Thoughtful 19th century furnace

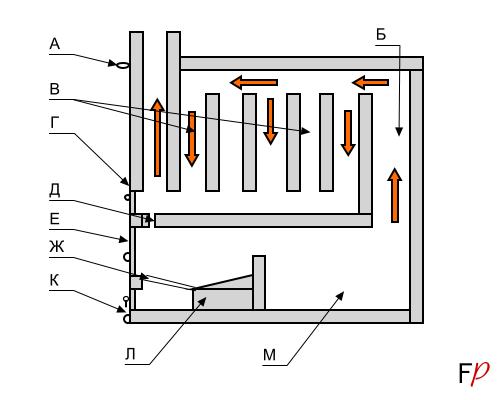

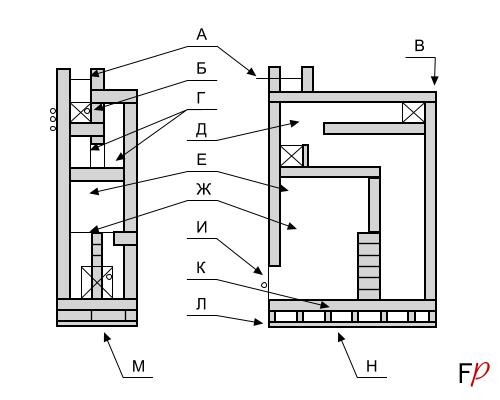

Heating stove, the diagram of which is shown in the figure

| Fig. 17. Diagram of one of the most technically thought-out furnaces of the 19th century | |

| A. Common draft gate B. First lift well C. Parallel wells D. Clean-out door E. Direct draft suction E. Furnace door G. Grizzly plates K. Blowing door L. Under the furnace M. Afterburner chamber |

> This stove can be easily converted into a cooking-heating stove if the firebox is taken out to the side of the stove, correspondingly equipped with a stove, and the bottom of the flue ducts is lowered to the floor level.

A feature of this furnace, which was obviously developed by V.A.Stroganov, is the presence of: a) afterburner chamber; b) technically competent distribution of the direction and location of the channels, allowing to achieve uniform heating of the entire area of the smoke wells of the furnace; c) a calibrated direct draft suction hole; d) just one cleaning door, which makes it easy and simple to clean all the wells; if necessary, through it, you can get rid of the overturning of the draft in the furnace; e) grate and hearth of the furnace, which are arranged under well thought-out slopes, contributing to more efficient combustion of fuel residues than in furnaces with a strictly horizontal arrangement of the grate and hearth of the furnace. The stove with this arrangement of chimneys will evenly warm up over its entire heat-transfer area. The draft in such ovens is always good.

4. A heating stove with horizontal smoke wells (Fig. 18) is good in that it does not require strict and precise fixed markings at the chimney outlet. In pre-revolutionary times, such markings could only be done by a senior kiln master. The marking of the foundation and the laying of the first row has never been entrusted to apprentices. And not at all because it was a "matter of honor." The reason for this strictest subordination was by no means a formality, but the possibility of committing a fatal mistake.

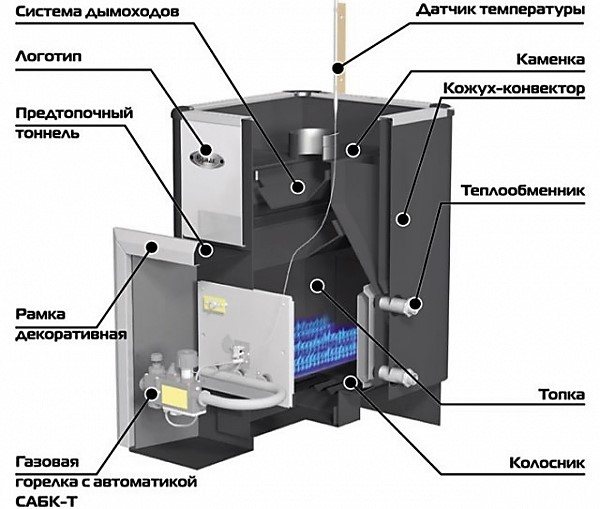

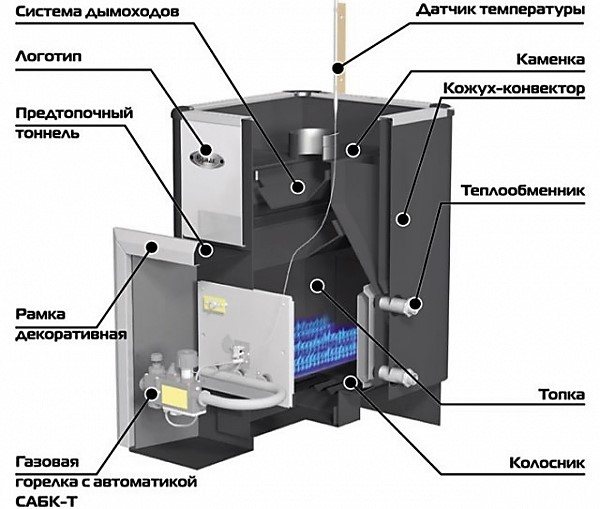

Drawing conclusions

All of the above parameters and features, with the right choice and further operation, will provide heat to the available areas, as well as exclude the use of an electric oven. It is worth paying attention to the fact that any gas systems have detailed instructions, so you can do all the work yourself, without the involvement of specialists.

Thanks to this, the owner will fully familiarize himself with the available technical characteristics and internal content, and will also be able to save significant money. At the end of the work, it is better to invite a qualified stove-operator to make sure that it is safe to use.

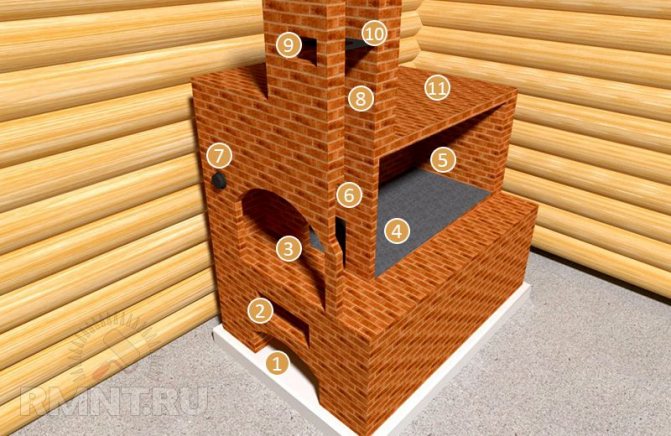

Heating stove made of bricks by Sergei Mikhailov (drawings)

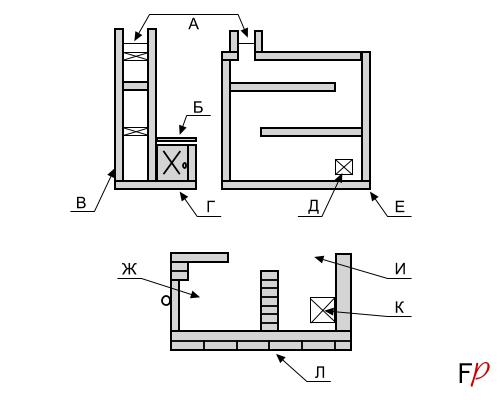

| Fig. 18. Oven by Sergei Mikhailov. The location of all technological units of the furnace is given taking into account the recommendations given in this chapter. | |

| A. Common draft gate valve B. Stove C. Chimney section (front view) D. Furnace door E. Exit from the furnace to the first well (hailo) E. Chimney section (side view) J. Furnace I. Stove K. Haylo L. Section of the furnace furnace (side view) |

The fact is that the senior kiln master had to "keep in mind" the whole oven. He "saw" all the higher ceilings, directions, the number of future chimneys, etc. All this is true now, but not in relation to stoves with a horizontal arrangement of smoke channels. Such a stove (Fig. 18) does not require any special design skills, because all the technological difficulties in the chimney "linking" the dimensions of the stove move from the horizontal plane to the vertical one.

Furnaces with horizontal wells were undeservedly forgotten.The cause of forgetting is either ignorance or ignorance of the laws that I described in chapters 28 and 29 of this book. There is an opinion that stoves with horizontal wells are supposedly quickly clogged with ash, it is more difficult to clean them, etc. This is absolutely wrong. You can get rid of these completely unfounded prejudices by reading the chapters above in more detail.

Now I will limit myself to only a brief listing of the main advantages of a furnace with horizontal wells: a) does not require an exact calculation when marking the first row; b) it warms up evenly (the hottest parts of the furnace, which allow intensive heat removal, are at the bottom, and the less hot ones gradually move to the upper zone of the heated room); c) cools down evenly (heat from the lower rows of the furnace is gradually transferred to the upper rows. And since the period of intense heat transfer and cooling of the furnace is the same period, measured in several hours, this is another plus of the furnace with horizontally located smoke channels); d) allows you to completely integrate arched dryers into the oven masonry (Fig. 19).

It is recommended to place the oven on a trench hearth (see fig. 1 and item 11 of chapter 15).

| Fig. 19. Sergei Mikhailov's stove with a built-in niche-dryer, side section (the proportions of the combustion chamber are shown in Fig. 18) | |

| A. Gate valve B. Clean-out door C. Dryer D. Clean-out door D. Haylo E. Sectional view of smoke wells, side view | |

| Fig. 20. Scheme of wells: summer and winter options, side section | |

| A. Winter valve B. Summer valve V. Haylo | |

If the customer relied entirely on my choice, I have always preferred a horizontal well stove. "Complaints" about this type of stove were surprisingly monotonous: for every extra log thrown into a burning furnace, one had to pay with the unbearable heat in the house.

5. Smoke wells, the diagram of which is shown in fig. 20, can be useful when laying a heating and cooking stove, taking into account the "summer version".

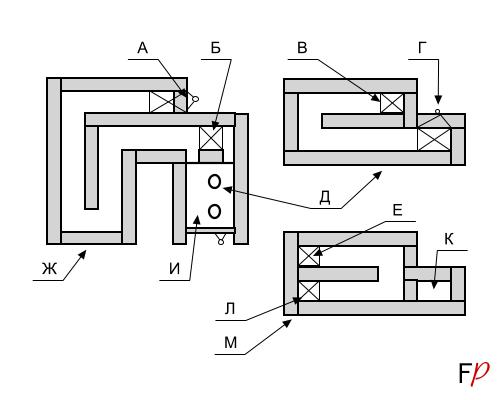

6. The furnace, the horizontal sections of which are shown in fig. 21, allowed the author of this book to heat it once a day, even with the onset of prolonged 35-degree frosts. At the same time, the air temperature in the room never dropped below + 19 °.

The features of this furnace scheme are as follows: a) eight short horizontal wells; b) the maximum area of heat transfer in the lower part of the furnace (it is recommended to lay the furnace on a trench hearth, see Fig. 11, as well as paragraph 11 of Chapter 15); c) significant heat capacity; d) additional gate valve with "summer option"; e) a horizontal portable "lounger" on which it is convenient to dry wet shoes, clothes, etc.

Classification of gas ovens

Today there are a number of all kinds of modifications of hearth gas ovens used both for cauldrons and for baking bread, which can easily compete with an electric oven. Therefore, in order to determine the most suitable model, it is necessary to clearly define the necessary parameters on which future work will be based.

Gas ovens can be classified into three types:

- heating, intended for heating and used in private households;

- heating, designed to provide hot water supply;

- household, intended for a cauldron, baking bread and heating rooms with a large area.

For example, for a bath, it is better to mount a heating heating system, which can have various cladding options, the type of burner, as well as the technology and method of heating the water available in the bath. It is not safe to use an electric stove.

Author's brick oven by Sergei Mikhailov

| Fig. 21. Author's stove by Sergei Mikhailov. | |

| A. Winter valve B. Summer haylo C. Entrance to the fifth well D. Summer valve D. Section of the second row E. Entrance to the seventh well J. Section of the bottom row of wells I. Fire chamber K. Pipe L.Exit from the eighth well in the sixth M. Section of the third row |

7. The heating stove on the trench (Fig. 22) has one (in my opinion, insignificant) drawback: it does not have grates. Deaf under (no grate) in cooking-heating and heating ovens in Soviet times was even prohibited by a special directive! The reason for the ban was "unsatisfactory combustion of fuel in such a firebox, firewood, and even more so coal, peat and briquettes." The "All-Union Generalissimo for Stove Construction", to put it mildly, has gone too far in this matter. But when using coal, peat and briquettes as fuel, it is really impossible to do without a grate in the furnace.

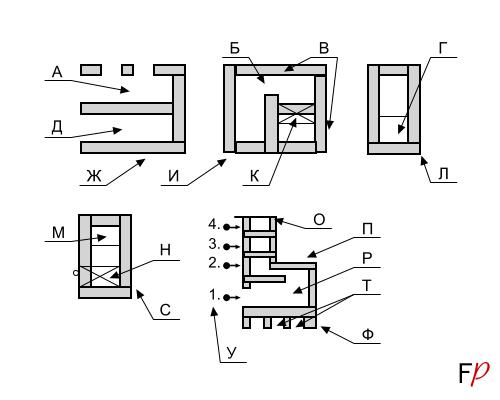

| Fig. 22. Author's stove-fireplace by Sergei Mikhailov. | |

| A. Empty well B. Entrance to the first well C. Lezhak D. Entrance to the second well D. Fire chamber J. Section of the first row I. Entrance to the third well K. Khailo L. Section of the third row M. Entrance to the third well N. Catch O. Latch P. Lezhak R. Fireplace C. Section of the fourth row T. Shantsy U. Numbering of sections F. Vertical section, side view |

A feature of this type of oven is: a) the presence of a remote (high) "lounger"; b) the absence of a stove door, which tells the stove many of the advantages of a fireplace with its high efficiency; c) very good heating of the lowest layers of air in the living room. But this is very important when there are small children in the house - as you know, they spend most of their time on the floor. Note that bread is baked well and evenly in this oven. I also had to heat this stove only once a day, even during the most severe and prolonged frosts. Many authors of books on stove that I respect, express serious doubts that a stove with an open fire door will keep the house warm. Indeed, in this case, the inner walls of the smoke wells are cooled with air that does not participate in the chemical processes of complete combustion of the fuel. All of this is true. But not for the type of oven shown in fig. 22. After all, as mentioned above, she has no stove door at all.

Why is that? I will briefly explain: a) the area of the inlet was, of course, not a fireplace, it had a height of 25 cm and a width of 30 cm. Even the smallest increase in these dimensions would necessarily lead to a weakening of the overall draft of the stove and even to the fact that it would start to smoke; b) there were no grates in the oven; c) a high firebox, obviously, significantly slowed down the speed of movement of air masses, and the air slowly passing through the firebox had time to warm up thoroughly. A characteristic feature of this furnace was that after three years of its intensive operation, I could not scrape together even 500 grams of ash residues at the entrance to the first horizontal rise (where the most ash usually accumulates).

8. In fig. 23 shows a diagram of a Dutch cooking and heating woman on the trenches. Actually, there are no Dutch cooking and heating women. Dutch woman Is a heating stove without a stove, the wells of which are located above the firebox.

Rotary ovens

It is difficult to imagine the full-fledged work of any bakery or confectionery production without the use of such equipment as rotary or hearth ovens. Such rotary ovens can be tunnel and hearth, differing in the type of activity, are economical and easy to operate, which allows you to cope with large volumes.

Such an infrared portable oven can be either gas or electric (heating occurs thanks to heating elements or a burner). Rotary ovens are quite economical, and an automatic system with an understandable and convenient touch panel allows you to set the start of work at a specific time. Existing locks make the workflow much easier and avoid unpleasant moments.

Dutch woman made of bricks by Sergei Mikhailov

| Fig. 23. Designer Dutch oven by Sergei Mikhailov. | |

| A. Latch B. Clearing door C. Passage to the fourth well D.Double wells D. transition to the third horizontal well E. Nisha J. Slab I. Furnace door K. Shantsy L. Fireproof masonry M. Front section N. Side section |

But there is a popular belief that the stove, the wells of which are located above the furnace, is a Dutch woman. And in the outback, any stove is generally accepted for a Dutch woman, at least slightly different from the classic Russian one.

This oven is convenient in rooms with limited space. Its characteristic features are: a) a vertical post at the rear of the furnace, designed to support the stove; b) trenches, which greatly increases the area of intense heat removal; c) horizontal wells, the merits of which were mentioned in paragraph 4 of this chapter; d) significant (almost maximum) heat capacity, intended for furnaces of medium power, periodic furnace. It is indisputable that stoves designed for a permanent fire can have a high heat capacity. But it should be borne in mind that the combustion processes in continuous furnaces, and even more so in furnaces designed for solid and liquid fuel, as well as the principles of constructing a furnace and furnace wells (continuous operation) will differ significantly from the principles recommended for batch furnaces (1, 5-2 hours of heating in the morning and evening every day).

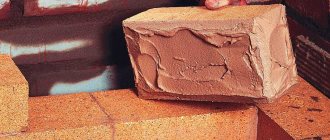

Briefly about the differences between batch and continuous ovens, the following can be said. With intermittent heating, after 0.5-1 hour, the inner surface of the walls can heat up to 800-900 ° C. Hence the inevitable appearance of cracks and ruptures in the furnace seams already in the first year of operation of batch furnaces. With continuous firing, fuel consumption is sharply reduced (as applied to coal, gas and liquid fuel) and the heating temperature of the walls is reduced to 450-500 C. Therefore, fireboxes of intermittent furnaces are usually lined with refractory bricks (the temperature limit of high-quality red bricks usually reaches only 700-750 C), and fireboxes of continuous stoves do not need this (excluding the use of anthracite).

9. In fig. 24 shows a diagram of a kitchen summer stove.

Advantages of a hearth gas oven

This infrared design for the kitchen, cauldron, baking bread or firing ceramics has a number of advantages that distinguish and affect its wide popularity, in contrast to the electric model.

The most important positive quality that gas stoves for summer cottages and cauldrons have is economy, even if you use a cylinder. This is due to the relatively low cost of gas and the degree of its availability.

You can save significant money on maintenance of a gas hearth furnace when compared with an electric or solid fuel model. Equipment that runs on gas does not require excessive attention and is quite easy to use, unlike the electric model. There is practically no soot and ash in such a device, the chimney and firebox practically do not need to be cleaned. There is no need to talk about durability, since it is difficult to find an analogue in terms of operating time.

The simplest brick kitchen stove

| Fig. 24. The simplest kitchen oven. | |

| A. Latch B. Spark-extinguishing tooth C. Slab D. Fire chamber D. Slab E. Side cut G. Front cut | |

Characteristics:

a) very low height of the firebox - only 21 cm (if someone does not like this size, the height of the firebox can be raised, but in this case, you will need two to three times more firewood for cooking). It is best to use an old picket fence and unnecessary remnants of lumber as firewood in a stove with a similar furnace height. Two or three old pickets will be enough to prepare a full meal in the summer for a family of six.However, in our time, when the majority of rural residents use gas or electricity for cooking, an oven of this height is unlikely to find its mass user;

b) the presence of a spark extinguishing tooth and the absence of everything superfluous.

Gas oven models

All types of gas heating devices are united by their simplicity in their operation. Let's take a look at some of them:

- Gas heaters connected to a cylinder. They are lightweight, compact and easy to use. They can warm up the house well in a short time.

- Stoves with a coaxial chimney are very expensive, but they can be installed not only in a private house, but also in an apartment.

A gas stove is a great solution for creating warmth and comfort.

It is better to contact a specialist who will help you install it, observing all the rules and regulations, which will ensure a safe and comfortable stay in the house.