How is an electric mini boiler room arranged.

A mini boiler room is an electric boiler, which is equipped with additional equipment. This equipment usually includes the following things:

- Circulation pump.

- Safety valve.

- Automatic air vent.

- Closed expansion tank (expansomat).

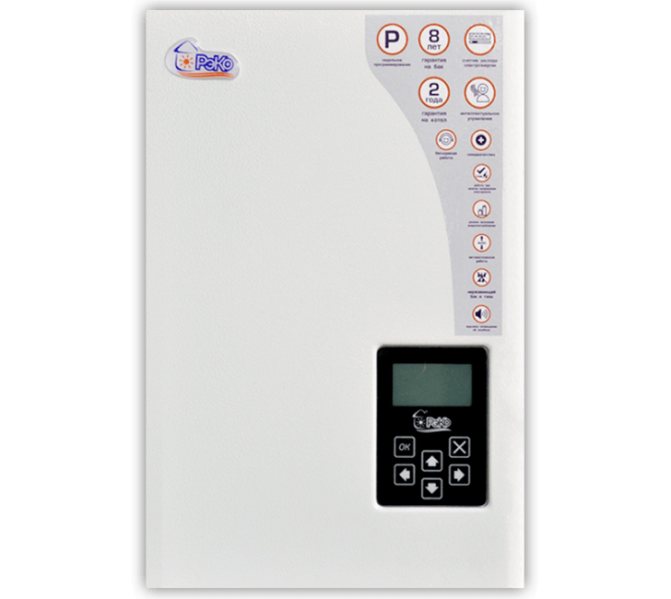

In addition, additional equipment can be included in the mini boiler room. For example, a GSM module for controlling the operation of a heating system. This arrangement saves space and simplifies the installation of the heating system. As you can see from the picture, a mini boiler room is very similar in structure to a wall-mounted gas boiler, only instead of gas, electricity is supplied to it. Now let's talk about the main disadvantage of mini boiler rooms - their prices.

Types of electric boilers used in electric boiler rooms

Electric boilers also differ in the type of electric heating equipment:

- electric boilers on heating boilers

- electric boiler rooms on electrode boilers

- electric boilers on induction boilers (inductive-conductive boilers).

Electric boilers with heating elements

A heating element is a tubular electric heater, in which a conductive filament is heated under the action of a current, the outer case of a heating element is heated from it, and then the heat is removed by a circulating heat carrier. The main advantage of heating elements is the low cost of both the electric boiler itself and replaceable elements (those very heating elements). The main disadvantage is that these replaceable elements will have to be replaced regularly. The durability of the heating element is low. In addition, heating elements tend to become overgrown with scale, which very quickly leads to a decrease in heating efficiency, that is, it practically negates all the advantages of electric heating as such. But if we are talking about equipment of low power (within 15-25 kW), the advantages of heating elements still outweigh their disadvantages. Another thing is that such power is insufficient for an electric boiler house. When installing heating element boilers of high power (from 50 kW and above), the costs of repair and operation proportionally increase, which can make the operation of such equipment troublesome and unprofitable.

Electric boiler rooms on electrode boilers

Electrode boilers can provide very significant heating power - up to hundreds and thousands of kilowatts. The electrode boiler is a direct heating electric boiler, in which the coolant is heated directly when an electric current passes through it. As you know, water is a good conductor of electricity. And if you add a special additive to the water that increases its mineralization, it will quickly and efficiently heat up, because there are no intermediaries between electricity and water, therefore, there is no energy loss. However, this type of equipment has its drawbacks: low electrical safety, natural failure of the electrodes, a decrease in boiler power due to the deposition of scale on the electrodes, the need to control the chemical composition of the coolant. In fact, it is not water that is heated, but the electrolyte - a very aggressive environment that reduces the durability and reliability of the entire heat supply system.

Electric boilers on induction boilers

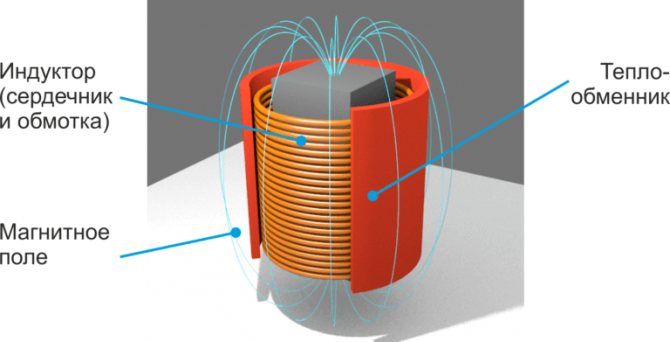

An induction electric water heater (boiler) is a device that heats water (heat transfer fluid) by transferring heat from a heat exchanger heated by an alternating magnetic field.There are no heating elements or electrodes in it, but there are elements such as an inductor (primary winding) and a heat exchanger (secondary winding). By the way, a dry-type power transformer consists of the same elements. Therefore, sometimes induction electric boilers are also called transformer-type boilers.

When electricity passes through a conductor, an electromagnetic field arises (is induced) around it. So in an induction heater, when current passes through the primary winding, an alternating magnetic field arises in it, which generates induction currents in the metal of the heat exchanger. In turn, this heat is transferred to the heat carrier circulating through the heater.

The use of induction electric boilers makes it possible to create electric boilers on their basis, which have all the advantages of electric boilers, as such, but at the same time, the reliability, safety and durability of the equipment will be at an extremely high level.

Is it worth overpaying buying a mini boiler room?

Each person must answer this question for himself, based on the installation conditions (for example, the limited dimensions of the installation room) and the configuration of the heating system. The fact that all the main units are collected in one small cabinet is an absolute plus of such electric boilers, compared to conventional ones. For the simplest systems, installation can be limited to the supply of two pipes (supply and return) and a power cable. If you are well versed in the installation of heating or do not lack space for a boiler, then it will be cheaper to buy all the units you need separately and assemble everything yourself. Think for yourself, decide for yourself ...

The secrets of popularity

Despite the high price, electric boiler houses are considered leaders in terms of the safety of residential premises, and this greatly simplifies their installation and operation and contributes to widespread popularity:

- they do not need a separate room for them;

- the absence of combustion products relieves the owner of the installation of chimneys and ventilation systems;

- easy to install, do not cause problems in operation and maintenance;

- do not create noise;

- have high efficiency.

Selecting the power of a mini boiler room.

The power of a mini boiler room is the power of the heating element unit and is selected according to the heating system project, which must be done before starting installation work. If there is no system design, then you can roughly estimate the required power for the heated area, based on the ratio of 1 kW of power per 10 square meters of area, or you can use the calculator to calculate heat losses on my blog.

Electric boiler room in modular design "Termanik Module"

One of the leading manufacturers of modular electric boiler rooms, in which induction-type electric heaters are installed, is NPP "Thermal Technologies". This enterprise has its own patented developments, which are used in the production of only Termanik induction heaters. The properties of induction heating equipment are usually:

- autonomy and unpretentious operation;

- high energy characteristics (efficiency 98% and power factor 0.98-0.99);

- relatively low cost (although it is higher than that of heating elements and electrode electric boiler rooms, it is lower than that of gas ones).

- high electrical and fire safety of heating equipment

- high reliability due to the absence of replaceable, failing elements. Induction heaters are structurally more resistant to scale deposits.

- durability (the service life of an induction heater is more than a dozen years). Moreover, during this entire period, there is no reduction in power.

Unlike induction heaters used in metallurgy and mechanical engineering, TERMANIK induction boilers operate from the mains with an industrial frequency of current (50 Hz), because in heating systems there is no need to heat up to temperatures above 100-120 ° C.

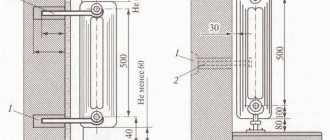

Features of the installation of a mini boiler room.

The first thing to do before installing a mini boiler room is to read its instructions from start to finish. Especially the section that describes the installation. It's not enough just to read what is written there, you still need to do it all in practice. The requirements for the installation of mini boiler rooms can be very different, for example:

- Use of a certain type of heating medium, for example, only water.

- Connection via a low loss header (hydraulic arrow).

- Requirements for cross-sections of pipelines.

- Requirements for the room in which the heating device will be located.

- If you want to use room thermostats or other automation, you first need to find out their compatibility.

In general, the installation of a mini boiler room should be easier and faster than the installation of a conventional electric boiler. After all, you do not have to connect a circulation pump, a safety group and an expansion tank. All this is already built into the design. If the volume of the built-in expansion tank is insufficient for this system, an additional expansion tank must be installed.

Above, I spoke about the installation of a mini boiler room through a hydraulic separator (the second name of a hydraulic arrow). It should be used if there is more than one circulation pump in the system. In order to figure out why you need a hydraulic arrow, follow this link.

Areas of application of boiler rooms for electric boilers

Electric boilers are used in the field of heating and hot water supply. The prerequisites for the use of modular electric boiler rooms are also the lack of a dedicated room for a boiler room inside the consumer building. A modular boiler room is installed outside the building and does not depend on it in any way.

The fields of application of electric boilers are as follows:

Heating:

- heating of detached buildings;

- heating of workshops, warehouses;

- heat supply for shift camps of oil workers, builders, geologists;

- heat supply of objects in specially protected natural areas (sanatoriums, houses and recreation centers);

- heating of isolated microdistricts, groups of buildings and structures;

- emergency (backup) heat supply

Hot water supply (DHW):

- hot water supply for showers, canteens

- hot water supply of individual buildings, as well as their groups (microdistricts);

- DHW facilities in specially protected natural areas with increased requirements for the environmental friendliness of boiler equipment;

- backup hot water supply, hot water supply during seasonal shutdown of hot water

Advantages and disadvantages of small horizontal electric boilers

Electric horizontal electric boilers are a great option heating for cottages, summer cottages, private houses.

They have their pros and cons.

- Volatility:

it is impossible to install the device away from the mains. If there are interruptions in the supply of current, then there will be problems, since the equipment will simply fail. - Costs:

higher electricity consumption also means higher costs. - Scale formation:

on models with heating elements, water scale builds up over time, and it is necessary to change the heating element.

In addition to the characteristics considered, it is worth paying attention to some features:

- Power

- calculated individually for each type of boilers. It depends on the power whether the heating of the room will be sufficient. - Efficiency—

for electric boilers, the efficiency is high -

95-98%. - Power adjustment

- can be stepped or smooth. In models with an independent heating element, step regulation is used.Smooth is possible only in devices with a rheostat. - Price

- depends on many indicators: type of electric boiler (heating element, ionic), power, manufacturer, additional functions.

Reference!

Special attention should also be paid to

dimensions, weight

electric boiler,

economy, type of premises

which he will heat.

Schematic diagram of the device

The mini-boiler room assembly is a relatively small unit for wall or floor mounting. Mini-boilers can operate on a variety of energy sources, but they are most often purchased for apartments and private houses.

The main difference between a mini-boiler house and a conventional electric boiler is its equipment. Such a device has all the components necessary for connection to heating circuits and the effective functioning of the system as a whole. Complete heating boilers can have a very different configuration, but the main structural elements remain unchanged:

- A heat exchanger with heaters is the main part of the device, in which the heat carrier is heated. Heating elements are most often used as heating elements, and their configuration and number are determined by the mini-boiler model and its power.

- Expansion tank - a reservoir in which there is a supply of coolant. The presence allows maintaining the pressure in the circuits at a constant level.

- Hydro group - devices that ensure optimal distribution of the coolant in the system. As a rule, the hydro group includes the one responsible for the circulation of hot water, pressure sensors and safety valves.

- The control module is an electronics unit that is responsible for adjusting the basic parameters of the boiler. Heating and pumping equipment is usually connected to the control module, which provides flexible system settings.

- Loops and outlets - in addition to the main elements, the complete heating electric boiler also includes pipes that connect all the components into a single system. Also, the design includes branch pipes for connecting the supply and return lines of the heating system.

Note! not included in the boiler package. At the same time, the design of most assembled electric boilers provides for the possibility of connecting such devices.

All the described components of the mini-boiler house are located in a single housing. Thanks to this, the device not only turns out to be quite compact, but also looks quite neat. In situations where the boiler must be installed in a residential area, this becomes a tangible advantage.

Electric mini-boiler rooms Protherm SKAT

An example of a mini-boiler room in the collection of a classic design can serve as electric boilers, presented in the catalog of the Alfatep online store in a fairly wide range.

These devices are characterized by the following features:

Another advantage of the system is the boiler frost protection. Thus, it can be used even in those houses that are heated only periodically: with minimal maintenance, the risk of formation of ice plugs, violating the integrity of the circuits, will be excluded.