The modern heating control system allows the implementation of the most complex and advanced programs and schemes for adjusting the operating modes of the equipment, achieve great energy savings, and provide remote heating control. We would like to consider the heating control unit from the standpoint of its structural and advantages and operational features.

How it works

The operating principle of the heating system control unit is very simple:

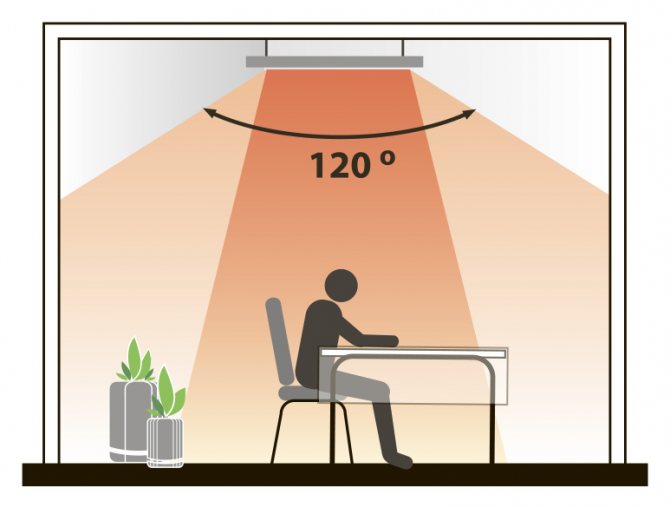

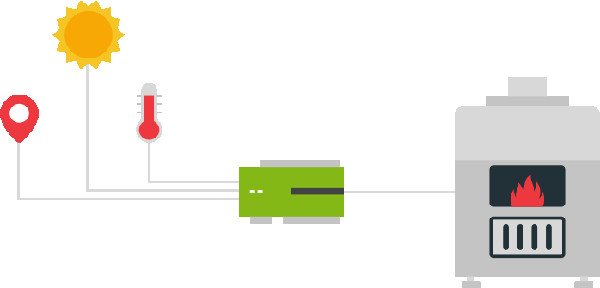

When the outside temperature drops, for example to -20 ° C, the heating control unit supplies more heat to the rooms, thereby maintaining the indoor temperature at the required level, for example +20 ° C.

And vice versa.

When the outside temperature rises, for example to + 5 ° C, the weather control unit, as it is also called, delivers less heat to the premises.

Thus, heat consumption is reduced, and the temperature in the premises remains at the level we need, for example, +20 ° С and does not increase to +28 ° С, as is often the case during a sharp warming.

The temperature does not rise to +28 ° С

And if scientifically, the weather control unit is designed to ensure and maintain the required temperature of the coolant in the supply pipeline, depending on the outside air temperature.

The main advantages of installing an automated heating control unit

As we have already said, the goal of this energy-saving measure is to optimize the consumption of thermal energy in the building, namely:

- a significant reduction in the cost of heating buildings and structures,

- improving the quality and reliability of heat supply,

- automatic regulation of heat supply to buildings and structures,

- the ability to remotely monitor the parameters of the coolant and the operating modes of the heat supply equipment,

- the ability, at no additional cost, to reconfigure the operation of the heating system, for example, after insulating facades, replacing windows, renovating a building,

- automation of the heat energy consumption metering system.

As practice shows, an automated control unit (AUU) saves about 25% - 37% of thermal energy and provides comfortable living conditions in each room.

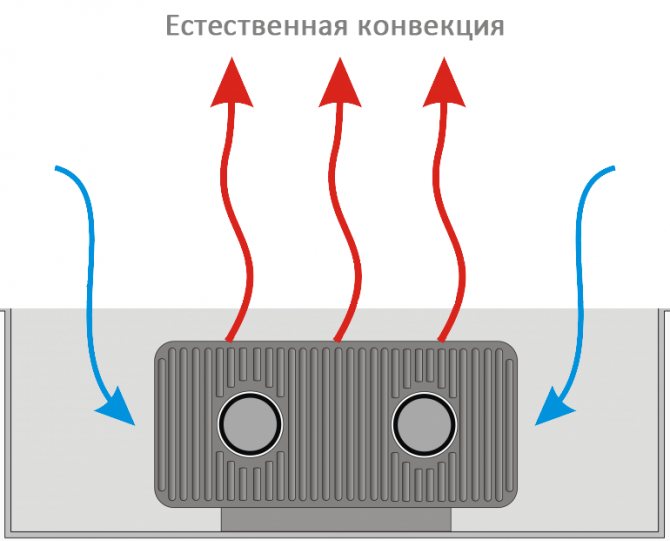

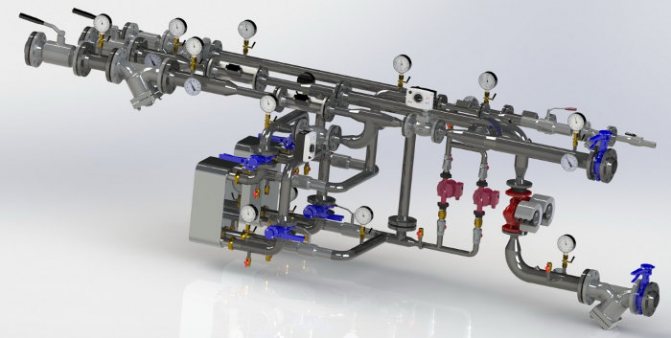

The device and principle of operation of the heating elevator

At the entry point of the heating network pipeline, usually in the basement, a knot that connects the supply and return pipes is striking. This is an elevator - a mixing unit for heating a house. The elevator is manufactured in the form of a cast iron or steel structure equipped with three flanges. This is an ordinary heating elevator, its principle of operation is based on the laws of physics. Inside the elevator there is a nozzle, a receiving chamber, a mixing neck and a diffuser. The receiving chamber is connected to the "return" by means of a flange. Superheated water enters the inlet of the elevator and flows into the nozzle. Due to the narrowing of the nozzle, the flow rate increases and the pressure decreases (Bernoulli's law). Water from the "return" is sucked into the area of reduced pressure and mixed in the mixing chamber of the elevator. The water reduces the temperature to the desired level and at the same time decreases the pressure. The elevator works simultaneously as a circulation pump and a mixer. This is, in brief, the principle of operation of an elevator in the heating system of a building or structure.

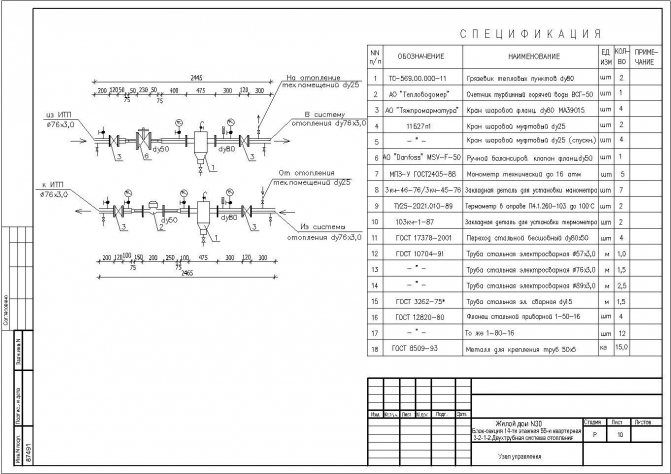

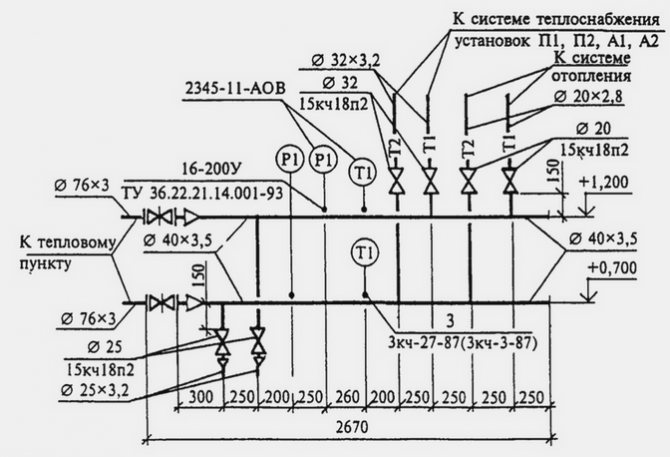

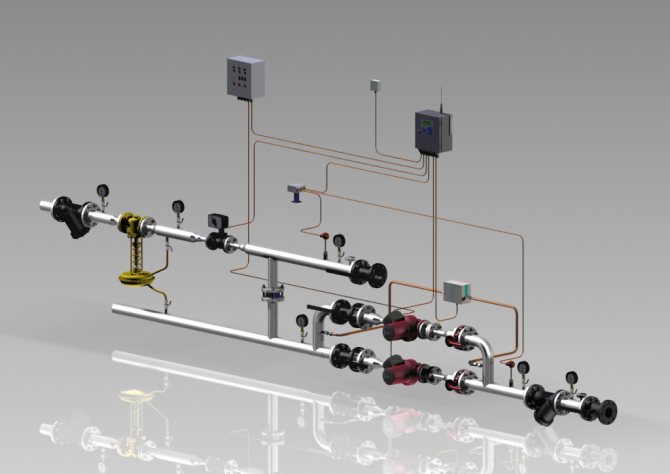

Heating unit diagram

The adjustment of the coolant supply is carried out by the elevator heating units of the house. The elevator is the main element of the heating unit; it needs strapping.The regulating equipment is sensitive to contamination, therefore, mud filters are included in the piping, which are connected to the "supply" and "return".

The elevator trim includes:

- mud filters;

- pressure gauges (inlet and outlet);

- temperature sensors (thermometers at the inlet of the elevator, at the outlet and at the "return");

- gate valves (for preventive or emergency work).

This is the simplest version of the circuit for adjusting the temperature of the coolant, but it is often used as the basic device of the heating unit. The basic unit for elevator heating of any buildings and structures, provides regulation of the temperature and pressure of the coolant in the circuit.

The advantages of using it for heating large buildings, houses and high-rise buildings:

- reliability due to the simplicity of the design;

- low cost of assembly and component parts;

- absolute non-volatility;

- significant savings in heat carrier consumption up to 30%.

But in the presence of indisputable advantages of using an elevator for heating systems, the disadvantages of using this device should also be noted:

- the calculation is done individually for each system;

- you need a mandatory pressure drop in the heating system of the facility;

- if the elevator is not adjustable, it is not possible to change the parameters of the heating circuit.

Elevator with automatic adjustment

Currently, there are elevator designs in which, with the help of electronic adjustment, the nozzle cross-section can be changed. Such an elevator has a mechanism that moves the throttle needle. It changes the lumen of the nozzle and, as a result, the flow rate of the coolant changes. Changing the clearance changes the speed of movement of the water. As a result, the mixing ratio of hot water and water from the "return" changes, thereby changing the temperature of the coolant in the "supply". Now it is clear why water pressure is needed in the heating system.

The elevator regulates the flow and pressure of the heating medium, and its pressure drives the flow in the heating circuit.

When is it advisable to install AUU - examples and calculation of the payback period

Let's look at 3 examples of installing a metering unit and calculate the payback period for this event.

All examples are from real life and are based on energy surveys that we have conducted.

And so, we have three administrative buildings (offices):

- Building 1 with an area of 1300 m2

- Building 2 with an area of 4800 m2

- Building 3 with an area of 18,500 m2

All three buildings are located in Moscow.

Here are the main results of installing a heating system control unit:

| Area, m2 | Total heat consumption for the heating period before the installation of AUU | Total heat consumption for the heating period after the installation of the AUU | Reduction of heat consumption Gcal | Cost of Gcal thousand rubles. (2018 y.) | Savings for the heating period thousand rubles. | |

| Building No. 1 | 1 300 | 340 | 266 | 74 | 2,0 | 148 |

| Building No. 2 | 4 800 | 550 | 418 | 132 | 2,0 | 264 |

| Building No. 3 | 18 500 | 4 400 | 3 720 | 680 | 2,0 | 1 360 |

As can be seen from the table, the installation of a heating control unit helped to reduce heat consumption during the heating period by:

- Building No. 1 - 74 Gcal,

- Building No. 2 - 132 Gcal,

- Building No. 3 - 680 Gcal.

Such a significant difference in the reduction in consumption is mainly due to:

- the size of buildings (area and number of storeys)

- the number of hours of operation,

- appointment.

The following table shows:

- saving heat for the heating period (based on the cost of 2 thousand rubles per Gcal)

- the cost of installing and installing the heating control unit and

- payback period.

| Savings for the heating period thousand rubles. | AUU cost (equipment and installation) | Simple payback period in years | |

| Building No. 1 | 148 | 1 556 | 10,5 |

| Building No. 2 | 264 | 1 856 | 7,0 |

| Building No. 3 | 1 360 | 2 000 | 1,5 |

The main conclusion that we can draw from the calculation of the payback period of the AUU

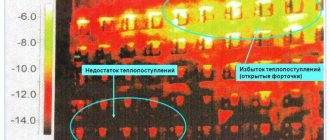

It is advisable to install an automated heating control unit in buildings with significant heat energy consumption and in buildings with overheating.

In small buildings and buildings with low thermal energy consumption, an automated heating control unit will pay off for a very long time or never.

In small buildings, it is more advisable to revise the elevator units or install them, as well as install a system of balancing valves on the main risers of the heating system.

Heating system control unit

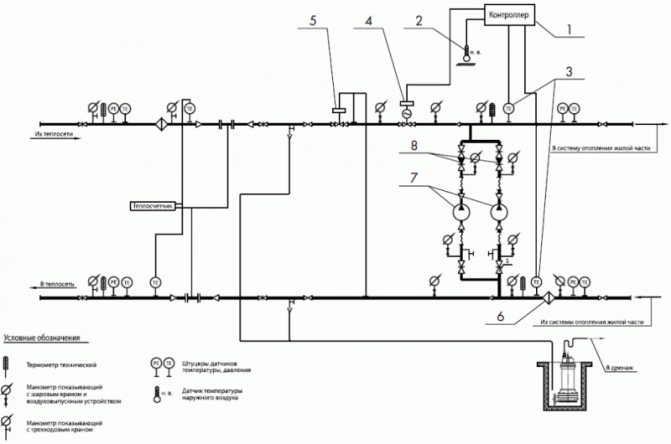

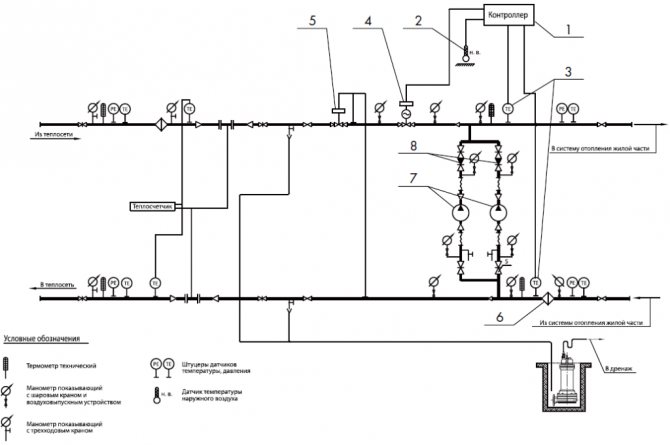

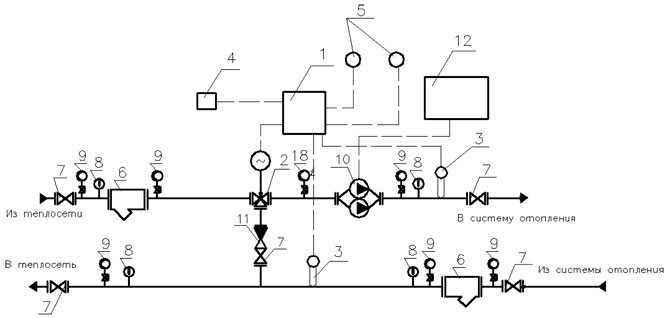

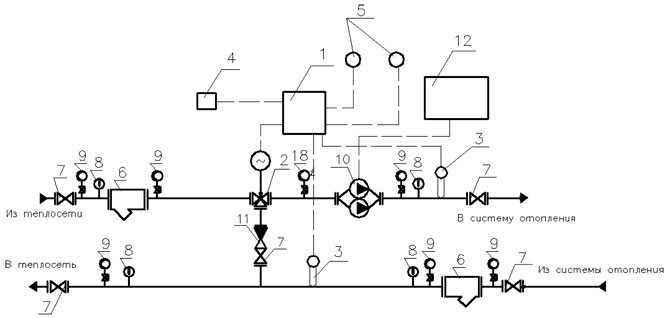

An example of the implementation of scheme 1 AUU

Schematic diagram of an automated control unit with a sufficient available pressure drop at the inlet

(P1 - P2> 6 mWC) for temperatures up to AUU t = 95-70 ° С

The modern world has long been unable to do without innovative technologies. There is no technology or system that does not use revolutionary solutions. The heating system is no exception. This is due to the fact that this is a rather significant technology, which is designed to provide a comfortable existence.

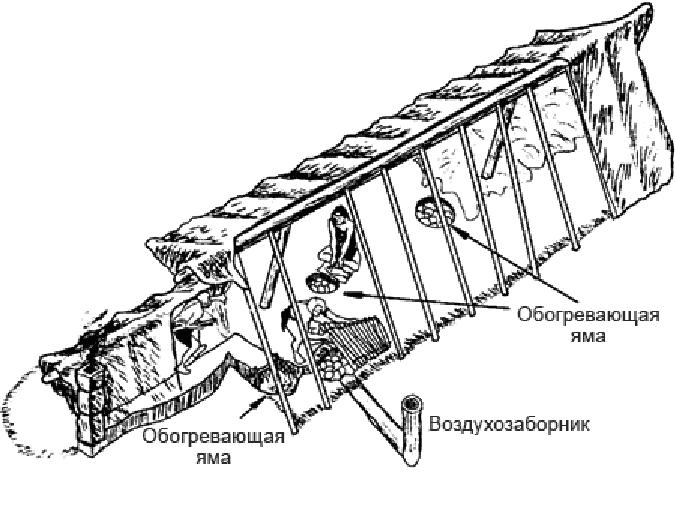

For obvious reasons, special attention is paid when designing a house. Since ancient times, houses were built from a stove, that is, first a stove was erected, and then it was overgrown with walls and a ceiling

This was done for a reason, for this we need to say "thanks" to our climate.

Starting from the middle zone of our spacious country and ending with distant Sakhalin, a rather uncomfortable temperature reigns most of the year. The thermometer column ranges from +30 to -50 degrees.

Due to the rather complex temperature resonance, the heating system is just as important as the electricity supply. Previously, a competent stove-maker who knew how to make the right stove was valued at the level of a blacksmith. After all, you need to correctly calculate the size of the firebox, the diameter of the chimney, besides, the stove had to be multifunctional:

- food was prepared in it;

- she heated the room;

- warmed up the water;

- served as a small sleeping place.

That is why the construction of the furnace was difficult and time consuming. She had to have sufficient draft so that all combustion products did not enter the room. But with all this, she had to be economical.

Today, in principle, little has changed. The main functions and requirements for the heating system remain the same:

- saving;

- maximum efficiency;

- multifunctionality;

- simplicity of design;

- quality and durability;

- minimum operating costs;

- safety.

Fire served as the first source of heat for man. And even now its relevance has not lost its significance. The most primitive way of heating was to make a fire, which provided protection from predators, low temperatures, and served as a source of light.

Further, over time, humanity began to tame the gift of Hermes. Stoves appeared, they were usually built from clay and stones. Later, with the progress of technology, they began to use ceramic bricks. And it was then that the first appeared.

Steel furnaces appeared much later, they determined the formation of the Steel Age. Coal, firewood, peat served as fuel for the stoves. With the gasification of cities, furnaces of steel. And all this time, people have been striving to improve the heating system.

Why is it more profitable to install AUU in buildings with high heat consumption?

The heating control unit costs about the same for large and small buildings (the difference in the cost of equipment and installation is 20% -30%).

At the same time, a large building can save 5-10 times more heat energy than a small building.

In our example, we see:

- The heating control unit pays for itself in 10.5 years in building No. 1, with an area of 1,300 m2 and a heat consumption of 340 Gcal before the installation of the AUU.

- The same unit pays for itself in 1.5 years in building No. 3, with an area of 18,500 m2 and heat consumption before the installation of AUU 4,400 Gcal.

Our analysis and calculation are not universal.

They only give you a basic understanding in which buildings it is more expedient to install automated heating control units.

We recommend making a calculation of the feasibility and payback period of the heating control unit individually for each building, based on the specific circumstances and conditions.

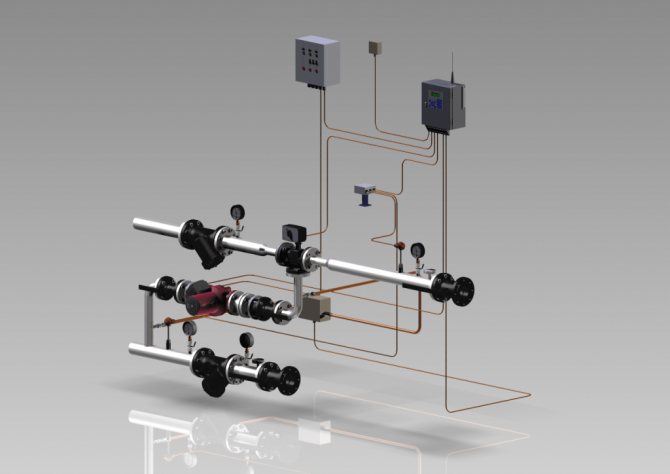

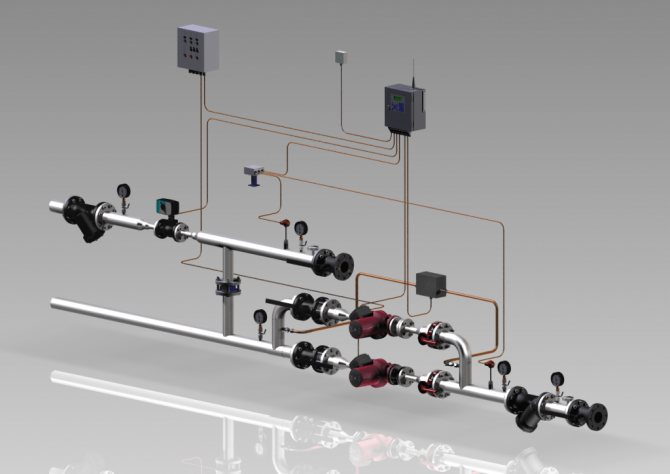

How is the installation of an automated heating system control unit

There is no fundamental change in the heat supply scheme of a building when installing an automated heating system control unit (AUU).

Unlike elevator units installed on each section of a house, AUU is mounted, as a rule, one per building.

Connection of the control unit is performed after the heat energy metering unit.

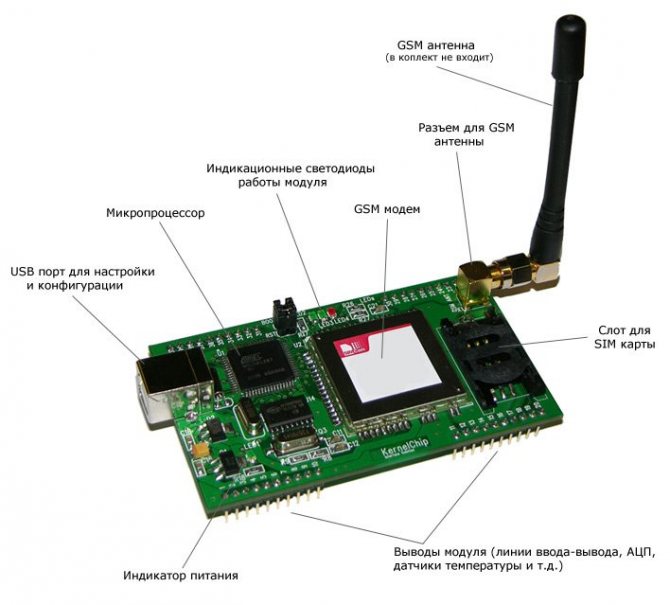

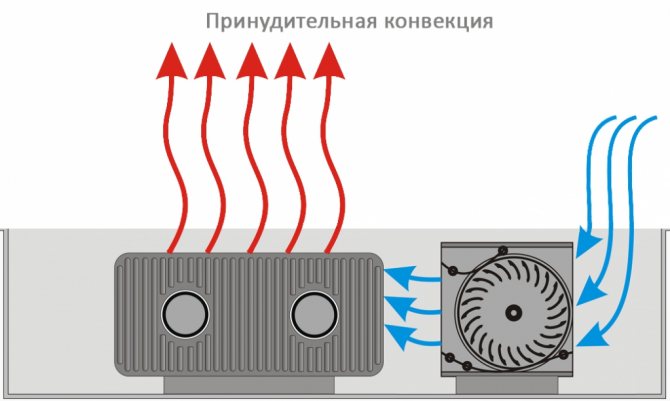

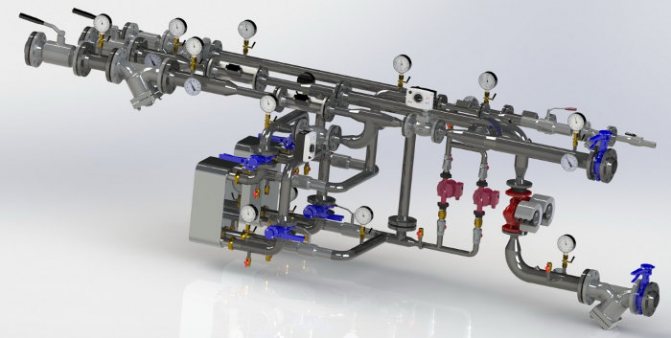

The weather control unit includes the following elements:

- control element,

- control valve with an actuator,

- circulation pump,

- outdoor temperature sensors,

- room temperature sensors.

The control element of the weather control unit allows you to manually change the settings that determine the operating mode of the heating system and allow you to maintain different temperatures in the building at different times.

For example, in office buildings on weekends and holidays, you can reduce the air temperature inside to +12 ° C.

On weekdays, the temperature can be raised to +18 ° C.

The diagram and general view of the automated weather control unit are shown in the figures below.

The scheme provides for:

- automatic switching between the main and standby pump in case of failure of one of the pumps,

- the possibility of introducing a flexible schedule for regulating the air temperature in the premises, taking into account the night time, weekends and holidays for the entire heating season,

- mandatory control of the return heat carrier temperature,

- maintaining the temperature schedule.

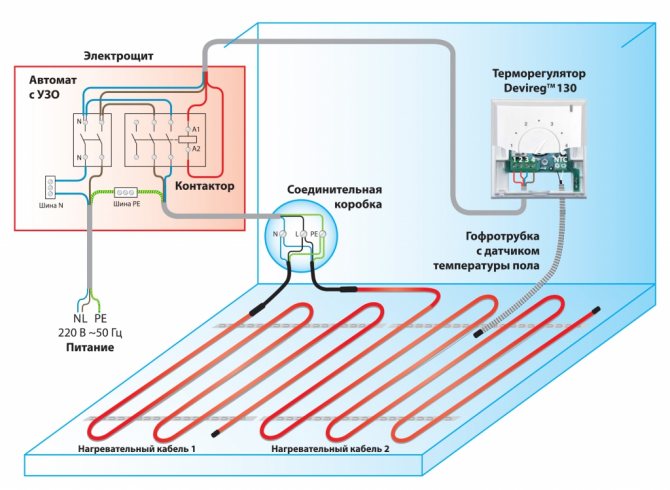

The temperature of the heating system is controlled by changing the throughput of the valve and adding heating water using a circulation pump.

During operation, the controller:

- periodically polls the coolant temperature sensors, the indoor air sensor (if any) and the outdoor air sensor,

- processes the information received and

- generates control signals giving a command to the actuator to open or close.

The control action from the controller changes the opening of the flow area of the control valve.

In the absence of an indoor air sensor, the main control priority is to maintain the temperature schedule.

Features of installation and verification

It should be noted right away that the installation and verification of the operation of the elevator unit and the heating system is the prerogative of the representatives of the service company. The residents of the house are strictly prohibited from doing this. However, knowledge of the layout of the elevator units of the central heating system is recommended.

During design and installation, the characteristics of the incoming heat carrier are taken into account

The branching of the network in the house, the number of heating devices and the temperature regime of operation are also taken into account. Any automatic elevator unit for heating consists of two parts

- Adjusting the flow rate of incoming hot water, as well as measuring its technical indicators - temperature and pressure;

- Directly the mixing unit itself.

The main characteristic is the mixing ratio. This is the ratio of the volumes of hot and cold water. This parameter is the result of accurate calculations. It cannot be constant, since it depends on external factors. Installation should be carried out strictly according to the scheme of the elevator unit of the heating system. After that, fine tuning is done.Maximum load is recommended to reduce error. Thus, the water temperature in the return pipe will be minimal. This is a prerequisite for precise control of the automatic gate valve.

After a certain period of time, scheduled checks of the operation of the elevator unit and the heating system as a whole are required. The exact procedure depends on the specific scheme. However, you can draw up a general plan, which includes the following mandatory procedures:

- Checking the integrity of pipes, valves and devices, as well as the compliance of their parameters with the passport data;

- Alignment of temperature and pressure sensors;

- Determination of pressure losses during the passage of the coolant through the nozzle;

- Calculation of the displacement coefficient. Even for the most accurate heating scheme of the elevator unit, equipment and pipelines wear out over time. This correction must be taken into account when setting up.

After completing these works, the automatic elevator central heating unit must be sealed to prevent unauthorized interference.

Do not use homemade elevator node schemes for central heating systems. They often do not take into account the most important characteristics, which can not only reduce the efficiency of work, but also cause an emergency.

Effective use of automated metering stations

The use of AUU is most effective:

- in large buildings with significant heat consumption,

- in houses connected to city heating networks,

- in buildings with insufficient pressure drop in the central heating system and with the obligatory installation of central heating pumps,

- in buildings with decentralized hot water supply and central heating.