Among heating systems, a flueless boiler using natural or liquefied gas occupies a special place. Having appeared on the market relatively recently, these devices have become a real breakthrough in the application of new technologies in heating systems. Consumers also appreciated it - recognizing the convenience of use and reliability of these boilers. However, when choosing a device for an individual heating system, you should carefully study all the qualities in order to be sure of the right choice.

What are smokeless boilers

In the design of heating boilers, a large place is occupied by the problem of removing combustion products. In gas boilers, in comparison with other types of heat-generating devices, there are much fewer such products than in solid fuel ones, but despite this, their design is a very responsible matter.

The classic installation scheme for a gas boiler, like a solid fuel unit, requires that a chimney be provided in the building structure itself. And this is a rather complex structure erected during the construction of the entire structure of the house. A smokeless gas boiler is another matter; its installation does not require a high chimney and smoke ducts in the walls of buildings. And the place of installation of this device is not so rigidly tied to the structure of the building and the communications laid in its premises.

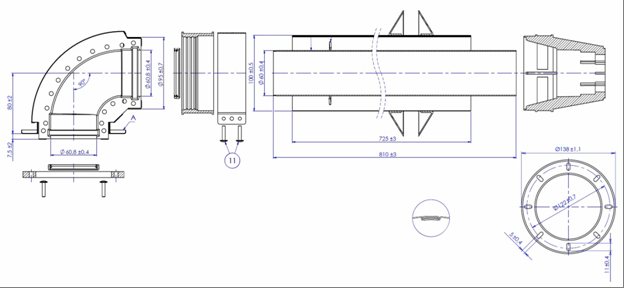

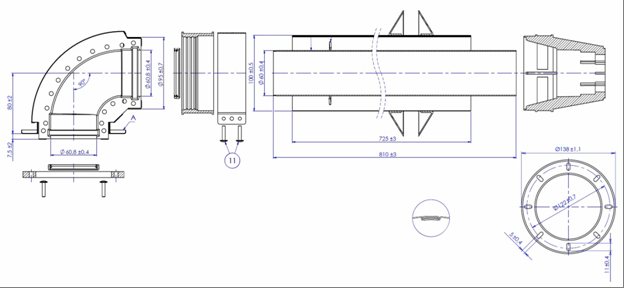

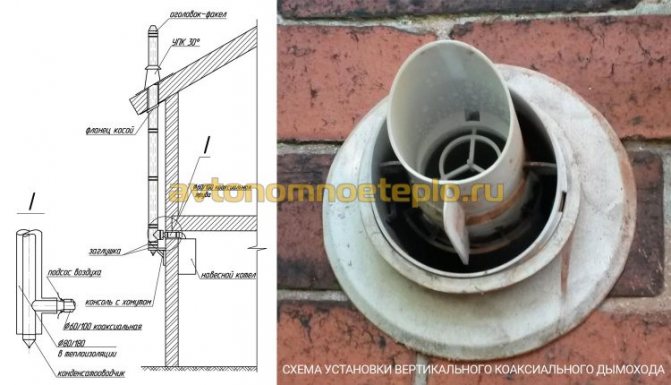

In the technology of smokeless heating boilers, a scheme is implemented in which air is supplied for fuel combustion and combustion products are removed through a coaxial channel. This is the fundamental difference between conventional chimney boilers with an open gas burner and a closed combustion chamber. As for the design of the coaxial channel, it is nothing more than two pipes inserted into one another, in which a thin inner one is designed to remove combustion products, and the second, of a larger diameter, is intended for the flow of atmospheric air.

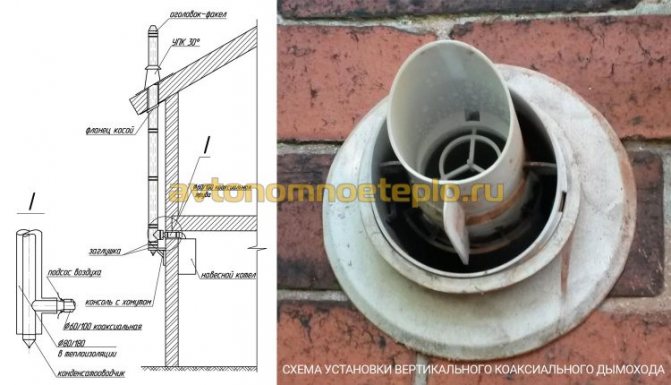

Such a coaxial chimney can be installed in any outer wall of the building, which allows for the most convenient location of heating equipment inside the building.

The principle of operation of chimney boilers

In principle, this group of heating devices is no different from conventional boilers with an open burner. In the heat exchanger above the gas burner, the heating medium for the heating system and water for hot water supply are heated. The movement of the coolant through the system is carried out under pressure created by a circulation pump. Burner ignition is controlled by a control system that reacts to data changes with a temperature and water flow sensor. The difference lies in how atmospheric air is supplied to the combustion chamber and how the exhaust gases are discharged.

The gas burner is located in a closed circuit, when a signal is sent from the control board, an electric turbine starts to work before igniting the piezoelectric element. Its design has two independent chambers with impellers located. One impeller wheel draws air into the combustion chamber circuit from the channel between the pipes of the coaxial chimney. The second impeller creates flow through an internal duct that draws air to the outside. 2-4 seconds after the start of the turbine, gas is supplied to the burner and the flame is ignited.

During operation, combustion products are removed through an internal pipeline.At the same time, given that the temperature of the exhaust gases is high, the air supplied to the combustion chamber is heated, which has a positive effect on the operation of the boiler.

The design of the coaxial channel is as follows, outside the building, the pipe extends 30-50 cm, depending on the design of the chimney. The outer contour is located at a distance of 15-25 cm from the plane of the wall, and the pipe through which the gases are discharged is extended beyond the outer contour by 10-15 cm. So during operation, both flows do not mix.

Floor standing gas boilers with coaxial chimney: price and types

When heating large premises, fuel consumption and price are of particular importance. At the moment, one of the most economical options for generators are floor-standing gas boilers with a coaxial chimney. With their help, you can provide heating of premises of any type and area, heating water for household and other needs.

The principle of operation of a floor-standing gas boiler

Natural or liquefied methane or propane-butane most often acts as a fuel for such a generator. In the process of its combustion, a huge amount of energy is generated, which the generator redirects to the coolant. An element is provided in the combustion chamber that ensures the ignition of the fuel. All boilers of this type have a fuse that cuts off the gas supply when the ignition is turned off.

Gas boilers are divided into two types - floor-standing and wall-mounted. Wall-mounted generators are more compact, due to which its power is reduced. Such boilers are suitable for intermittent heating of small spaces such as greenhouses, small industrial buildings, living quarters.

Floor standing gas boilers are characterized by increased power and high efficiency. Such parameters are achieved primarily due to the larger combustion chamber and the housing as a whole.

Floor-standing heat generators are used for heating or providing buckwheat with water for industrial premises or residential buildings of a large area.

The principle of operation of a coaxial chimney

Any boilers operating by burning fuel, in the course of their work, produce a large number of harmful emissions into the atmosphere. The operation of such a boiler is impossible without arranging a chimney. At the moment, floor-standing gas boilers with a coaxial chimney are especially popular. A chimney of this type has a double-circuit design, i.e. consists of two pipes, the smaller of which is inside the larger one. It provides two functions at once. Smoke and other combustion products escape from the boiler through an inner pipe with a smaller diameter. The large chimney provides a constant flow of combustion air. Thanks to such a chimney, the efficiency of the generator increases by 10-12%, the supply of air to the boiler and the removal of combustion products are localized in one place.

Both of these advantages are possible due to the transfer of heat energy from the air flow from the boiler to the air flow from the street. Heated air from the street increases the combustion time of a unit of fuel, thereby reducing its consumption. Combustion products, passing the way from the generator to the street, lower their temperature by an average of 10 ° C. Thanks to this, the outer part of the chimney can be made to the side of the room.

Types of floor-standing gas boilers with a coaxial chimney

A gas floor boiler with a coaxial chimney can be convection and condensing. The principle of such a division is determined by the completeness of fuel use. Convection gas boilers are very common due to the fact that the average cost of such equipment is on average 20-30% cheaper than the second option. The boiler operates at the expense of the lower combustion heat. The term net calorific value refers to the amount of infrared energy that a unit of fuel emits without considering additional factors.The design of such a generator ensures that condensation is prevented from forming on the walls of all its parts. Condensing boilers, in addition to the energy of fuel combustion, use the heat that forms during the evaporation of condensate. The design provides for areas with a dew point - a temperature difference at which water in a gaseous state is converted into condensate. The body of such a boiler is much larger than that of a convection boiler, because in addition to the main parts, an economizer is provided in its design - a generator element made of straight or corrugated cast-iron pipes on the walls of which condensate accumulates. Fuel consumption when using this element is significantly reduced.

Price of a floor-standing gas boiler with a coaxial chimney As a rule, the chimney and the boiler are purchased separately. The average cost of a chimney, regardless of the configuration and the manufacturer's firm, varies within 4 thousand rubles. Quite often, large companies selling heating boilers arrange promotions, during which the chimney acts as a gift to the generator. The generator itself will cost about 20-30 thousand rubles, depending on the capacity.

What requirements should be considered for the installation of smokeless boilers

As with other gas equipment, flue-free boilers must comply with stringent government regulations regarding safe installation and operation. True, it is worth noting that the installation of such equipment is much safer than conventional chimney models with an open combustion chamber. Otherwise, the requirements for these devices are standard - they cannot be installed above the plates, the set distance must be maintained, the room must have a working alarm.

Devices are selected in terms of power, depending on the area of the heated room and the requirements for the volume and temperature of heated water. As for the coaxial chimney, it can be installed horizontally or vertically. When installed horizontally, it is done at a slope of 2-3 degrees towards the wall, so that the condensate formed between the circuits does not enter the combustion chamber.

A vertical chimney is installed when it is not possible to install a horizontal chimney, for example, when the distance between adjacent buildings is less than 1.5 meters or the chimney is located near a window. Under such circumstances, the horizontal gas discharge scheme is unsafe and the vertical chimney scheme is used.

The height of the vertical coaxial chimney must be such that the total length of the chimney does not exceed 5 meters. Another condition for installing a vertical chimney is that there should be no more than 2 bends in the structure.

Theoretically, a coaxial chimney can be made independently, there is nothing complicated about it. But on the other hand, professionals advise using branded components for the boiler and chimney. The fact is that manufacturers are developing universal chimney systems for different brands of boilers, but of their own production. At the same time, for other brands, these components may not be suitable both in size and in the method of fastening.

In branded accessories for the internal pipeline, stainless steel is used, and for the external one, either high-quality plastic or stainless steel.

Heat exchanger, power and combustion chamber

If you decide to buy a smokeless gas boiler, we recommend choosing the appropriate model, relying on such a parameter as the power, which should be suitable for a particular house or apartment, living area.

Determination of power is performed according to the following recommendations and instructions:

- If we talk about the standards and the general opinion of specialists, then about 1-1.5 kW of power is spent on heating 10 square meters of living space. In this case, the ceiling should be standard and have a height of no more than 3 meters;

- The resulting power indicator must be increased by an average of 15-25 percent, since during the heating process, heat can be lost if it is very cold in the house, there is a big minus outside, windows and entrance doors are periodically opened and drafts are observed;

- You can find out more about the maximum and minimum power your boiler has in the accompanying instructions and technical specifications for the device;

- An important role is played by such an indicator as the performance of the heating unit, it is also indicated in the standard documentation. Also, it is important to take into account how long and in what volumes you will be heated hot water, how many points of water intake you are going to connect and use.

A single-circuit smokeless boiler has one more significant difference from a double-circuit one. It can be equipped with a secondary or bithermal heat exchanger. The first is a curved pipe that has turns combined with ribbed plates. As a supplement to such a system, an outlet and an inlet branch pipe is used; in this case, the water is heated by means of a secondary heat exchange element, which is located in the lower part under the firebox.

The primary and secondary circuits also differ in their temperatures. In the primary, the water warms up by no more than 80-90 degrees Celsius, the secondary has an even lower temperature, not exceeding 60-65 degrees. Thus, you will not be able to burn yourself on such a pipe even if accidentally touched, and if necessary, the pipe belonging to the primary circuit can be thickened or additionally protected.

If, during long-term operation, you need to clean a certain section of the pipe, you can simply drive out the water. If the contamination is more complex, it is not necessary to disassemble and dismantle the entire structure, it is enough just to unscrew the necessary unit and, after cleaning, connect it to its original place.

Bitermal designs have a more budgetary cost, in contrast to the primary ones. Primary ones, in turn, can be supplemented with an electromechanical valve. The bithermal heat exchange medium has the following features:

- It is presented as one, combined by a heat exchanger unit;

- Consists of four branch pipes, two of which are hot water supply and the second two are connected to the heating circuit;

- The nozzles are characterized by a cellular structure, the circulation of water is carried out and controlled by a central channel;

- Small dimensions and similar weight, while the hearth is not equipped with a three-way valve and additional wiring;

- The price for the installation and the equipment itself with such a heat exchanger is lower than other models and variations;

- Water is able to heat up, but in one of the circuits it is in a stationary state, on the basis of which a layer of scale forms on the inner walls of the pipe. The channels are complemented by a small and narrow lumen.

Even if the circuit is closed, the water in it continues to regularly heat up to the highest possible temperatures. Therefore, in the event that you decide to open the tap, do not put your hands under the water right away, as boiling water may pour out of the tap.

The disadvantage of a double-circuit system, in comparison with single-circuit boilers, is the complexity of such units, they are supplemented by various pipes and wiring. As a result, there are often leaky areas that can cause water leaks.

The combustion chamber may differ in its type, variety. Based on this, they can be:

- Open type. Air enters the hearth directly from the room. All exhaust gases are introduced through the chimney.The advantages of the variety include efficiency, since the products are not supplemented with fans, due to this, the noise level is significantly reduced. In order to install such boiler equipment, it is necessary to use the services of a professional, since the draft in this case, as well as the ventilation, must be in good working order. Based on this, boilers with an open combustion chamber are more expensive;

- Closed type. Such variations are more effective, in this case the air is taken directly from the street, through the presence of forced ventilation. You can connect such a hearth to a coaxial chimney, due to which, installation can be done not only in the house, but also in the apartment. The disadvantages include the fact that in the cold season, the chimney can become icy, since a large amount of condensate forms inside it, which must be removed in a timely manner.

In this video clip, an overview of the Lemax Patriot gas parapet floor-standing chimney boiler is presented:

Turbocharged boilers, which do not require a stationary chimney, have a number of advantages:

- The device can be installed almost anywhere, not only where the chimney was laid in the structure of the room. The coaxial pipe, which provides air intake and removal of combustion products, has a compact size and can be installed with relatively little labor costs.

- Fuel combustion takes place in a sealed chamber that does not come into contact with the atmosphere of the room. Therefore, neither the "burning" of oxygen in the house, much less carbon monoxide poisoning, you are definitely not threatened!

- High energy efficiency. The presence of a turbine allows complete combustion of the fuel and activates heat exchange. The efficiency is also increased due to the use of modern boiler control systems, which automatically regulate the intensity of its operation depending on the preset settings.

If we talk about the disadvantages of devices, then first of all a higher price comes to mind (compared to standard boilers that require connection to a stationary chimney). But saving resources due to more efficient combustion of fuel, increased safety, as well as the ability to install almost anywhere, allows you to put up with this minus.

When choosing a turbocharged boiler for installation in a house or apartment, you should pay attention to the following factors:

- Device design. For a separate boiler room in a private house, floor-standing models are more suitable, for an apartment - more compact wall-mounted ones.

- Boiler functionality. If you need both heating and hot water supply, choose a two-circuit model. If you get hot water from other sources, then you should not overpay - it is better to purchase a more affordable single-circuit option.

- Heat exchanger material. The higher its thermal conductivity, the better. So the best choice is a model with copper heat exchangers, which ensure that heat loss is minimized.

- Automation system. Here you need to choose based on your wishes. For some, a model with the simplest adjustment and the minimum number of settings is suitable, and for others, a boiler with intelligent control and the ability to program the work.

- Power. Probably the most important parameter - how efficiently the boiler will heat the room depends on the correct selection of power. For typical houses and apartments with ceilings no higher than 3 m, it is advisable to choose heating devices at the rate of at least 1 - 1.2 kW per 10 m2 of area.

In addition, when installing a wall-mounted boiler, the coaxial chimney will take up more space, and its installation will take place with less labor costs.

Gas boilers? PULSATOR ?: a fundamental novelty on the market

These boilers? a vivid demonstration of a revolutionary breakthrough in a completely unexpected direction.

The new model series of floor-standing gas boilers? PULSA-TOIRE? (? PULSATOR?) Of the French company AUER Gianola can be called not only because this boiler is just beginning to find its application in Russia, but also because it implements a completely new operating principle. According to the developers of the boiler, they borrowed the idea from the well-known military development of the Wehrmacht? missile V-1.

The essence of its work is reflected already in the name "pulsator". As with the V-1, the gas / air mixture is fed into the combustion chamber, which has a movable diaphragm and a "spark plug". When the boiler just starts to work (? Warm up?), The mixture is ignited by a spark. After some time, does the mixture ignite from the hot surface of the combustion chamber? the candle does not work. Surely the mixture doesn't just burn? it explodes. During an explosion, the pressure in the chamber rises sharply, the movable diaphragm closes and hot gases (by analogy, like a jet in V-1) have only one outlet? go down through the spiral pipes, which are washed by a countercurrent coolant (water).

The gas-air mixture, before entering the combustion chamber, is prepared in a special mixing chamber. Indeed, for optimal combustion of fuel in general, and gas in particular, it is very important to maintain the required gas-air ratio. This is exactly what is done in the mixing chamber. Gas is supplied to it from the gas block through a nozzle, and air is mixed in by injection. Combustion air is taken either directly from the room or from outside through an air duct.

Since almost all the heat contained in the gases is transferred to water, their outlet temperature is only slightly higher than the temperature of the coolant at the boiler inlet (? Return?). Under certain conditions, condensate is released from the waste gases, i.e. the boiler is condensing.

One more remark regarding the principle of operation: since the heat transfer process is of an impulsive nature, the gases in the tubes also move turbulently. Does this mean that there is no boundary layer at the boundary with the pipe wall? heat transfer occurs without hindrance, which affects the efficiency, and therefore also the economy.

To reduce the noise level of the boiler operation (constant mini-explosions of the mixture occur in it, and not its combustion), as in cars, a silencer is used. In addition, the boiler thermal insulation also plays the role of sound insulation, and the most important structural elements do not have rigid contact with each other, but are absorbed. Thanks to this, the boiler can be installed in a residential area, it will not create noise discomfort: it works no louder than the refrigerator.

One of the most important advantages of this boiler? no need to arrange a regular chimney. Since the temperature of the exhaust gases is low, it can be made from PVC pipes, but due to their high pressure (recall, in the combustion chamber we have not constant combustion, but mini-explosions? Impulses)? any configuration. So, is it not worth making the chimney vertical with a minimum number of bends? you can safely adjust to existing conditions and external factors. In other words, the cost of installing a chimney is minimal.

Since the usual one is absent, there is no need to make any adjustments for gas, therefore the volume of service is minimized. Moreover, the boiler can operate both on natural and on liquefied gas. To switch from one type to another, you just need to change the nozzle.

Are there any restrictions on the boiler temperature schedule? it can be up to 25/20? C (if we only have underfloor heating, then it is not necessary to use mixing units).

The boiler has a built-in control device that can carry out weather-dependent control of 3 independent circuits (radiators, underfloor heating, hot water supply).

The model range of boilers of this series has 3 powers: 20, 32 and 40 kW. If more power is required, several boilers can be connected in parallel.

All the necessary levels of protection, of course, are there: in the event of an abnormal situation, the boiler will simply turn off.

So, with the help of these boilers, it becomes possible to reduce the costs of installing the chimney, while maintaining the appearance of the building as much as possible, to program the control of the entire heating and hot water supply system; for installers? have a small amount of spare parts, carry out minimal service and use these boilers where it would be problematic to use others.

Good luck with your construction! World heat company.

If it is impossible to install a classic vertical chimney for heating, smokeless gas boilers are used. For such heating equipment, a ventilated separate room for natural draft is not equipped.

Despite the name "chimneyless", such boilers have a chimney. Its role is played by a compact coaxial pipe, which provides traction and removal of smoke masses from the combustion chamber.

External outlet for coaxial flue gas vent

What features do you need to be prepared for when the boiler is operating

What you need to pay attention to

First of all, turbo boilers are dependent on electricity. In the event of a power outage, it automatically turns off. On the one hand, this is fraught with cooling of the premises and the lack of hot water supply. But on the other hand, this means that the gas valve shuts off the gas supply, and the blocking system does not allow the burner to ignite. So in places where the power supply is unstable and where there are frequent power outages, you will have to think about the issue of emergency power supply.

The second feature is the need for regular maintenance by service center specialists. This is especially true for regions where natural gas has a large amount of impurities. Cleaning in the device requires not only the burner with a combustion chamber, but also the turbine.

The third point is that quite often chimney-free gas boilers that are too short, or vice versa, long chimneys can be blown out by gusts of wind. In most cases, this problem is solved by installing a deflector instead of a decorative grill.

Malfunctions of a smokeless gas boiler

As for characteristic faults, gas boilers without a chimney have the same typical faults as conventional chimney ones:

- Control board malfunctions - most often the cause of the malfunction is a factory defect, voltage drops or water leakage from the heat exchanger (for many wall-mounted models, the control board is located in the lower part, under the main equipment);

- Electrical faults - sensors for temperature, pressure, water flow, centrifugal pump and turbine usually fail after a long period of operation;

- Heat exchanger leakage is especially common in double-circuit gas boilers without a chimney after 7-10 years of operation. In the places where copper plates or pipes are soldered, holes are usually formed through which water or coolant seeps;

- A coaxial chimney often simply needs to be cleaned of dust and carbon deposits. But if this is not done regularly, during the maintenance of the boiler, the likelihood of debris getting into the combustion chamber and clogging the burner nozzles increases significantly.

But, despite this, smokeless gas heating boilers are currently one of the most reliable and safe heating devices. In a closed combustion chamber, when the turbine is stopped during blowing by the wind, the gas supply is instantly cut off. The burner will reignite only when the automatics diagnose all equipment and allow gas to start again.

How to make a chimney for a smokeless boiler

Reviews of smokeless boilers, advantages and disadvantages

The advantages and disadvantages of chimney-type boilers have already been discussed more than once in all kinds of construction forums. In Europe, units have a well-deserved reputation for being economical and reliable with low installation requirements. Under domestic operating conditions, boilers have a slightly reduced efficiency and productivity.

Several aspects can be distinguished as advantages:

- There is no need to agree with the gas service when installing a turbo boiler, subject to the purchase of licensed and certified equipment.

- It is allowed to install the boiler in rooms with a limited area, in apartment buildings and private houses. There is no need for forced ventilation of the room.

- Productivity - chimneyless units use the temperature of the heated chimney gases to obtain additional heat energy, which increases the efficiency and efficiency of the devices.

What malfunctions do chimney boilers often have?

Most malfunctions occur due to improper operation or installation of equipment. The specialist will try to find out the reasons why the smokeless boiler goes out and will eliminate them. There are several factors leading to this:

- Poor traction - failure to comply with the requirements for the installation of the coaxial pipe: exceeding the permissible vertical and horizontal sections, leads to the shutdown of the equipment.

- Voltage failures - in most cases, sensitive automation is installed in chimney-free units. In case of voltage failures, the processor gives a shutdown signal.

- Violations in the operation of automation - the design provides for a large number of monitoring sensors: traction, heating of hot water and coolant, etc. Failure of any sensor leads to a halt in operation.

If you follow the rules for installing smokeless wall-mounted heating boilers and carry out regular maintenance, the devices work without complaints and difficulties throughout the entire period of operation.

How to deal with blowing out of a chimneyless turbo boiler?

One of the main problems faced by owners of chimneyless heating equipment is the shutdown of work due to poor draft or blowing out of the boiler. The danger of back draft of the chimney for a boiler with a closed combustion chamber lies in the likelihood of carbon dioxide entering the room, as well as the failure of individual components.

There are several ways to fix the problem:

- Improve the draft in the boiler by installing a deflector that increases the draft by approximately 1.5 times.

- Install a windscreen - a unit mounted on the pipe head reliably protects against wind ingress.

- If the situation is not corrected, the coaxial chimney is redesigned, taking into account the technical requirements for the location of the chimney, when installing a turbocharged boiler with a closed combustion chamber in a private house.

In Europe, it is mandatory to install a gas detector when operating any gas equipment. In our country, this is a desirable measure that has saved more than a dozen lives.

Which boiler is better - chimney or chimneyless, expert opinion

When answering this question, it should be borne in mind that condensing / chimney boilers were created for operating conditions in a low-temperature mode of heating the coolant. The manufacturer's declared efficiency of 95% is possible only if the return flow temperature is no more than 40 ° C. In the conditions of the harsh Russian winter, it is quite difficult to fulfill this condition.

Installing a boiler with a closed combustion chamber in a regular chimney, when replacing old equipment with new ones, is prohibited. We'll have to redo the smoke exhaust system, which is quite costly. Chimney-free units are ideal for well-insulated buildings located in temperate climates.

How to choose the right chimney boiler for your home

First of all, when choosing, it is necessary to determine the place of installation of a gas flueless boiler in the room itself. Among the models of many manufacturers, there are both parapet and wall models. To install the parapet model, it is necessary to take into account the location of the windows - the chimney should not be at the same level or below the level of the windows.

It is recommended to install a wall-mounted gas flue gas boiler on the outer wall of the room. As an exception, installation on internal walls is allowed, but the length of the coaxial chimney should not be more than 5 meters.

Boiler power is selected depending on the area of the heated room. As for a specific brand, here professionals advise you to pay attention to how much this brand is represented on the market, and whether this brand has a network of service centers. This is an important point, since the maintenance of this equipment requires not only trained specialists, but also the availability of branded spare parts. So, most domestic brands, like global brands of manufacturers of climatic equipment, advise to carry out diagnostics and maintenance of smokeless boilers at least once a year, before the start of the heating season.

A chimneyless gas boiler allows you to solve the problems of the device of individual heating in almost any houses and apartments, providing warmth and comfort in the most severe frosts.