04/03/2017 2806 Pechnik (Moscow) If you want to find an inexpensive and at the same time high-quality material for facing fireplace and stove units, we recommend that you opt for tiles. Tiles for finishing stoves and fireplaces have their own advantages and distinctive features, having familiarized yourself with which in more detail in this article, you can be guaranteed to make the right choice.

The main characteristics of the refractory lining:

- Environmental friendliness. When heated, any materials emit substances into the space, since heat-resistant cladding is used in residential premises, it should not contain toxic and hazardous substances.

- Heat resistance. To obtain this quality, the slabs go through one or two firing. This is reflected in the marking with a flame tongue symbol and a number. The result is a material capable of heating at least +1000 degrees C.

- Thermal conductivity. Plates must transmit heat as they are used on heating appliances for space heating.

- Water absorption. This parameter cannot be more than 3%. In the marking, it is indicated by the letter E, and a number that shows the specific values for this modification.

- Strength and rigidity. The thickness of heat-resistant tiles should be at least 8 mm, these dimensions provide the necessary strength characteristics and stop the risk of deformation.

- Expansion at temperatures. This figure should be in the range from 7 to 8%.

- Resistance to mechanical stress. Only fine-pored materials have this quality. The smaller the pores, the stronger the veneer. In the marking, this characteristic is indicated by the letters PEI and Roman numerals up to V, the higher they are, the greater mechanical stress the heat-resistant ceramic plate will withstand.

Important! In addition to technical characteristics, the cladding should have an aesthetic appearance, keep it for a long time not only when heated, but also during temperature extremes, for example, in a bath.

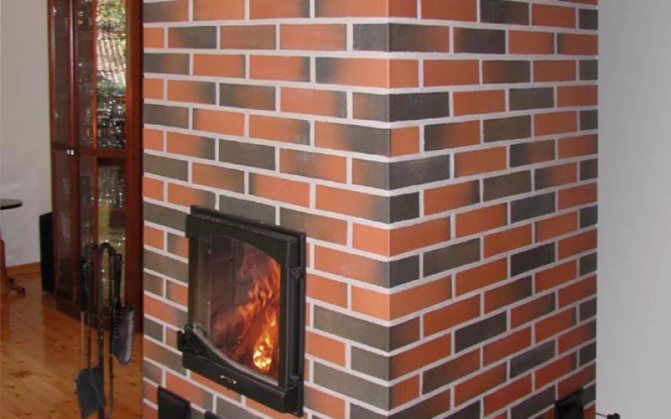

Heat-resistant tiles are stable in contact with open fire

Tile marking (designations)

The labeling (marking on the tile) on the packaging will help you to tell which tiles to use for facing the ovens. Depending on the type of tile, the following can be used:

- Letter "T" - denotes heat resistance.

- The numbers 1 and 2 against the background of the flame indicate the number of burnings. The higher the better.

- Letter "E" and number - water absorption is marked. The higher the number, the more moisture the surface can absorb. For a furnace, the indicator should not exceed 3%. For comparison, the water absorption of granite is 0.5%.

- The designations "A" or "B" on the packaging or the inside of the clinker tiles indicate the technology of their manufacture. Option "A" is more technological and has clear dimensions.

- The PEI index in grades from I to V will indicate the wear resistance of the tile. You can use any for the oven

- The EN 122 standard, ranging from A to D, denotes the product's resistance to chemical attack.

Related article: Do-it-yourself door insulation with a collapsible and non-collapsible canvas (video)

Tile cost

The price of facing tiles and the reputation of the manufacturer are far from the last argument when choosing. Masters advise not to save on purchases, because the constant replacement of cheap tiles will ultimately turn out to be more expensive. The cost of tiles by type is shown in the table.

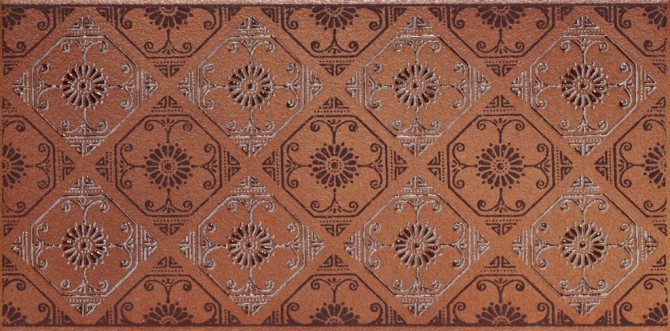

Based on this, it is easy to decide which tiles are needed for facing the stoves. But do not forget that the chosen tiles should correspond to the general style of the interior of the room.

Features of the choice of materials

The choice of refractory tiles for a stove or fireplace is carried out according to several criteria:

- Cost. If the price is high, you should not buy the material less than you need or exactly in the calculation, there will be mistakes during installation.

- Strength. The larger it is, the higher the guarantee of reliability and durability.

- Heat capacity. It is important that the facing layer does not retain heat from the heater and distributes it evenly.

- Porosity. Low porosity guarantees moisture resistance and mechanical strength.

- Thickness. This size cannot be less than 8 millimeters.

- Styling and care. The cladding should fit well and be easy to maintain.

Note! When choosing refractory tiles for the wall behind the stove, hearth or fireplace, you can pay attention to modifications with lower fire-resistant parameters. By design, they can repeat the design of the hearth, harmonize with it or contrast.

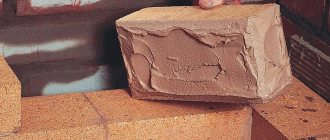

Chamotte finish in package

Styling features

In principle, the installation of the facing layer on heating devices differs little from laying ordinary tiles, but there are some nuances:

- the overall structure can be reinforced with a metal braid with 15x15 cm cells or aluminum corners, these devices are placed between the stove and the tile, they are fixed with nails or self-tapping screws;

- the reinforcing layer is covered with a solution of sand, clay and cement, the mark of which should not be less than M400, experts also recommend adding glue with polymer additives based on aluminate cement to it, the layer thickness should not be more than 1.5 cm, otherwise there is cracking risks;

- if metal elements are used for rigidity, the distance between them and the cladding itself must be at least 1 centimeter;

- the tile is laid through the usual stopper-limiters, when it is all installed, they are taken out;

- the seams between the elements are closed with grout.

Attention! For installation, you need to choose an adhesive with heat-resistant qualities. These can be materials based on alkaline metal silicates. Other species will not be able to withstand the upcoming operating conditions.

Laying the cladding on the oven

Output

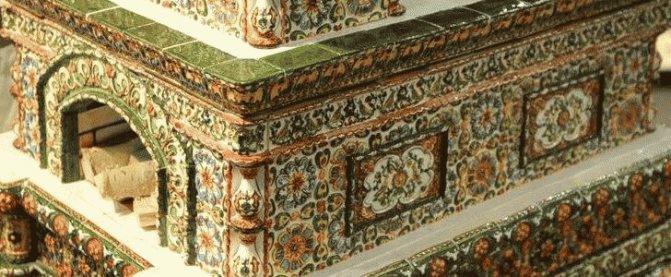

For 100 years, clinker tiles for stoves and fireplaces not only have not lost their relevance, but also managed to reach a qualitatively new level. Production volumes are constantly growing due to huge demand, characteristics are increasing, and buyers still prefer proven brands. It is important to understand that there is simply no alternative for cladding fireplaces and stoves with high-quality material.

The cladding does not provide for repairs and alterations throughout the entire working cycle of the fireplace or stove. As it was done once, so it will be, you should not save on auxiliary materials. Special adhesives, additives and other consumables will greatly improve the quality of the coating.

The fireplace is an extremely fashionable accessory for the living room, both classic and modern. In a country house, you can find both such an option, and a more traditional one - a stove, both Russian and Dutch.

And if the hearth plays only a decorative role, then there are no problems with its finishing - any material is suitable. But when it comes to the current design, questions arise. How it works and how much it costs to lay clinker tiles, we will tell you in this article.

Trade marks

- BayKer. Products of an Italian company. It is produced in a variety of types, has excellent user reviews, effective design, reliable and durable. Cost - from 2 thousand rubles per package.

- Terracotta. Russian product. The manufacturer specializes in the production of tiles and all materials for their installation: glue, mastic and others. Various models. Price - available: from 500 rubles per package.

- Alliance tiles. Russian manufacturer of refractory cladding, porcelain stoneware, clinker. The products are characterized by spectacular design and decent performance parameters. Cost - from 1 thousand rubles.

- Aparici Agate. The Spanish manufacturer offers plain, fireproof and mosaic tiles.The building material is characterized by exceptional performance and author's design. Semi-precious minerals are used in the decoration. Price - from 5 thousand rubles per package.

- Dado Ceramica. Mosaic and standard cladding design with emphasized style and laconicism. Cool tones and urban flair are characteristic of the Italian material. Price - 1 thousand rubles per package.

- Polycor. The Russian manufacturer specializes in refractories. The production has ancient traditions, the workshop was opened in 1894. High quality products with traditional designs. The choice is quite narrow, the cost is from 1000 rubles.

- Mosplitka. The metropolitan enterprise offers a large selection of tiles for residential and commercial premises. Good value for money. A network of retail outlets throughout the Russian Federation, an interesting offer of "own design", regular promotions, flexible prices - from 1,000 rubles.

Important! The refractory material is accompanied by a certificate of conformity, which specifies the exact parameters. It is issued to the manufacturer based on the results of tests in a specialized laboratory.

Fire safety certificate

How the stove is lined with refractory tiles, see this video:

Top brands

- STRÖHER Is a German manufacturer that has been honing and polishing the craftsmanship of ceramic products for over 120 years. Market analysis shows that the most popular tile from this manufacturer is Zeitlos 354 bronzebruch. Its physical dimensions are 240x71x14 mm, the consumption of 48 tiles for laying one square meter, the exact weight of 24.624 kg. The price of clinker tiles for stoves and fireplaces from this manufacturer, excluding related materials, starts at 3500 rubles.

- Feldhaus Klinker - another German manufacturer of clinker tiles with a rich history. According to the management of the company Feldhaus Klinker has been improving its production cycle for over 160 years. The most interesting is the Classic series, which imitates the texture of brickwork. Available in three sizes NF, DF and LDF. The average cost varies between 3500-5000 rubles per square meter.

- King Klinker - a high-tech manufacturer of clinker tiles from Poland. The plant is fully automated, which allows it to carefully monitor the manufacturing process. The most successful series is King Klinker Old Castle, which traditionally imitates brickwork and is available in a single standard size of 240 x 71 x 10 mm. The cost of King Klinker products differs markedly, downward, from manufacturers from Germany. The approximate price range for 1 square meter is 1500 - 3000 rubles per square meter.

- ABC-Klinker - another German manufacturer with a worldwide reputation. Clinker tiles for cladding ovens produced under the ABC-Klinker brand are distinguished by their durability and reasonable cost. The company is extremely proud of its rich history and strives to 100% meet the high requirements that they themselves set. The most popular series is ABC KLINKER CLASSIC TILE, it has gone through many improvements and upgrades, but has not lost its relevance for decades.

- Is a Russian manufacturer of clinker tiles that is rapidly gaining ground on the market of facing materials for fireplaces and stoves. Due to the quality of products and low cost, production volumes have increased many times over the past 5 years. The enterprise has a multi-stage quality control of both manufactured products and raw materials.

- Cerrad Is a Polish company that was the first to introduce deep firing and dry press methods into its production cycle. The technology is unique in Europe, but this did not affect the cost of production. On average, you will have to pay 1200-1800 rubles per square meter of tiles. According to the official website of the company, the most bought series is Cerrad Retro Brick Salt.

Let's summarize

Fireplace tiles are more expensive than conventional tiles. But the market in this segment is fiercely competitive, so you can find good-quality and inexpensive modifications. To further reduce costs, it is advisable to purchase it from chain construction retailers: Leroy Merlin, Your House and similar retail outlets. Another option is to buy directly from the manufacturer, in which case you will avoid trade margins. But for stoves, fireplaces and hearths, ordinary materials cannot be used, otherwise there will be regular restoration of the facing layer and additional costs.