Options for converting the stove into a fireplace

How is a fireplace made from a stove? There are several options here, much depends on the initial state of the structure. The simplest option for making a fireplace out of an old stove is that you just need to update the firebox, slightly expand it to an acceptable size, and then put a special glass door, which is also called Finnish.

This option is the simplest, there is no need to make changes to the design, it remains the same, but the oven itself must be cleaned. The new door will make the structure as similar as possible to the fireplace, and if you also make decorative cladding, for example, using tiles or marble tiles, then the similarity with the fireplace will be maximum.

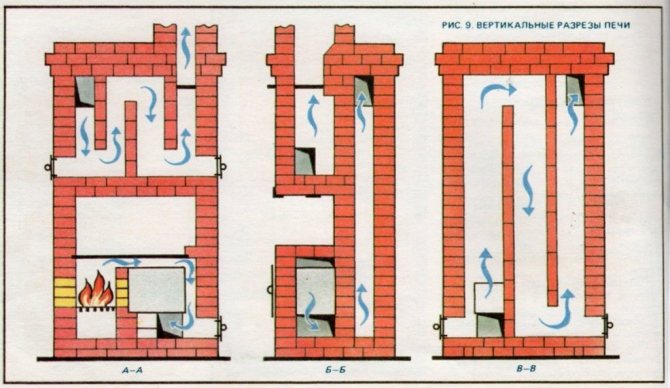

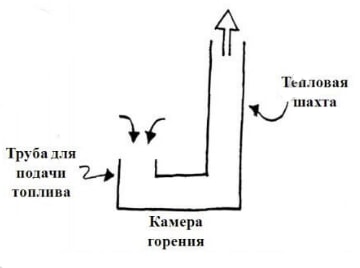

The scheme of the brick oven.

There are other options on how to make a fireplace from a conventional stove. The most expensive and difficult part is disassembling the old structure and assembling a new one. First, the furnace is dismantled, after which it is required to inspect the base, it may be necessary to add new sand. After that, a layer of waterproofing from roofing felt is laid on the surface, a new masonry is made according to the selected scheme.

The work process in this case looks like this:

- The old furnace is dismantled, the base is inspected for damage.

- The podium is masonry, which is necessary to protect the base from high temperatures when burning firewood.

- According to the prepared scheme, the laying of the fireplace is performed, which is no different from the usual one. For this, special furnace and refractory bricks are used. The firebox itself can have different sizes, it is recommended to install a glass door, which will not only increase heat transfer, but also make the use of the fireplace safer. The floor around such a structure must be laid out with a refractory material, such as ceramic or stone tiles. The surface of the fireplace is decorated with different finishing materials, of the most stylish it is necessary to note the tiled tiles, which are ideal for any interior.

Buying an old country house, the new owners discover an old stove that has not been used for its intended purpose for quite a long time.

The time has long passed when in every country house a traditional stove was necessarily provided, serving people both as a way of keeping warm in the cold winter time, and as a place for preparing food.

The widespread gasification has led to the fact that instead of stoves, fireplaces are gaining special relevance, which can also be useful in everyday life, but almost always perform an exclusively decorative function. A fireplace placed in any room of the house creates a really cozy atmosphere.

A fireplace is a rather time-consuming and costly element, therefore, when planning and creating it, it is worth contacting really experienced masters of their craft. The version of the electronic fireplace is also popular, which lives up to its name only visually, but at the same time being inferior to the genuine fireplace in all respects.

A well-tried stove is an excellent basis for constructing a real fireplace. The first step is to visually assess its condition, while the main work on turning it into a fireplace will most often consist in expanding the firebox, updating the chimney pipe, installing the door and other relevant attributes.

Where to begin?

- You should carefully check the condition of the old stove, the level of deterioration of the chimney, and this step is the most important for everyone who lives in the house.A chimney with good maneuverability and confident draft is something without which the fireplace will not function.

It is important to check that the cross-section is not less than the size of at least one brick, otherwise the thrust will not be enough. A chimney with insufficient draft is dismantled in order to replace it with a new one, suitable in all respects. - As a rule, the area of the stove is very small, which is not suitable for a fireplace.

Accordingly, the right decision would be to increase the firebox during reconstruction. You can also equip the fireplace with a glass door covering the firebox so that ash and sparks do not fall on foreign objects in the room - this optional element serves as an excellent decorative element. - The body of the furnace structure should also be inspected for large cracks, falling out brick elements and other deformations. Even if no visible damage is visible, it is worth updating the surface in order to make it sophisticated and attractive.

Undoubtedly, a lot depends on the initial state of the existing structure.

First option. The easiest way is to update and expand the firebox, install a glass (Finnish) door. With this option, there is no need to make significant changes to the structure of the existing oven, but it is worth cleaning it. Decorative cladding with wrought iron elements or tiles will give the stove an absolute resemblance to a fireplace.

When operating a ready-made fireplace, it is important to remember that only dry firewood and logs are used for the firebox, coal is not used for this purpose.

Second option. The most difficult and expensive method, as it involves a complete disassembly of the old structure with the subsequent assembly of the updated one. Initially, the elements of the furnace are dismantled, then the base is inspected for the need for additional sand filling.

Next, a waterproofing material is laid, and only after that a new masonry follows, identical to any other, but at the same time a refractory brick is used - it is specially made for such purposes. A floor that is resistant to firepower is a must when installing a fireplace.

Tiles are perfect for this role, tiles look good as a decorating material, but in general, the decor depends on the imagination of the owners.

The old stove, once used for household purposes, was traditionally installed in a large central room and did not take up too much space. However, the appearance of the stove structure did not always evoke aesthetic satisfaction. All the more willingly, new owners will want to use an unnecessary relic of the past as an excellent addition to the new interior.

Thus, for all repair actions to convert the stove into a fireplace, you should stock up on the necessary tools, fixtures and materials, which include:

- refractory kiln bricks, the amount of which depends on the amount of work. Finding it is not difficult: the easiest way is to visit the nearest construction market or a construction supermarket;

- cement mortar;

- level;

- clay for mortar;

- Master OK;

- Bulgarian;

- chimney (in case the old one is in an unsatisfactory condition and needs to be replaced);

- facing tiles;

- fireplace door.

To simplify and visualize the desired result, a drawing of the desired fireplace should be prepared in advance, the external design of which is largely determined by the initial state of the stove. An examination of the existing furnace is carried out to find out its reliability, the durability of the existing body, the condition of the foundation.

There is an opinion that earlier, in the Soviet era, everything was done much better, "for centuries" - of course, this opinion is not unfounded, but you should not rely on it too literally: after all, time takes its toll.

Therefore, it is better to make sure of the correctness several times than to soon engage in alteration of a new, but already damaged fireplace.

To the depth of the firebox, 50 centimeters should be allocated, and the inner body of the fireplace is always laid out with refractory bricks.

If all the necessary conditions are met, the transition to the inspection of the existing chimney is carried out, because it will almost certainly need to be rebuilt.

The requirements for chimneys for stoves and fireplaces are somewhat different: the chimney of a fireplace needs seven meters in height, a cross-section of 13 * 25 centimeters at least. Further, it is necessary to provide for the presence of specialized channels necessary for the presence inside the entire structure in order to control the air flows passing along the doors.

Thanks to this method, soot will not constantly and abundantly accumulate on the glass of the fireplace door.

As mentioned earlier, the conversion process will not cause difficulties if you responsibly approached the stage of checking the old design and found that it was reliable enough. In this case, they are limited to expanding the opening of the firebox to give it convenience and beauty. Then a glass fireplace door is installed, which has a protective and decorative function.

Thus, after the completion of all major repairs, they begin to finish the existing fireplace.

It is important to use a heat-resistant and reliable material so that it does not get damaged or deformed under high heat loads, and also does not provoke a fire attempt.

We invite you to familiarize yourself with the Tobacco mosaic virus was discovered

Natural or decorated stone, which gives sophistication and presentability to the appearance of the fireplace, is an excellent solution for such purposes. Ordinary heat-resistant brick is also quite popular - it would seem that it is a completely unpretentious material.

Fulfilling a childhood dream of your own fabulous fireplace is not as difficult as it might seem. Nowadays, no one will find it difficult to buy a house in the countryside and equip it as a quiet place to relax from the bustle of the city. And the quiet sound of logs peacefully crackling in the fireplace will surely give you pacification, peace and comfort - something that is really lacking.

Construction technology

There is a step-by-step instruction for a fireplace stove with your own hands. The operation of laying and preparing tools and materials must be broken down into several stages:

- Selection and purchase of building materials.

- Preparation of tools.

- Installation of the foundation.

- Brickwork of the base of the fireplace and chimney.

- Drying and first use.

Kiln bricks and mix should be selected taking into account the basic requirements:

- For laying the base, it is necessary to purchase medium-sized solid ceramic bricks.

- The walls of the firebox are mounted from fireclay materials.

- You can use clay instead of fireclay bricks. The main thing is that it should be free of cracks and chips.

- The body of the stove can be laid out from a used ceramic, but you need to carefully inspect it for cracks, damp places and other things.

- If finances permit, you can buy materials with rounded edges.

Don't forget about the appropriate materials for the fireplace

As for the solution, you can buy it at a hardware store. The same goes for the refractory mixture. If finances are limited, then the solution can be made by hand:

- All unnecessary details must be removed from natural clay - grass, pebbles, branches.

- Next, the resulting material must be poured into a large container and left to soak in water for two days.

- After the specified time, water is added to the clay until a cream-like consistency is obtained. This mixture is passed through a sieve to remove foreign objects.

- Sand passed through a sieve is added to the resulting solution.

The solution is considered suitable when it is possible to roll "sausages" with a diameter of about 10 cm from it and wrap around a thin wooden stick. The finished mixture can be stored for as long as you like. If it hardens, it can be easily diluted with water.

A mortar of clay and sand is not suitable for laying the base and walls of the chimney; cement and lime must be added there. Also additional materials required:

- Portland cement.

- Stones of different sizes.

- Roofing material.

- Formwork boards.

- Basalt cardboard or felt.

- Steel wire.

- Asbestos cord.

Of course, stove accessories - doors, dampers, etc. - come in handy.

The next step is the required set of tools. An ordinary master may not have a complete list of everything you need, therefore there is a minimum composition:

- A rubber or wooden hammer.

- Pick.

- Bucket, broom, scoop.

- Level, measuring tape.

- Square, plumb line and rope.

- Brush, heavy duty cleaning material.

- Master OK.

- Pliers, ruler, scribe.

Foundation installation and preliminary laying

It is best to install the foundation for the stove together with the general foundation of the house. But if this is not possible, then you will have to remove the cover and dismantle the screed. The size of the opening in the floors should be 15-20 cm larger than the required size for the foundation. If a tape base was chosen for the house, then a solid foundation is required for the furnace:

- A pit 50-60 cm deep is digging in the ground under the floor. A 10-centimeter sandy "pillow" is poured into the bottom of the pit. Crushed stone is laid on top in the same layer. The whole structure is compacted tightly.

- Formwork is knocked down from the bottom of the pit, where the solution will be poured.

- Since the foundation is quite deep, the solution is poured in several stages.

- The top of the base is leveled and given time to harden. This is usually 3-4 weeks.

When the solution grasps and hardens, a layer of roofing material is laid on it, where the first row of the furnace will fit.

Even the most experienced craftsmen measure the future structure. For this, bricks are laid out without mortar. This is done to determine the required amount of materials and their layout. It is necessary to measure a distance of 5 mm between the bricks so that all joints are of the same size.

After all the procedures, you can lay the brick on the mortar. Homemade clay mortar can be used, but it is recommended to use special refractory mixtures for ovens.

Laying scheme

The purpose of the diagrams is a visual representation of both the masonry of the fireplace and the movement of air along the air ducts. Such a scheme helps the wizard to understand where and what will be located. The correct drawing will allow you to build a high-quality fireplace stove with your own hands, and it will keep heat for a long time and reliably remove combustion products, protecting human health.

The most popular diagrams provide a clear example of a cutaway oven. Here you can clearly see the placement of the furnaces and the outbreak of the flame, as well as the air flows.

In addition, such drawings will show the master the location of each row, the place where the grate, doors, latches, etc. will be. In no case should you deviate from the order, because even a small part of the brick located in the wrong place can disrupt the whole order.

Construction construction

Work must be done slowlythinking through every step. Sometimes during laying, only a piece of brick is needed. In this case, the brick is separated with a pick or grinder. If the material is broken with a pickaxe, then the initial blow is applied weakly in order to mark the necessary part. The second hit is a control one.

The mortar is placed on the brick with a layer of 5-8 mm. Then the material is placed on the stacked row and pressed. The excess mixture is washed with a trowel. After 6-7 rows have been laid, the seams are sewn up so that the bricks take a neat look. It is advisable to remove the mixture from the material immediately, then it will be difficult to wipe it off.

The initial row of masonry is displayed as evenly as possible - it is he who sets the tone for the entire structure. For greater accuracy, the edges of the base are drawn on the roofing material with chalk. First, just bricks are laid on it, without mortar, then they make real masonry.

From the second row, duct channels, the device's firebox, and the blowing chamber already appear. In the next row, the blower door looms. It is propped up with bricks and wire.

In the fourth layer, where there will be a firebox, 2 strips of metal are laid at a distance, so that bricks can then be attached there. Walls are mounted around the blower.

On the fifth circle, the grate is attached, on the sixth - the firebox door. The door is attached in the same way as the blower door. Further, up to the tenth circle, the building material is laid without additional elements. On the eleventh, a cast iron hob is mounted. The thirteenth layer assumes the basis for overlapping the firebox. A chimney will then form from it.

The nineteenth circle overlaps the hob with a sheet of metal, where the next row of bricks is then laid. Up to the twenty-fourth layer, the work proceeds without metallic inclusions.

On the twenty-fifth circle, a primary valve made of cast iron is attached. Further, up to the fifty-third layer, the masonry goes without auxiliary elements. From the fifty-fourth circle, the laying out of the chimney begins.

The sixty-fifth row assumes the presence of valvesthat block the chimney channels. This is done to protect against moisture and debris from entering the oven during the summer. Next, an opening is cut in the ceiling for the pipe to exit to the attic. The pipe is framed with a heat-resistant material to prevent a fire in the ceiling. Usually, the thickness of such material is at least 10 cm - these are asbestos slabs or fine expanded clay.

Next comes the usual masonry, upon reaching the level of the roof, a layer of waterproofing is laid around the pipe. This helps prevent moisture from entering between the chimney and the roof.

The last step is to lay the umbrella, which protects the fireplace from moisture and debris through the chimney.

Drying the finished device

After completing all the work, do not intensively heat the stove, as it takes time for it to dry out. The average drying time is 10-15 days. During this period, it is necessary to open all the latches and doors. There is another type of drying - artificial, when a heat fan or a lighting lamp is installed in the firebox. This method will be an excellent preparation for an active firebox.

Fireplace starts to heat up graduallypiling up a small amount of firewood several times a day for a week. You can find out if the oven is ready for use by looking at the doors. If no condensation forms on them, i.e. no drops are visible, which means that the fireplace is dry and can be heated in intensive mode.

If the masonry technology has been violated, it will be noticeable during the first fire - cracks may form in the bricks. You shouldn't cover them up right away, you need to wait a couple of months and monitor the situation. If the cracks become critical, through which carbon monoxide can penetrate, then they should be repaired immediately.

A do-it-yourself fireplace stove for a summer residence or a country private house is an excellent option that solves many problems. Even if the house has gas or electric heating, a traditional fireplace never gets in the way.

What should you pay attention to?

When converting a furnace, it is imperative to perform the following preparatory steps:

- Checking, assessing the state of the structure of the furnace and chimney. This is done without fail, since further safety of use depends on the quality. There should be good passability at the chimney, since the fireplace simply will not work without draft. The section must be at least the size of one brick.Otherwise, the thrust will be very small, completely insufficient. Usually, the chimney is immediately dismantled, after which a new one is installed in its place.

- The stove has a small firebox; this is not enough for a fireplace. This means that during the reconstruction, the size of the firebox must be increased to the required size. You can install a glass door that will cover the firebox, ensuring the safety of the structure. But this door is not obligatory, it is not necessary to specially mount it.

- It is required to carefully inspect the structure body. If it is intact, there are no cracks, traces of deformation, numerous falling bricks on it, then there is no need to disassemble it. It is better to decorate the surface of the case after all the work, making it more attractive.

Converting a stove into a fireplace is not required so often, usually such work is planned when there is already a stove in the house, but it is used extremely rarely. Having spent not so much time and money, you can make a beautiful and stylish fireplace from such a stove, which will not only heat the house, but also become a real decoration for any interior. Stoves are not so difficult to convert into decorative structures.

Fireplace device diagram.

Often such stoves are located in kitchens, in central rooms, they do not take up much space, but their appearance is not always aesthetically pleasing. Therefore, you can safely take on the alteration and use the fireplace as an additional source for heating the room.

To transform the stove into a comfortable and beautiful fireplace, you need to prepare the following tools and materials:

- stove brick and refractory, its volume depends on how much the stove will have to be redone as much as possible;

- building level;

- Bulgarian;

- cement;

- clay masonry mortar;

- chimney ready-made pipe (if the old one has to be completely removed);

- Master OK;

- putty knife;

- cladding tiles;

- glass door for the fireplace.

Before you start converting the stove into a fireplace, it is necessary to take into account that the fireplace is heated differently. Only special wood briquettes or dry firewood are suitable. Therefore, it is recommended to immediately take care that there is always a certain amount of fuel.

All the specified materials and tools should be prepared, an individual drawing of the future fireplace should be drawn up. Its appearance depends on the original furnace. It is imperative to inspect the furnace, find out how well the body is made, in what condition the foundation is. If everything is in order, then you should not disassemble the already standing structure, the work is carried out on the material that is. There should be a gap of 25 cm between the common foundation of the floor of the house and the base for the stove, it is completely covered with sand.

At the firebox, the depth should be 50 cm, the body inside the furnace must be lined with refractory bricks.

If all the conditions meet the required ones, then it is necessary to proceed to the inspection of the chimney, as it may have to be rebuilt. For fireplaces, the requirements for chimneys differ from those for stoves, the height should be from 7 m, the cross section should be at least 13 * 25 cm. It is necessary to have special channels that will control the air flows along the doors inside the structure. This will prevent soot from constantly settling on the door glass. A variant of the converted furnace structure can be seen in the figure. IMAGE 1.

If all the necessary conditions are met, the transition to the inspection of the existing chimney is carried out, because it will almost certainly need to be rebuilt. The requirements for chimneys for stoves and fireplaces are somewhat different: the chimney of a fireplace needs seven meters in height, a cross-section of 13 * 25 centimeters at least.

Before you convert the fireplace yourself into a stove, you should carry out certain preparatory work, namely:

- Check and assess the physical condition of the old heating structure and its chimney.This must be done without fail, since such procedures will guarantee the full and safe use of the fireplace. The chimney must have good cross-section and one brick size.

- An old stove usually has a very small firebox that is not suitable for logs. This means that you will have to expand this part of the future fireplace, and then make a forged, lattice or glass door for it, which will prevent heat loss.

- If there are no cracks, defects or destruction on the stove body, it is not necessary to shift it. Upon completion of all work, it is simply covered with a new layer of plaster or decorative material.

The scheme of the fireplace stove.

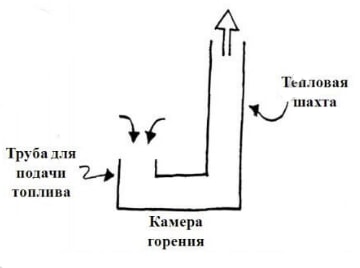

Chimney diagram.

If all the conditions meet the required ones, then it is necessary to proceed to the inspection of the chimney, as it may have to be rebuilt. For fireplaces, the requirements for chimneys differ from those for stoves, the height should be from 7 m, the cross section should be at least 13 * 25 cm. It is necessary to have special channels that will control the air flows along the doors inside the structure. This will prevent soot from constantly settling on the door glass. A variant of the converted furnace structure can be seen in the figure. IMAGE 1.

An even simpler version of the stove

If the previous option seemed difficult to someone (although it was not so), you can offer an extremely simplified heating structure. This oven with your own hands can be laid out in literally an hour, even if your hands are generally far from being called golden.

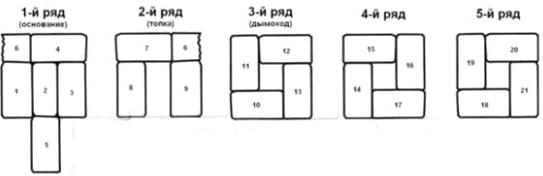

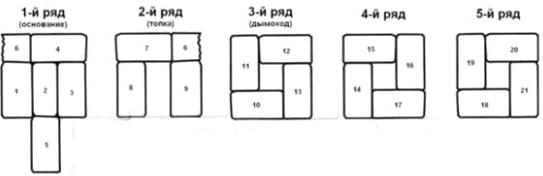

Figure 4. The simplest brick oven

The principle of the structure is simple. Solid fuel burns below, but here it settles under the influence of its own mass. Temperature differences create a draft that carries hot air currents upward. In this case, the firewood burns out almost without residue - the smoke is minimal.

For masonry, you need only two dozen whole bricks and two halves. The stove consists of five rows. The design is so simple that there is no point in describing the order. The procedure is clearly shown in the illustration.

Figure 5. Ordering of the simplest brick structure

Figure 6. Masonry process

Figure 7. Finished mobile brick oven

For those who want an intermediate option, we can recommend a slightly more complicated option.

Figure 8. Diagram of a simple stove device

Figure 9. L-shaped stove

The creation of this structure will also require 20-30 bricks. This option can be mastered by yourself in a couple of hours, if the skills of a bricklayer are completely absent. The construction will be subordinated to a specialist in a matter of minutes.

The advantages of the simplest furnace designs

- very high installation speed - from a day to several minutes;

- does not require a foundation; the stove can be folded anywhere; and if you do not use a binder mixture, the stove comes out collapsible and easily moves;

- as fuel - everything that burns: logs, branches, cones, corn stalks, leaves, chipboard, furniture remains, etc .;

- fuel consumption is several times less than, for example, in the case of a potbelly stove;

- the simplest option - without the use of clay - allows you to get more heat transfer than from a fire; therefore, such constructions are a godsend for those who do not want to constantly support the fire during the campaign;

- almost complete absence of smoke - fuel burns with a minimum of waste;

- the temperature of the bricks reaches 1000 degrees - good heating and quick cooking are ensured.

Where can you see the Russian stove

We answer all your questions step by step. A huge part of the population lives in our country far from civilization. In the 90s, there was a tendency for the extinction of villages. Young people left their parental homes and went to the city in search of a better life. Many buildings were simply abandoned.

Most of the village houses were equipped with stove heating.In order to dismantle the stove, it is necessary to redecorate the flooring and seal the hole in the roof for the chimney. Not everyone had the desire and opportunity for this, so there are still symbols of warmth in the house and comfort, sung in Russian fairy tales.

Gasification made it possible to install a burner in the stove and give the structure a second life. But the modern approach to renovation implies that it will be converted into a functional, stylish fireplace.

How to disassemble a brick oven: the procedure and features of dismantling furnace equipment

Now we proceed to disassemble the stove in the room. To do this, open windows and doors to bring in fresh air. We take a bottle of water, put a spray on it and spray water on each brick of the row that we will disassemble. Splattered? We do not regret water in this matter, but it is better for us, less dust will fly. Now we gently knock with a hammer and slowly remove brick by brick. You can, of course, with a sledgehammer) So the whole stove will quickly fall apart. BUT it's too dusty, and then suddenly you will need these bricks for something, you never know what happens. The more carefully you do everything, the better for you. Well, and so on until the very end. The bottom line is simple: spray, disassemble. And yet, before proceeding directly to breaking the stove, take care in advance about where you will put the old bricks so that you do not drag them from place to place later. That's all, actually. After all this, you just have to clean up and take out all the trash. Good luck!

No matter how good the old stove is, sooner or later, many of its owners come to the conclusion that it needs to be disassembled. The reasons are different: the desire to expand the living space, the acquisition of an alternative heating system, the desire to change the interior design. In general, there are many reasons. The stove can be partially disassembled by converting it into a fireplace or simply rebuilding several partitions.

If you decide to disassemble an old oven, take a close look at it. Any work begins with the head, at the stove it has a chimney.

Open the ceiling above the stove and make sure nothing is leaning against the chimney. Do not forget to cover or take things out of the room, there will be a huge amount of dust and ash. Carefully, starting from the roof, widen the hole around the chimney and brick by brick dismantle the masonry, gradually going down into the house. Be careful not to stack a lot of bricks on the roof, or you risk falling. In the attic and indoors, masonry can be broken with a sledgehammer or something heavy, but be careful not to damage the beams and walls that will still come in handy. Carefully brick the holes in the ceiling and roof remaining from the chimney.

Next, we proceed to disassemble the central and largest part of the stove, on which many loved to soak up when the stove was still in use. The main part of the oven cannot be completely disassembled; only one wall can be removed. Adapt the remaining walls for niches or shelves.

If you decide to disassemble the entire stove, then again check if the body of the stove is resting on something, and also disassemble the floor around the stove and inspect its foundation. Check how the walls are stacked, how the bricks are connected to each other (clay or cement). If later you are going to build a new furnace, then you will need a price-list for a building brick. If the stove is lined with clay, then everything is simple, the walls are quite easy to disassemble, but if cement is already involved, then you will have to sweat.

Options for converting the stove into a fireplace

Already passing several rows will give a complete picture of the smoke channel arrangement. At this stage, you will have to determine whether you will leave the chimney in the same form or build a fireplace option, which is a regular vertical channel.

Having compared the diagram of a real device with the most suitable fireplace project, decide which part of the masonry will remain intact.Evaluate the possibilities of modifying the rows and then proceed to cleaning all the cavities of the body. It is much easier to clean the disassembled oven than in the current one.

Each brick should be cleaned of old mortar and soot. If necessary, you can use water. These bricks are most likely unsuitable for the outer layers, as modern materials are more aesthetic and attractive. But when installing the chimney, they will be irreplaceable.

In the case when it is impossible to delve into the circuit and after partial disassembly the picture does not become clear, you will have to continue to disassemble the furnace. If there is a lot of damage in the masonry, then fixing them can be more time consuming and expensive than building a new fireplace. This idea forms the basis of the second method, how to convert a stove into a fireplace.

When disassembling the stove, do not regret the design. With a lot of cracks, it would cause a lot of problems. The very existence of the foundation and foundation is a huge legacy left by the fireplace stove. Having carefully examined the state of the base, you can carry out installation work on it. But verification is not only about integrity control. Using a level, you need to make sure that the plane is horizontal.

We offer you to familiarize yourself with Heliotrope - planting and care, photo

The remaining foundation indicates the boundaries of the fireplace complex. With such dimensions, it will be possible to build not just a decorative element, but a real functional fireplace with a hob for cooking. In addition to the fact that the firebox will need to be performed according to the dimensions calculated according to the parameters of the room, immediately orient yourself with the location of the chimney so that it goes as close as possible to the existing hole in the roof of the house.

A fireplace made from a stove with its full or partial disassembly can radically change the style of a room's layout. In some cases, the oven undergoes minimal changes. They mainly relate to the size of the firebox. Then it makes sense to keep it in its original form, decorating it with folk art painting. Naturally, modern materials are used for this, which do not leave traces and retain their appearance after long-term use.

It should be noted that with the help of such solutions, two important tasks can be solved: to equip a fireplace and to preserve the memory of Russian craftsmen in the house. After all, the Russian stove differs from the designs of other countries by the presence of a stove bench. This stove bench can be left for decoration, or it can be turned into a working fireplace unit.

It is also important to assess the state of the furnace itself and the foundation. If all is well, then you can proceed to the next stage.

The simplest modification option would be to convert the stove into a decorative fireplace. It doesn't take much time and effort.

The necessary materials and tools will be:

- new chimney;

- bricks;

- mortar for masonry;

- putty knife;

- Master OK;

- several bags of cement;

- a sufficient amount of clay;

- level;

- finishing material (for example, tiles);

- glass door optional.

When converting, it is necessary to comply with the conditions for the fireplace.

It is important to check the chimney pipe:

- its height should be at least 7 m (preferably more);

- section - more than 13x25 cm;

- the depth of the firebox should be about 50 cm, but not less.

When all the stages are completed, then the finishing stage begins. Here, of course, everything is individual. The choice of materials depends on the personal tastes and preferences of the owners, as well as on the style of the interior. The main materials that are used for decoration: stone, tiles, tiles. Undoubtedly, a stone-trimmed fireplace will look very impressive and chic.

We offer the simplest advice on how to convert a stove into a fireplace.It consists in expanding the firebox of the old design, after which it is covered with a decorative door made of tempered glass or other material. In this case, there is no need to change the outdated structure, although the stove itself will still have to be thoroughly cleaned. It is recommended to make decorative wall covering in the form of tiles, tiles or artificial stone.

Complete disassembly of the stove and the subsequent construction of the fireplace is the most expensive and time consuming option. The original structure is completely dismantled, the base is inspected and sand is added. In place of the future fireplace, waterproofing in the form of roofing material is laid, after which a new heating element can be assembled.

In this situation, the following sequence of actions should be performed:

- Dismantle the old stove, inspect the base and repair any possible damage on it.

- To protect the base from the high combustion temperature, you need to fold the brick podium.

- According to a previously prepared scheme, lay the fireplace, for which a specific stove brick with refractory capabilities is used. It is recommended to make the firebox as wide as possible, which will not only create an excellent decorative effect, but also make the use of the finished structure extremely safe. It is recommended to lay the floor and walls around the fireplace with non-combustible material in the form of tiled tiles, real or artificial stone.

How to disassemble a stove without dismantling the chimney

It is better to entrust the performance of such work to specialists. If mistakes are made, then after assembling the stove, smoke may enter the house. If you want to dismantle the stove yourself without touching the chimney, it is important to adhere to the following instructions:

- Fix the lower part of the chimney. To do this, you need to bring a strong and stable metal support element under it. In most cases, corners are used.

- Make a groove around the perimeter of the pipe, which goes through the seam of the masonry, and place one of the corner shelves there.

- Fasten the structure at the corners with tacks.

- In the lower part, install the fasteners, resting them on the floor.

- After that, disassemble the required section of the product.

It is important to fix the chimney correctly in order to prevent subsidence

- Install a new stove with its pipe leading to the old chimney device.

- Lay bricks to fasten the new structure and the old chimney.

- With the help of a grinder, cut off the tack and fixture from the corner around the perimeter of the pipe.

- Dismantle the racks.

- The fixing points of the new stove with a chimney and all old masonry should be whitewashed.

- When the whitewash is dry, make a test fire.

- If during the repair the masonry was broken, then soot will be visible in the places where gaps appear. These places should be reinforced with a clay mixture. Old masonry seams must first be cleaned.

In order not to disturb the laying of the chimney, it is important to monitor the absence of deformations and subsidence.

It must be remembered that it is not allowed to use unsuitable fuel for heating the stove. If you incinerate household waste in it, it can negatively affect the functioning.

What will the reconstruction of the furnace give

The Russian stove in the house is installed in such a way as to warm up the maximum living area, and the location in the center was not excluded. Now think, isn't this modern style?

In our view, the stove bears the image of a certain structure with uneven edges and whitewash that leaves marks on clothes in the event of an accidental touch, and if you align the edges and use modern materials, then interesting projects appear offhand, which, according to the originality of the idea, will not yield to leading design developments.

The possibility of building island types, wall options, stylizing the room for the decoration of a peasant hut (a promising direction). All this awaits us after the conversion of the old stove into a modern fireplace.

Medium repair

The draft can be blocked by a brick that has collapsed into the chimney

If during the restoration of the stove it is planned to replace the tiles, it is necessary to take into account the aesthetic correspondence of the installed elements to the interior of the room.

Replacing the firebox

The walls are dismantled and new masonry is installed sequentially. This method of repairing a Russian stove with your own hands involves replacing all the bricks that form the structure of the firebox.

As a rule, problems in this category are associated with the need to install new partitions in the channels. To access the work area, you will have to consistently disassemble and restore the walls. If necessary, several sections are repaired according to a similar scheme until the functionality of the smoke exhaust system is fully restored.

Indoor masonry is created using a standard oven solution. The outer part of the structure - with the addition of cement to the building mixture. At this stage, you need to check the correct placement of the outlet relative to the ridge of the roof.

How the stove differs from the fireplace

Now let's dive into the realities of the upcoming work and note their laboriousness and complexity of implementation in technical and theoretical terms. To understand how to make a fireplace from a stove, it is necessary to determine all types of work required. Only a real pro can do this, so attracting a master will most likely become a prerequisite. But for the sake of information, we will explain how to carry out the reconstruction analysis.

The stove is no different from the fireplace. Both devices work by burning fuel and both are involved in heating the room. Still, one of them is called a stove, and the other is called a fireplace.

- The functions of the furnace are not designed to provide an opportunity to observe the flame, therefore, all technological nuances are aimed at high-quality and efficient use of heat. The firebox door is made of metal and hides the combustion process from the eyes of the observer.

- The gases produced after combustion are at a high temperature. I don't really want to give such energy to nature, so the chimney in the furnace body is made in the form of a labyrinth. When moving, heated gases give off their heat to the bricks of the stove.

- The firebox of the Russian stove is somewhat smaller than, according to calculations, there should be a fireplace for such a room.

Otherwise, the differences concern only external elements, which can be used in the converted structure.

How to decorate a fireplace?

It is not so difficult to make a fireplace out of a stove, if the structure is strong and reliable, then you can only expand the hole for the firebox, make a beautiful and convenient portal out of it. After that, you can mount a glass fireplace door, which will add integrity and decorativeness to the entire structure. Finishing work is carried out last, for this we can use any material with which fireplaces are faced.

The question of how to make a fireplace out of a stove arises among many summer residents. There may be several options for such alteration, the work itself must be started with a careful examination of the stove, it is quite possible that you will not have to do the masonry from scratch. This will significantly save your budget and time.

- Choosing a heating boiler for a private house

- Furnace heating design

- Technologies for insulating the floor of the first floor in a wooden house

It is not so difficult to make a fireplace out of a stove, if the structure is strong and reliable, then you can only expand the hole for the firebox, make a beautiful and convenient portal out of it. After that, you can mount a glass fireplace door, which will add integrity and decorativeness to the entire structure. Finishing work is carried out last, for this we can use any material with which fireplaces are faced.

Brick stove repair: popular breakdowns and how to fix them

First of all, you need to decide on the scale of work and assess the current situation.In cases where it is planned to replace the stove with a new one, you should make an audit of the chimney and consider the option in which it remains. If it becomes possible to conduct gas, then the stove equipment can be completely dismantled or a small fireplace can be built on the basis of the chimney.

Work begins with a careful examination of the structure in the area of the ceiling. In old houses, Russian stoves, as a rule, were erected together with the house and used as an additional ceiling support. You can start dismantling only after making sure that the roof does not rest on the chimney, and its structure will not be disturbed after disassembling the channels.

Dismantling the oven is a dirty and dusty job. If you have to perform it not at the stage of major repairs, it is necessary to take out everything that is possible from the room, and cover the remaining pieces of furniture with foil. You can also build something like curtains made of dense polyethylene, fencing off the desired area from the rest of the room.

The set of tools for dismantling brickwork depends on the composition used to build the mortar. Here is a list of the tools that are most likely to be needed for the job:

- heavy hammer or sledgehammer;

- scrap;

- pick;

- chisel;

- puncher;

- steel wedges.

It is recommended to work in a respirator, and to use gloves to protect your hands. It is better to choose clothes that you do not mind throwing away. During disassembly, not only dust will fly, but also soot, and it is very problematic to wash it off.

Helpful information

The easiest way to work with buildings made of clay, which becomes pliable after preliminary soaking.

Depending on the strength of the masonry, a suitable tool is used in the work, for example, a chisel and a hammer.

note

The point needs to be guided into the masonry seams - this will not only simplify the work, but also reduce the amount of debris, and also help save the building material for later use.

The hardest part is to disassemble the cement masonry; in this case, soaking the joints will not help. For dismantling, steel wedges are driven into horizontal seams with a sledgehammer, violating their integrity. After that, row by row, they disassemble the masonry, using a perforator for work, and if there is no such tool, then they wield a crowbar.

The stove can only be dismantled from top to bottom, all other options can lead to serious consequences.

Most often, in one-story houses, the pipe comes out of the oven and is led out through the ceiling and roof. Less common are complex smoke ducts located in the walls of the building. Sometimes an external chimney can be found towering next to the wall.

The easiest way is to dismantle the pipe coming out of the oven. It will not be difficult to remove the metal pipe, having previously loosened it in different directions.

If the pipe is made of bricks, it is carefully disassembled brick by brick, moving from top to bottom and trying not to damage the ceilings and walls. Dismantling begins from a site that rises above the roof.

It is even more difficult to disassemble a plastered brick, but what should add strength is that further work will go faster and easier.

After completing the disassembly of the outer pipe, they smoothly move to the attic.

But first, the resulting hole in the roof is closed with a sheet of roofing iron or the roof is covered with the same material that covers the entire roof.

To prevent the plaster from collapsing on the ceiling, it is recommended to make grooves along the perimeter of the pipe from the side of the room. Seams made of sand-clay mortar are easily broken with a chisel and a hammer.

Having completed the work in the attic, they proceed to dismantle the stove in the house. There is no need to rush to remove the doors - it is better to close them tightly to prevent soot from entering the room.

Some inexperienced craftsmen make a common mistake and try to speed up the process by breaking the masonry at the bottom of the structure - this cannot be done, since a heavy brick building can collapse and damage the floor ceiling.

Another mistake, which is also made by non-professionals who want to speed up the process, is taking the stove out of the room without disassembling the masonry. Indeed, if the hearth is on a foundation and the first row is made without mortar, this is possible.

Important

But a standard stove weighs several tons, so only a few people can lift it and take it out without dropping it. In this case, it is necessary to carry the load correctly so that the structure does not fall apart along the way.

Considering that during the operation, the masonry weakens significantly, the risk that the stove will collapse and damage the floor is very high.

It is better to act slowly, orderly dismantling the walls, moving in a circle. If the structure is lined with tiles, you will first have to get rid of the cladding with a punch. The plaster may not be completely removed, but it will have to be cleaned at the seams. Naturally, the smaller the stove and the simpler the design of the heating hearth, the faster the process will go.

When working with a Russian stove, difficulties arise when dismantling the vault - here it is recommended to put a sheet of iron and make supports so that the structure does not collapse ahead of time. The vault is best disassembled from the back.

If the stove has a separate foundation, then it must also be dismantled. A brick or stone base is easy to destroy with a crowbar, and a concrete slab is broken with a jackhammer.

Before proceeding with the independent dismantling of the stove in the house, it is recommended to weigh all the benefits and risks. Sometimes calling a professional with special equipment is cheaper than eliminating the consequences of independent attempts.

We offer you to familiarize yourself with the Vibrator for concrete with your own hands

Maintenance

If you notice that the heating system has begun to function incorrectly, then you should carry out a step-by-step problem solving.

This must be done in a timely manner so that the structure is not damaged, and the operation is without negative impact on the atmosphere in the room.

Let's figure out how to carry out a quick repair of frequently occurring problems of the Russian stove, which is also called current, since it is necessary all the time.

Lack of traction

The draft inside the chimney can disappear precisely due to insufficient maintenance of the furnace structure. To prevent this problem from ancient times, aspen firewood has been used for heating, which helps to clean the chimney. Heat the stove with aspen chips, make sure that the smoke coming out of the chimney changes its color from black to light gray.

The formation of soot inside the chimney occurs due to the use of low-quality raw materials when firing in the furnace. Garbage incinerated in the structure carries the greatest danger, therefore it is strictly forbidden to use it as fuel. Heating with raw wood can also lead to the formation of a large amount of soot.

You can clean a brick oven through a special metal door, or using a special device through the chimney pipe on the roof of the building, which is presented in the form of a long cable with a heavy load and a brush at the end.

Cracks

Due to the appearance of cracks and cracks in the furnace structure, serious problems may arise during its operation:

- Cold air enters through the holes and the efficiency of the heating system is significantly reduced;

- Carbon monoxide gas may escape from the holes, which can cause poisoning and suffocation of those in the room;

- Small cracks can expand and if they are not eliminated in a timely manner, then a major overhaul of the structure will be required.

But on the building materials market today you can buy a special solution for brick stoves and fireplaces, which is used to cover up the holes that have appeared. The most popular are: "TerraKot", "Pechnik", "Parade". The correct consistencies are indicated on the packaging.

If visually visible damage has appeared in the furnace structure in the form of cracks, breaks, cracks or other holes, then you should not panic - these problems can be easily solved without calling specialists. Purchase a spatula and a special compound intended for the repair of fireplaces and brick stoves in advance, then you can proceed with the current repair of the heating system structure.

- Clean the appeared damage from dust;

- Prepare a solution of the desired consistency from the purchased mixture, in a small amount so that the excess solution does not harden;

- Using a spatula, seal the previously cleaned cracks;

- Allow the solution to dry; for visual beauty, the places of the repair work carried out can be treated with whitewash or special paint.

Under strong mechanical stress and high temperatures, between the masonry and the fire door or the hob, gaps may appear, which lead to gases hazardous to human health entering the room. To eliminate this problem, it is necessary to seal the furnace door or hob with a special cord and repair mortar. All of this can be purchased at a hardware store.

The Russian stove is a unique structure, one of the features of which can be considered a possible independent repair, without the involvement of a stove-maker, whose services are quite expensive. Sealing the holes between the masonry of the furnace door and the hob is one of the easiest jobs to implement:

- Clean the area between the metal element and the masonry, from dust and dirt;

- Wash the gap, prime and process with heat-resistant oven glue;

- Purchase a specialized fireproof cord in advance;

- Insert the cord into the hole between the masonry and the fire door or hob - it will compensate for temperature changes and protect the solution from cracking;

- After that, rub the hole with the repair mortar using a spatula;

- Let the composition dry for at least a day.

You can save on the services of a stove-maker not only during routine repairs, but also when carrying out major work to eliminate serious problems.

Including with your own hands, you can re-lay the firebox, replace the firebox, restore the masonry and solve other problems.

In this case, only a specialized solution and refractory materials should be used in order to prevent the appearance of additional problems during the operation of a Russian brick oven.

Despite the properties of refractory bricks, over time, it becomes unusable, therefore, timely replacement of this component of the structure is also necessary. Do-it-yourself re-laying of the firebox is a rather complicated process and is often trusted by a professional stove-maker, but in order to save money, overhaul of the stove can be carried out independently.

Possible reconstruction options

There are several options for converting old stoves (Russian stove, "potbelly stove") into a fireplace, they all depend on the initial technical condition of the structure.

One of the easiest options is to update and expand the firebox to the required size, as well as install a glass "Finnish" door. This option is attractive for its simplicity, since there is no need to make drastic changes to the design, it is enough just to properly clean the oven. If you add a glass door and decorate the existing stove correctly, it will be as similar as possible to a fireplace.

The most expensive and time-consuming modification of a stove into a fireplace is a complete disassembly of the existing structure and the creation of a new one. The stove must be completely dismantled, if necessary, pour new sand into the base. Next, make a roofing roofing waterproofing flooring and create a new masonry according to one of the existing schemes.

Minor repairs

If smoke comes out through the crack, it is extremely dangerous for those living in the house.

Even minor faults require some preparation.In accordance with the work plan, consumables are purchased, the availability of the necessary tools and replaceable nozzles is checked. It is recommended to do a general inspection to identify other deficiencies. You should familiarize yourself with the technologies for small repair of a brick oven with your own hands, together with methods for recognizing defects.

Sealing cracks

The violation of the tightness is accompanied by a noticeable deterioration in the composition of the atmosphere in the room, with characteristic traces of soot. Eliminate the problems as follows:

- clean the damaged area, remove poorly attached pieces of plaster, deepen the cracks by 1.5-2 cm;

- create a working solution in proportions (in parts): sand (10), cement (1), clay (3);

- moisten the crack with water, rub the prepared solution;

- level the surface.

For accurate localization of damage, the oven must be preheated. It is necessary to prepare in advance the appropriate materials (tools) if the restoration of the decorative coating is planned.

The firebox is built of red brick - this is a violation of technology, a replacement is needed

The damaged structural element is removed completely, the old mortar is removed around the perimeter of the hole. A suitable brick is selected, the size is checked and there are sufficient gaps for correct installation. For styling use a liquid solution. It must be prepared by analogy with the original mixture that was used in the construction of the furnace.

Ensures that the bricks and the composition of the mortar are consistent with the components of the overall structure. At the same time, the stability of neighboring elements is checked.

Over time, the grates burn out, so they are replaced with a solid grate.

Do-it-yourself brick oven repairs are performed taking into account the uneven expansion of individual elements when heated. The acquired grate is mounted with gaps on the side of the ends. A technological gap (4-6 mm) is left along the perimeter, which is filled with sand. Taking into account the peculiarities of a certain design, they ensure the normal position of the installed part, control the slopes.

In this case, preliminary dismantling of the furnace is required. Next, take out the bricks, remove the mortar, clean the work surfaces. The masonry is restored according to the original drawings.

We offer you to familiarize yourself with Making a water filter with your own hands

Hog repair

According to the standard scheme, this structural element is located in the attic, so good lighting must be provided before starting work. When checking, the L-shaped transition to the horizontal section is especially carefully checked. If large cracks (1.5-2 cm) are found, minor repairs will not work. In this situation, the transfer of the corresponding part or the entire hog is performed.

The door can be put with heat resistant glass to watch the flame

Algorithm of actions:

- completely dismantle the fasteners;

- clean the working area;

- holes are drilled using an electric drill;

- install wire holders, a door;

- the protruding parts of the wire clips are bent into seams to provide a depression of 1.5-2.5 cm into the structure of the building structure.

Fireplace decoration: choosing the right material

Converting a stove into a decorative fireplace is not very difficult. This is mainly required in cases where an ordinary stove is already installed in the house, which is no longer used. It will not take a lot of effort and money to create a modern stylish fireplace from an ordinary stove that can heat the house, and in addition bring comfort to it.

Often, old stoves are located in houses in the kitchen or in the central room. The stove takes up little space, but the appearance leaves much to be desired.

We offer you to familiarize yourself with Ideas for giving with your own hands - Vegetable garden, garden, balcony

To convert the stove into a modern and stylish fireplace, you will need the following materials: bricks, cement, masonry mortar, chimney (to replace the old one), facing tiles, a glass door, as well as tools for minor repairs that every owner will certainly have. ... Next, you need to draw up a personal drawing of the fireplace to be created.

Another important requirement is that there should be a small gap between the base for the stove and the foundation of the house - about twenty-five centimeters, it must be completely covered with sand.

After these conditions are met, you can proceed to checking the chimney pipe. The requirements for its height are more than seven meters, and the cross section is more than 13 by 25 centimeters. And the last step is to provide for the presence of channels that can direct air flows along the doors, which will not allow soot to settle on the glass door all the time.

Particular attention should be paid to the appearance of the former stove. If you keep the old case, it may not look aesthetically pleasing enough in the interior of the room. This can be corrected with the help of competent finishing.

The time taken to finish the fireplace depends on the complexity of the decor.

Old masonry can be rendered beautifully if it is handled well. Using an abrasive material, you need to remove excess mortar from the seams. You can also update the seams by making them bulging. Another interesting decor option is to renew the seams with a solution with a colored pigment.

Brick trim can be painted with heat resistant paint

The brick itself can be painted with heat-resistant paint. If it is preserved in excellent condition, it will be enough to cover the brickwork with a paint and varnish composition that is resistant to high temperatures.

This method of finishing work can be considered one of the simplest and most affordable. Plaster does not require installation, such as stone or tiles.

The plaster mixture for the fireplace must be sufficiently strong. To do this, add salt and finely chopped fiberglass to the plaster. To add color you can add lime-based paint.

Before starting work, it is advisable to heat the fireplace, since the surface should be slightly warm. You also need to moisten the surface. The plaster is applied in several layers. The first layer must be applied with a trowel, the walls of the fireplace must be leveled. When it is dry, you can start applying the second coat. Its thickness should not exceed half a centimeter.

The layer is applied with a trowel or brush and smoothed in a circular motion. To apply the plaster with a wave effect, use a sponge or rubber trowel to apply the second layer.

Various types of natural stone are used to decorate fireplaces. The most difficult thing to work with is granite or marble, as it is a fairly durable material that cannot be processed without special tools. You can decorate the fireplace with such stones as limestone, shell rock, as well as rubble stone.

A cheaper finish is the use of artificial stone. You can purchase it or make it yourself. To do this, you should prepare in advance silicone molds that imitate real stone blocks. A mixture for artificial stone consists of cement, sand and paint of the desired shade.

A fireplace portal can become a real work of art if you apply curly stone carvings

Particular attention should be paid to the fireplace portal. Uneven stones can be stacked together to simulate a furnace from the days of knightly battles. A fireplace made of marble blocks will add luxury to the furnishings. You can build stone columns or use natural stone in several colors.

Another common finishing material for stoves and fireplaces is tile.

Several types of material are used:

- clinker tiles;

- porcelain stoneware;

- majolica;

- terracotta.

Before tiling the fireplace, remove the coating left over from the stove. You can leave it only if you first pull the metal mesh over the fireplace and fix it with self-tapping screws. The base of the fireplace is leveled with glue. When the mixture is dry, you can fix the tiles.

You can use a fireplace converted from a stove two weeks after finishing. Heat the hearth with only dry logs. During the first kindling, you need to check the operation of the chimney, assessing whether there is an unpleasant odor in the room. Smoke can go into the room due to too strong or weak draft in the chimney, as well as due to errors in calculations.

Natural or decorated stone, which gives sophistication and presentability to the appearance of the fireplace, is an excellent solution for such purposes. Ordinary heat-resistant brick is also quite popular - it would seem that it is a completely unpretentious material. In addition, the variety of ceramic tiles on the modern market can correspond, perhaps, to all kinds of decorating solutions that came to mind of the apartment owners. If you don't want to deal with decor and cladding, you can contact the knowledgeable masters of their craft.

How to clean the oven from soot

The soot in the stove does not accumulate as quickly as in the chimney. This is due to the fact that when the fuel burns out in the bunker, there is a continuous movement, so the soot does not have time to accumulate. When there is a need for kindling the stove, firewood is put in it. From time to time they are turned over using a long metal rod or poker. After that, ash is cleaned from the stove. Such actions are necessary in order to keep the structure clean.

The constant formation of soot can even lead to a complete blockage of the chimney.

In addition to minimal cleaning of the stove from soot, it may be necessary to thoroughly prevent cleaning. This includes:

- grate processing;

- cleaning the walls inside the structure;

- cleaning the entrance and exit to the chimney device.

These preventive measures are carried out exclusively after cleaning the chimney.

Chimney cleaning instructions

Today, there are several options for cleaning the chimney from soot:

- standard cleaning;

- high temperature cleaning;

- chemical method.

Chemical method

Chemicals are used for preventive cleaning. They help remove a thin layer of soot. Commercially available products can be supplied with or without brushes. The most popular are:

- "Kominchek";

- "Chimney sweep";

- "Composition against carbon deposits."

The substances can be used for chimneys that are not equipped with a smoke circulation system. Stove makers most often recommend the "Log Chimney Sweep" composition, which contains salt mixtures. They undergo a catalytic reaction that can cause the soot to break down. The powder should be added to the firebox along with the fuel. The tool works for about 30 days.

The cleansing effect lasts several days

Gloves must be worn when handling powders. It is not recommended to visit the house 5 days after cleaning, as an unpleasant smell will remain. After processing, the building needs mandatory ventilation.

High temperature cleaning

Another method that can be used to remove soot from the stove and chimney is high-temperature cleaning. Features of this method:

- it is dangerous, since it is necessary to work at elevated temperatures;

- suitable for substantial dirt, when the stove and chimney have not been cleaned for many years.

Sequencing:

- First of all, you need to prepare aspen firewood.

- The logs must be put in the oven and set on fire.

- When the fire covers all the fuel, open the dampers so that the stove burns out. This method can be used to blow through the pipes with hot smoke.

High combustion temperature provides powerful thrust

The method is effective exclusively for sound ovens. If the device is old, cracks may appear on the inside after cleaning.

The classic way of cleaning

To get rid of soot, you can use a brush with a load.

It is important to choose a tool that is most suitable in size to the cross-section of the chimney

The tool is a metal brush with a rope, at the end of which there is a wire or rope with a weight. Any iron object can be used as a weight: a weight, a piece of metal or a bearing. Part weight must be at least 3 kg. The length of the rope should be slightly longer than the length of the chimney pipe. The edge of the ruff should reach the stove in order to be able to thoroughly clean the channels. For cleaning, you will need to lower the brush into the chimney device and clean the walls with rotational movements.

You need to clean the chimney in clear calm weather.

This should be done with caution. In order not to fall from a height, it is recommended to tie a rope around the body and tie it to the roof. If the chimney is not heavily clogged, the cleaning process will take approximately 30 minutes. When rotating, the brush will scrape off debris and soot from the pipe walls. When the pipe is cleaned, you will need to remove the debris from the stove. You should also clean the view and the walls of the firebox.

Video: instructions for cleaning the chimney

Cleaning the well and coil from soot

Wells should be cleaned at least once every 3 years. They are located on three sides of the stove, except for the one where the hob is installed. At the entrance to the well, half of the brick lies on its edge.

- You will need to find voids by tapping with a trowel or spatula on the structure.

- Next, remove the plaster and take out part of the brick, which is the door to the well.

- Ash often settles in the wells, which must be removed with a scoop or deep shovel.

- After cleaning the wells, they must be covered with bricks and covered with a quick-hardening solution. Plaster or a mixture of clay, lime and water will do.

A lot of ash accumulates in the wells. It should not be thrown away, as ash is a good food for the garden.

The grates can be cleaned with household chemicals for washing various products.

Wait until the oven cools down before cleaning the grates.

To clean the coil, use a mechanical or steam-air method. It is difficult to do this work with your own hands. The steam-air method is burning fuel in a closed coil by supplying steam or air and heating the structure to the temperature required for burning. Mechanical cleaning is a time consuming operation that is carried out exclusively by specialists.

How to clean the stove with folk remedies

The easiest option is to use table salt. Thus, a thick layer of soot cannot be cleaned, therefore the method is used most often for prevention. For cleaning, salt must be added to the wood and allowed to burn out.

Another way is to use potato peelings. The released starch will begin to interact with the soot and then break it down. The consumption of raw materials depends on the size of the stove, on average 1 bucket takes.

Potato peels are poured onto burning coals

Preparatory work

Before making fireplaces with your own hands from the stove, it is worth measuring the sources.

It is necessary to check the following parameters of the Russian stove:

- Examine the stove for chipped brickwork or other damage. Check if the solution has weakened. If several bricks are deformed and may fall out, the stove will need to be completely disassembled. Notice if the inside of the oven is made of refractory material.

- Estimate the dimensions of the combustion hole. Since stoves were used as a heat source or for cooking, fireboxes were often small in size. To determine which insert is right for your fireplace, measure the dimensions of the room. The furnace should occupy 1/50 of the area of the room.2 parts of the height are 3 parts of the width. Consequently, the size of the furnace hole should be calculated so that when multiplying the width by the height, an area equal to one-fiftieth of the area of the room is obtained. The depth of the firebox must be at least 50 cm.

- The construction of a fireplace depends a lot on the foundation. The space between the foundations of the floor of the room and the stove should be about 25 cm. The gap should be filled with sand.

- The chimney should be examined carefully enough, since all further work of the fireplace depends on it. A strong draft must be generated in the chimney. The minimum permissible chimney height for a fireplace is 4.5 meters. The optimum height is 7 meters. The duct pipe should be such that a whole brick could easily be inserted into it.

If the stove has not suffered much over the years of operation, then it will be enough to expand the furnace hole and install the door

After checking the material and calculations, it is easy to determine the methods of how to make a fireplace out of the stove with your own hands. If the stove has not deformed at all over the years, it will be enough to expand the furnace hole and install a glass door. If the chimney is too narrow for the fireplace, you will need to dismantle the chimney. In the case of a weak foundation, the only way out is to completely dismantle the old stove and install a new fireplace.

Possible causes of oven malfunctions

The old stove can be completely repaired or some of its components can be moved.

Typical troubles are explained by various damage to the structure. When cracks appear, the tightness is broken. Deterioration of draft provokes clogging of the smoke exhaust system. A large temperature difference (inside the channel and the ambient air) can damage even high-quality masonry over time. In some situations, defects are formed due to user errors during operation.

In order to properly repair the stove, a preliminary check is needed. It is recommended to pay attention to relatively rare design problems:

- with the same height of the pipes located nearby, the smoke sucks in the second (inoperative) hole;

- supply ventilation performance may not be enough for the simultaneous operation of several heaters;

- the normal movement of air into the firebox is impeded by a closely installed staircase;

- exhaust ventilation outlet is made in one channel with smoke removal;

- the permissible number of pipe turns at an angle of 90 ° has been exceeded;

- air vents are installed too close to the fire door;

- the output channel is created not high enough, too narrow (wide).

Smoke obstruction can create soot deposits inside the pipe

It is recommended to clarify the external conditions. In the above situations, wind flows can provoke forced "pushing" of smoke into the building:

- the pipe is installed incorrectly in relation to the protruding ridge of the roof;

- parasitic turbulence is created by a large tree, another structure.

Converting the stove into a fireplace

The very first action that needs to be done before installing a new fireplace is to prepare a future drawing. All dimensions must be suitable for the old foundation.

Converting a stove into a fireplace takes place in several stages:

- The furnace foundation is reinforced with waterproofing. Roofing material is used as a waterproofing material. Several layers of material are placed on a clay-cement mortar.

- The next step is to install the base under the fireplace. You can build a new base or put in an oven if it is in excellent condition.

- The firebox is made according to the new drawings, since the furnace firebox is not suitable for a fireplace. To create a base for the firebox around the circumference, the structure is lined with brickwork.

- The firebox itself is being built. The walls should be made vertical.It is advisable to check the clarity of the lines of the future side walls of the firebox using a building level.

- Correct calculations are also important at the chimney construction stage. It is laid out with brickwork. Each several rows need to remove excess solution from the inside of the chimney, since soot may remain on them as a result. Because of this, the chimney will have to be cleaned frequently.

The air duct can be made not only of bricks. You can consider the option of a sandwich pipe, the streamlined shape and smooth walls of which do not impede the exit of smoke from the fireplace.

How to disassemble a brick oven: the procedure and features of dismantling furnace equipment

Now we proceed to disassemble the stove in the room. To do this, open windows and doors to bring in fresh air. We take a bottle of water, put a spray on it and spray water on each brick of the row that we will disassemble. Splattered? We do not regret water in this matter, but it is better for us, less dust will fly. Now gently knock with a hammer and slowly remove brick by brick. You can, of course, with a sledgehammer) So the whole stove will quickly fall apart. BUT it's too dusty, and then suddenly you will need these bricks for something, you never know what happens. The more carefully you do everything, the better for you. Well, and so on until the very end. The bottom line is simple: spray, disassemble. And yet, before proceeding directly to breaking the stove, take care in advance about where you will put the old bricks so that you do not drag them from place to place later. That's all, actually. After all this, you just have to clean up and take out all the trash. Good luck!

No matter how good the old stove is, sooner or later, many of its owners come to the conclusion that it needs to be disassembled. The reasons are different: the desire to expand the living space, the acquisition of an alternative heating system, the desire to change the interior design. In general, there are many reasons. The stove can be partially disassembled by converting it into a fireplace or simply rebuilding several partitions.

If you decide to disassemble an old oven, take a close look at it. Any work begins with the head, at the stove it has a chimney.