For a new private house, for a cottage or a summer cottage, equipment of the "warm floor" heating system will become a successful and effective way of heating. The information available today suggests that, in terms of its efficiency, such a heating system for residential premises is quite effective. Water underfloor heating today is becoming more and more popular in private households, given the large selection of technical means, materials and devices necessary for the installation of such a system. The quality of heating in any case depends on the heat source. If there are no special questions with gas and electric boilers during the installation of a warm floor, then a bundle of a solid fuel boiler and underfloor heating will make you tinker.

The main reason lies in the absence of a clear and effective mechanism for adjusting the heating temperature of the coolant. The boiler water temperature, which diverges along the floor heating circuit, must not exceed the permissible parameters. The slightest malfunction of the heating device and on your floor, right in the room, you can cook food. Let's consider the problem from different angles.

Underfloor heating - its efficiency and compatibility with solid fuel boilers

The main advantage that a heated floor has in comparison with other heating methods is the uniform heating area of the internal space. In a room that is equipped with a warm floor, there are practically no warm or cold zones. Heated flooring radiates heat. Warm air currents rise evenly upward, displacing cooler air. Due to natural convection, regular air exchange occurs in the heated room.

Important! In terms of its efficiency, underfloor heating, powered by a solid fuel heater, is only slightly inferior to similar systems powered by gas boilers.

Due to the fact that the temperature of the coolant in the heating circuit for a water-heated floor is lower than with convection heating, a significant saving of the fuel resource is achieved. In the case of solid fuel boilers, this fact is important. The heated screed is a kind of heat accumulator, which is capable of releasing the accumulated thermal energy into the internal space for a long time. Even when the boiler is stopped, the underfloor heating remains warm for a rather long time.

The proposed video describes in detail and shows the main technical subtleties and nuances that arise during the installation of this heating scheme.

For those who choose a home heating system with a warm floor from a solid fuel boiler, you need to take into account a whole range of nuances and technical aspects. Competent selection of a heating device for the heating system, correct piping and connection, will allow you to get the most expected result from the operation of heating equipment. Solid fuel boilers, due to their high inertia, represent a warm floor for the heating system, a "double-edged sword". On the one hand, it is good when the boiler cools down for a long time and hot coolant continues to flow into the pipeline for some time. This will allow for a while to avoid a rapid drop in temperature inside living quarters.

On the other hand, it is not possible to quickly reduce the heating temperature during the operation of solid fuel boilers. The system is difficult to adjust.It is required to install additional protective devices to compensate for the lack of technological flexibility of heating equipment operating on wood or coal.

The list of disadvantages associated with boiler equipment that runs on wood or coal can be continued:

- the need for regular loading of the next batch of fuel (at least at least once a day);

- cleaning and cleaning of the boiler is carried out manually, which will also take a lot of time;

- the need to store a certain stock of coal or firewood in the immediate vicinity of the fuel unit;

- regular checking of the chimney's performance and the state of ventilation in the house;

- a sharp drop in the efficiency of the heating system due to a decrease in the boiler power.

On a note: The last point for underfloor heating is not so relevant, recalling the ability of a concrete screed to play the role of a heat accumulator.

Despite the obvious difficulties, the water floor in a country house, powered by a solid fuel unit, has its positive aspects. The first place here is - autonomy. For a country house, such a plus in the heating system is, if not the most important, then the key. The economy and efficiency of heating units operating on wood, woodworking waste, coal or fuel briquettes are also important aspects that should be paid attention to.

Features of the operation of underfloor heating without radiators

To begin with, practitioners do not recommend using underfloor heating without the support of a radiator system, and here's why:

- To provide the room with a sufficient amount of heat, it will be necessary to raise the temperature of the floor surface to 30 ° C and higher, which is already uncomfortable for those living in the house.

- Batteries equipped with thermostatic valves react faster to changes in room temperature than heated floors. The latter are more inert due to the massiveness and heat capacity of the screed.

- Any water boilers, except for electric ones, cannot work efficiently in the minimum combustion mode, when it is necessary to maintain a low temperature of the coolant. Imagine that the efficiency of gas and solid fuel units at the same time drops by 5-20%, and think how much fuel you will burn in vain.

If the gas heat generator is switched to normal operation, setting the water heating temperature to at least 60 ° C, then the burner will often ignite and turn off (the so-called clock will appear), since the underfloor heating system does not require a large amount of heat. This mode is unsuitable for the heater, it can quickly fail.

For normal joint operation of gas and other boilers with underfloor heating, but without radiators, there is an optimal way out - installing a buffer tank. Even a small tank will avoid the “cycle” of a natural gas fired unit.

We will consider an example of installing a buffer tank in conjunction with a solid fuel boiler, which cannot do without it when supplying heat to underfloor heating.

Methods for connecting a solid fuel boiler to a floor heating system

Solving the main problem

The main problem is that the majority of solid fuel heating devices used in private houses lack the automation that we are accustomed to when operating gas or electric units. In most models, the boiler is stopped in a semi-automatic mode, the blower is closed, the boiler is extinguished. Is this principle of operation of a heating boiler suitable for underfloor heating to work effectively in the house?

From a technological point of view, a warm floor is the equipment for which there is a fundamental limitation on the heating temperature. Overheating of the floor will lead to the fact that you will have to forget about the comfort in the house for a while.A working boiler produces an order of magnitude more heat energy than is necessary to supply the heating circuit. The problem can be partially solved by installing a mixing valve or an electric pump in the system, which will circulate the hot coolant through the pipes. However, in this case, the main advantage of solid-fuel devices, their autonomy, is lost.

For reference: the recommended temperature of the floor surface in residential premises should not exceed 29-30 0 C. The maximum threshold of 33 degrees is allowed in bathrooms, in toilets, where the flooring is usually made of tiled or ceramic tiles.

Situations in winter are not uncommon when, in case of bad weather, the power supply of residential buildings is disrupted. In such a situation, stopping the circulation pump threatens not only overheating of the heating device, but also the destruction of the main components and elements of the heating system. The restoration of the power supply will lead to the fact that the overheated coolant will again begin to flow into the heating circuit, which is not able to withstand such temperatures. As a result, a breakthrough and failure of the entire heating system. What this is fraught with, you can imagine!

In order to protect yourself from such troubles, it is better to equip an autonomous heating system with additional devices for removing excess heat energy. It will not be possible to extinguish the boiler immediately and it will not be possible to immediately reduce the heating temperature, especially at night. Additional devices can do this work for you.

Method one. Connecting heating radiators

Important! Without installing a three-way valve (usually 3-8 pieces according to the number of circuits), the operation of your heating system will constantly be at risk. The mixing unit, equipped with three-way valves, will be able to solve the problem of cooling the heated coolant at the right time.

Having at our disposal a wood-fired heating boiler for underfloor heating, it is enough to install additional heating radiators in the house. The main task that is assigned to them is to compensate for the excess heat coming from a working heating device. The hot coolant will circulate freely through the batteries, giving off excess heat energy. Usually, 1-2 radiators are installed for this purpose, in rooms that are periodically visited by the inhabitants of the house (corridor, basement room, dressing rooms).

Heat storage system

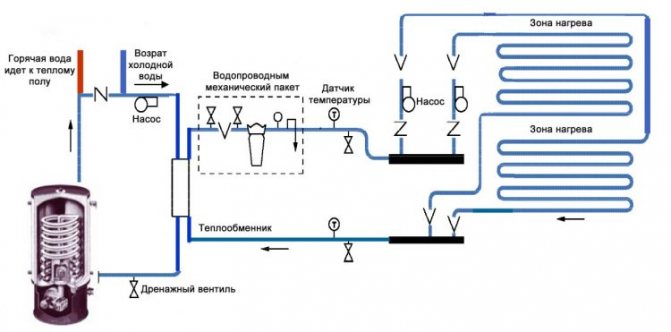

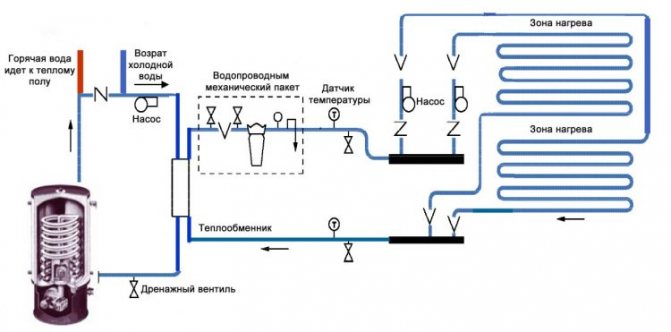

The piping of a solid fuel heating boiler, the circuit of which includes, differs in that it can have two circuits for the movement of the coolant:

- the first occurs between the boiler and the heat accumulator;

- the second is formed between the heat accumulator and radiators.

The scheme is as follows:

- Boiler.

- Security group.

- Heat accumulator.

- Heating devices.

- Main circulator pump. It is included in the pipe that extends from the heating radiators and goes to the heat accumulator.

- Diaphragm tank. Located after the heat accumulator.

- Additional circulating pump. It is located between the membrane tank and the return pipe of the heat exchanger.

The benefit of such a scheme is that it accumulates heat in itself, while simultaneously giving the required amount to radiators. It always delivers a normalized amount of heat, absorbing all its excess. As a result, the radiators do not overheat. In this mode, the coolant circulates throughout the system.

If it is necessary to stop the supply of heated water to the radiators for a while, it begins to circulate between the boiler and the heat accumulator. When the fuel in the boiler runs out and the fire goes out, the coolant circulates only between the heat accumulator and the heating radiators.

Choosing a solid fuel boiler for a warm floor

Having decided for yourself to create maximum comfort and coziness in the house with the help of a solid fuel boiler and a "warm floor" heating system, you should not build any special illusions. This circuit is so sensitive and gentle to work, so you need constant attention and control to the working equipment.

In order to at least somehow facilitate your task in the future, it is necessary to strictly treat the choice of a solid fuel unit.

It is possible to use a traditional wood-fired unit, only then you will have to spend more time on servicing it. The situation looks better with boiler equipment equipped with an automated fuel supply mechanism. Pellet solid fuel apparatuses are good in this regard. By installing a pellet hopper next to the heating unit, you can free up a lot of time for yourself.

For example: loading the bunker, on average 1-2 m3 with fuel in the form of pellets, will allow a 50 kW boiler to work without interruption for almost a week. The heating system is practically protected from defrosting during your long absence.

To balance the disadvantages characteristic of traditional solid fuel units, pyrolysis-type boilers will allow.

Even with manual loading, you only need to fully load the unit firebox 1-2 times. The duration of fuel burning in the furnace, the presence of a heat accumulator in the system, the physical properties of the concrete screed in the complex will provide the necessary and comfortable temperature inside the living quarters.

How to choose the power of a solid fuel boiler

A solid fuel boiler must be selected so that its rated heating power corresponds to the heat losses of the heated object.

Selecting a boiler with a too high rated power leads to the fact that the boiler operates in a mode of significant power limitation most of the time. And this, in turn, leads to a decrease in efficiency (increased fuel consumption), increased formation of deposits (soot, tar), accelerated corrosion of the boiler and chimney. The risk of overheating of the coolant in the boiler increases. The cost of boilers rises as the capacity increases.

therefore you should not buy a boiler with a significantly higher power

than the heat loss at home.

However, when choosing a boiler with a large power reserve, the burning time of one fuel tab increases - there is more firewood in the firebox. But, this advantage can be profitably realized only in a heating system with a heat accumulator.

Accurate calculation of the heat losses of the house and the power of the heating boiler is a rather difficult task, the solution of which is better to entrust to the design specialists. The managers of a company that sells boilers will most likely advise you to choose a boiler with excess capacity - it is profitable for them.

Roughly the power of the boiler for heating the house is chosen

, guided by the generally accepted values of the specific power per 10m 2 of the heated area by climatic zones:

- For the southern regions of Russia: 0.7 - 0.9 kW / 10m 2.

- For the middle strip - 1.2 - 1.5 kW / 10m 2.

- For the northern regions - 1.5 - 2 kW / 10m 2.

For example, for the Moscow region, a boiler with a capacity of 150m 2 x 1.2kW / 10m 2 = 18kW should be installed in a house with a heated area of 150 m2.

For a house built in compliance with modern energy saving requirements, the lower of the indicated values is used for the calculation.

It should also be borne in mind that the heat capacity of non-freezing liquids is 20% lower than that of water. When used as a heat carrier, the boiler power can drop by 10 - 15% of the nominal.

It is recommended to use a water heating system with natural circulation of the heat carrier in houses with a heated area of no more than 100 m2. In houses of a larger area or in heating systems with warm floors, forced circulation of the coolant is used with the installation of circulation pumps.

Design and principle of operation

The pellet boiler consists of a fuel hopper, automation and burner. Pellets are delivered through an external screw to the pre-furnace, and from it through an internal screw they are fed to the burner nozzle. After the granules hit the nozzle, there is automatic ignition and the supplied pellets are burned completely.

In terms of calorific value, combustion of 1 kg of pellets is comparable to half a liter of diesel fuel and amounts to 5 kW / h. When compared with firewood, due to the high density of the pellets, their combustion is much more efficient and productive, excluding the possibility of spontaneous combustion. In addition, ash cleaning can be done much less frequently, reducing this process to once a week. By using pellets as fuel, carbon dioxide emissions into the atmosphere are reduced, which leads to a decrease in the greenhouse effect.

Installation of a pellet boiler requires compliance some rules thanks to which it will be possible to avoid possible alterations during its operation:

- it is more expedient to install the boiler in a separate room, for example, a basement or an annex;

- the flooring in the boiler room must be made of ceramic tiles or concrete;

- there must be enough free space in the room that will be used as a boiler room to be able to repair and maintain the boiler;

- the room should be dry, well ventilated, with a constant temperature within +10 0 C.

An important indicator for any type of boiler equipment is its Efficiency... In order to more clearly understand the efficiency of a pellet boiler, let us compare it with other equipment used to heat a house. So the efficiency of wood is within 35%, natural gas - 87.1%, electric energy is 97%, and burned pellets in the range from 86% to 93%, depending on the model of the pellet boiler.

Electric boiler in the floor heating system and hot water supply

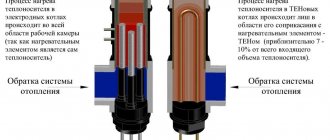

Only electric boilers with floor heating elements may be connected to heating water elements. They are equipped with two circular rings with an individual heating system.

Such a constructional device makes it possible to adjust the temperature of the water floor and water supply. Units with an electrode element are not connected to DHW. In the presence of such a boiler model, it is necessary to modify the heater.

To arrange such communications, you will need:

- Storage water heater. It provides heating of domestic water. To do this, the liquid must be heated to a temperature that is 15 degrees higher than for a heated floor. Heating systems with a gas unit function in a similar way.

- A comb equipped with a manifold. They do not directly connect the electric boiler to a warm floor, since there is a high probability of overheating. To prevent this, it is necessary to lower the heat due to the mixing unit, which is placed on the comb.

- Temperature sensors. Typically, temperature sensors that monitor the degree of heating of the liquid in the boiler are already installed in the system. But you will need another device that records the temperature in the room. This sensor is mounted at a distance of 20-25 centimeters from the floor.

- Filtration system for working medium and heating circuit make-up.

- Grounding for the electric boiler.

Units with tubular elements are connected to the power supply through an RCD, and boilers with electrodes are directly connected through automatic systems. How quickly the flooring can heat up, and hence the room, depends on the design features of the "warm floor". Electrode boiler systems do this in minutes. As for models with heating elements, they will need 5-15 minutes.

Automatic control mode

Pellet granules are stored in free-standing bunkerwhich is connected to the combustion chamber. Automation allows you to set a weekly program for feeding pellets into the boiler. In addition, according to the established program, the automation will turn on or off the burner, which saves fuel consumption and maintains the specified temperature regime depending on the time of day.Control can be done either with the remote control or using the buttons on the display.

The hopper with a volume of 200 to 300 liters provides continuous operation of the boiler for three days. For uninterrupted operation of the average boiler power in the range of 25 kW, the daily rate is 5 kg. It is possible to install an external hopper, which will significantly increase the volume of pellet loading, thereby increasing the operating time of the boiler without your intervention. Responsible for the operation of the burner control system, pellets are fed into the combustion chamber in small batches, which excludes the possibility of overheating. If you need to turn off the boiler, then after pressing the function button, its operation will automatically stop after 5-10 minutes, which is required for the complete combustion of the loaded batch of pellets.

Environmental Safety

Thanks to special design of pellet boilers, nothing threatens the ecology of your premises. In them, the circuit through which the air is supplied for complete combustion of the fuel is located separately from the circuit through which the room is heated. Due to this design, there is no "burnout»Oxygen and therefore you will always feel comfortable. Some users additionally take air from the boiler room, thereby dehumidifying and ventilating it. In addition, to advantages a pellet boiler includes the following factors:

- energy saving and low noise fan, is able to provide uniform efficient circulation of warm air;

- low power consumption, within 60 watts, for the operation of automation and fan;

- small volume of ash and soot, in comparison with solid fuel boilers;

- the boiler drum does not heat up, therefore, it is absolutely safe for animals and small children;

- implementation automatic fuel loading from the bunker;

- intelligent control system, timer and thermostat control and ensure continuous operation of the boiler, depending on the set program.

The principle of operation of warm water floors with an electric boiler

The main component in the boiler design is the tank, which is equipped with heating elements. A safety system in the form of pressure sensors and a safety valve is installed on the pipe leaving it. They will prevent the device from burning out if the circulation of the liquid stops.

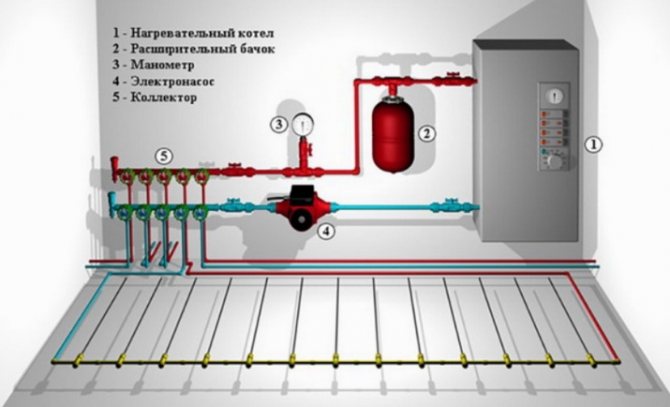

An electric boiler for a water-heated floor operates according to the following algorithm:

- The heat carrier fills the container with the heating elements.

- The heating process takes place to the set temperature. The heating method differs depending on the type of heating elements. In tubular electric heaters, the indirect heating method is used, and in electrode boilers, heating elements have been abandoned in favor of natural processes: the temperature of the liquid rises by the effect of an electric current on it.

- The heated water is sent to the distribution manifold. It evenly and without lowering the pressure level distributes the incoming fluid to all components of the structure. The collector is an indispensable part for the long-term and correct functioning of the boiler. And it doesn't matter for what purpose it is used: to heat the whole room or just the floor.

- When the temperature of the coolant drops, it returns to the reservoir.

Circulation pumps play a key role in the circulation of liquid. They are usually included in the delivery set, but you should additionally install them for each node separately.

It might be interesting

Thermal insulation

Distinctive features and variety of ceiling tiles ...

Thermal insulation

How to insulate the ceiling in a wooden house?

Thermal insulation

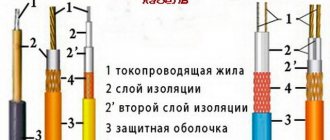

What is a heating cable?

Thermal insulation

Warm "pie" for a metal chimney

Disadvantages of pellet boilers

Speaking about the advantages of this type of solid fuel boilers, it is worth mentioning their disadvantages.

- despite the fact that pellets are made from wood waste, the unit of heat generated will cost more when compared with wood-fired boiler equipment;

- storage of pellets is required in a dry room, since under the influence of moisture they begin to swell and fall apart, which causes the augers to clog

- to work offline in remote suburban areas you will need to purchase a generator and additional equipment, what can make purchasing a pellet boiler an expensive pleasure;

- pellet consumption per month can be about 1 ton... Knowing the price of pellets in your region, it is not difficult to calculate how much it will cost you to heat a country house in winter. As practice shows, your costs will be comparable to the use of electric boilers and exceed the costs if you use natural gas as fuel.

The perfect solution

The most convenient electric boiler for underfloor heating is single-circuit. Here, the scheme of work is clear and transparent: the device heats the water by means of heating elements, the circulation pump creates pressure on the hydraulic distribution grid of the heating network, the temperature of the liquid in the structure can be adjusted.

For rational-minded owners, it is recommended to create separate water treatment and heating systems in the house, for the latter, the use of its own single-circuit boiler looks optimal.

The use of indirect heating boilers is a convenient solution for those who want to get a controlled efficient heating system and hot water without complicating the electrical network of a house or apartment. A single-circuit electric boiler is capable of supplying water not directly to the warm floor, but through the heat exchanger of the water heater.

The operation of the indirect heating boiler is stable, therefore, in a system that has entered a stable mode, it is impossible for a situation to arise when the consumption of hot water will sharply reduce the heating performance of the rooms.

Electric boiler from the boiler

Pellet boiler reviews

A year ago, I installed a KST-25 boiler with a 14/40 kW burner installed. The decision to switch to a pellet boiler came after we received bills for electricity for October in the amount of 15,000 rubles. Since we have problems with the purchase of pellets from shavings or wood chips in our region, and wholesale delivery is carried out only with an order of 20 tons, I began to look for alternative options.

I found an alternative option in the form of sunflower husk, which cost me 1,500 rubles per ton. Over the winter, I spent 14 thousand rubles to maintain the optimal temperature in my beauty salon, which I was very pleased with.

Having calculated the economic benefit, I decided to install a pellet boiler at home, but with an increased ash pan volume in order to reduce the time for its maintenance. Now there is a gas boiler at home and its use cost 29 thousand rubles with the same square as in a beauty salon. If I install a pellet boiler, I will reduce my expenses by 15-16 thousand rubles over the winter.

I have been using the Faci pellet boiler for almost a year now. Pleases economical fuel consumption, environmental safety use, quiet operation, excellent design. The purchase has justified itself economically, so now I recommend to my friends to install a pellet boiler of this brand. I clean it twice a week and it does not take much time, the rest is done by automatic equipment.

The only advantages of the Biomaster pellet boiler can be called its environmental friendliness and low cost.It has been operating for more than two years, but during this time it had to be repaired several times. The breakdowns are insignificant, but their elimination also requires spending free time and incurring additional costs. I am not going to completely abandon the use of a pellet boiler, since it is economically profitable, I may just look for a more reliable and improved model that will not break down so often.

Separately about the technical design of heating systems

Underfloor heating is a well-known and effective heating structure. It is widely used. Therefore, it is not surprising that manufacturers of heating equipment offer boilers to which the connection of underfloor heating is provided for by the design.

If the use of underfloor heating is provided by the manufacturer of the electric boiler, the power supplied to the coolant is separately indicated in the documentation for the device. You need to choose a specific model for this parameter in accordance with the figure obtained in the calculations. Other types of boilers are selected according to power consumption.