The ventilation fungus is the final element of the ventilation system, which removes polluted air from residential and office premises. The absence of an exhaust hood, incorrect installation of the fungus - all this leads to the formation of condensate in the ventilation ducts, the ingress of precipitation, insects into the air duct, as a result - poor-quality ventilation of the building.

Roof ventilation fungi

What is it and what is it for?

The external element of the ventilation system, installed on the roof of the building and made of metal or plastic material in the shape of a mushroom, is called a ventilation fungus. Fungus for the ventilation system is an element that completes the cycle of moving a mass of air from internal living quarters to the external environment. It ensures the removal of carbon dioxide, unpleasant odors, regulates humidity.

This ventilation element is installed on residential buildings, buildings that store materials exposed to moisture. Fungi protect air ducts from precipitation, debris, small insects, birds. When installing such a cap on a pipe, be sure to follow all the rules. A wide range of fungi allows you to give the building an attractive look.

What is a cap on a chimney pipe for?

The tradition of installing hoods on chimneys came to us from the past. Back in the 19th century, they were only forged, because there were simply no other ways to make an iron product. Since the work of a blacksmith was not cheap, not everyone could afford such a decoration on the roof. But on rich houses and castles, chimney caps were decorated with whole metal compositions. Most often, figures of people, animals and birds were depicted. Sometimes the owners of any business ordered an image of an object as a weather vane, which symbolized the owner's occupation. Such a visual advertisement.

Chimney vane

In fact, there are several functions of an umbrella installed on a chimney:

- Protects the pipe from water and snow ingress. In case of heavy precipitation, there may be enough moisture in the pipe to "lock" the draft. The hood, which is put on top, but does not interfere with the exit of smoke, significantly reduces its amount. Therefore, the shape of the cap should be selected based not only on aesthetic considerations: if a lot of snow falls in your region, then the best option is a cap in the form of a small roll roof with a sufficiently large angle. Snow comes off well from such umbrellas.

- The cap on the brick chimney protects the brick from destruction. Most of modern products have special grooves for draining condensate, which inevitably forms on a cold metal surface, in contact with heated smoke (or air, if this is a ventilation duct outlet).

- Prevents insects, animals, birds, leaves and other objects from entering the chimney that can be carried by the wind.

- Improves traction. Deflectors of various modifications have been developed specifically to improve traction, but any fungus on the pipe also copes well with this task: it rises by about 20%.

Why you need an umbrella over the chimney pipe is now clear. It remains to understand what to make it from and which shape is better to choose.

How does a fungus work?

Initially, the roof fungus was made of galvanized steel. Especially popular are structures made of impact-resistant polypropylene, which is slightly exposed to the sun, frost, and corrosion. In some types of hoods, the inner tube is made of steel alloy.The ventilation fungus includes a number of elements:

- 2 pipes (for gas outlet, fixings with a horizontal section of the air duct);

- fasteners (flanges);

- container for the accumulation of condensate;

- air valve, which is responsible for the necessary air circulation;

- rings for support, fastening;

- aerator (a device that saturates the room with oxygen);

- deflector (a device that increases the draft of air flows);

- valves.

Roof ventilation fungus

What to put an umbrella or deflector in the chimney head?

According to building codes, a deflector cannot be installed on the outlet of gas boilers. This is due to the fact that in winter, due to low temperatures of the outlet flow, icicles are formed in the horizontal sections of the pipe, which worsen the draft. The deflector only aggravates this picture. Therefore, only simple umbrellas are placed on the outlets of gas boilers to protect against debris and precipitation.

Aerodynamic chimney hoods. One of the options

Experts recommend installing deflectors on a metal pipe of solid fuel boilers. In all other variants, chimney hoods are recommended. The shape of the hood is selected in accordance with the shape of the chimney: round umbrellas are usually placed on round ones, on square and rectangular ones - in the form of a small pitched roof. It should be noted that on sandwich chimneys, chimneys must have a special skirt that will cover the thermal insulation. For brick chimneys, it is recommended to make a cap with a base that will cover all the bricks protruding above the roof.

Not a very good attitude from experts to weather vane: constant vibration and considerable weight quickly destroy even capitally constructed pipes. So if you wanted to have a weather vane, think about it well: it not only adversely affects the chimney, but also wears out quickly due to constant friction.

Principle of operation

The ventilation system is based on the principle of upward movement of warm air mass, and downward movement of cold air. For air extraction, natural ventilation, the distance between the source of pollution and the upper section of the air duct is important: the greater this distance, the more efficiently the process proceeds.

Umbrellas are mounted on the air ducts leaving the bathroom, basement, chimneys of the heating boiler. In the cold season, ice build-up is possible in the ventilation pipe and on the umbrella, so they are insulated with heat-insulating materials (mineral wool, polystyrene foam, polypropylene foam, polyethylene foam insulation).

What materials are used to make caps for their fasteners

The chimney cap was invented a long time ago. It solves several practical problems:

- protects the chimney from external factors: rain, snow and wind;

- acts as an additional roof decoration.

It is important to provide, first of all, protection from wind and precipitation, otherwise the walls of the chimney will be destroyed under the influence of weather conditions.

The hood must be selected in accordance with:

- channel type;

- hole diameter.

Based on these indicators, select:

- a cap made of chrome and nickel, if the house is heated with gas;

- removable product if the apartment is heated by a fireplace, solid fuel boiler or wood-burning stove.

The main types are considered models with a round and square base, stationary or folding, made of tin - chrome-nickel or black. Many modifications are groundless. They are fixed directly to the chimney duct.

Today there are chimneys made of galvanized or stainless steel, copper. It is also possible to select modifications so that the shade of the cap matches the color of the roof. The selected option should correspond in functionality to the specific type of pipe. It should also match the style of the building.

As for the architectural shape of the hood, the multi-slope weather vane is capable of excellent protection from atmospheric precipitation and snow. Such a chimney looks very impressive, especially if you install figures of any animals made of metal on top.

Models with a flat surface are more often used. There are pop-up caps that are popular too. They are convenient for the prevention and unhindered maintenance of the chimney. A deflector with a ventilation hole in the housing significantly improves traction.

But the chimney is not always used. There is virtually no need for it in areas where precipitation rarely occurs and there is practically no wind. But for Russian latitudes, it is a necessity.

When choosing a hood design, one should take into account what material the chimney is made of and the type of fuel used to operate the heater.

This is due to different flue gas temperatures and heater efficiency:

- for a brick oven with a square or rectangular chimney, also made of bricks, a special hood is suitable - a deflector. A special feature of chimneys of this shape is the risk of turbulence, which impairs draft. In addition, more soot, soot and dust are deposited on rough surfaces of brickwork, narrowing the pipe lumen, which can greatly impair traction, up to a complete stop. The deflector will protect the chimney walls from excessive moisture, which will reduce the adhesion of combustion products and act as a draft amplifier. It will create a vacuum in the upper part of the channel and facilitate the outflow of air from the furnace;

- Solid fuel boilers are usually equipped with ceramic tubes or double-walled sandwich chimneys. They have a smoother surface than brick structures, are equipped with a condensate trap, where condensate and precipitation flow down, so they have much less soot deposits on the inner walls. The draft stability of such boilers depends on the height of the chimney. If you do not organize forced draft, then you need to install a very high pipe (up to 8 m). When installing a deflector, the height of the chimney can be reduced by 15-25%, while the stability and traction force will remain at the same level, and the installation of a reduced pipe structure will be less difficult. In the presence of a boiler, the operation of which is based on the principle of pyrolysis, it is better to install a hood with an open nozzle on the chimney. It will be able to protect the channel from the ingress of debris and precipitation, but will not become an obstacle to the release of low-temperature smoke;

- for gas and diesel boilers, it is also recommended to use a hood with an open nozzle. In them, traction is carried out forcibly, so there is no need to increase traction with the help of a chimney - a deflector.

- With a downwind, vortex phenomena are formed under the hood, which impair traction. If you install a reverse cone under it, then it will reflect the air flow, cut it and bring it out;

- if a circular section device is installed on a brick pipe, then the installation of a corresponding adapter is additionally required;

- the chimney should be no lower than the roof ridge, ventilation exhaust pipes and other structures, if they are located close to the chimney.

Oddly enough, first of all, the choice of the hood depends on the type of boiler plant and the type of fuel burned. For example, nozzles for chimneys serving gas boilers can be installed in only one design - in the form of a nozzle, with an open top.

The reason is the condensation that precipitates on the cold metal upon contact with the products of combustion at a low temperature. Smoke from high-efficiency boilers, that is, gas-fired, has such a temperature. Because of this, the hood should not be placed on a brick chimney pipe.

Another thing is when the boiler is solid fuel, its efficiency varies within 70-80%, and the temperature of the gases at the outlet is from 150 to 250 ºС. Here you can safely pick up a nozzle, especially on a brick channel, destroyed by precipitation. Just remember that it will quickly become covered with black soot.

When the issue of boiler installations is clarified, let's move on to the gas exhaust pipe itself. The easiest way is, if it is assembled from a three-layer modular sandwich, then protection of the chimney from rain is not required at all.

The ingress of precipitation into the canal even benefits him, the pipe is washed from the inside, and then the water is discharged into the condensate collector. For a gas boiler, we choose a nozzle, for a solid fuel boiler - any other nozzle, most preferable from a technical point of view - a deflector-vane.

It is clearly seen here that the hood is made as a protective box that completely covers the brick base. Since the photo shows a pipe with several channels, some of which are ventilation, the pipes and umbrellas are different. But nozzles are installed on the chimney ducts in accordance with the norms.

The hoods for the chimney are made of materials that are resistant to corrosion, withstand high temperatures and have a long service life. The temperature requirement applies only if you close the chimney.

- Galvanized steel

- Stainless steel

- Copper

- Zinc-titanium alloy

Copper flutes (chimneys) serve for a long time, from 50 to 100 years. This is one of the most durable materials, but when installing it, you must use copper hardware. Otherwise, active corrosion processes will begin, which will significantly reduce the life of the device.

The installation of a zinc-titanium hood on the chimney provides for the use of only galvanized hardware for the same reasons. Zinc-titanium is a new alloy that was recently used only for the manufacture of roofing materials, but today many companies have begun to produce hoods for the chimney from it.

They have a half-century warranty and the price is much less than that of copper ones. You can install caps made of other materials on the pipe with ordinary hardware, although it is better to take those that do not lend themselves to oxidation and destruction: most of the weather vane can last for decades, and climbing on the roof because it was blown off by the wind due to a collapsed fastening is not the most good time.

If we talk about a brick pipe, then you can use either ordinary long nails or threaded ones (but it is almost impossible to dismantle them), you can use dowels. In each case, the fastening system is selected based on the shape and material of the pipe, the available holes for fastening, etc.

The most popular type of this product is a stainless steel chimney with or without polymer coating. The service life in this case is 20 years, but the price is much lower. The option with a polymer coating is especially popular - the color can be matched to the tone of the roof, and if the design is in the style of the roof, this option looks great.

Types, shape and design

Depending on the room in which the fungus is installed, a conventional or heat-resistant type of structure is selected. Conventional hoods are suitable for a bathroom, toilet, kitchen and basement area, cellar. Heat-resistant fungi are mounted on pipes exposed to heating and installed in the boiler room.

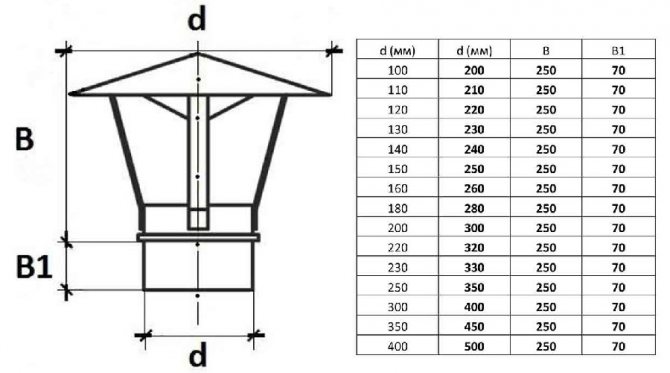

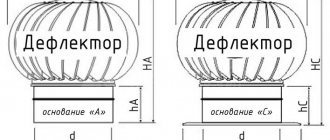

The volume of gas discharged from the room determines the size of the duct, the fungus. The diameters of the structures are different, they range from 1 to 3 cm. The simplest option consists of a pipe and an umbrella made of sheet metal. More expensive models are practical and aesthetically pleasing and include a larger set of elements (glass for excess moisture, heat-insulating material).Both types of ventilation fungus are installed on the roof, fixed with fasteners.

Types and forms of fungi

Tips & Tricks

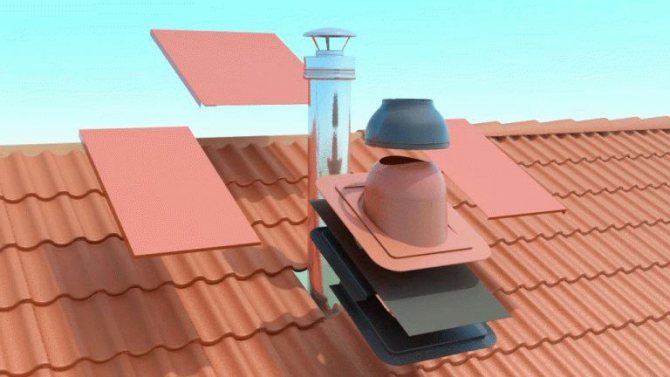

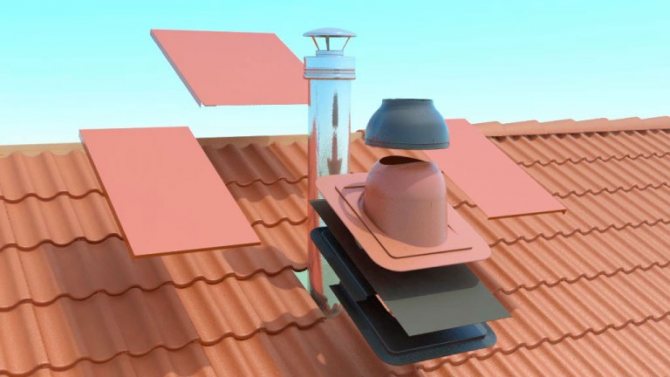

Many experts recommend that you approach the installation of a ventilation outlet for metal tiles as carefully as possible. In order for the installation to be of high quality, it is necessary to adhere to building codes and requirements, according to which the size of the pipes used is determined. It is better to plan all work on the installation of ventilation fungi at the time of drawing up a project for the construction of a house.

Since it will be necessary to cut the metal tile for fungi, it should be understood that in this case the integrity of the material will be violated. As a result, the roofing material can be susceptible to the appearance of fungus and rust. In this case, it is worth immediately treating the cut points with special protective compounds.

After the installation of the fungi is completed, it is necessary to close up all the gaps as carefully as possible in order to prevent the penetration of natural precipitation into the under-roof space, while the operational period will remain at the proper level.

Important! At the same time, you can start arranging a roof hood made of metal tiles.

Advantages and disadvantages

The accumulated carbon monoxide and carbon dioxide are invisible to humans, but they cause poisoning of the body. The ventilation ducts are always led out to the roof: this ensures natural air circulation. The exhaust pipe rises to the maximum height, a fungus is installed on it. Thanks to ventilation fungi, polluted air is removed regularly, regardless of the weather and the area of the room. The main disadvantage of the hubcaps is the high cost of factory models. The advantages of factory designs are undeniable:

- lightness, structural strength;

- protection of the air duct from clogging;

- protection against reverse draft, smoke.

Materials and tools for installation

However, if you wish, you can also use pipes made of galvanized, aluminum, stainless steel, polyester. In terms of shape, it is better to choose a round diameter, although some people prefer a rectangular duct. A set of tools that will be needed when installing the outer part of the ventilation duct. Generally speaking, you should have at hand:

- rubber gaskets;

- silicone;

- passage assembly with or without valve;

- screwdriver;

- roofing screws;

- felt-tip pen;

- insulation for pipes;

- electric shears for metal;

- drill;

- jigsaw

The specified "arsenal", for example, will definitely satisfy the needs when arranging a roof made of metal tiles.

Life time

Caps for ventilation pipes have a long service life if they are not subjected to strong mechanical stress (hurricane wind, falling branches). Products made of asbestos cement and steel serve 10-15 years. Modern models, based on polymer plastic with a UV protection function, are designed for a long service life - 50 years. Their service life depends on several factors:

- corrosion resistance;

- product thickness;

- the presence of a container for collecting moisture;

- the quality of the installation performed;

- insulation of the ventilation duct with heat-insulating materials.

Modern fungus models can last up to 50 years

Roofing cake and its device

- Group: Administrators

- Posts: 410

- Registration: 31 December 09

Posted 14 May 2010 - 11:17

Almost the entire roof is susceptible to the appearance of thickets of fungus. As a rule, it begins to grow from the north side. Manufacturers of natural roofing recommend treating with an antiseptic every five, six years, sprinkling the roof.

Some may have a question: why do you need to conduct ventilation at all and spend additional funds when you can do without these works. The answer is obvious. First of all, ventilation maintains a beneficial microclimate inside the roof.

This will help each of its elements to calmly carry out their work, without fear of destruction. Also, the quality of the work of thermal insulation depends on ventilation, if you performed these works when installing the roof, taking into account the height of the pipe above the ridge.

Improper operation of ventilation or its absence at all can lead to the following problems:

- Condensation on materials. Wood materials such as rafters and beams will prematurely deteriorate or rot. Condensation on metal and other elements will cause their corrosion, and in the future, and complete destruction (read the article: "How to eliminate condensation under the roof").

- Moisture also forms on the roof surface. This can already lead to the formation of ice and the destruction of some types of roofing material.

- Steam condensation on the insulation. The insulation layer will get wet and subsequently lose its thermal insulation properties. This means that it can be worse with insulation than without it.

We suggest you familiarize yourself with: Unisan from nail fungus

DIY manufacturing and installation

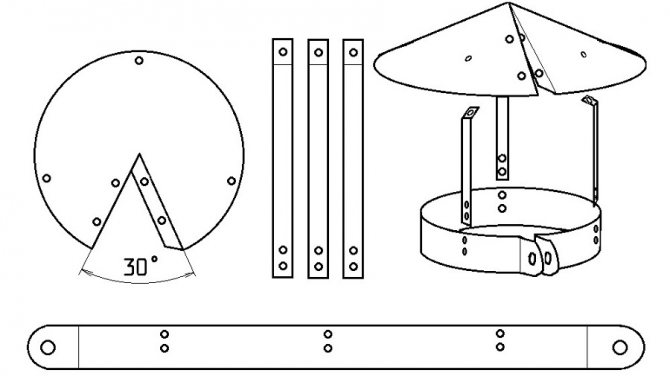

A roof ventilation hood can be made at home using the tools and materials at hand. To do this, it is enough to take two metal pipes (larger and smaller diameter), a flat disc, and a welding machine.

The source material is selected depending on the size of the duct. Installing the fungus will require intervention not only in ventilation, but also in the roof of the building. A hole is cut in the roof pie through which the pipe is led out. The vent fungus is placed on top of this airway tube.

Material selection

The service life of a roofing cap is determined not only by the quality of installation, but also by the choice of material for its manufacture at home. When preparing for work, the following should be considered:

- the main pipe must be made of polymer plastic or stainless steel;

- ventilation hoods are best made of plastic (high temperatures will lead to configuration changes);

- opt for fasteners made of aluminum and stainless steel (do not corrode);

- exclude wood, sand-lime brick, black steel and asbestos cement as a starting material (they quickly deteriorate).

Calculation of dimensions

Exhaust hoods are installed in the roof of the building with complete exclusion of the possibility of smoke from entering them from a working oven. The inner section of the fungus is taken into account: it must be no less than the section of the supply channel. For example, the diameter of the flue is 30 cm, then the cross-section of the hood should be the same. The hood installed on the roof slope must rise by more than 20 cm. When the roof is used as a recreation area, the pipe is raised by 2–2.5 meters.

Installation features

An ideal ventilation system includes several air ducts that exit in a strictly vertical direction without horizontal bends. When installing the ventilation outlet, the following sequence of actions is observed:

- A hole is cut in the roof of the building (for this, metal scissors or a saber saw are used), a metal gasket is mounted on top of it, previously sealed with a liquid sealant. The gasket is attached with self-tapping screws.

- A special adapter is installed on the gasket, which will henceforth protect the outlet from precipitation and fix the cap.

- The fungus is mounted inside the adapter, inserted into the duct pipe, fastened with bolts, nuts.

- Using the building level, the verticality of the installed fungus is checked.

It is advisable to install a duct pipe with a ventilation fungus at the highest point of the roof. This will provide strong traction and air circulation. The best option is the ridge of the building, which separates the parts of the gable roof.If it is impossible to implement this option, the fungus is located as close to the ridge as possible. The ventilation outlet, located far from the ridge, is equipped with a high fungus. Insufficient height of the structure will lead to low pressure in the pipe, as a result - ineffective ventilation.

Possible mistakes

The most common mistake when installing a fungus is the lack of insulation on the ventilation duct and the product itself. Basalt wool is more often used as a heater; a stainless steel cylinder is fixed on top. Another option is to cover the channel with construction foam. Other errors are possible when installing the fume hood:

- joints are not sealed with special means;

- materials that are prone to corrosion are used as the material of the ventilation ducts;

- pipes that come out of the rooms at different levels are connected into a single passage;

- the wrong place is chosen for the vent fungus.

Ventilation fungus is a metal or plastic product resembling a mushroom and installed on the roof of a building. It protects the air duct outlet from precipitation, increases the draft in ventilation (removes polluted air, carbon dioxide and other gases).

Self-assembly of the ventilation hood is not particularly difficult. The main thing is to comply with the installation rules and select a high-quality exhaust fungus. You can use a ready-made factory design or make a do-it-yourself vent fungus. Correct size calculation and selection of suitable material is the key to effective ventilation, which will provide a healthy and comfortable microclimate in the room.

Choosing a place to bring ventilation to a roof made of metal tiles

The installation of a ventilation pipe on a metal roof should be thought out at the time of designing a house. The conclusion must be carried out through the roof, on the surface of which special ventilation fungi are installed. During the implementation of the work, it is recommended to adhere to building codes and regulations that govern the height, as well as the diameter of the pipes used, the material and location, taking into account the slope of the roof. In order to ensure high-quality ventilation of the under-roof space, the presence of wind is necessary in the area where the construction of the dwelling is being carried out.

During the installation of a ventilation outlet on a metal tile, it is recommended to adhere to the following rules:

- for every 60 sq. m should have 1 ventilation fungus;

- during installation work, it is necessary to indent from the ridge, which is a maximum of 60 cm;

- if it is planned to draw a conclusion for several pipes on the roof surface, then the holes to be prepared must be at the same level;

- after the work has been carried out, with the help of a sealant, it will be necessary to seal all the places where the fungi are expelled as carefully as possible - this is necessary so that atmospheric precipitation does not get into the under-roof space through the existing holes;

- in the process of arranging the output, it is recommended to use a special template that comes with the purchased products, such a template should be attached to the roof surface, circle, and then install fasteners for attaching the fungi.

In the process of installation work, the manufacturer advises to use only those fasteners that come with the purchased product. This approach will allow you to get a reliable design, while the installation will be of fairly high quality.