Among the entire range of heating stoves, a special place is occupied by the slobozhanka - a device for long burning. This device is characterized not only by energy efficiency, but also by the relative cheapness of the fuel used, which can be almost any plant raw material. Even people who are ignorant of the construction trade will be able to equip their household with such a device. It is enough to have a blank and working equipment with you.

Before embodying the idea with your own hands, you need to prepare. The required toolkit consists of the following items:

- a hammer;

- drill or drilling machine;

- chisel;

- electric welding machine (automatic or semi-automatic);

- grinder, for which both cutting and cleaning discs are useful;

- any general purpose welding electrodes.

From the materials you need to have: several parts of a pipe with thick walls, sheet steel in the form of two fragments with a thickness of 5 and 10 millimeters and a barrel (alternatively, you can take a gas cylinder or a steel cylinder).

What is the benefit of autonomous heat generators of long burning

Why are standalone stoves more profitable than centralized heating? The fact is that powerful industrial heating boilers with 100% efficiency lose up to 30% of heat when passing through the main and distribution pipelines. Autonomous heating works without heat loss, and its performance is determined by the efficiency of the boiler used for heating. Homemade stoves can be unpretentious in appearance, but have an efficiency of more than 90%. You can heat them with wood, coal and waste.

Efficient and economical wood-fired pyrolysis boiler keeps heat for a long time

How pyrolysis proceeds

The pyrolysis process goes through four stages:

- Drying - excess moisture is removed from the wood. It is carried out during the preparation process or in the firebox due to its heat.

- Pyrolysis - sublimation of volatile components, decomposition of heavy components - resins and bitumen to volatile. The fuel mass begins to carbonize, that is, char.

- Combustion of pyrolysis gases upon reaching the flash point under the influence of high temperature and free oxygen. Carbon combustion begins when the temperature rises above 600 degrees.

- After the combustion of volatile components and the bulk of carbon, reduction reactions begin - the release of carbon monoxide, free hydrogen and oxygen.

In order for the efficiency to be high, when designing the equipment, it is necessary to ensure that the reducing gases are retained in the hot zone and heated fresh air is provided there. When it cools down quickly, the energy spent on recovery will fly out into the pipe. It should not be forgotten that carbon monoxide is poisonous.

Note: One of the main advantages of a slow burning oven is ease of use. Once or twice a day, firewood is loaded into it, once or twice a week, ash is raked out.

For car enthusiasts

Initially, the stove was created for heating greenhouses, poultry houses, workshops, for drying rooms. Slobozhanka especially delighted motorists, those who have a small workshop in their garage. And there are already many craftsmen who make garage ovens with their own hands. After all, this is where a reliable and simple heating system with a high level of safety and efficiency is required.

Do-it-yourself Slobozhanka stove can be made quite easily.For garage owners, both homemade and industrially manufactured Slobozhanka are equally effective.

By the way! One fuel load allows the furnace to operate for up to 10 hours, that is, a whole working day. That is, it is enough to light the stove in the morning, and the whole day of work in the workshop will be performed in a warm room.

The stove is fireproof, which is of particular value for motorists. Volatile combustion products through the chimney system are completely removed outside the premises, eliminating the possibility of carbon monoxide poisoning. It is also worth noting that the chimney for a stove or boiler must be taken seriously, because neglecting this can be poisoned by carbon monoxide. In addition, Slobozhanka's modifications appeared, capable of operating on used engine oil. Compact heating devices provide comfortable working conditions and can significantly save on fuel.

Solid fuel stove potbelly stove

Outside the cities, firewood is the most affordable, so the most popular long-burning stove is wood-burning. It is heated not only with firewood from the ridge, but also with waste wood - shavings, sawdust, fiberboard and chipboard waste, small brushwood, straw, etc. There are many heating systems for wood and wood waste. Let's consider the most efficient ones, the efficiency of which is more than 70%.

The simplest potbelly stove can be made by hand

The potbelly stove is an economical stove that appeared in Russia after the revolution, during the war communism, when many had to endure hardships. The genius of the potbelly stove is that it instantly warms up, as well as the simplicity of its device, the prototype of which is the Russian stove. The upper door is for storing firewood, the lower one is for regulating combustion by supplying air through the slightly open door.

The task of the stove is to keep warm in at least one room at a minimum cost. When using coal, the grate is removed, and the air from the blower is directed to the firebox. It is important not to stuff it with a jam - the volume of the bookmark should be no more than a quarter of its volume. The afterburner is a long horizontal or slightly inclined part of the chimney. Made of metal, it keeps the room warm.

Important! The potbelly stove can operate on all types of solid fuels, except for sawdust. It is made in the form of a box from sheet steel or round from a barrel. Chimney diameter - 85 - 150 mm.

Such a potbelly stove will not only warm, but also decorate the interior.

When stoking any potbelly stove is red-hot, so its upper surface can be used as a cooking stove. On the sides, a screen should be installed at a distance of 40-60 mm from the oven. It protects the room from infrared rays and maintains the temperature at an optimal level.

On the basis of a potbelly stove, you can make a homemade boiler for long burning on wood. To do this, instead of the screen, a U-shaped metal water heater is installed. The distance between the furnace body and the boiler should be the same as the screen offset.

Straw house

Kievans Irina and Aleksey Kravchenko built a country house out of straw for themselves. Not a hut, but a two-story mansion with excellent renovation. There was no problem to buy a brick and make it "like the people" - Irina is the findirector, Alexey is also the chief accountant of the wholesale business there, so they can afford to build a dacha. But I wanted a special home. To live in harmony with yourself and nature. Therefore, Irina and Alexei decided to build a house, observing the basic Vedic principles in construction, such as the orientation of the house relative to the cardinal points, proportions, purpose and arrangement of rooms.

- This is our training house, - Irina clarifies, - only having built it, I realized what kind of house we needed. We have the goal is to create a family estate in our ecovillage Nutcracker, such a piece of the Motherland for our three sons.

European straw manor, first snow on the roof

- Will the estate also be made of straw?

- Absolutely, since the tested technology has fully justified itself, despite the mistakes made. For example, we used drywall, which, as it turned out, is applicable only in combination with heating with radiators in each room, since it does not allow heat to pass through, but accumulates cold.

In addition, straw does not tolerate emptiness, but between straw coated with clay and drywall a good 5-7 cm. This space is now a thermos of cold and a place for mice to live.

Or the attic is a source of heat loss, since traditional roof insulation (mineral wool and polystyrene) cannot be compared with straw bales, it does not hold heat so well. Finishing of such a "broken" space is much more expensive, and repair and maintenance of the roof is difficult.

It was better to make the second floor and the non-residential roof, insulating the ceiling with straw bales. But, despite the mistakes made, the house is more than competitive in terms of heat saving.

The reputation of the straw house was ruined by piglets

Thatched houses are nothing new. They began to be built many centuries ago. In different parts of the world. And they built it in different ways. One of the options - the straw was dipped in clay, pulled out and stuffed with the help of formwork into a wooden frame. Since the invention of the baler, straw technology has entered a new stage of development. If you use straw soaked in clay and stuff it into the formwork, then the process of erecting walls on a house of 100 sq.m. will take 3-4 months and some time to dry, depending on the climate and weather conditions. Straw bales, on the other hand, allow finishing the erection of the walls in 3-4 days and for some time for plastering immediately, without leaving the straw open for a long time. The faster the better.

- We in our house experienced the most severe frosts - when it reached 30 degrees, - says Irina, - during the Epiphany frosts, all the neighbors left for the city, despite gas heating, electronics, electric heaters. The neighbors' walls were frozen through and through. And my children and I had a great time outside the city. They stoked it in a stove.

Straw retains heat better than brick 4 times and 7 times better than concrete. And it is easier to breathe in a straw house - it is made of natural material. Yes, you go through, you will see for yourself.

Inside the house it smells like wood, straw. On the ground floor there is a living room, a bedroom, a bath-toilet, a nursery. On the second - the room of freedom. The entire area under the roof is not blocked by anything, one continuous space. And there is no furniture - carpets and pillows on the floor.

- What about strength and fire resistance? No wonder they say: it burns like straw ...

- The reputation of the straw houses was greatly spoiled by the fairy tale about three pigs, - Aleksey laughs. - This is a straw house in the cartoon scatters from the fact that a wolf blew on it. In fact, such houses have been standing for several centuries, and their walls are fireproof.

Check - with the help of tests: the wall is burned with fire for some time and they see through what interval it can catch fire. So, a straw wall made of bales withstands 45 minutes of direct exposure to fire, while the lime-cement plaster cracks and charred, the straw under it also charred a little, but never caught fire. Such indicators are considered superfire-resistant. Straw clay is smeared outside and inside. And clay is a refractory material. Straw for building a house is used pressed, in dense briquettes. Setting fire to a briquette is not so easy - it's like with paper: a sheet will take over quickly, but a thick book cannot be set on fire so easily.

The stove heats the water in winter, the sun in summer

This system works simply - water is supplied by an electric pump to a tank installed in the attic on the pediment, from a well and from a tank it flows by gravity to all plumbing points - a sink, a shower cabin, a toilet bowl, a kitchen sink and a washing machine, infrared saunas, as well as a tank installed in the oven for heating water.

“In winter, hot water is heated by a stove,” says Irina. - And in the summer, when the stove is not heated, solar collectors will heat the water, now we are installing them. We have already tested their work on a dacha shower, the efficiency exceeded all expectations.

- I expected to see a hut with straw “feathers” sticking out of it.And you have a completely modern home. How did you build it?

- The walls are made of bales of straw - remember, as in "Well, wait!" the wolf drove a combine and everything that he raked fell out of the car in the form of briquettes.

The bales are tight - you can't stick your hand. The height of such a straw bale is 36 cm, width - 45, and length - 90 cm. This is the cheapest material for building a house - straw brick costs $ 1. In total, 400 bricks went to the house - consider, $ 400. Brick walls would cost us $ 6,000.

It is best to use rye straw for building a house - no one eats it, the poet does not start in it, therefore rye straw is used in agriculture for bedding for animals or simply burned.

In addition to very favorable cost, heat-saving qualities, we were attracted by the fact that straw is a rapidly regenerating resource. So a tree needs 30 years to grow to become a building material, in straw for six months. Of course, the heat-saving properties of straw when heated with gas or electricity significantly reduce the consumption of these already heavily depleted resources.

Having laid out the walls, they are smeared with clay.

- Did you smear it yourself?

- Yes, together with friends. How were houses built before? The whole village got together and built a house in a couple of days. Then the whole village is satisfied with Toloka. We also arranged - we called all friends and relatives along with the children. They brought two trucks of clay from the quarry, prepared a festive table. And all together they kneaded the clay and straw with their feet, threw it at the walls like snowballs and smeared the clay on the walls and on each other - all to the music.

The holiday lasted for two days. This is such a boost of energy! Our guests demanded the continuation of the banquet. And the next weekend we kneaded the clay again - smeared the inner walls. There was no need to call anyone, but everyone called and asked if it was possible to come again.

Then the specialists started to work - the interior decoration of the house began. But we are a bit tough with specialists, so most of the work was still done by friends who quickly learned from specialists. I must say, it turned out not only not worse, but sometimes even better. The main thing is to do it with a soul.

Stove in a straw house

- And how was the stove laid out?

- This is a separate story. We invited a stove-maker from the village of Lukyanovka - an 80-year-old grandfather. You should have seen how he laid! In one breath. Tired - a brick under his head and sleep for an hour or two, back to work. The guys asked to teach him, and he says that it is a woman's business to create a hearth, so his grandmother taught him, and her mother, and so from time immemorial, women put the stoves.

- Is the well also your job?

- And, of course, they dug a well. We have only central electricity. Water, heat and sewerage - autonomous. We plan to make autonomous support in Kedrovka as well - it is much more reasonable than pulling pipes in all sections, and more environmentally friendly.

- Will Kedrovka be a village of straw houses, or will everyone build their own dwelling, from what they want?

- Of course, from whatever he wants. We just tested this option and suggest it as the most economical and environmentally friendly. You can, of course, build a wooden house - also a natural material. But, firstly, there is no good tree in Ukraine, and secondly, forests are already cut down, and you also want to breathe and preferably clean air now, and not in 30 years, and the straw will resume in one season.

If there is bread, there will be building materials. $ 400 for walls, here add a roof, ceilings, a floor - such a construction is within the power of almost every family. And finishing inside is a flexible cost. Can be sheathed with cork, or wallpaper can be glued. The main thing is that the house is reliable, economical and comfortable. Checked.

Interviewed by Svetlana Skarlosh, Newspaper in Kiev

Share the post "Interview: Mansion made of straw with" European-quality repair "- the main thing is to do with soul"

This entry is also read:

- How to bring water into the house? List of questions for which ...

- A linen house - a new know-how as a substitute for straw?

The first method or boiler number 1

The natural vortex is replaced by forced pressurization, and pyrolysis is divided into two stages in space: a pyrolysis chamber, a nozzle (nozzle) that forms a flow of pyrolysis gases, and a combustion chamber. The nozzle is made so that there are no parasitic turbulence behind the mass of fuel. For full control over the process, a through-blow is required.

Features of direct-flow and heat storage pyrolysis boilers:

Note: the type of fuel affects the pyrolysis rate and the composition of the gases. These factors are taken into account by regulating the outlet back pressure by throttling the chimney. Regulators for industrial solid fuel boilers are marked with the recommended fuel type.

The efficiency of once-through boilers can be higher than 90%. They require a power supply to operate. When shutting down, for further start-up of the system, it is necessary to scoop out the caked mass and make a new bookmark in the firebox.

Steam-free solid fuel boilers use different types of fuel

Functioning principle

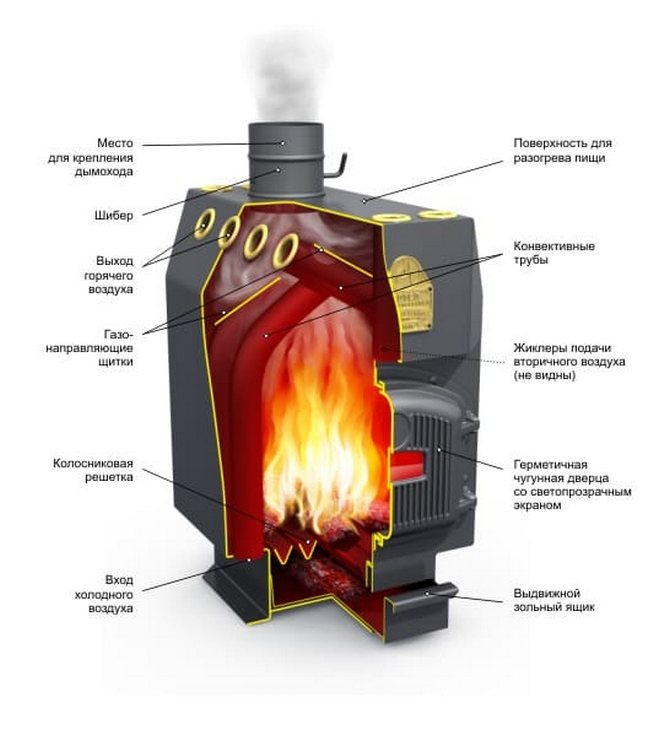

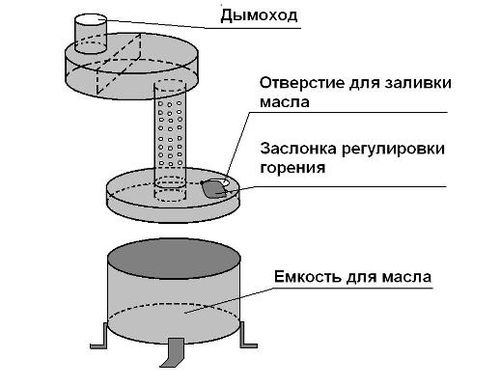

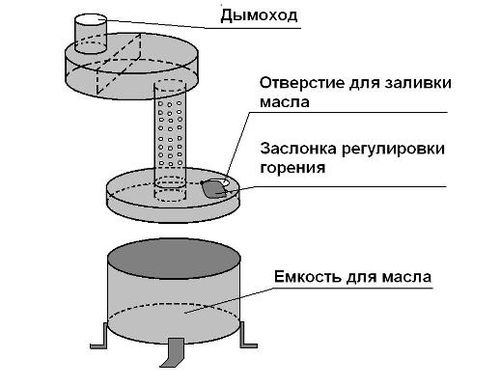

The Slobozhanka stove has the following operating principle. The fuel burns out gradually, starting from the top layer and ending with the lowest, that is, from top to bottom, and not from bottom to top, as in classic stoves.

The air heats up and transfers thermal energy to the walls of the case, rises upward, warming up the chimney.

The degree of oxygen supply intensity, and hence the temperature, the intensity of combustion (smoldering) are regulated by dampers, there may be several of them, it all depends on the design features of a particular model.

The combustion chamber has a "jacket" through which cold air is sucked in from below, it heats up during its passage and, when it leaves the stove, heats up the room, providing continuous circulation of air masses. The volume of heated air in most cases is regulated using a reflector cover, which also allows you to adjust the temperature in the room.

From theory to practice

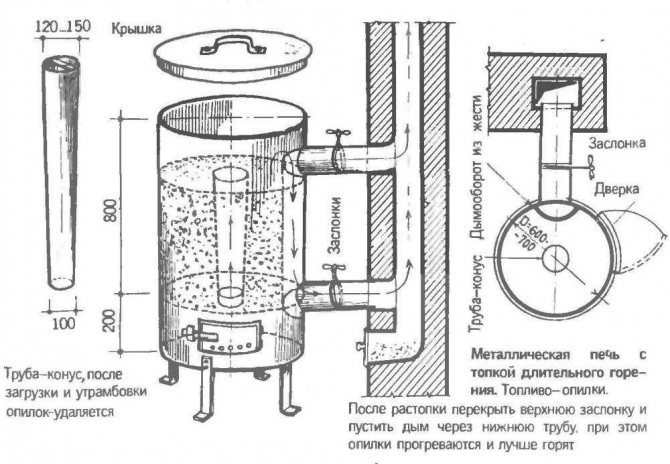

So, let's move from theory to practice. Let's take a model with a central air supply to the combustion chamber.

We need to make an air supply and distribution channel. It is made from a thick-walled pipe. Just take a piece of pipe along a length that does not exceed the height of the combustion chamber. At the bottom, you need to weld the bolt. Then cut a penny out of sheet steel in a diameter equal to the diameter of the pipe, drill a hole and fasten it to the bolt with a nut. It turns out that the pipe in the lower part is closed by a penny shifting along the axis, and the intensity of oxygen supply to the furnace depends on how closed the section is, and therefore the nature of fuel combustion and the temperature in the room. Using an angle grinder, cut grooves in the pipe for supplying air to the firebox with a width of at least 10.00 mm. You also need to weld the circle. To do this, cut out a "pancake" from steel - a circle with a diameter smaller than the diameter of the combustion chamber, cut a hole in the center corresponding to the diameter of the pipe. It remains only to put the circle on the pipe, 20-30 centimeters and weld. Now let's move on to the body. You can use a gas cylinder, barrel, or weld a sheet steel cylinder. In a cylinder or barrel, it is necessary to cut off the upper part, and weld the bottom in the cylinder; In the upper side part of the body, a hole is cut for a chimney, with a diameter of at least 100 mm for the removal of combustion products and welded on a pipe of the corresponding diameter; A hole is cut in the center of the bottom for the installation of the oxygen supply pipe we have made. The hole diameter is equal to the outer diameter of the pipe, which is installed as an air duct; We turn to the manufacture of the heat-dissipating disc. Use sheet steel 10 mm thick.Cut a circle in diameter slightly less than the diameter of the body, you can weld a handle from steel wire or reinforcement for convenience; Next, we need to make a convection jacket (oven casing). To do this, take sheet steel and weld a cylinder with a diameter that exceeds the diameter of the main body of the stove by a few centimeters. It is difficult to imagine a Slobozhanka oven without a convection jacket; We connect the main body and the convection jacket. For this, cylinders of the solid or tubular type with heads can be used. Make the holes with a drill. Then fasten the heads to the rivets with a riveter; We make a cover for the main body

You can take the cut off top of the cylinder or the barrel lid and weld the handles from reinforcement or large diameter steel wire; An important condition. The stove must be at least 25 centimeters above floor level. This is necessary to ensure air circulation in the convection jacket.

Therefore, do not forget to weld the legs, for example, from a corner of the appropriate length to the body.

This is necessary to ensure air circulation in the convection jacket. Therefore, do not forget to weld the legs, for example, from a corner of the appropriate length to the body.

As you can see, the Slobozhanka oven is not easy to assemble on its own, but very simple. The only thing but, as noted above, heating devices of this type can differ significantly in design features, so adhere to the selected drawing and general recommendations specified in our article.

The second method or boiler No. 2

A pyrolysis boiler with a water heater, which does not require electricity and automation, works according to the principle of opposition of the two laws of a square-cube. This refers to the filling of fuel and the lining of fireclay bricks. The algorithm of the brick kiln:

The loading of wood or coal into the boiler with a thermal buffer is carried out gradually. Sharp temperature fluctuations are contraindicated for her. If too sluggish fuel is used, it can stall. If the fuel is too flammable, there is a risk of an emergency. If the first heat is not suppressed, the efficiency will not exceed 76-78%, since instant heat transfer from the lining to the outside is excluded.

Principle of operation

Fuel for long-burning furnaces can be:

- coal;

- pellets;

- peat;

- household waste;

- firewood.

Each fuel has advantages and disadvantages. For example, the main advantage of coal is its high heat transfer. But more often than not, users prefer wood, because this type of fuel is available, and if the greenhouse is not very large, then it will be enough to load firewood into the firebox once a day.

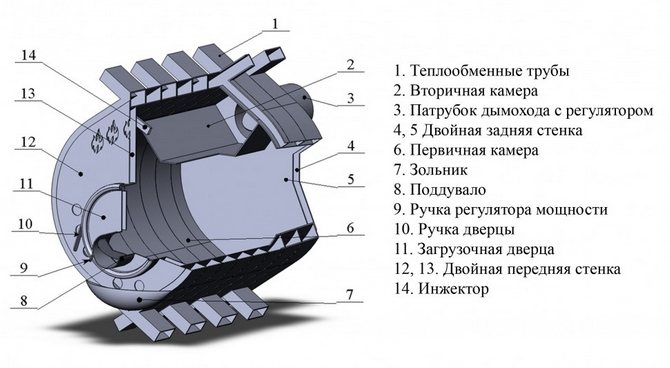

The main details that are present in each greenhouse oven:

- Combustion chamber: the combustion process takes place in it.

- Channels that redistribute the movement of air.

- Convection jacket.

The operation of the long burning stove is based on the continuous burning of wood for 18-24 hours. The logs completely burn out and after them there is practically no ash left, on this basis, the oven can be cleaned once every two to three weeks.

In order to load fuel less frequently, it is recommended to use brown coal and hardwood logs.

English fireplace

There are legends about the attractiveness of fire, its decorative and aesthetic function is of great importance for a person.Can an ordinary person build a long-burning fireplace in his home in order to enjoy not only the warmth, but also the beauty of fire? The main thing in such devices is not heat transfer and efficiency, but the ability to contemplate fire during the day.

English-style fireplace made with your own hands will decorate your interior

There are such designs, and the British came up with them. The classic English fireplace has a smoke tooth, reminiscent of a sill in a Russian stove, which forms the circulation of flue gases, which does not let fresh air upward, directing it to the bookmark, as it happens in a stove.

Due to the large mouth, the efficiency of the fireplace is small - no more than 50%, even if there are smoke flows in the chimney. Smoldering and heat generation from evening to morning occurs only when using Cornish coal or similar coking coal. They say that in the old days the English lords stoked fireplaces with the rhizomes of pines growing on the coastal rocks.

An example of another "long" fireplace is a common Dutch woman. The blower is closed before kindling, the firewood is loaded onto a quarter of the furnace, its door remains wide open. Most of the heat escapes into the pipe, but the decorative effect is ensured.

Preparatory process

The kindling of the Russian stove is a kind of ritual that does not tolerate fuss and haste. It is imperative to prepare the kindling, dry firewood, open the view and check the draft.

How to choose firewood?

I well remember how firewood for the Russian stove was stacked in a separate woodpile in the woodshed. Selected dry logs of the same length, fairly even. If you suddenly came across wet firewood, then they flared up badly and smoked terribly, it was difficult to breathe in the rooms. Of the trees, preference was given to birch, it burns evenly and hotly, and emits a large amount of heat.

Hardwood wood also burns out perfectly and leaves a minimum of soot: oak, ash, beech. Now they began to heat Russian stoves with peat briquettes, pressed shavings and straw. But you can't do without firewood. For sufficient heat, a few logs are first burned to form charcoal, only then briquettes are placed on top.

Oak firewood

How to prepare the kindling?

A stock of birch bark and finely chopped splinters should always be kept in the flood. On occasion, birch bark is brought from the forest or peeled off with a sharp knife from already chopped logs. A luchina, the size of pencils, is splintered with a sharp knife or hatchet from even, knot-free logs.

Advice: how to check traction in a Russian stove. Pull the view as far as possible, light a match near the blower door and observe the flame. If the smoke from a lit match goes into the blower, then this indicates good traction. The smoke is not fully drawn out, the room smells burnt, which means the draft is not strong enough. In this case, it is better to postpone the furnace until the evening (when it gets cooler) or a change of weather.

How much fuel should I put in at the same time?

The basic rule here is this: you need to fill with firewood two-thirds of the volume of the firebox. In this case, the logs are not stacked tightly, leaving gaps between them. If you lay out firewood with a well, then two or three tiers, 8 or 12 pieces are enough. When kindling, they put thinner, even and well-dried wood. In the process of burning, fuel briquettes and lower-quality firewood are added.

Firewood in the firebox

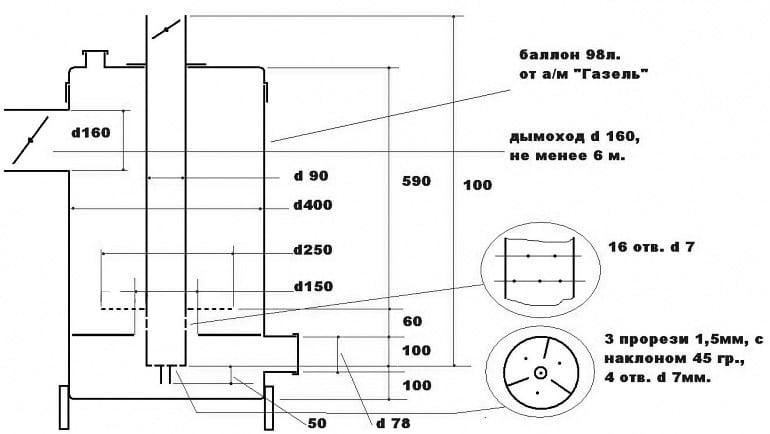

The simplest do-it-yourself stove

Solid fuel boilers of long burning, which were mentioned above, are difficult to make with your own hands according to the scheme. The drawings below will help the DIY master build the simplest heating device on his own. Equipment power - 35 kW, efficiency - up to 85%, burning time - 12 hours. Coal or fuel pellets are used as fuel. Loading with wood reduces the efficiency to 75%, the burning time is reduced to 8-10 hours.

A drawing of the design of the furnace will help you make it yourself

Furnace device

So what is the oven design?

This is a vertical furnace with one combustion chamber, which is loaded with fuel from above. Rather, not just from above, but from above and from the side. This allows you to conveniently load fuel, including during the operation of the furnace, without waiting for the first tab to burn out. At the bottom of the furnace there is a hatch for ash removal, which facilitates the maintenance of the heating device. On industrial models, special dampers are installed to regulate the air supply, as well as the gas outlet. A casing is fixed on top of the combustion chamber, passing through which cold air is heated and removed back to heat the entire room. A special chimney removes volatile combustion products outside the room.

The Slobozhanka oven drawing can be easily found on the Internet in the public domain. Inventors do not hide the characteristics of their development. On the contrary, in their opinion, Slobozhanka will enjoy special trust and demand among rural residents after they learn more about it.

Scheme and the possibility of design improvement

Slobozhanka is a full-fledged miracle wood-fired oven with a hob. Air is supplied to the smoldering tab from the side along a U-shaped trajectory: down the L-shaped duct and then through the perforated casing. Access is provided to all layers, which contributes to more active pyrolysis, therefore Slobozhanka works well on coal and pellets. It is an economical device with an efficiency of over 80%.

The power of the equipment can be increased by complicating its design: stretching the inner perforated casing over the entire circumference. To equip a blower with a throttle, a third narrow casing is made to cover the air intakes from the outside.

Vertical Slobozhanka is made on the basis of a barrel

Slobozhanka with a mushroom hat

The traditional Slobozhanka has disadvantages:

- She does not accept oily and tarry fuels. Household waste, chipboard and fiberboard waste form hard deposits at the edges of the holes in the inner casing and the perforated casing of the air duct.

- Careful refueling of the incomplete bookmark is required, since at least a small smoldering area should remain free near the perforation of the casing. If this is not foreseen, after the bookmark burns out, the stove will cool down.

The design with a central conical perforated air duct with a mushroom head is the development of one of the Soviet p / i. Created on the basis of the Slobozhanka. The cone was freely installed in the firebox discharge hatch and removed for cleaning.

The edges of the cap threw fuel to the edges, and a glowing ring was formed under it, which was necessary to light the stove. Additional loading could be done in any quantity and at any time. Due to the edges of the hat, the air was directed into the decay zone, which ensured the omnivorous design.

The disadvantage of the "slobozhanka with a fungus" was that when burning household waste or raw pine, it was necessary to check the carbon deposits. The cone could stick tightly. To take it out without distorting it, in this case it was difficult.

Necessary materials

Before looking for drawings for the Slobozhanka oven with your own hands, you need to thoroughly prepare. It is necessary to select materials for the construction:

- metal barrel or gas cylinder for the body;

- steel sheets;

- thick-walled pipe for air supply.

You will also need some tools to work:

- crayons or marker;

- electric welding machine;

- chisel;

- grinder, stripping and cutting discs for metal;

- drill with metal drills;

- construction hammer.

To assemble the Slobozhanka stove, which provides long-term burning, with our own hands, using drawings and photos, we will need the following tools:

- electric welding machine (automatic or semi-automatic);

- chisel;

- grinder (angle grinder, do not forget about the circles, you will need cleaning and cutting);

- a drill that can be replaced with a drilling machine;

- welding electrodes ANO, UONI (that is, any general purpose);

- a hammer.

Fuel

As for materials, the assembly scheme assumes the use of:

- several fragments of a thick-walled pipe;

- sheet steel (you can take two sheets with a thickness of 5.00 mm and 10.00 mm.);

- barrels (easily replaceable with a gas cylinder or sheet steel cylinder).