiency to the stove because of the wide open firebox, which leads to a deterioration in draft. A large amount of heat escapes through the pipe with smoke.

It adds a graceful and romantic sophistication to the interior and allows you to truly enjoy the atmosphere of home comfort.

Main structural elements:

- firebox - space for fire, back, sometimes side walls are laid out at an angle;

- smoke chamber - combines the chimney and the firebox, the main function is to collect gases with strong smoke formation;

- chimney - used to remove smoke, its shape can be made in the form of a circle, square or rectangle;

- portal - framing the firebox, at the same time performs a decorative function and limits the working area.

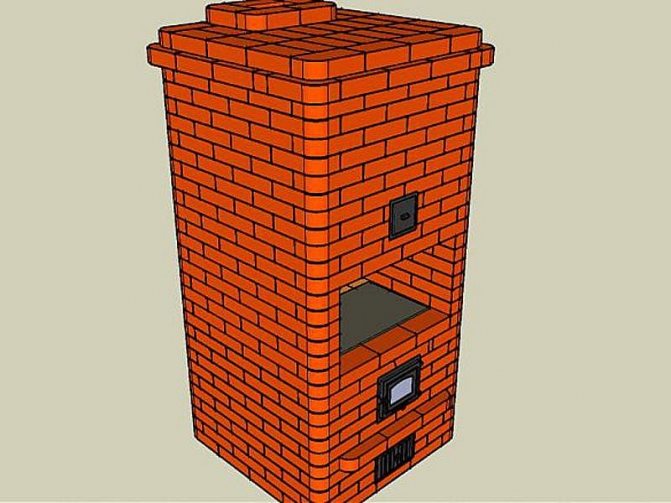

False fireplace made of bricks

This option allows you to achieve the most realistic appearance. But at the same time, both efforts and costs require much more than in the previous versions. For masonry, facing brick is used.

The only nuance of this method is the weight of the finished structure, especially if it has considerable dimensions.

Therefore, before starting work, assess the condition of your floors. If you are sure that they can easily withstand a considerable load, feel free to get down to business. You will need:

- N pieces of bricks;

- mix for brickwork;

- Master OK;

- primer;

- container for mixing the solution;

- drill whisk.

To solve the main problem, how many bricks are needed, a drawing with all dimensions is needed. Knowing the size of one brick, you can easily navigate the total quantity in the store. In any case, the seller will always help you.

It will not be difficult to lay the masonry.

The main thing is to check the straightness of each row. To give yourself a guideline, mark the floor and wall. This will help avoid distortions.Mix the solution, strictly following the instructions, and observe the specified proportions. Otherwise, your clutch may "crawl" and all your work will go down the drain.

Use a whisk drill attachment to achieve a more uniform paste.

Do not spread the solution in a thin layer, but do not apply it in heaps. It is necessary to adhere to the same thickness, distributing the mixture evenly. A little tip - do not put it on the entire surface of the brick, leave about 1 cm free from each edge. When you lay the brick on top, you need to tap it a little so that it holds well.

In this case, the solution will necessarily protrude and stain the bottom row. If you follow our advice, you will be able to avoid this, and the seams will turn out to be smooth and neat.

Do not forget that the finished mixture has the required properties only for a certain period of time. Usually it is 60-120 minutes, read more specifically on the package. Therefore, you should not be distracted while working. Checkerboard masonry looks most effective, but in this case you cannot avoid the need for cutting. A grinder and a diamond wheel will help you cope with this. Don't forget about personal protective equipment.

A stone fireplace will need to be closed with a lid on top. The finished brick portal does not need external finishing.

We calculate the height, width and area of the combustion air hole

Determine the height and width of the fireplace insert, the so-called firebox portal. There is also a relationship here - for a small fireplace, this will be 2: 3 (height to width). That is, for our fireplace, the dimensions of the portal will be respectively: - 0.2 sq. m - 36x45cm - 0.3 sq. m - 48x63cm (approximately our option) - 0.4 sq. m - 52x77cm. The depth of the fireplace firebox with the height of the portal should be in a ratio of 1: 2–2: 3, this dimension must also be observed, since a greater depth reduces heat transfer in the room, and a smaller one causes smoke. In our case, this depth will be: kladka-kamina.ru

The area of the smoke hole for our fireplace depends on the selected area of the fireplace insert, it should be 8-15 times less, i.e. with a furnace area of 0.2 m2 - 0.02 m2, with an area of 0.3 m2 - 0.03 m2 and with an area of 0.4 m2 - 0.04 m2.

A chimney made of bricks will have the following length and width: 14x14 cm and 14x27 cm. If a chimney with a rounded cross section is planned, it will be from 8 to 14 cm in diameter. For small and medium-sized fireplaces, a chimney with a height of 4 to 5 meters is required.

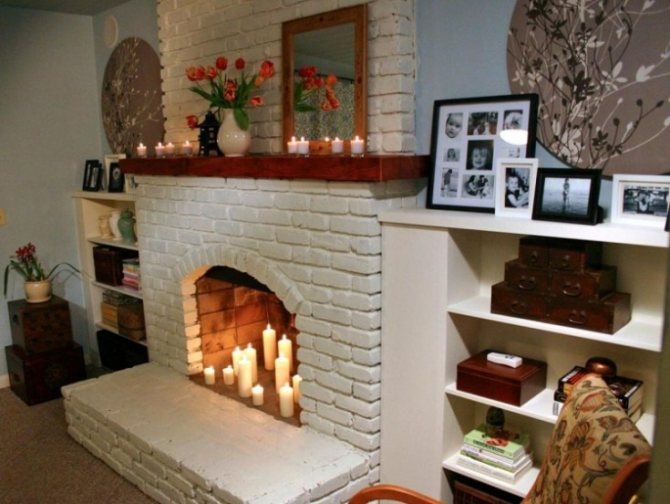

Maximum realism

This type of fireplace assumes a plausible reproduction of absolutely all elements of the fireplace, imitating a real design. Therefore, it is necessary to respect the real dimensions of ordinary classic fireplaces and create the effect of a real flame.

For this, electric fireplaces or electronic photo frames with video images of flames are installed inside the portal. This option is the most expensive, but the most realistic.

Components of the fireplace

Fireplace scheme and its principle of operation

Before starting to assemble the fireplace, I will show you what the main parts it consists of.

Of course, many people know that its main components are a firebox and a chimney, but there are also many other elements:

- Ash pan.

- Smoke collector.

- Convection system.

- Heating device.

- Ash cleaning valve.

- Grate.

- Lining (Internal protective facing layer).

- Flame cutter.

- Doors for protection.

Each of these elements ensures comfortable and safe work with the fireplace, while the main process falls on the firebox and chimney, which ensures stable air circulation inside the fireplace system. Do not forget about the "portal" - it is this part of the fireplace that falls under the decor.

Partial imitation fireplace

In contrast to the most realistic look, partial imitation is a simpler and more affordable option.

To build a partial imitation of the fireplace, a portal is erected in the form of a protrusion from the wall, and a cover. In doing so, you can even imitate brick or masonry, or natural wood.

Inside the fireplace insert there are decorative elements that represent the hearth. From the outside, the design seems very comfortable and convincing, as can be seen from the photo of false fireplaces.

Color palette

Quite often, bright hearths are installed in the room, which can cheer up, forget about cloudy weather outside. The combination of different shades allows you to create a certain emotional background. Warm tones promote revitalization, cold tones have relaxing properties. The fireplace multiplies the effect of the effect of flowers, the interior is instantly transformed.

Thanks to the installation of a real fireplace, apartment owners have many options for interesting design solutions.

Hearths of all shades of glaze (finishing with tiles, ceramics) are in great demand. Models with portals and metal housings also conquered a share of the market. Such designs differ from tiled ones in mobility, lightness, and modern appearance.

Technologies make it possible to create fireplaces of different colors and shades; powder spraying and finishing are used in the manufacture of models.

Fireplace symbol

The symbolic designation of a fireplace in this design only in general terms resembles the shape of a traditional fireplace.

Outlines with a shape similar to the original image are marked on the wall with wooden guides, decorative stripes, stucco and other details on the wall surface.

To faithfully reproduce the fireplace, paintings are often applied to the walls, even imitating fire. The symbolic false fireplace is ideal for those who like non-standard solutions.

Types by shape

Classic home fireplaces are characterized by a U-shape and a massive contour. Columns imitating a bas-relief are quite common. The shape depends on the style of the fireplace; English designs are equipped with cast-iron gratings, fences.

A real wood-burning fireplace in a modern apartment is almost a fantastic picture, however, it can be realized.

Varieties of decorative fireplaces by style

A false fireplace plays a leading role in the interior, however, it is important that it blends beautifully with the entire furnishings of the room, organically fitting into the design. Therefore, before you make a false fireplace with your own hands, you need to decide on the style of the future design device.

- Classic. More than others, a square or rectangular hearth belongs to the classics. It is often decorated with stucco, bas-reliefs, and artificial stones that look like jewelry.

It is better to finish this type of fireplaces from tiles that imitate marble or brick.

- Country style. It is characterized by rough materials. Imitation is carried out as simply as possible, and any flower-leaves in this case are not appropriate.

- Modern. Any glossy surfaces with a reflective effect can be used for it. And for high-tech style, a designer product with sharp corners and mirrored details will fit perfectly.

Helpful advice from fireplace masonry experts

Helpful hints:

- the optimal time for laying is the middle of summer; in warm weather, the hearth will have time to dry out;

- the first heating should be done early in the morning;

- Installing 5m thick copper plates on the back wall will help increase heat dissipation.

Such a fireplace will be successfully combined with both antique furniture and modern interior options.

Photos of finished false fireplaces, would be distinguished from the real one?

Materials for building a fireplace

Refractory brick

You have probably already guessed that the most popular material for building a fireplace is brick. This popularity is due to the simpler way of laying a brick fireplace, as well as the low cost of the brick itself.

To build an average fireplace, you will need the following materials:

- Clay.

- Cement.

- Red brick.

- Sand.

- Crushed stone.

- Rubble stone.

Fireplace decoration using rubble stone

This is not a complete list of components, but they are the most essential. Also, materials depend only on your financial capabilities and on the type of fireplace. Please note that the brick should be of the best quality, including a uniform structure and a straight shape. It is best if you check each brick for damage when you buy.

It is advisable to abandon the purchase of light-colored bricks, since a brick that has not undergone a good heat treatment has a lighter shade, as well as an inhomogeneous structure. Therefore, it is better to take only red ones. Their number is determined by the type and design of the chosen construction.

Summing up

Artificial stone fireplace

As you can see for yourself, it is not so easy to make a home fireplace, but it is quite possible. The main thing is to adhere to maximum accuracy and accuracy at every stage. If you make a mistake at some point, then further layers can be greatly ruined. But if you follow the instructions above, you can avoid many problems. And the video in this article will help you get even more useful information on this process. If you have any questions - ask them in the comments.

False fireplace as wall decor

This element can be given the name "flat false fireplace". Such a pseudo-hearth does not have a niche imitating a firebox. Usually, only the facade of the portal is created, that is, the front decorative frame, which is fixed to the wall. In this case, a flat fireplace can be supplemented with a wall shelf - narrow or very wide. We can say that a false fireplace of this kind is an analogue of a console table.

Another type of this type of false fireplaces is a painted hearth. Yes, yes, just like in Papa Carlo's closet. Combined options are interesting: some of the details can be real (portal frame, shelf), and some can be drawn.