Very often people do not know if it is possible to connect several fireplaces or two stoves in one chimney. In addition, they do not know if it is possible to use stoves connected to one chimney on separate floors of the house. And also they do not know for sure whether it is realistic to connect a fireplace and a gas water heater to the flue duct at the same time. All these questions arise for the reason that today often in a private house there is not only a fireplace and a stove or as many as 2 fireplaces or two stoves, but also fireplaces on separate floors, gas boilers, baths, all kinds of barbecues and etc.

So, not every owner wants to make separate chimneys for all this, because the owner of the house believes that such construction is uneconomical, it will take a lot of brick and time. In addition, such questions torment many for the reason that there is no complete answer to them in SNiPs.

Can two ovens be connected to one chimney?

In theory, such a plan can be implemented, but in fact, all the same, systems of this type are capable of functioning normally only under certain conditions, namely:

- the most suitable height and the structure of the chimney itself;

- larger section for the chimney channel;

- the presence of several dampers for absolute blocking of the chimney channel;

- the implementation of the kindling of fireplaces in sequence;

- correct draft control in both of these fireplaces.

Now I would like to consider the possible operating conditions for a pair of ovens on different floors. So, in the first case, the furnace firebox is provided exclusively on the first floor. At the same time, it is important to prevent the penetration of flue gases into the room where the second stove or other source is located.

Exception to the rule

Unfortunately, for some people, the law is not written. If, nevertheless, the option of two fireplaces or a fireplace plus a stove in one smoke channel is being considered, then some nuances should be taken into account so that such a system works correctly:

- suitable shape and height of the chimney;

- a channel with a larger cross section than for one device;

- the presence of several dampers to completely block the smoke channel;

- alternate kindling of devices;

- the distance between the entrances of the chimneys into the channel must be at least 1 meter;

- correct adjustment of draft in each fireplace and full ventilation;

- the fuel in both devices must be the same.

Only by observing all these rules, it is possible to achieve uninterrupted operation of the chimney when several heating devices are connected to it at once.

Is it possible to output two stoves into one chimney

It is important to understand that the gate valve will not help in any way here. In the second situation, only the oven on the second floor is in operation. Here it is already necessary to prevent air from sucking in from below and the ingress of smoke into the first fireplace. The third option provides for the possibility that both fireplaces cannot be operated. Since in a situation where the chimney is not blocked, air exchange of rooms on other floors will pass through it, which is not allowed. The fourth option provides for the operation of two fireplaces. But at the same time, in theory, the lower fireplace will work normally, and with the upper one there will be problems such as smoke, poor draft and poor flame regulation.

By using dense dampers, you prevent the possibility of smoke entering one of those rooms where the fireplace or stove is located. However, in this case, it is in no way possible to operate two centers at the same time. By operating two fireplaces, you will get a full room of smoke and poor draft in the second fireplace. And the most important issue here is the regulation of air exchange in the whole house.

Firebox walls

The walls of the firebox of fireplaces with increased heat transfer (Fig. 5.2, 1-3) are placed "on the edge" with an indent from the fireplace body by 6 cm to form an air chamber behind the walls. The side walls of the upper firebox 1, in accordance with the recommendations for the construction of a classic fireplace, are installed at a slight angle with respect to the side walls of the fireplace body.

Let us remind you that the turn of the firebox walls is done to better reflect heat into the room. Some experts believe that it is better to use the reversal of the walls to maintain the combustion process of the fuel, therefore they try to concentrate this direction in the middle of the firebox. For this reason (due to low efficiency) in fireplace 2 (this is fireplace A = 51 cm) the side walls of the firebox are placed without turning, they are parallel to the walls of the fireplace body.

A different picture in the firebox of fireplaces of medium and large groups, which can be seen from the firebox on the right (4-6). But even in these cases, it is inappropriate to preset a specific angle that determines the position of the side walls of the firebox. It is clear that it will depend not only on the width of the portal (size A), but also on the chosen depth of the fireplace body (and accordingly, the depth of the firebox).

Therefore, for fireplaces of medium and large groups, the specified angle is also impractical to set in advance, usually it is ~ 30 °. The decision is best left to the discretion of the designer or contractor.

Rear wall of the firebox

Firebox No. 4 is the only one where the rear inclined wall is laid in horizontal rows, and the inclined wall surface is formed due to the angular cut of the brick (20o from the vertical). Accordingly, the outermost bricks are bound with side walls, which are laid with a bevel. Due to this, the entire firebox receives strength qualities:

Pages: - - | - - | - - | - - | - - | - - | - -

We offer you to familiarize yourself with How to decorate the walls near the stove in the house

What are the special features of flue gas discharge into one pipe?

Naturally, such a smoke exhaust has its own characteristics, which we will talk about in more detail. In particular, as already noted, when stoves connected to the same chimney are located on different floors, it is better to fire them separately. Also, you cannot install a gas boiler and a wood-burning fireplace in the same chimney. After all, this type of device must necessarily have their own chimneys. But at the same time, you can still install in one shaft, a chimney, a pipe for a boiler and ventilation.

However, even here they must be completely separated by special hermetic partitions. Ventilation pipes and chimney should never be shared. And the tunnel fireplace insert, which is located between the rooms, is a separate fireplace connected to such a chimney device with two portals. If it is planned to connect two hearths located on the same floor to a common chimney, then it is important to understand that there must be a distance of at least one meter between them. In addition, in this case, it is also necessary to expand the section of the chimney. It is also necessary that two such devices be fired with the same fuel. So, their joint exploitation should not bring any difficulties. But the more powerful device needs to be melted first.

Thus, it should be said that when connecting two hearths to one chimney, a lot of difficult questions arise. In particular, you need to think over all the connection options, take care of proper air exchange, a device for high-quality ventilation, regulation of draft and combustion. Due to such a large number of questions, we can safely say that it will be easier to build its own chimney for each hearth. This way you will spend less energy and make everything more secure.

Article rating:

Is it possible to bring pipes from two sources at different heights and from different sides into a single-pass ceramic chimney, for example, Ton. For example, from a heating stove and a water heater with the condition that they will not be heated at the same time? Or do you still need a two-pass chimney in this case?

You can, but with serious restrictions:

- Gas heat generators should only have separate chimneys.

Metal sandwich chimney device

Steel chimneys are popular both in industrial construction and for the improvement of the private sector. Their installation resembles the assembly of a ceramic structure, respectively, it is easier than building a brick pipe. Let's consider in more detail how to make a metal chimney correctly, avoiding mistakes.

Materials for installing a metal structure

The sandwich chimney is a sealed system of pipes and adapters leading from the heat generator to the roof space. It can run inside the building (internal) and outside, along the wall (external).

A sandwich pipe is a three-layer part consisting of two steel pipes, between which a layer of insulation is laid. Fragments of stainless steel are joined by welding

Non-combustible heat-insulating material has different thicknesses - on average from 2.5 cm to 10 cm. Manufacturers most often use one of the best materials - dense basalt wool (from 200 kg / m³).

To assemble a chimney, you will need to connect several parts of various shapes, using the method of connecting tapered ends and sockets. Simply put, one element is inserted into another. From the outside, the joints are reinforced with overhead clamps, which are tightly tightened after installation.

The advantages of a three-layer design: protection of the chimney duct, minimal formation of condensation, organization of stable draft, the ability to install the system both from the inside and from the outside of the house

When installing a steel chimney inside a building, the holes in the ceilings and roof are much smaller in diameter than for brick or ceramic counterparts.

Sandwich chimney installation diagrams

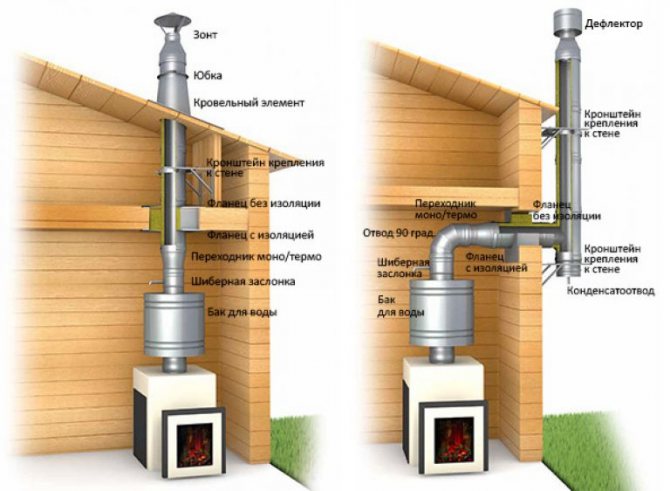

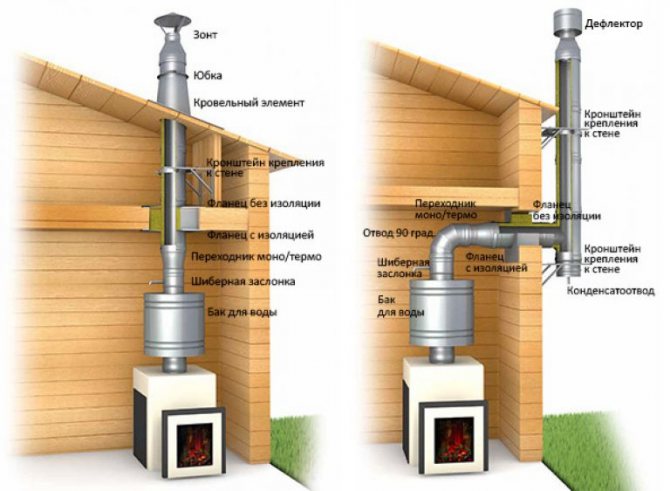

Consider two schemes for installing a sandwich chimney: with an internal arrangement, which requires the organization of holes in the roof and ceilings, and with external installation, which is made from the outside and installed parallel to the wall of the house.

Each of the schemes has advantages: the internal equipment forms less condensation, the external device is lighter in design and is produced with only one hole device

The internal installation scheme is often used in baths, since a steel pipe can simultaneously heat both stones and a tank with water. If the bathhouse is not installed separately, but is an extension to the house, this is the most appropriate and effective option.

The disadvantages of the internal system are the need to make holes in the ceilings and roofs, as well as a decrease in usable space.

To mount an external system, it is enough to make one hole in the wall and ensure the vertical position of the pipes using brackets. Exiting the pipes reduces the risk of poisoning from combustion waste. Minus - the arrangement of additional protection from the effects of the external environment.

Installation work order:

- connection to the boiler (or other heat source) of the adapter;

- punching a hole in the wall (average size - 40 cm x 40 cm), upholstery with fire-resistant material;

- installation in the wall of a pass-through block with thermal insulation;

- installation of a horizontal section of the pipe from the boiler (furnace) to the hole in the wall;

- arrangement of the support unit from the outside (platforms on brackets);

- installation of a vertical pipe;

- mount at the top of the cone and head.

When assembling, it is necessary to be guided by the technical documentation prepared in the process of drawing up the project.

Tips for constructing the inner pipe

When choosing an internal model, it is necessary to remember some technological nuances. For example, it is important to install a valve in the transition area from the boiler so that heat can be retained.

Docking of two adjacent elements on the transition section is prohibited. The location of attic rafters and beams should be taken into account: the further they are from the chimney, the better. Read more about self-assembly of a sandwich chimney in this material.

Floor and roof crossings require the use of fire retardant thermal insulation materials, such as mineral wool, and protective blocks, which can be called "sandwich in a sandwich"

Can two stoves be combined into one chimney?

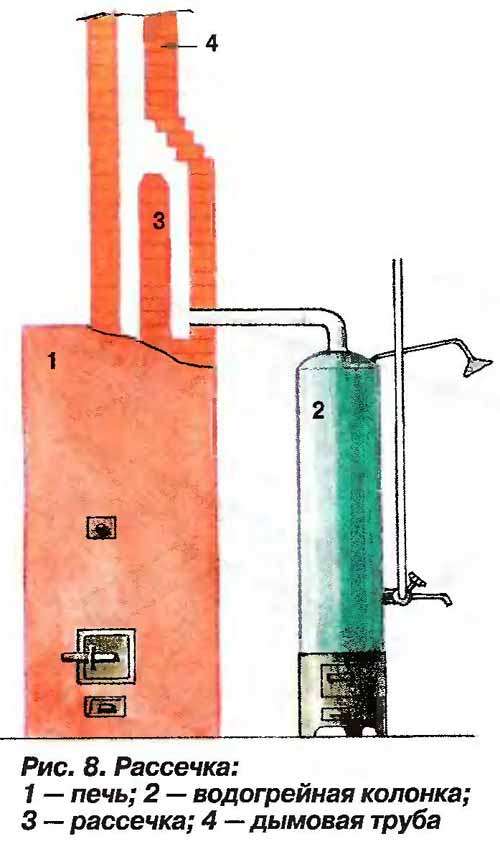

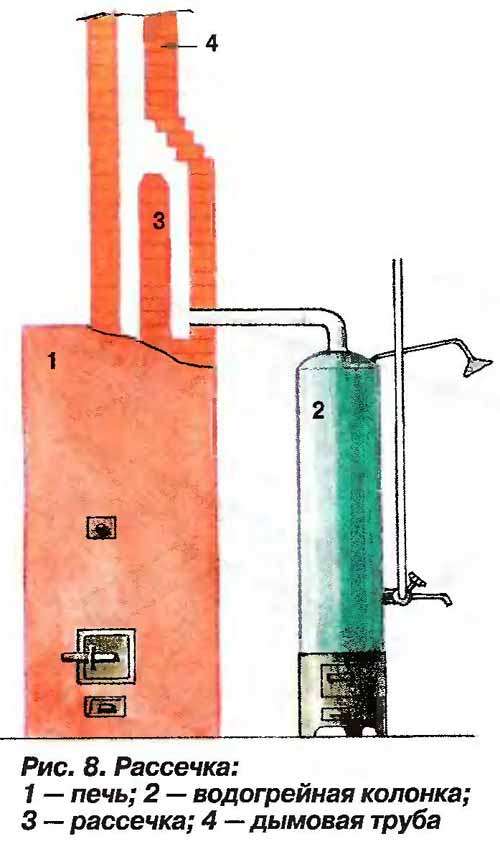

As an exception, in the conditions of reconstruction, it is allowed to connect two gas columns to one chimney if there is a cut with a height of at least 0.5 m.

The cross-section of the combined part of the chimney must be equal to the sum of the cross-sections of the channels to be connected

Building codes do not give any concessions in the event that heating devices are not used at the same time. Theoretically, the operation of heaters, even gas heaters, in a separate mode is possible, but in practice you will not be able to convince either a gas service representative or an EMERCOM inspector of this. They simply won't sign documents for you, they won't connect the gas. In addition, the norms are not written just at the whim of engineers, they establish safe rules for the use of heating equipment.

To summarize: for gas appliances - definitely not, for solid fuel - yes, with the above reservations. The norms should be adhered to, because the fire inspector is obliged to check the smoke exhaust systems in your home. We advise you to find an opportunity to install a separate chimney even if all your heat generators are solid fuel. Still, potential draft problems are not worth the money you can save on a chimney. In addition, if you ever change equipment for gas, there will be no problems with chimneys.

You can find more detailed information in the following documents:

- For Russia - SP 60.13330.2012 SNiP 41-01-2003 "Heating, ventilation and air conditioning"; "Rules for the production of pipe and furnace works" of VDPO, agreed in 2001 in the GUGPS of the Ministry of Internal Affairs of the Russian Federation and Gostekhnadzor.

- For Ukraine - DBN V.2.5-20-2001.

- For Belarus - SNB 4.02.01-03

Loading ...

When building a new house, many owners of suburban areas think about installing two stoves, but do not know how to properly equip the smoke outlet. To avoid unnecessary costs and problems, you can consider several options for the design of the heating system. To make the release of combustion products more efficient, two stoves should be combined into one chimney.

Due to the fact that in many houses not only one hearth is built, but there are two fireplaces or two stoves, a fireplace and a cooking stove, fireplaces on different floors, a fireplace (first floor) and a gas boiler (basement), a bathhouse in the basement and a fireplace on the ground floor, and a barbecue and outdoor oven in the gazebo. The owners of two hearths in the house do not want to build two chimneys, using excuses: it is uneconomical, a lot of bricks will go away, one of the planned chimney ducts will be adjacent to a wooden beam or ceiling, or they believe that two chimneys made of bricks weigh a lot.

Questions about the possibility of connecting two fireplaces to one chimney arise due to the incomplete and incomplete disclosure of this topic in SNiPs.

Russia. Excerpts from SNiP 41-01-2003 clause 6.6.9 and the rules for pipe and furnace work clause 3.6.3. “For each stove, as a rule, a separate chimney or channel (hereinafter - chimney) should be provided. It is allowed to connect two stoves located in one apartment on the same floor to one chimney. When connecting chimneys, they should provide for cuts with a height of at least 1 meter from the bottom of the connection of the branch pipes. "

Excerpts from SP 7.13130.2009 clause 5.47. “In multi-storey residential and public buildings, it is allowed to install solid fuel fireplaces, provided that each fireplace is connected to an individual or collective chimney. The connection to the collective chimney must be made through an air lock, as a rule, with the connection to the vertical collector of air duct branches through the floor (at the level of each overlying floor). "

Ukraine. Excerpts from DBN V.2.5-20-2001. G.3. The removal of combustion products from household gas appliances, stoves and other household gas equipment, the design of which provides for the removal of combustion products into the chimney, should be provided from each device, unit or furnace through a separate chimney. G.6. Non-household gas appliances (restaurant stoves, cooking pots, etc.) may be connected to both a separate and a common chimney. It is allowed to provide for connecting flue pipes common to several units. The introduction of combustion products into a common chimney for several devices should be provided at different levels or at the same level with the diffusion device in accordance with Zh.3. The cross-sectional area of chimneys and connecting pipes should be determined by calculation, based on the condition of the simultaneous operation of all devices connected to the chimney. In the regulatory documents there are distinctions for connecting gas devices and solid fuel fireplaces (wood-burning fireplaces and stoves) to one chimney. Building codes state: there is a separate chimney for each stove, with the specification “as a rule”. But the Slavs have an interesting mentality - laws are not a decree, and everyone loves to experiment, without thinking about the consequences. In practice, we came across fireplaces on two floors connected to one chimney. The upper fireplace had poor draft and smoke on the second floor from the operation of the lower fireplace. The owners built themselves, then converted the upper open fireplace into a fireplace with a closed firebox. The problems remained.

Theoretically, you can connect. But practice shows that such systems work only under many additional conditions: optimal design and height of the chimney, increased cross-section of the smoke channel, installation of several dampers (complete overlap of the smoke channel), compliance with the order of kindling fireplaces (hearths), regulation of draft in two fireplaces (the most difficult moment). Let's admit several options for the operation of two fireplaces on different floors with one chimney.

Option 1: only the fireplace on the ground floor is heated. It is necessary to exclude the ingress of smoke into the room with a fireplace on the second floor. A fireplace damper on the second floor will not help.

Option 2: only the fireplace on the second floor is operated.It is necessary to exclude the ingress of flue gases to the first floor and to prevent air inflow from below. Block the chimney between the first and second floors? But this is problematic for both a modular stainless steel chimney and a modular ceramic one. The chimney gate is not suitable - it provides for an incomplete overlap of the smoke channel.

Option 3: Both fireplaces are not working. If we do not block the chimney, then we will get air exchange of rooms on different floors through the chimney, and this is prohibited.

Option 4: both fireplaces are heated. First, the bottom is melted. In theory, the lower one will burn better - stronger thrust. Problems with the fireplace on the second floor - poor draft and smoke, poor regulation of the combustion mode.

Dense dampers solve the problem of smoke entering one of the rooms, excluding the simultaneous operation of two fireplaces. Smoke on the second floor and poor draft of the second fireplace are consequences, and the main question is air exchange in the house: how to regulate the draft and combustion modes of firewood? How is the supply ventilation arranged in both rooms? What are the conditions for air exchange in the house? (the premises are connected via a flight of stairs or complete insulation). There are more questions than solutions. Our opinion: each fireplace has a separate chimney.

For gas chimneys: it is allowed to connect several gas devices to a common chimney. The situation with apartment heating (gas) and the discharge of combustion products into a common chimney is different. Closed gas boilers are equipped with an automatic combustion control system and work with a drop in gas pressure. Modern wood-burning fireplaces and fireboxes are devoid of such functions. All furnace work is done either by specialized companies or by licensed professionals. There are no universal recommendations and solutions - they are considered individually.

In the case of connecting two fireplaces on the same floor to one smoke channel, the distance between the connection pipes must be at least one meter, and the chimney cross-section must be increased. Both heating devices must run on the same fuel. Simultaneous operation is not a problem. First, a more powerful hearth is melted.

The discharge of flue gases into a common chimney has its own characteristics:

- If fireplaces on two floors have already been built, then it is better to heat them separately (excluding the "suction" of air from the second hearth, completely blocking the flue duct).

- It is forbidden to connect a gas boiler and a wood-burning fireplace to the same chimney. Chimneys for a wood-burning fireplace and a gas boiler must be separate, and several separate channels can be located in a common shaft (fireplace chimney, a pipe from a gas boiler, ventilation ducts), and they must be separated along the entire height by sealed partitions.

- It is forbidden to connect the chimney to the ventilation duct.

- A tunnel or through-hole fireplace insert built between rooms is one fireplace connected to one chimney, with two portals or claddings.

Chimney design and connection options, air exchange in rooms, supply ventilation, draft regulation and combustion maintenance are the main issues when heating several hearths with a common chimney at the same time. There are many questions, but the best solution is for two fireplaces on different floors of the house: one fireplace - one chimney, two fireplaces - two separate chimneys.

Copyright © 2009 CAMMEO

Features of smoke removal

It is worth remembering that you cannot connect a gas boiler and a wood-burning fireplace to the same pipe. If the stoves are located on different floors, then the chimney must be built in such a way that the exit of combustion products from the upper floor is carried out first through a dedicated passage that runs next to the main one. In this case, the height of the partition must be at least one and a half meters. This will heat two stoves at the same time.

It is worth remembering that first the furnace that is large is ignited, which will help to normalize the craving. The cross-section of the chimney at the point where the two outlet ducts are connected should be almost twice as large. To exclude the possibility of smoke from one stove to another, you should make not one, but several dense dampers that ensure a reliable pipe shut-off.

According to the rules for the construction of stoves, if they are located on different floors, then it is not recommended to combine them into one chimney. This is done when they are located at the same level. Install two stoves in one pipe with the expectation that its length should be equal to 5 meters, if you count from the grate. This is necessary for normal smoke output.

Due to the fact that the draft in the lower stove will be better, it is worth making it larger and starting to heat the house from it. Only after the fire flares up in it, the second is activated.

Advantages of collapsible joints and how to reduce the pipe diameter at home?

The optimal connection option is dismountable, which ensures proper tightness, safety and the possibility of dismantling.

Chimney parts

- The easiest way is to connect pipes of different diameters using a clamping collar or an adapter matched to the pipe size. The difference in diameters should be minimal. Reducing the cross section of the chimney can adversely affect its performance. The so-called cravings can deteriorate by 20-30%. In practice, this means inefficient fuel combustion and a decrease in the efficiency of the system as a whole.

- The second option is a threaded connection using a threaded coupling. If necessary, the pipe can be disassembled, for example, to replace a damaged fragment.

- It is practically impossible to cut threads on large-diameter pipes by hand, so the advantages of a threaded connection can be realized after contacting a specialized company.

A butt joint followed by a clamp with a clamp is not the most successful option, since it is difficult to obtain an exact mating at the joint. Heat leakage can lead to overheating of the clamp itself, which is unsafe in terms of fire.

Home craftsmen offer their own connection option. To do this, shallow cuts are made along the diameter of one pipe, with a length of 30-50 mm crimping which can be reduced to a specified value. The connection is partially telescopic, so overheating of the clamp is practically excluded.

Practice has shown that an increase in the diameter of the pipe end makes the clamp design more complicated; moreover, such a connection looks less compact.

What problems can arise?

During the construction of two stoves and combining their chimney, the owners of country houses are faced with the following difficulties:

- smoke on the upper floor,

- weak cravings,

- the inability to melt the upper furnace due to the small height of the pipe.

The first problem can be solved by creating two separate chimneys in the pipe. Thanks to this, smoke will be excluded, as well as the normal draft will be maintained during operation of the upper furnace. It is also possible to bring the upper chimney to the main pipe at an angle.

Smoke can also be associated with irregularities in the pipe. If during the masonry the builder allowed the appearance of protrusions or, conversely, an increase in the cross-section of the passage, this may affect the movement of combustion products. When it enters a section of a pipe with irregularities, the smoke begins to change its trajectory and form “eddies”. As a result, he can get into the second connected passage and further into the room.

When building two furnaces, you should think carefully - is it really necessary to connect them into one pipe. If possible, then the venture should be abandoned. But if you follow the rules for laying the chimney, there should be no problems.

To cook or not to cook?

The first thing that comes to mind is the connection of pipes by electric welding.The idea is not the most successful, since the main range of chimneys is made of stainless steel. Welding work on such materials requires special equipment that can only be found in specialized companies. In addition to everything else, such a connection belongs to the group of one-piece, therefore it can create many problems during routine repairs.

Strong welded joints are unsafe due to the increased brittleness of the seam. Constant static loads can initiate the formation of cracks, through which toxic combustion products, in particular carbon monoxide, can enter the house.

Order today the current repair of a copper roof and a metal chimney from the professionals of our company!