Why automatically control the heating temperature

In Russia, owners often begin to realize the need for automatic temperature control after the house is built, the heating system is already installed and working, and gas bills begin to come.

It turns out that outside the house, the air temperature, direction and strength of the wind are constantly changing. Day or night - the temperature of the outside air, even during the day, often changes by a dozen degrees. A changeable wind blows through the house, then no, The changeable sun, then heats up the house, then no. Heat loss at home is constantly changing by different amounts.

In addition, heat is supplied to the house not only from the heating system. Each person in the house serves as a kind of heating radiator with a rather large surface with a temperature of 36 ° C. Moreover, the number of such additional radiators in each room of the house is constantly changing.

All the energy consumed in the home by electrical appliances and other devices is ultimately converted to heat. Turning on and off each electrical device changes the flow of heat into the room.

The sun through the window, the work of a gas stove or oven - all this creates a constantly changing flow of additional heat into the premises of the house.

Rapid changes in energy flows outside and inside the house lead to constant fluctuations in air temperature in each room. They require the heating system to react equally quickly to these fluctuations.

In order not to bother with all this mess, the owner of the house manually sets the heating water temperature on the boiler, so that the temperature in the house is warmer, with a margin. And at the end of the month he looks with surprise at the numbers on the gas bill and scratches his “turnips”. Read the comments to the article - there are many such "owners" there.

The owner learns that it is beneficial to keep a lower temperature in rarely visited areas of the house. Building rules recommend that the air temperature during the heating season in different rooms of the house be maintained in the range from +12 to +26 ° C. (See the table from GOST with the temperature parameters in the premises of the house at the end of the article). In the rich countries of the European Union, the room temperature set at night usually does not exceed 16-17 degrees. This is evidenced by the 2014 report presented by the German thermostat manufacturer Tado.

That a change in the room temperature by only 1 ° C leads to an increase or savings in the amount of gas for heating by about 4-5%.

what it is impossible to maintain manually, without automation, a different temperature in each room, but with such high accuracy.

The owner learns that in order to equip the house with automatic temperature control, something needs to be thrown away, replaced and redone in the heating system, and additional equipment must be installed. And for this you will have to buy, drill, chisel, lay, trim, and, most importantly, pay for everything again. That all this automation would be much cheaper if installed immediately, when building a house.

And having connected a room thermostat to the boiler, the owner is surprised to see that the temperature in the house remains constant, while the boiler does not turn on for half a day and does not consume gas... The owner of such savings is in a slight panic and asks a question in the comments - why is this?

Watch this video:

Room thermostat saves gas

For automatic control of the temperature in the house, boiler manufacturers recommend using room or weather-compensated controller with continuous temperature control principle boiler flow.

Also, you can use two-point principle room thermostat (ON / OFF), but with less efficiency.

Luxury boilers, as a rule, are immediately equipped with a remote control unit. Mounted on the wall of a room, such a unit allows remote control and monitoring of the boiler, and also serves as a room thermostat.

The room regulator allows you to maintain a constant temperature in the heated room with high accuracy. With manual control, the range of temperature fluctuations is larger and deviations are more often in the direction of a higher temperature. Every extra degree in the room leads to an increase in gas consumption for heating. In addition, with the help of the thermostat, you can program an automatic decrease in the temperature in the house in certain periods (at night ...). Refusal of manual control of heating temperature and installation of an automatic regulator to maintain the required temperature in the room, significantly reduce gas consumption for heating.

In addition, the owner does not need to run to the boiler room to change the boiler settings. Custom boiler settings can be changed right in the house, on the thermostat.

A room thermostat or room thermostat temperature sensor is always installed in the largest room in a house or apartment.

Room thermostat saves energy

When the boiler is operating without a room thermostat, the circulation pump runs constantly, consuming electricity. The room thermostat controls not only the gas burner, but also the circulation pump. The circulation pump, controlled by a room thermostat, operates intermittently, which saves energy and pump life.

Options for calculating the power of solid fuel units

The accuracy of your calculations depends on taking into account all the factors and indicators that we paid attention to above. For clarity, you can follow a series of steps that will give you an idea of how this is done.

The specific power of the heating device is designated by the letter W. For regions of our country with a harsh climate, this parameter is 1.2-2 kW. In the southern regions, the specific size of the heater varies within 0.7-0.9 kW. The average value in this case is 1.2-1.5 kW.

To begin with, we determine the area of the premises to be heated. Further, we divide the obtained area data by the specific value of the power of the boiler installed in the house on a certain territory. Divide the result by 10, based on the theoretical ratio of the consumed power of the heating equipment for heating 10 sq. meters.

For example: Calculate the load limit of a coal-fired heating boiler for an average residential building of 150 m2.

- The living area is 150 sq. meters.

- The specific power of the heater for heating 10 m2 is 1.5 kW.

We use the following formula for work: W = (150 x 1.5) / 10. As a result, we get 22.5 kW. The resulting value is the starting point for choosing an autonomous solid fuel boiler, taking into account the technological capabilities of the heating system and your own household needs.

On a note: having found a similar model of heating equipment, throw 20-30% of the power to increase the technological capabilities of all heating equipment. The load on the DHW system, the comfortable temperature in the house, provided that the boiler is operating at optimal modes, depends on the number of residents in the house.

According to a similar scenario, you can calculate the required resource of the heating apparatus for a house of any size.Always take into account climatic conditions and your own needs for boiler equipment.

Weather regulation of temperature reduces gas consumption

All building structures of the house have the property of thermal inertia. For example, when the outside air temperature changes, the outer walls slowly heat up and do not cool down immediately. That is, a change in the outside temperature leads to a change in the indoor temperature with some delay.

When regulating with a room thermostat, the temperature of the heating medium in the system will not change until it starts, for example, to rise in the room due to warming outside. Only after this, the temperature of the coolant will begin to decrease, but due to the thermal inertia of walls, radiators and other structures, the heat release will continue for some time, and the temperature in the room will be higher than the set one all this time.

For this reason, the accuracy of maintaining the room temperature with a room thermostat will not be very high. The range of temperature fluctuations in the house will be greater than the value that is set by the thermostat hysteresis setting.

If the temperature of the heating medium is changed simultaneously with fluctuations in the outside temperature, then the accuracy of regulation of the air temperature in the room can be increased, which will increase comfort and reduce the gas consumption for heating.

Weather control of the room temperature can be done in one of three ways:

- By connecting only the outdoor temperature sensor to the boiler, without connecting a room thermostat.

- Connecting a temperature sensor and a two-position thermostat to the boiler.

- By connecting a temperature sensor to a room thermostat, if its design provides for such a possibility.

The best temperature stability, which means comfort and energy savings, can be achieved by using the third method of weather regulation.

The first option, with only an outside temperature sensor connected to the boiler, provides a minimum cost - no need to purchase a thermostat.

Connecting an outside temperature sensor and a two-position room thermostat to the boiler is the best option for weather regulation.

A boiler with an outside temperature sensor will react to changes in weather conditions, and the room thermostat will adjust the temperature of the heating medium, depending on the air temperature in the room. The fact is that the temperature in the room depends not only on the heat that comes from the heating system. The temperature in the house changes if, for example, a window is open or the sun is shining through the window, electrical appliances are working, or there are many people in the room. The room thermostat will react to all this, adjusting the temperature in the heating system.

Outside air temperature sensor for gas boiler Protherm

For Protherm boilers, the plant produces an NTC type outdoor temperature sensor with code S010075. The sensor is placed outside, on the facade of the house protected from the sun. The sensor is mounted on a bracket, at some distance from the wall so that the wall temperature does not affect the sensor. The sensor is connected to the boiler with a two-core copper wire with a cross section of at least 0.75 mm2.

Dependence of resistance on temperature for a thermistor of an outdoor temperature sensor of a gas boiler Proterm. Order number: 0020040797.

There is experience of using as an outside temperature sensor, NTC thermistor B57164-K 222-J, 2.2 kOhm, 5%, from Epcos. You can buy it in the online store. In parallel with the thermistor, you must connect a conventional resistor with a resistance of 2.2 kOhm. This is necessary so that the dependence of the resistance of the outdoor sensor on temperature approximately corresponds to the data indicated in the table.

For weather protection, the thermistor is placed in a suitable box.The cost of such a self-made sensor with a thermistor is much lower than that of a factory sensor.

Thermostatic valve on the radiator reduces gas consumption

Thermostatic valve - a thermostat for a radiator reduces gas consumption for heating. Installing a thermostat on a radiator is a mandatory requirement of building codes.

Weather regulation changes the temperature of the heating water in the heating system depending on the outside temperature.

The room thermostat regulates, adjusts the temperature of the heating water depending on the temperature in one room, where it is installed.

A room thermostat is always installed in the largest room of a house or apartment. The temperature in other rooms will differ from that which is required in one direction or another. For example, in order to save gas, it is beneficial to keep the temperature in rarely visited rooms lower.

The temperature in other rooms can be regulated using thermostats installed at the heating water inlet to the radiator. A thermostatic valve or an electronic radiator thermostat is used as radiator thermostats.

Thermostatic valve regulates the flow of heating water through the radiator so that the room temperature remains constant, set on the scale of the thermostatic head. The control head of the thermostatic valve contains a bellows filled with liquid or gas. When the temperature in the room changes, the temperature of the liquid (gas) changes. As a result of thermal expansion of the liquid (gas), the bellows changes its position and acts on the valve stem of the valve on the radiator pipe.

On sale you can find thermostatic valves with remote temperature sensor... Such devices provide a more stable temperature in the room, since the influence of a nearby radiator and window is excluded.

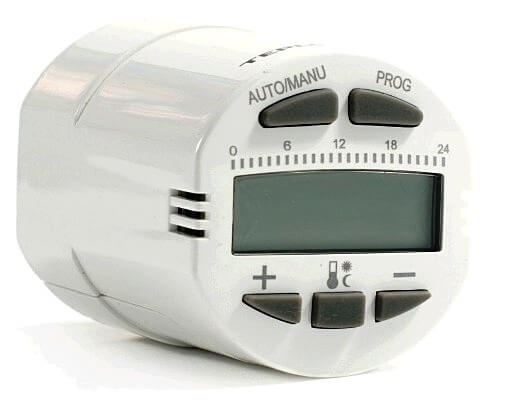

Electronic radiator thermostat

Electronic programmable thermostat for heating radiator. Powered by AA batteries, 2 pcs. Adjustment temperature from 5 ° C to 35 ° C. Hysteresis ± 0.5 ° C. LCD display.

The electronic radiator thermostat, like the head of the thermostatic valve, is mounted on a control valve on the pipe to the radiator. Compared to a thermostatic valve, it has many more control functions.

The radiator thermostat consists of a built-in or remote temperature sensor and a servo-drive that opens and closes the valve on the radiator.

In the programmable radiator thermostat, you can select the temperature mode for daytime and nighttime, for different days of the week. This allows for greater comfort and gas saving... For owners of a country house, a programmable thermostat will maintain an economical heat mode on weekdays, and will switch to warming up mode before arrival.

An electronic programmable radiator thermostat can provide:

- Indoor temperature indication.

- Battery discharge indication.

- System malfunction indication.

- Operating mode indication.

- Installation of an economical and comfortable temperature regime.

- Setting a schedule for alternating between comfort and economy mode for each day of the week.

- Childproof lock function.

- Room ventilation function.

- Function of protecting the valve from acidification.

- System frost protection function.

Automatic temperature control in a house with underfloor heating

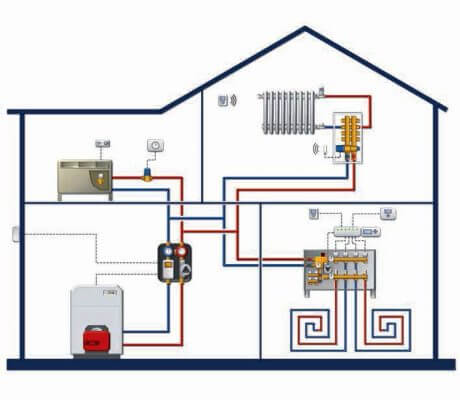

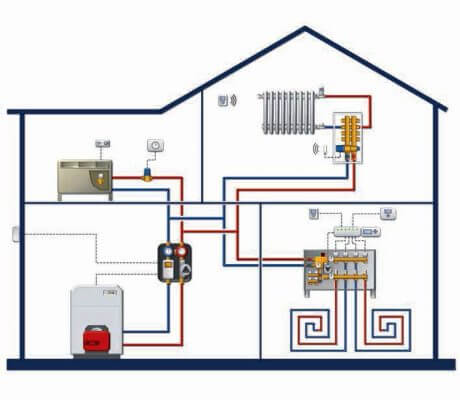

In a house with underfloor heating it is necessary to have three automatic control systems temperature: 1 - underfloor heating according to the room temperature, but with the floor temperature limitation; 2 - radiators according to the air temperature in the room; 3 - boiler weather control according to the outside air temperature.

As known, underfloor heating can be either "comfortable" or "heating".

"Comfortable" warm floor

slightly warms up the surface and provides a pleasant sensation when a person is on the floor. The main supply of heat to the room is provided by radiators. For a comfortable warm floor, it is necessary to maintain a constant temperature of the coolant.

"Heating" warm floor,

in addition to comfort, it provides complete heating of the room.

In the conditions of the Russian climate, the relatively low heat output of the warm floor makes it suitable most often only for comfortable heating.

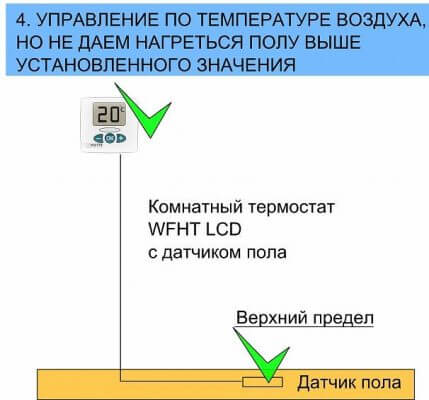

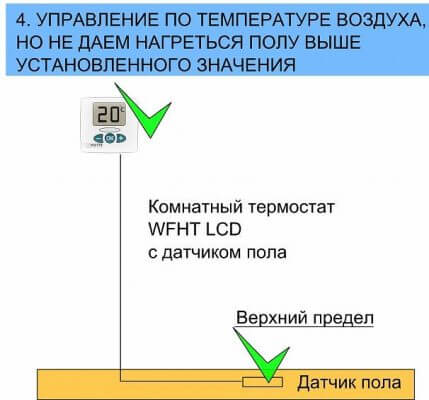

An air temperature sensor in the thermostat housing and a sensor in the floor provide room temperature control and protect the floor from overheating

In a home with a comfortable underfloor heating for temperature control it is necessary to have three automatic control systems.

One system that regulates the work of the warm floor, should be controlled by the room temperature until the floor surface temperature reaches a comfortable level. That is, in the off-season, the house will be heated with warm floor heating.

If the floor temperature has reached the upper limit, and the air temperature in the rooms decreases, then the automatic radiator control system... Radiators will warm up the air in the room, add their own heat to the heat that will constantly come from the warm floor.

The mode of heating the coolant by the boiler must be regulated by one more automatic weather control system that reacts to the outside temperature.

Considering that the underfloor heating system has a high inertia (heats up slowly and cools slowly), it is recommended to use weather automation to control its operation. Then the temperature of the heating medium supplied to the system will be adapted to the outside temperature. Due to this, together with a change in the outside temperature, the temperature of the heating medium circulating in the floor changes.

Mixing unit with a circulation pump - on the left. On the right, a collector of underfloor heating pipes is connected to the mixing unit. The manifold is equipped with servo-driven control valves. The valve is controlled by a thermostat through a servo-actuator, which regulates the supply of heat carrier to the underfloor heating circuit, depending on the temperature of the floor surface and the temperature of the air in the room.

Each room with a "warm floor" is at least one circuit (one pipe loop). All these circuits must somehow be combined into one and connected to a boiler or other heat source. Both ends of the pipe of each underfloor heating circuit are connected to a manifold.

To control the temperature of the underfloor heating, it is necessary to select and install a manifold equipped with servo drives on the control valves.

A servo drive is a device that, when an electric current is supplied to it from a thermostat, acts on a valve, opens or closes it. The servo works like a switch, opening or closing the valve completely. The temperature of the underfloor heating surface will be maintained with an accuracy of +/- 0.5 - 1 ° C.

Underfloor heating thermostats

A thermostat is a device that measures the temperature of something, compares this temperature with a predetermined temperature and, depending on the result of the comparison, commands the servo to turn on or off the control valve. Thus, by turning on or off the heat supply, the thermostat maintains the temperature of something with minimal deviations from the set value, usually with an accuracy of + \ - 0.5 ° C.

To measure temperature, the thermostat can have a temperature sensor built into the body of the device. The temperature sensor can also be remote. The remote sensor is connected to the thermostat with wires.

The thermostat always has buttons or wheels, with the help of which the temperature is set, the stability of which it must ensure.All thermostats have an indication of the current state - "heating on" or "heating off".

The thermostat, depending on the method of connection with the executive servo drive, can be wired or wireless.

The smallest budget option is a wired thermostat. The device itself is installed in a room where it must maintain the temperature. The collector for underfloor heating with servo drives can be installed in another place, for example, in a boiler room. These devices are connected to each other by thin wires.

The wireless thermostat transmits the control command to the collector servo drive via radio. For this, there is a radio transmitter in the thermostat housing, and a radio receiving unit is installed near the collector. Installing a wireless thermostat can be beneficial when automation work is carried out in an already built house - there is no need to lay wires and disturb the decoration of the premises.

Thermostat with the function of regulating the room temperature and the temperature of the warm floor. It works with two temperature sensors, one in the device case, the other remote, in a warm floor.

To regulate the air temperature and the temperature of the warm floor in accordance with the algorithm - we adjust the air temperature in the room, but do not let the floor heat up above the set temperature, a thermostat with the appropriate functions is needed.

Floor heating thermostat:

- Must work with two temperature sensors: a built-in air temperature sensor and a remote floor temperature sensor.

- The thermostat must be able to set separately the air temperature and the temperature of the warm floor.

- An algorithm for regulating the air temperature with the limitation of the temperature of the underfloor heating surface must be laid down.

Switching module for connecting several underfloor heating circuits to one thermostat

One thermostat can control several servo actuators installed on one manifold. The thermostat with servo drives is connected through a special block - switching module.

Heat carrier temperature

Gas saving is also associated with the correct regulation of the heat carrier. The standard equipment of a gas boiler does not include an outside temperature sensor, therefore, it is necessary to independently regulate the temperature regime depending on the weather. For example, add or subtract. This method is not suitable for everyone, since it is necessary to constantly monitor the temperature regime. Gas boilers Baxi have the ability to connect additional functions. Therefore, you can purchase a separate outdoor temperature sensor and connect it. Thus, the temperature will be automatically adjusted in accordance with changes in the weather. In addition, you can use weather-dependent automation. In the equipment settings, you must select the climatic curve. In accordance with the parameters, the gas boiler will consume less gas.

Selecting a room thermostat - thermostat

Let us consider the choice of automation devices for controlling the heating system in a private house using the example of an equipment manufacturer of the Protherm trademark.

A room thermostat installed in the room measures the current air temperature and, if the temperature deviates from the value set in the settings, sends a control signal to the boiler.

The room thermostat, which controls the operation of the boiler, isinstalled in the largest room of the house... Radiators in the room in which the thermostat is installed should not have valves that regulate the flow rate of the coolant. In other rooms, a thermostatic valve must be installed on each radiator, which regulates the flow of the coolant through the radiator, depending on the temperature in this room.

In heating systems with underfloor heating and radiators, the automatic air temperature control system is more complex.

Read: "Automatic control of air temperature in a house with underfloor heating and radiators".

The signal from the thermostat to the boiler can go through wires, or maybe wirelessly. In the latter version, a unit for receiving a radio signal from a wireless thermostat is installed on the boiler.

It is recommended to use thermostats of the same brand to control Protherm boilers. The manufacturer of boilers under the Protherm trademark produces several modifications of room thermostats for their gas boilers.

How to turn a conventional solid fuel boiler into a long burning solid fuel boiler

Ecology of consumption. Science and technology: The traditional heating system based on a solid fuel boiler has a number of disadvantages. The solution to the problems is the use of a solid fuel boiler in conjunction with a heat accumulator and effective control of operating modes.

The traditional heating system based on a solid fuel boiler has several disadvantages.

In this article, we will tell you how to solve the problems when using a boiler that runs on wood or pellets, to make the heating system with a solid fuel boiler as automated as possible and turn an ordinary solid fuel boiler into the long-burning solid fuel boiler so desired by everyone.

More about problems

photo: bbm.com.ua

Frequent downloads... One of the main problems when using solid fuel boilers in a traditional once-through system is that fuel (firewood, coal) has to be loaded quite often. Intervals between downloads are usually measured in several hours. Naturally, this is very inconvenient and takes a lot of effort.

Not optimal boiler operation - its quick failure. A significant part of the time, a solid fuel boiler operates at reduced power, which leads to a decrease in efficiency, low-temperature corrosion and an increase in the formation of soot and tar.

Overheating of the boiler when the power supply is cut off... In the case of natural circulation, there will be no problems. Consider a situation where a solid fuel boiler operates in a forced circulation system (using a pump). In the event of a power outage, the circulation pump stops, the movement of the coolant stops, but a solid fuel boiler cannot quickly stop generating heat, like gas, electric or liquid fuel. Excess heat in the combustion chamber of the boiler leads to the boiling of the coolant and the failure of the boiler.

How to solve problems?

One of the main ways to solve problems is to use a solid fuel boiler in conjunction with a heat accumulator: the boiler operates at full capacity, regardless of weather conditions, and excess heat accumulates in the tank, from which it is gradually spent on heating the room, including when the boiler is off.

In this case, of course, it is important to choose a high-quality heat accumulator and create the correct control system that will effectively control the operation of the boiler together with the heat accumulator.

The regulation of such a system is carried out by creating two circuits, one of which, the boiler, will be used to return part of the heated water to the boiler, and the second, heating, to distribute heat to consumers (radiators, water heaters, floor heating, etc.). Heat is distributed between the circuits by a special regulator, and the actuator is a three- or four-way mixing valve with a servomotor, to which a signal from the regulator is supplied.

This is how solid fuel heating systems were designed until recently. But engineering science does not stand still, and recently a wonderful device Laddomat (Laddomat) appeared on the market (including the Russian one), which successfully replaces the classic connections of individual elements and allows you to optimize the operation of the boiler together with the heat accumulator. The device is produced by the Swedish company Termoventiler AB.The use of Laddomat with a heat accumulator solves all the problems described above.

How does the Laddomat system differ from the traditional system?

In order to answer this question, let's first look into the storage tank. The work of the tank is based on a physical principle: hot water is lighter than cold water. Hot water from the boiler goes to the top of the tank, while cold water goes to the bottom. For this process to function properly, there must be a sharp boundary between the layers of hot and cold water. Then hot water is in the upper part of the tank and in the heating system even when the water in the lower part of the tank has already cooled down.

If hot and cold water is mixed, the efficiency of the process decreases, and in the worst case, there is not enough warm water even to take a shower.

That is, the main secret of the successful operation of a system with an accumulation tank is in a sharp temperature drop between a layer of hot and a layer of cold water. Therefore, the main task of the regulating device is reduced to controlling the rate of water circulation so that it does not violate the boundaries of the temperature layers. With effective temperature stratification (separation into layers), the thermal storage tank generates 50% more heat between boiler firing up. Thus, a 1000 liter tank in the presence of temperature stratification of water layers generates the same amount of heat as a normal 1500 liter tank.

It is for this purpose (creation of optimal temperature stratification of layers when filling the tank with water) that the Laddomat device was designed.

How does Laddomat solve the problem of solid fuel systems?

Frequent downloads... Laddomat quickly brings the boiler to operating mode, since at the beginning of the cycle, water circulates along the small (boiler) circuit. After the boiler reaches operating mode, heated water begins to be supplied to the tank and the heating system. When the tank is filled with hot water, the boiler will start to cool down gradually, but the system will continue to be heated with heat from the storage tank.

In systems without a storage tank, the boiler must be fired several times a day in order to keep it warm. Heat loss occurs every time the system is started. Obviously, the tank system is more efficient: fewer starts - less losses.

Optimum boiler operation. As already mentioned, the accumulation of excess heat in the tank allows the boiler to work constantly at full capacity, even during relatively warm weather, which is the optimal operating mode for the boiler. This also protects the boiler from corrosion that occurs when operating at low temperatures.

Overheating of the boiler when the power supply is cut off... When the power supply is cut off, Laddomat will switch the heating medium circulation mode from forced (through the pump) to gravitational (natural). The heat from the boiler will go to the tank. The pressure in the natural circulation system will fill the boiler with cold water. The flame will be maintained for some time with low output until electricity reappears or the boiler has completely cooled down. published

P.S. And remember, just by changing your consumption - together we are changing the world! © econet

And you can also make your home more energy efficient and optimize the cost of gas heating by installing a gas boiler in the house or apartment, where there is free access to gas communications.

Two-position thermostats - thermostats for gas boiler

Electromechanical two-position room thermostat Protherm Exabasic for a gas boiler is simple, cheap, but temperature fluctuations in the heated room will be significant - about 2-3 ° C.

Electronic two-position room thermostat Protherm Exacontrol provides higher accuracy and stability of maintaining the temperature in the room, has a function of protecting the heating system from freezing. The display shows the current room temperature.

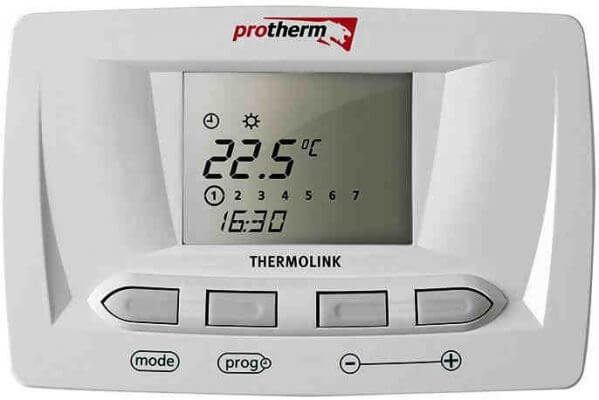

Electronic two-position programmable room thermostat - thermostat Protherm Thermolink S

Thermolink S is an electronic two-position programmable regulator, which differs from previous models in that it allows you to set the temperature according to one weekly program with the possibility of combinations of three different time intervals (morning, afternoon, evening).

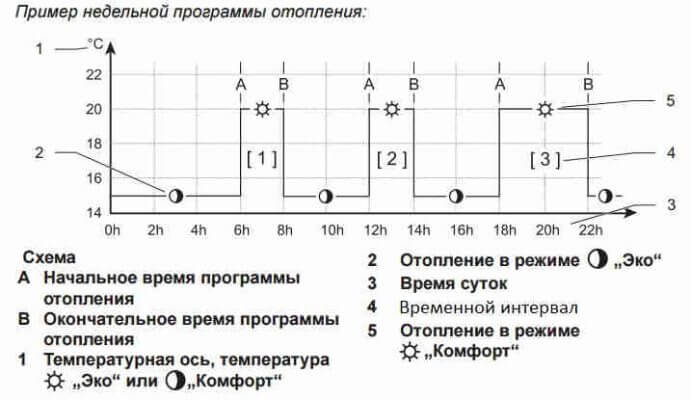

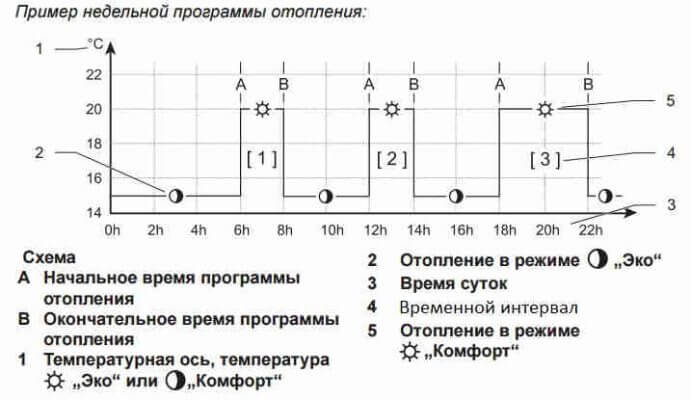

Weekly program for regulating the heating temperature in a house, apartment with a room thermostat Protherm Thermolink S

In addition, it is possible to set one of three temperature modes: "Comfort", "Eco" (economy) or "Vacation" mode.

Thermolink S regulator supports the function of frost protection of the heating system when the room temperature drops to 3 ° C.

The display shows the current room temperature, as well as the time and day of the week.

Features of the boiler with a two-position thermostat

Two-position thermostats have a relay with contacts at the output. Contacts can be in one of two positions: closed or open. Closed thermostat contacts connected to the boiler switch on the boiler heating mode. When the contacts are opened, the heating mode is switched off. The boiler works in cycles - on / off. There are no changes in the heating mode settings on the boiler itself.

The cyclic operation of the boiler under the control of a two-position room thermostat can hide the boiler timing, which occurs due to a significant discrepancy between the capacities of the boiler and heating devices (for timing, read the beginning of the article).

Many even argue that the boiler clock can be eliminated not by adjusting the gas valve, but by installing a room thermostat.

However, if the power of the boiler significantly exceeds the power of the heating devices, then the frequency of the boiler operation cycles with a two-position thermostat increases. The boiler switches on and off more often. In addition, the range of temperature fluctuations in the room expands.

Correct setting of the power of the gas boiler is necessary and when the boiler is operating under the control of a room thermostat.

The sensitivity of the electronic two-position room thermostat is 0.5 ° C. The thermostat switches contacts when the room temperature changes by half a degree.

The two-position room thermostat uses self-learning algorithm TPI - regulation... Fuzzy logic pulse width control. adapts to ambient conditions and ensures precise temperature control and minimum gas consumption. More details. ... ...

Methods for increasing the power of the boiler room

It often happens that over time the number of heat consumers increases and, accordingly, the capacity of the boiler room is no longer enough. What to do if there is not enough capacity in the existing boiler house?

There are several common solutions to this problem:

- Installing a new, more powerful boiler room is the most expensive method of solving the problem, as it entails a large amount of costs. The boiler house itself has a high cost, plus it is necessary to develop design documentation for the boiler house, as well as design documentation for its binding on the ground. The peculiarities of this method are: long term of equipment manufacturing, additional costs for transportation, large volume of installation work.

- Reconstruction of the old boiler house is a less costly method, but associated with a large amount of work. It is necessary to dismantle the old equipment, then remove it from the boiler room, and for this, as a rule, it is necessary to disassemble part of the boiler room, and after installing the new equipment, reassemble it. There are also cases when the small size of the boiler room does not allow placing more powerful equipment.The peculiarities of this method are: the development of design documentation for the reconstruction of the boiler house, the purchase of the necessary equipment, the costs of transport logistics (equipment is purchased, as a rule, from different suppliers), the installation of the equipment received on site.

- Outdoor boiler installation - use of a ready-made solution that reduces costs. For its installation, a minimum of changes in the existing boiler room are required. The features of this method are: a minimum of difficulties during transportation, ease of installation work, the need to develop project documentation, the possibility of additional installation of various warning systems.

An outdoor boiler is a heat-insulated metal box, inside of which from one to 3 boilers are placed. It is installed on a foundation designed for the weight of the boiler, then connected to the existing heating main.

Another feature of using an outdoor boiler is the need for a heating point, because the boiler is not equipped with a make-up system, an expansion tank, a DHW circuit, etc. Therefore, all of the listed nodes must be located in a heating point.

The specialists of BorKotloMash LLC are ready to help you with choosing the best solution for your situation. If you have any questions or need help in the selection of equipment, then call the toll-free number 8-800-100-02-43 or use the feedback form.

Boiler temperature controllers

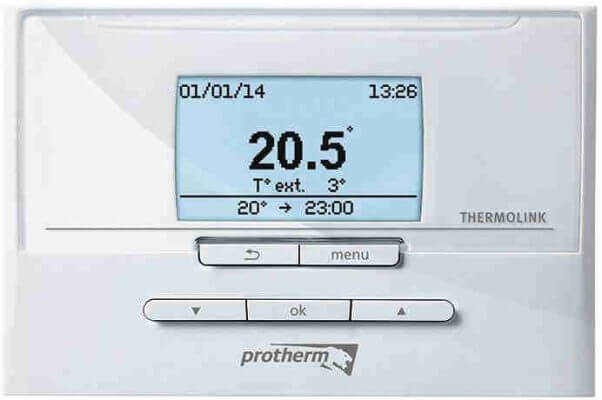

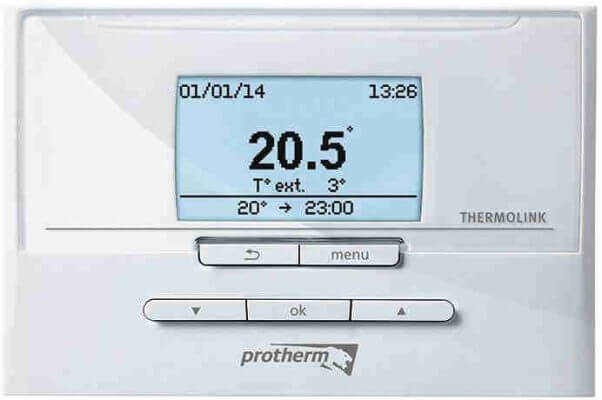

Protherm Thermolink P programmable thermostat

Room programmable thermostat Protherm Thermolink P with interface (eBus) for gas boiler Protherm Gepard (Panther)

The Protherm Thermolink P programmable thermostat allows you to set the temperature according to one weekly program with the possibility of combinations of 3 different time intervals (morning, afternoon, evening).

It is possible to set one of three heating temperature modes: "Comfort", "Eco" or "Vacation" mode. It is possible to set the hot water temperature.

The Thermolink P thermostat supports the frost protection of the heating system when the room temperature drops to 3 ° C.

The display shows the current room temperature, time and day of the week.

Interface regulator Thermolink RC is a modification of Thermolink P with similar properties and parameters, however with wireless connection to the boiler.

The difference between the interface Thermolink P and the two-position Thermolink S

The Thermolink P room temperature controller is connected to the boiler via the eBus communication bus. This bus is used to exchange data between the microprocessors of the thermostat and the boiler. The thermostat has the ability to change the boiler settings.

Thermolink two-position thermostat S maintains the required temperature in the room due to the fact that at a certain moment it turns on and off the boiler.

Thermostat Protherm Thermolink P with the (eBus) interface provides room temperature control by changing the boiler settings - the boiler burner power and the heat carrier temperature are changed. The boiler runs continuously, not in cycles.

In addition, the owner does not need to run to the boiler room to change the boiler settings. Custom boiler settings can be changed directly on the thermostat. For example, adjust the hot water temperature. The boiler autodiagnostics codes are also shown on the thermostat display.

The interface controller can work in conjunction with an external air temperature sensor connected to it.

Setting the weather regulation on the boiler

In order for the temperature in the house to remain constant, the temperature of the heating water in the system, when the outside temperature changes, must change according to a certain law. This pattern is determined by the magnitude and nature of the building's heat loss, as well as the parameters of the heating system.

The dependence of the heating water temperature on the outside temperature is shown on the graph by the heating curve. The slope of the heating curve is very individual for each building.

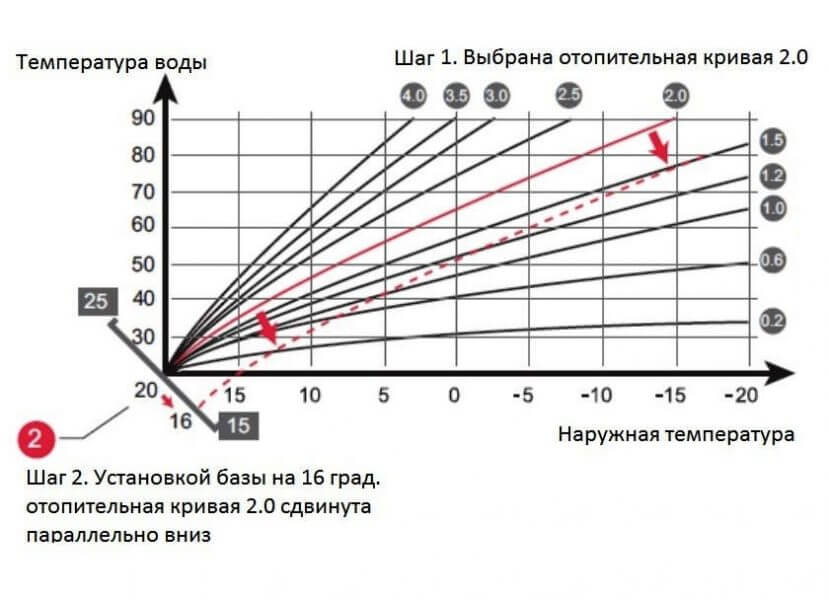

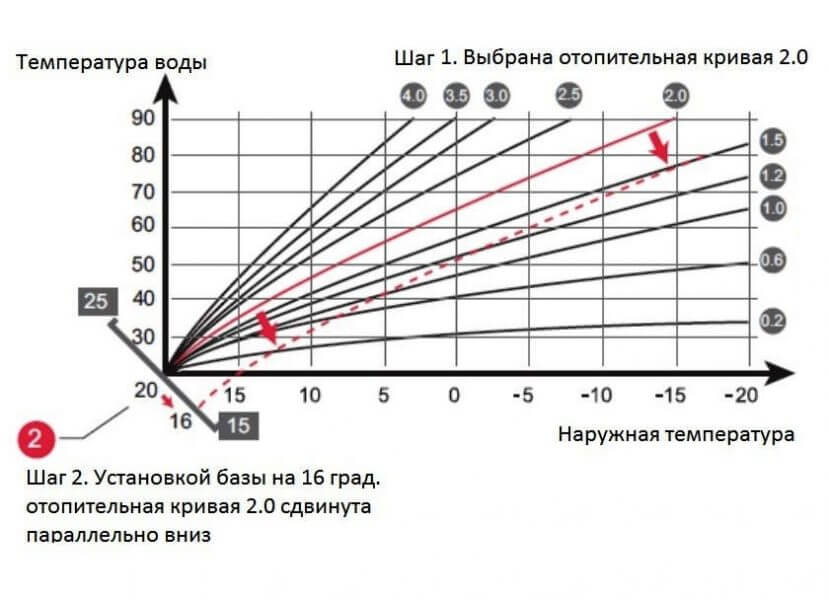

Heating curves for some parameter values in line d.43 of the service menu of the Protherm Gepard (Panther) boiler ..

To work with an outside temperature sensor connected to the boiler, the heating curve for the house is selected in two steps.

Step 1. In line d.43 of the service menu, select the parameter that sets the slope of the heating curve (in the graph above). Factory setting of the parameter = 1.2. Select the parameter that corresponds to the heating curve passing through the known intersection point on the heating water temperature and outside temperature graph. These temperatures (this point) are determined by calculation. Often no calculations are made and this point is not known in advance.

Usually, the parameter of the slope of the heating curve in line d.43 is selected empirically. Leave the factory setting of the parameter in line d.43 and observe in which direction the room temperature changes when the outside temperature fluctuates. If, when the outside temperature drops, the room temperature rises, then it is necessary to reduce the slope of the heating curve, i.e. decrease the value of the parameter in line d.43, and vice versa. The task is to choose such a parameter value at which a change in the outside temperature will not lead to temperature fluctuations in the house. At this step, the main thing is to achieve a stable temperature in the room, regardless of the absolute value of this temperature.

Step 2. In line d.45 of the service menu, select the base temperature of the heating curve in the range of 15 - 25 ° C. Parameter factory setting = 20. The parameter in line d.45 sets the absolute value of the room temperature. If, after selecting the slope of the heating curve in step 1, the room temperature is stable, but low, then the temperature parameter in line d.45 is increased, and vice versa. In this case, the heating curve on the graph rises or falls, but its slope does not change.

If line d.47 is called in the service menu, the display screen will show the temperature, which is measured by the outside temperature sensor.

Read: How to enter the service menu of the Protherm Gepard (Panther) boiler

Connecting the thermostat and outside temperature sensor to the gas boiler

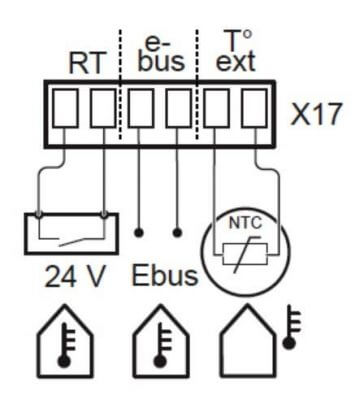

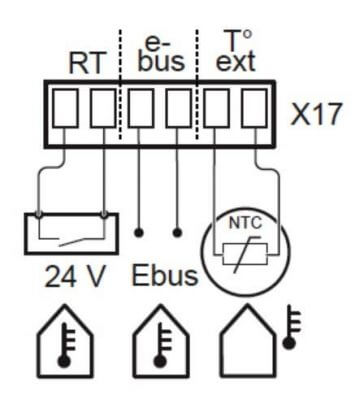

The wires from the room thermostat - thermostat are connected to the terminal block marked as X17 (in the black figure on the left) in the 24 V compartment of the control panel of the Protherm Gepard (Panther) gas boiler.

The wires from the two-position thermostat are connected on the block to the RT terminals, instead of a jumper.

The wires from the Thermolink P interface thermostat are connected to the same block, but to the terminals marked "e-Bus". The jumper between the RT terminals is left in place.

An outdoor temperature sensor can be connected to the Toext terminals.

Connecting a two-position wireless thermostat to the boiler - video

The wireless room thermostat consists of two units.

The executive unit is installed near the boiler and connected to the boiler with wires, to the same terminals as a conventional wired thermostat. To power the executive unit, it is also connected to a 220 volt power grid.

The measuring (control) unit with a display is mounted on the wall of the heated room. The signal from the measuring unit goes to the executive unit via a radio channel.

Gas boiler operation factors

The main parameters affecting the functioning of the wall heater are:

- Efficiency (coefficient of performance).

- Wall-hung boiler design.

- The technical condition of the equipment.

- Gas quality.

- Correspondence of the power of the heater in relation to the area of the house.

Taking all five metrics into account will help you understand which settings might be optimal for a particular model installed in your home.

Optimum operation of a wall-mounted gas boiler

1024 768 Optimum operation of a wall-mounted gas boiler

Air temperature standards in the living quarters of the house

In a private house, when setting up the heating system, it is recommended to be guided by the air temperature standards in the premises established by "GOST 30494-2011. Interstate standard. Residential and public buildings. Indoor microclimate parameters ":

| The name of a room | Temperature (оС), optimal / permissible |

| Living room | 20-22 / 18-24 |

| The same, but in areas with the outdoor temperature of the coldest five-day period -31 ° C and below | 21-23 / 20-24 |

| Kitchen, toilet | 19-21 / 18-26 |

| Bathroom, combined bathroom | 24-26 / 18-26 |

| Staircase, lobby | 16-18 / 14-22 |

| Pantry | 16-18 / 12-22 |

In addition to temperature, another important parameter of the indoor microclimate is the relative humidity. The standard also regulates the relative humidity of air during the heating season for living rooms is optimal in the amount of 45-30%. The permissible air humidity in all rooms of the house should not exceed 60%.

Measurement of air temperature and humidity should be carried out in the center of the room at a height of 1.7 m, in cloudy weather and the outside air temperature is below -5 ° C.

Optimal microclimate parameters - a combination of values of microclimate indicators, which, with prolonged and systematic exposure to a person, provide a normal thermal state of the body with a minimum stress of thermoregulation mechanisms and a feeling of comfort for at least 80% of people in the room.

Permissible microclimate parameters - a combination of values of microclimate indicators, which, with prolonged and systematic exposure to a person, can cause a general and local feeling of discomfort, a deterioration in well-being and a decrease in working capacity with increased tension of thermoregulation mechanisms and do not cause damage or deterioration in health.

In residential buildings, in accordance with SP 60.13330.2010 "SNiP 41-01-2003 Heating, ventilation and air conditioning" during the cold period of the year, when there are no people in them, it is allowed to reduce the microclimate indicators, taking the air temperature below the standard, but not lower than: 15 ° С - in residential premises; 12 ° С - in public, administrative and household premises. The normalized temperature in the premises must be ensured before the start of use.

In the basement of the house, the air temperature should not be lower than +5 ° C.

Tips for the developer

How to reduce the high gas consumption by the boiler for heating the house:

- Choose the power of one gas boiler, the minimum required to compensate for heat losses at home. When installing two boilers, their total total power must be equal to the minimum required.

- In order to save gas and comfort, it is advantageous to use a heating and hot water supply system with a single-circuit boiler and a boiler. With a heating system power of less than 15 kW. it is better to refuse the use of a double-circuit boiler, a system with a boiler will be most profitable.

- Choose a gas boiler with an open combustion chamber, atmosphere.

- When choosing a boiler brand, among other characteristics, be sure to evaluate the boiler efficiency specified in the technical documentation.

- Clean the soot from the boiler heat exchanger annually.

- Check the function and immediately eliminate any defects in the air supply and flue gas discharge of the boiler.

- Be sure to connect a room thermostat and an outdoor temperature sensor to the boiler. Installing a simple two-position thermostat and outdoor temperature sensor will pay off in one to two years.

- Install a thermostatic valve for each radiator in all rooms (except for the room with a room thermostat). This will allow avoiding overheating in many rooms and keeping the temperature lower.

- Rooms with underfloor heating should be equipped with automatic room temperature controllers with protection against floor overheating.

Only in this way, bit by bit, by fulfilling these conditions, it is possible to reduce to a minimum the gas consumption associated with the operation of the heating system.

What does the boiler power affect?

If it is too small, then a powerful solid fuel boiler will not "burn out" the remaining fuel due to lack of air supply, the chimney will quickly clog up and the fuel consumption will be excessive. Gas or liquid fuel (ZhT) boilers will quickly heat a small amount of water and turn off the burners. This burning time will be the less, the more powerful the boilers. In such a short time, the removed combustion products will not have time to warm up the chimney, and condensate will accumulate there. Acids formed quickly will be rendered useless like a chimney, and the boiler itself.

Long burner operation time allows the chimney to warm up and condensation disappears. Frequent switching on of the boiler leads to wear and tear of it and the chimney, as well as increased fuel consumption due to the need to warm up the chimney and the boiler itself. To calculate the power of a liquid fuel (diesel) boiler, you can use

calculator program, taking into account many of the features described above (structures, materials, windows, insulation), but an express analysis can be performed using the given method.

It is believed that heating 10 squares of house area requires 1-1.5 kW of boiler power. DHW is not taken into account in a house that has high-quality insulation, without heat loss, with an area of 100 sq. m. Coefficients for the level of insulation used to calculate the required power of the ZhT boiler:

- 0,11- apartment, 1st and last floors of an apartment building;

- 0,065 - an apartment in an apartment building;

- 0,15 (0,16)- private house, 1.5 brick wall, without insulation;

- 0,07 (0,08)- private house, wall 2 bricks, 1 layer of insulation.

For calculation, the area is 100 sq. m. is multiplied by a factor of 0.07 (0.08). The received power is 70-80 W per 1 sq. m. area. Boiler power is reserved for 10-20%, for DHW the reserve is increased to 50%. This calculation is very rough.

Knowing the heat losses, we can say about the required amount of heat generated. Usually, for comfort in the home, the value +20 degrees Celsius... Since there is a period of minimum temperatures during the year, the demand for the amount of heat increases dramatically on these days. Taking into account the periods when the temperatures fluctuate around the average for the winter, the boiler power can be taken equal to half of the previously obtained value. In this case, the calculation includes compensation for heat losses due to other heat sources.