Types of boilers

Types of boiler equipment:

- gas. Highly effective, but not worth making at home. The units are classified as devices of increased hazard level. Creation requires skills, technology;

A gas boiler

- electric boilers. Unpretentious in terms of creation, operation. You can make your own heater. There are no increased safety requirements;

- liquid fuel. The construction is simple. Any man can handle the work. Difficulty in adjusting the nozzles;

- solid fuel. Effective, versatile. Easy to operate and manufacture. Easily modified, rebuilt for another fuel. The units are also used for heating industrial areas.

It is important to choose the material from which the electric boiler will be made.

Heat-resistant stainless steel has good technical parameters. But she's dear. Equipment is required to process the material. You can choose cast iron.

When making your own, it is better to take sheet steel or a pipe with a thickness of at least 4 mm. Cast iron properties are good. Simple, easy to handle. Ordinary household devices can handle it.

Why do you need a stabilizer for an electric boiler?

A voltage stabilizer is an automation for electric heating boilers, which, like a thermostat, allows you to save money. But in this case, we are not talking about the efficient consumption of the energy carrier, but about the integrity and operability of the heating element as a whole.

A stabilizer for an electric heating boiler allows you to smooth out all the differences in the operating characteristics of the electrical network during the day and get the voltage of the correct sinusoid at the output, which will have a beneficial effect on the durability of the boiler. Stabilizers provide a high degree of protection of electrical appliances from ripple and voltage surges. High-quality equipment is characterized by high sensitivity, which is important for the electronic part of the boiler and the thermostat. Stabilizers are distinguished by an increased margin for the output power of the network. This allows you to maintain the operating characteristics of the electrical network at the proper level even when the boiler is turned on.

Before buying a stabilizer, you must consult a specialist and clearly determine the type of equipment required, its power.

Features of electric boilers

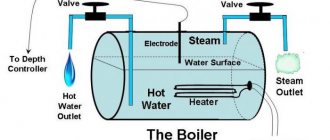

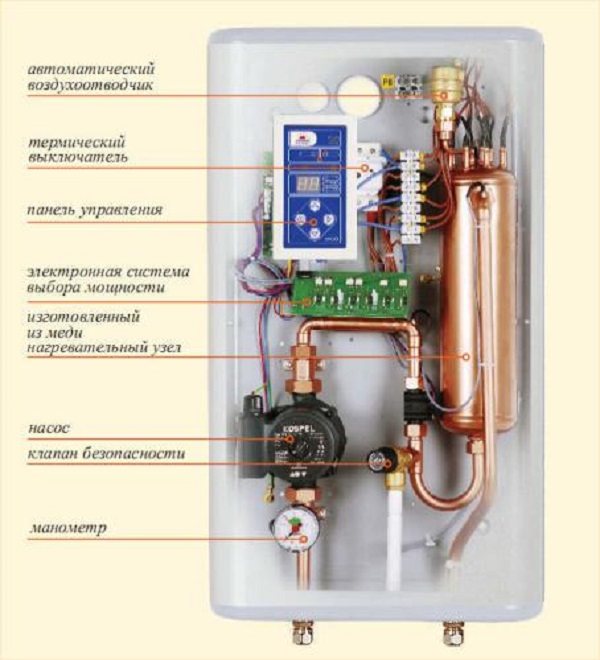

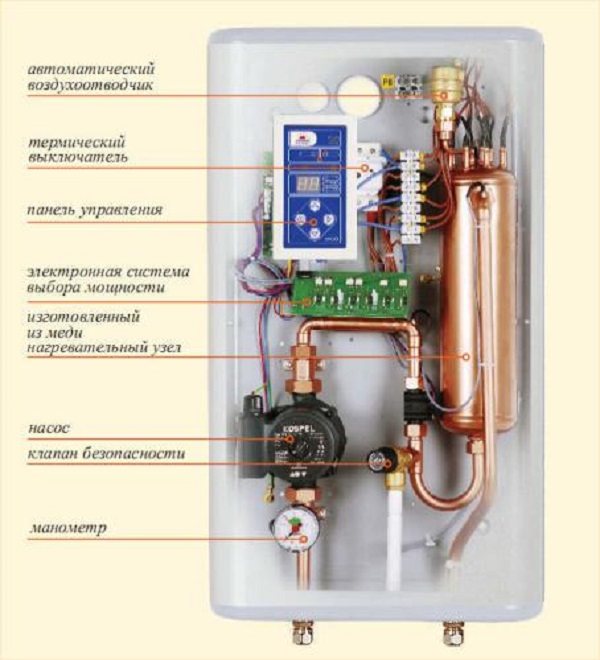

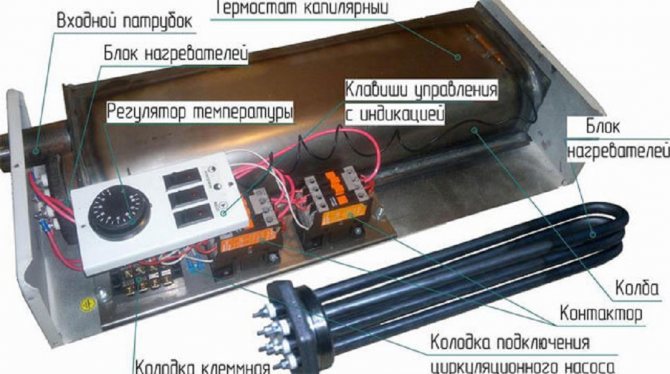

The peculiarity of the electric boiler is a heat exchanger with a heating element for heating water. A pump is used to organize forced circulation. There is an inlet for a cold one, an outlet for a hot coolant.

Design

The mechanism of operation of the heating unit is simple. Cold water is supplied to the heat exchanger. The heating element is heated by electric current. Thanks to the circulation pump, the liquid is distributed to the heating radiators.

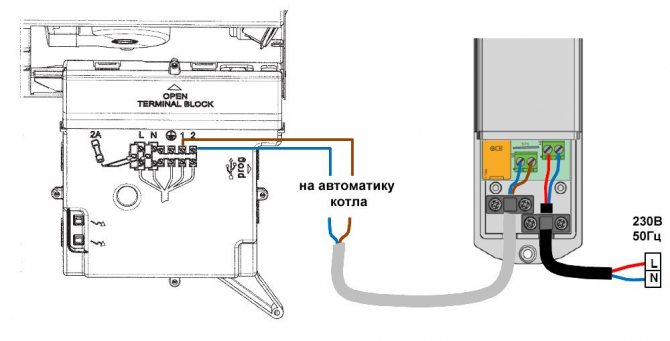

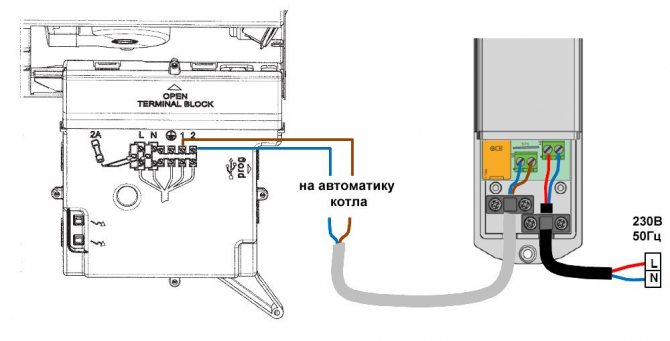

Electrical wiring diagrams

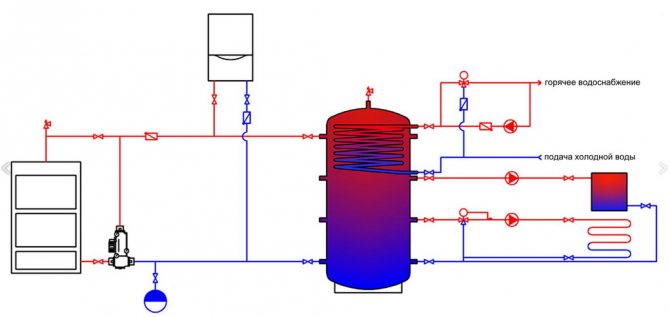

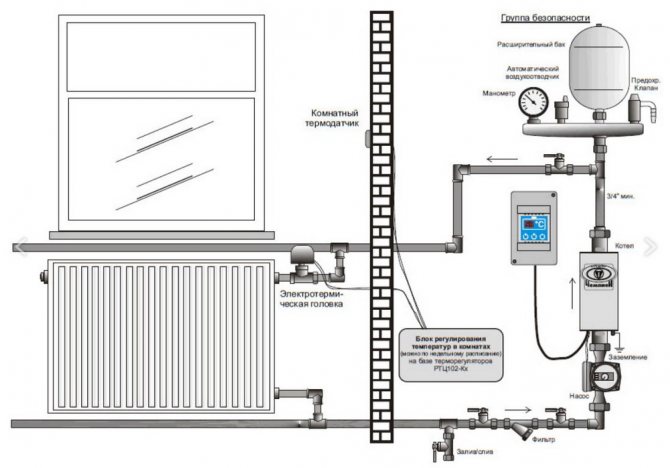

So, to your attention there are several typical diagrams for connecting an electric boiler in a house with your own hands:

As you can see, the projects are quite simple and consist of the water heater itself, a transport line (pipes), a circulation pump and radiators. Your task is to correctly connect all the elements to each other, and then turn on the power supply.

Automation, electrical for manufacturing

The electrical part is responsible for the normal operation of the boiler equipment. For work, an electrical panel is assembled, a three-phase input. The electrical panel is often metal. Comprises:

- tumbler;

- machine gun;

- control buttons;

- relay;

- magnetic starter.

Automation is designed to simplify, ease of control of the unit. Responsible for the safety of the equipment.

Automation

Sensors can be used. They are installed to maintain a comfortable microclimate according to the specified parameters. In case of deviations from the normal operation of the heating system, the sensors turn off everything. Allows you to secure the owners, save property.

Load control relay

This type of device is placed between the input circuit breaker and the load. In continuous mode, the device monitors the total network load, comparing it with the set maximum. If the load exceeds the permissible value, the device automatically shuts off the lower priority electrical circuits, leaving the higher priority circuits to work.

A simple example. The house has three group chains:

- Group 1 power sockets in rooms and light;

- Group 2, power load sockets, electric stove, kettles, iron, maybe a kitchen boiler, as well as outlets in utility rooms;

- Group 3, heating boiler.

Each harness group becomes a priority in any order you choose. Further, each group is connected to the terminals of the load control relay in the order of the selected priority. If the total power of the connected devices exceeds the maximum allowable, then the relay will disconnect the lower priority group and allow the higher priority to work.

Examples of load control relays:

- Load control relay ABB LSS1 / 2,

- Relay off non-priority loads Legrand0038,

- Load relays CDS Schne> Switches by priority

These devices DO NOT monitor the total power of the network. They simply disable non-priority circuits when priority circuits are enabled. For example, if the heating boiler is a priority circuit, when it is turned on, the power sockets of the rooms or kitchen will turn off.

Examples of switches by priority:

- Siemens N5TT6 101-103,

- ABB E450,

- Stiebel Eltron LR1-A.

What to consider when assembling a structure

The electric boiler must have a built-in electrical cabinet. It houses input devices, metering, protection, control of the heating unit. The function of switching the operating modes of the heating system is provided.

The electrical cable from the boiler equipment is fed into the electrical panel. The boiler is connected to the input machine.

Depending on the area of the room, you need to calculate the power of a homemade electric boiler. For 1 sq. m of area accounts for 0.1 kW of thermal power of the heating device. To create a heating system for a house with an area of 100 sq. m you need to make a boiler with a capacity of 10 kW.

The thermal calculation for the house must be done immediately. The cross-section of the wire, elements of the boiler device, automation depend on the power.

It is necessary to lay an electric cable on the territory of the house according to safety rules. If the structure is made of wood, the cable is laid openly or in pipes. For buildings made of stone, brick, foam block, the wire is laid hidden or in boxes.

Homemade boiler

Any twisting, soldering, welding not provided for by the design of the boiler equipment is prohibited.

The boiler requires strict compliance with safety measures.

Correct connection of the thermostat to the electric boiler

When choosing an installation site, it must be borne in mind that:

- installation near windows, ventilation or entrance doors is not recommended due to constant temperature changes;

- heated air masses are concentrated near the ceiling, closer to the floor the temperature is lower, therefore it is recommended to install the thermostat at a height of 1-1.5 m;

- Household appliances in the kitchen can generate heat, which affects the accuracy of measuring the overall climate in the workroom.

- it is not recommended to install too close to a frequently closed door;

- direct connection is not recommended if the load exceeds 10 A (connection is made via a modular contactor).

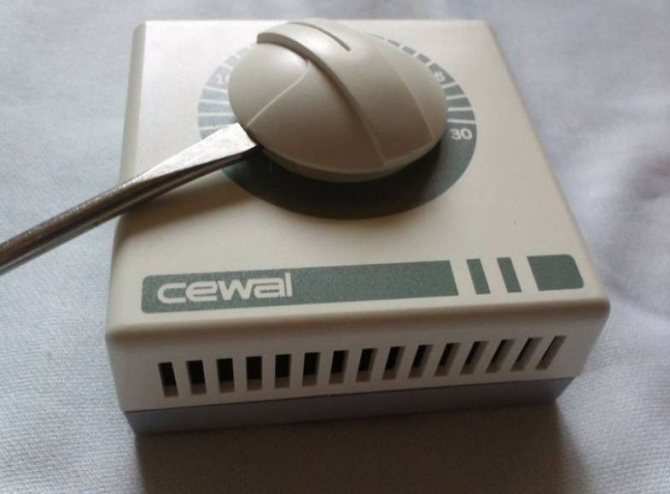

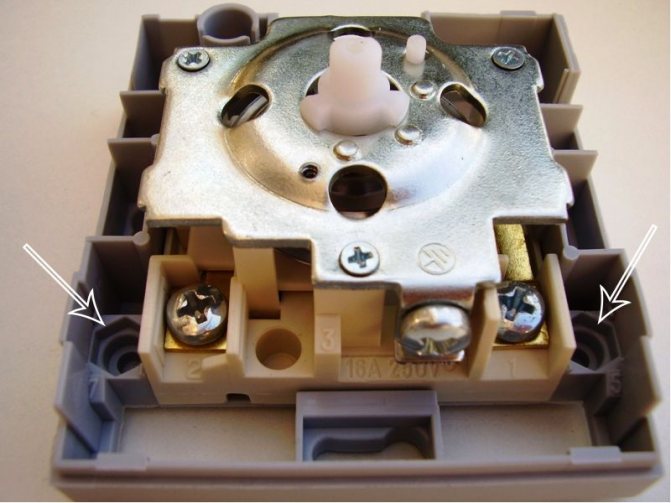

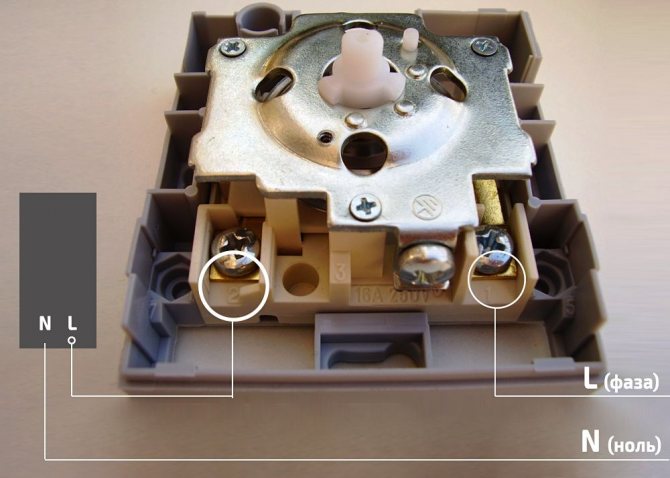

Connection instructions using the example of a mechanical Cewal RQ-10:

| Photo | Process description |

| Remove the rotator |

| Unscrew the screws by removing the front cover of the thermostat |

| Attach the device to the wall using the appropriate holes |

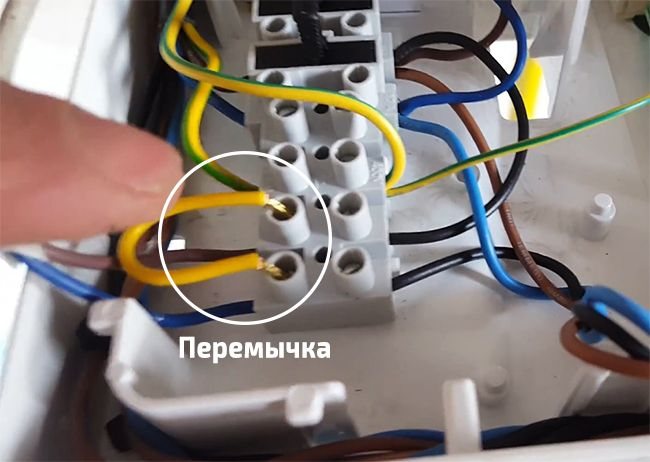

| Connect the ground. According to the diagram in the photo (click to enlarge), it is necessary to connect the thermostat contacts to the electric boiler board. |

| Individually... There can be a jumper between the "TA" contacts of the boiler board; it must be replaced with a two-core insulated cable with a conductor cross-section of 0.5-0.75 mm 2. |

Modern thermostats are powered by AA batteries, but connection to the mains may also be required according to the diagram below:

Connection diagrams and a detailed algorithm are described in the instructions for each of the thermostats. However, each case is different and requires certain basic knowledge and skills. Therefore, the traditional advice - in case of difficulties and difficulties, contact the specialists.

Step-by-step manufacturing instructions

Tools, materials should be at hand. You can get to work:

- Take the cut piece of metal pipe. Cut threads on both sides. On one side, a sleeve with electrodes is inserted, on the other, a plug.

- It is necessary to weld the threaded pipes. They will be the fasteners for the thermal communication of the system.

- Two bolts are welded to the pipe. The first is for the "neutral wire", the second is for the ground loop.

- For the well-coordinated work of the resulting product with a common heating system, pipes are supplied to the branch pipes.

- The electrode is connected to the phase conductor terminal.

- The terminal of the "neutral wire", the ground wire, is connected to the previously welded bolted connections.

- You can start installing the pressure gauge, fuse system.

- After connecting the automation system, you can start connecting to the dashboard.

Boiler arrangement:

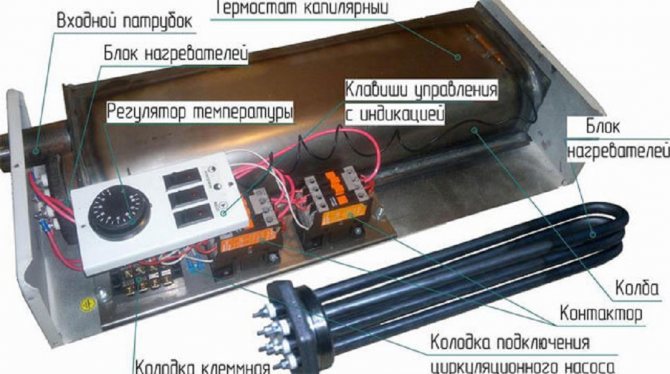

You can independently make an electric boiler with heating elements. For this, a tank is selected in which the heating elements are installed. They are bought in the store. The amount depends on the case, heating area. More often two, three. Products include a threaded head.

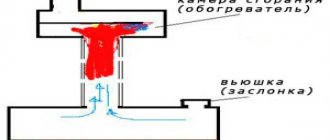

The boiler body is a metal pipe. On the side, nozzles for supply and return are soldered. It is better to install heating elements from above to facilitate replacement. You don't have to drain the water. To eliminate the problem of air accumulation, an automatic gas vent is provided.

Nuts are screwed onto the installed heating elements and welded. A pipe for draining water is installed at the bottom of the body. Threads are cut on the branch pipes. It will allow you to bring the pipes of the heating system to the electric boiler.

The unit is installed on the heating circuit, connected to the electrical network. The connection of the device to the panel, the machine is identical. The power of the device is being calculated.

Advantage and scope of electric boilers

Most often, electric boilers are used when installing heating in the country and in a private house. This is due to the fact that this equipment has a low cost and at the same time you can install it yourself, without calling the wizard.

Among the main advantages of electric boilers are:

- the equipment is safe (the design does not include an open flame or the presence of flammable fuel sources);

- water heaters can be off for up to six months, while without harm to their performance (relevant for summer cottages and country houses that are rarely visited);

- dimensions are relatively small, so it can be placed in any room;

- today there is a huge variety of electric boilers, different in power, installation method and principle of operation;

- when water is heated, soot does not appear, which is dangerous for both humans and the environment.

Heating system automation

Such automation of the heating system, which is represented by room temperature controllers, has the following advantages:

- The device is responsible for controlling the temperature in the air, not inside the coolant. Considering the fact that the volume of air is greater than the volume of water, there will be no sudden temperature jumps. This will have a positive effect on the operating period of the boiler, since there will be much less shutdowns and shutdowns. Experts note that the use of such automation can provide 30% savings;

- The device is programmable. It can be installed in such a way that the same air temperature will be kept until the evening, and before the arrival of residents, it will rise. Savings in this case are obvious. It is noteworthy that each lower degree of air temperature provides 6% fuel economy;

- There are also more functional sensors, which consist of two devices, one of which is installed directly inside the house, the second on the street. This is necessary so that the temperature in the house is completely dependent on the temperature outside. Such devices are called weather-dependent;

- With the help of such a device, you can control the process of heating water in the boiler, as well as control the circulation of the coolant along the circuits on different floors, as well as in the underfloor heating system. Another big plus of such a system is that it can be controlled via the Internet or via SMS chat.

Heating system automation

What is the advantage? The fact is that expensive automation for the heating system will affect the operation of the heater itself, constantly turning it on and off. As for the thermo valves, they will have nothing to do with the boiler, since they will only monitor the temperature in the room where they were installed. But there is one small drawback here. For example, in one room where the room temperature controller is installed, several people have gathered. Of course, the temperature in this room will begin to rise rapidly. Accordingly, the automation will react to these changes and the fuel supply to the boiler will be sharply reduced. Naturally, this will lead to the fact that the temperature throughout the house will begin to decrease. If it will be quite comfortable and warm in the room where people have gathered, then in other rooms it will become much cooler.

A completely logical question may arise - how quickly the automation will react to temperature changes. If we take into account the fact that a person emits about 100 watts of thermal energy, this indicator needs to be multiplied by the number of people and we will get the desired result. As practice shows, in an average room, where about 5 people have gathered, the air temperature will increase by 1 degree in half an hour. It is also worth considering the moment with the location of the room where the regulator is installed. If the room is on the south side, then it will always be warmer than in other rooms. All this must be taken into account before buying an automatic thermostat.

Where to buy thermostats for heating boilers

You can buy thermostats for gas boilers, electric and solid fuel heating equipment at specialized points for the sale of heating equipment, as well as on websites and in online stores for the sale of elements of heating systems. The catalogs contain a huge selection of modern thermostats of various types from leading manufacturers. All devices are accompanied by a manufacturer's warranty.

The modern market offers a huge selection of temperature controllers, both simple and the latest models.

The product range includes wired and wireless models, mechanical and electronic thermostats for solid fuel boilers, gas, electric and diesel installations, as well as convectors, infrared heaters and underfloor heating systems. All products from the catalog have quality certificates.

You can place an order and buy a thermostat for heating using a convenient search system on the Internet resource. Here you can not only familiarize yourself with the functions and appearance of the devices, but also consult with experts about the compatibility of devices with a specific type of heating equipment. Experienced managers are ready to share any necessary information regarding thermostats and their functionality.

By purchasing a thermostat through the online store, you will receive a high-quality device and expert advice

The advantage of online shopping is also that it is possible to get acquainted with the cost of devices in different companies and make a comparative review of prices. Choosing a thermostat, you can get competent advice on its installation, connection and configuration. Some companies offer services for the installation of the device and its adjustment. All questions you are interested in can be clarified by the phone numbers posted in the contact section.

Programmable room thermostat

The programmable electronic room thermostat allows you to select the desired and comfortable temperature at any time, it is easy to reconfigure and change the operating mode. The time timer allows you to set a different pattern for heating on weekdays and weekends. Some timers allow you to set different parameters for each day of the week, this can be useful for people working part-time or in shifts. Many Terneo and KChM models are equipped with such thermostats.

Programmable room thermostat

The programmable room thermostat allows you to set individual heating standards for each day in accordance with your lifestyle and maintain the temperature of the house at all times, regardless of the presence or departure of the owners. Video: Connecting a room thermostat to a gas boiler

If a boiler with a radiator is responsible for the heating system, as a rule, only one programmable room thermostat is needed to control the entire house. Some patterns need to be adjusted in the spring and fall when the clock has moved forward and backward, or a certain change in climatic conditions has occurred. We also recommend changing the temperature settings when changing day and night.

Thermostatic control valves

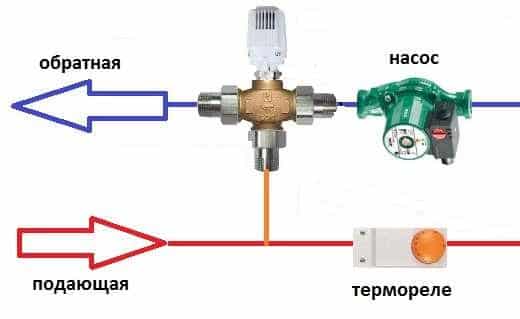

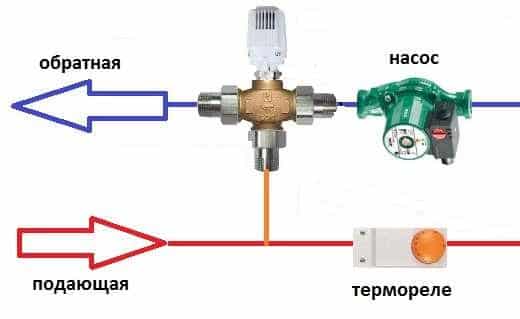

The thermostatic valve is a simple solution to the problem of obtaining a heat carrier of a given temperature by mixing colder water with warmer water. The three-way valve is shown below:

Three-way valve

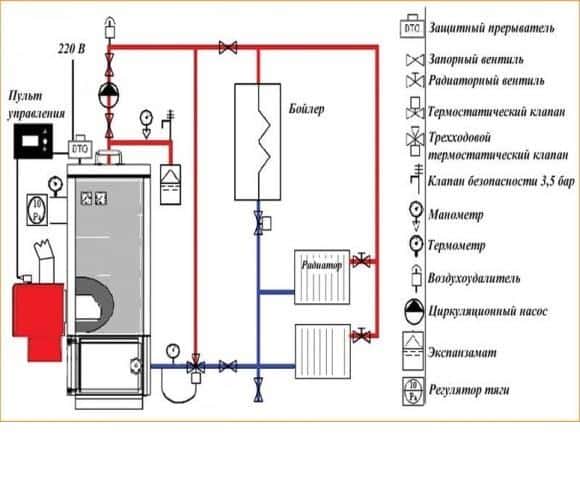

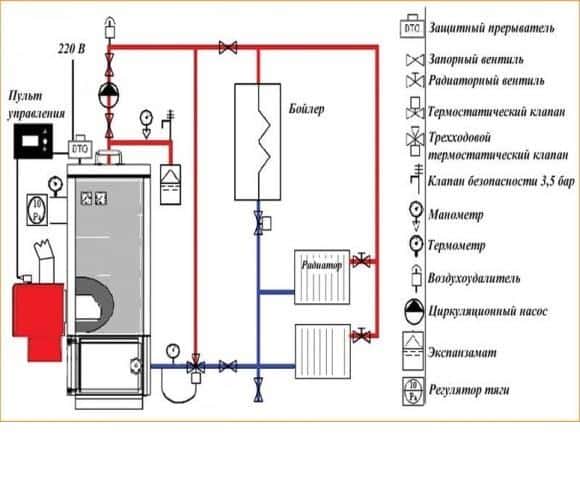

Scheme for connecting a three-way valve to the heating system:

Scheme for connecting a three-way valve to the heating system

Wiring diagram for a solid fuel boiler using a thermostatic three-way valve:

Diagram of a solid fuel boiler piping using a thermostatic three-way valve

Gas boiler piping diagram using a thermostatic three-way valve:

Gas boiler piping diagram using a thermostatic three-way valve

The thermostatic radiator valve allows you to control the room temperature by changing the flow of hot water through the radiator. They regulate the flow of hot water through the radiator, but do not control the boiler. Such devices must be installed in order to adjust the temperature that is needed in each individual room.

This idea should be considered as a complement to the thermoregulation installation.Also, such devices need periodic readjustment and regular performance checks (every six months during a change in operating modes).

Conclusions and useful video on the topic

There should not be any particular difficulties with the installation of the thermostat. You just need to choose the right one for a specific heating system. And the selected video materials will definitely help you with this.

Video # 1. Connecting a room thermostat to a gas boiler in all nuances:

Video # 2. Wall mounted thermostat overview:

Video # 3. Technology for connecting a contact thermostat to a system with a circulation pump:

An addition to a heating boiler in the form of a thermostat is a great way to save on heating your home, increase the comfort of living and reduce wear and tear on the equipment heating the coolant. The money spent on thermostats pays off in one winter season.

In this case, you can choose both a simple mechanical version with manual control, and a more advanced device with a programmer.

Do you want to tell how a boiler with a thermostat works in your country house? Do you have information that will be useful to site visitors? Please write comments, ask questions, post a photo on the topic of the article in the block below.

- Author: Maria Sukhorukikh

Rate the article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!