Mechanical models

The valve and the thermal head are the main elements, without which it is impossible to imagine almost any thermostat. In this case, the latter performs the function of a sensitive element. These parts do not need external energy in order to work properly.

In turn, the thermal head also has several components. This is a regulator and actuator, a liquid element, sometimes elastic or gas parts are found as an alternative to it.

Internal organization

When choosing a temperature regulator, it is necessary to take into account all the factors that may affect the operation of the device in the future. Its main parts are as follows:

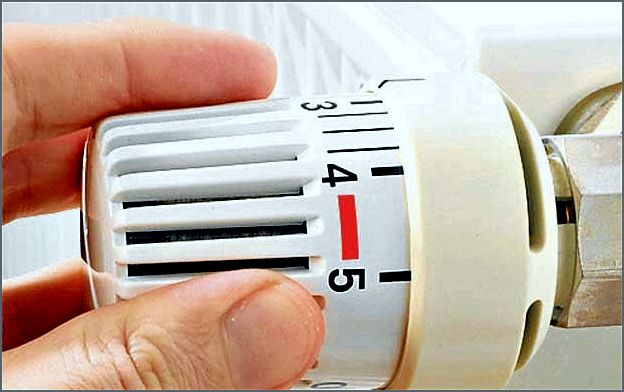

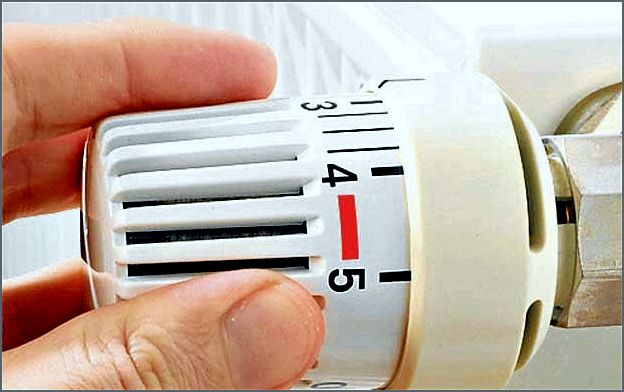

- scale with adjustment;

- fixing the set temperature, ring;

- mechanism of compensatory action;

- union nut;

- stock;

- spool;

- detachable connection;

- sensitive element;

- thermostatic element;

- thermostatic valve.

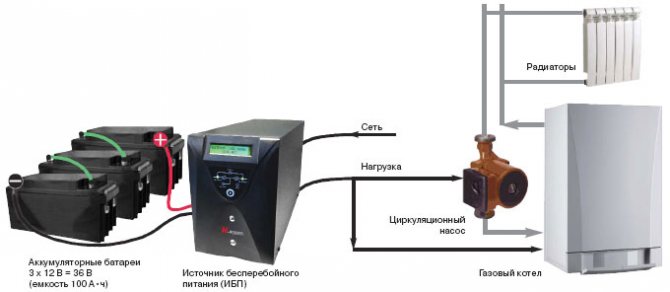

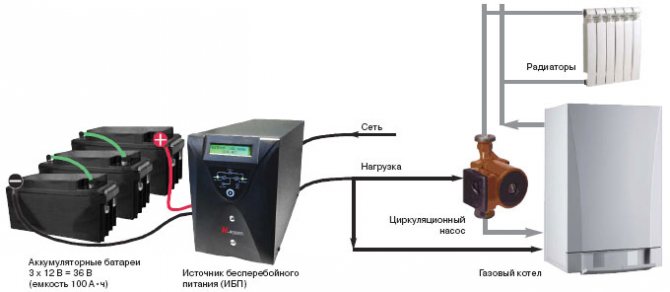

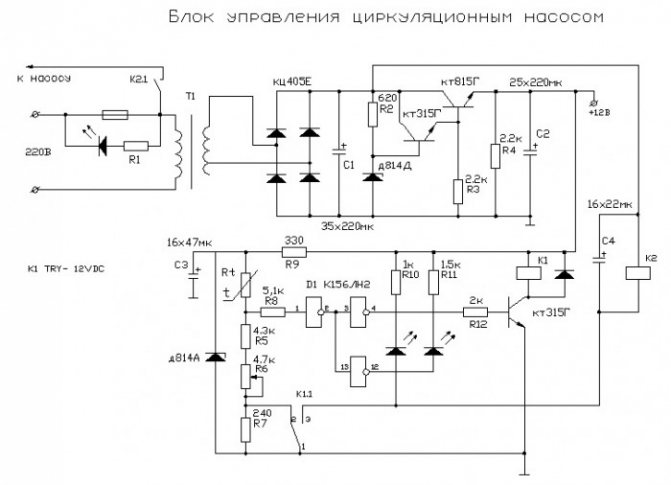

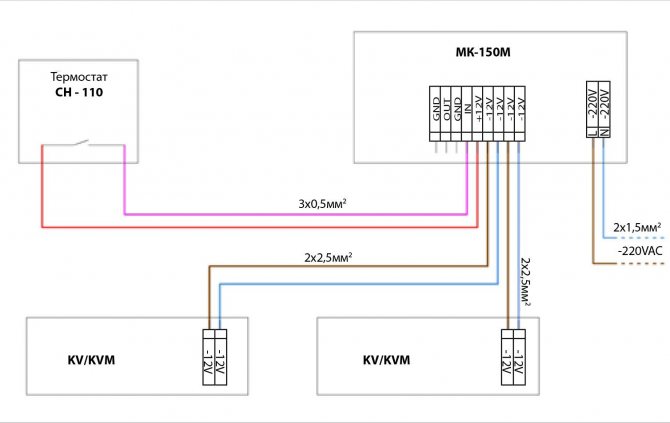

Automatic control unit for circulation pump

The circulation pump is controlled by means of a thermostat, a relay, an uninterruptible power supply unit. The complex is needed to regulate the heating of the coolant, to maintain the operation of the equipment.

Thermostats

The units combine the functions of a thermoelement and a valve; they are needed to adjust the temperature of water heating.

The thermostat for a heating circulation pump works like this:

- Reads information from the temperature sensor. Compares metrics with settings. To set the settings mode, a side menu is intended with a difference in the pump start temperature and hysteresis. Hysteresis - the time interval of the temperature lag when the heater is turned on and off.

- When the equipment is started, hysteresis is automatically added to the water heating indicator when the blower is turned on. When the pump is turned off, the hysteresis is subtracted from the total.

By default, the size of the hysteresis is taken as 1/10 of the heating medium heating temperature. Thus, when the water warms up at +50 C, the hysteresis is only 5 degrees. In order for the automatic control unit to start working, the water must warm up to +55 C. To turn off the unit, it must cool down to +45 C. Units with hysteresis are more convenient in operation. The equipment supports a temperature run-up of 5 degrees, therefore it is protected from constant on / off switching.

The thermostat should be selected with a firmware hysteresis of minimum +/- 1 degree, maximum +/- 10 degrees. Place the thermostat next to the boiler. Provided that it is adjusted taking into account the external temperature in the room, the boiler regulation should be capable of changing the indicator of the carrier.

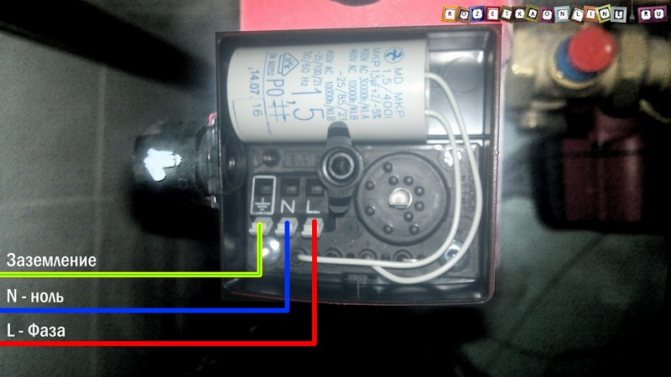

Uninterruptible power supply

The heating circulation pump control unit is volatile equipment, it will not work without electricity. A UPS (uninterruptible power supply) or generator will help eliminate the possibility of downtime. It is permissible to do without a power supply device by starting up the network in a gravity mode. But there is a risk of an error in laying out the pipelines, which will lead to the failure of the network.

The contours of the gravity heating network according to the layout technique are inclined towards the return circulation pipe. The slope is recommended to be maintained within a range of up to 3 cm for each meter of the pipeline. This requires accurate circuit calculations and increases the network layout area.

The return circulation line is mounted with a slope towards the heater, also taking into account the slope. If the level of decrease is small, there is a risk of stagnation of the coolant, the formation of an air lock.In addition, the heater should be installed at the lowest point of the circuit, which is difficult in the absence of a basement.

A circulation pump will help to avoid all problems, in order to provide it with power, a UPS or generator is built into the network. The choice depends on the user, however, the generator makes a lot of noise during operation, the UPS operates as quietly as possible.

On and off relay

This is a module for starting up the equipment and shutting down the unit. The relay for turning on the heating pump is an important unit responsible for maintaining the operation of the entire unit.

The unit's task is simple:

- decrease in the pressure level in the network - a signal to start the device into operation, the relay turns on the equipment;

- exceeding the set pressure rate - a signal to stop the equipment.

Thus, when the parsing of the coolant stops, the pressure in the network rises, the timer for the heating pump is triggered to turn off. The resumption of the analysis of hot water leads to a decrease in the pressure indicator, starts the device into operation. Whether or not to install a thermostat or a UPS is up to the owner.

A high-quality circulation pump with a temperature sensor has a number of advantages:

- reduces fuel consumption;

- ensures the maintenance of a comfortable temperature in the premises;

- makes it possible to quickly correct the operating mode.

Experts recommend choosing devices in accordance with the manufacturer's instructions. Manufacturers of equipment without an automatic control unit prescribe in the technical passport the parameters of a unit suitable for installation on devices.

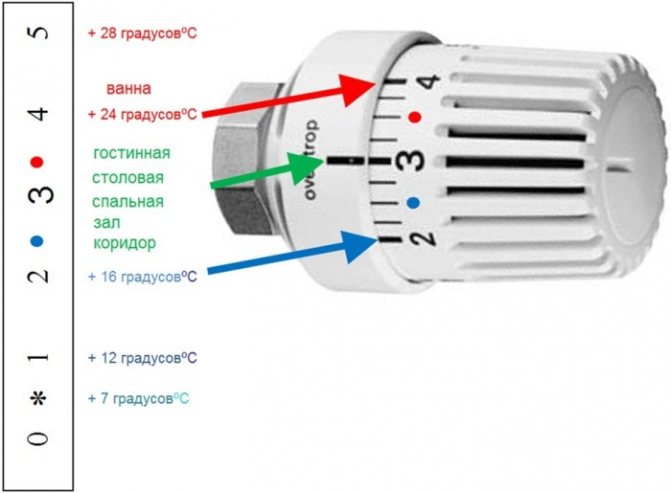

To simplify the regulation of the water flow in the battery, it is recommended to equip all batteries in the house with thermostats. When choosing them, it is necessary to take into account the gradations of the setting - the smaller the division, the more accurate the mode. It is more practical to take devices with a scale gradation of up to 5 degrees.

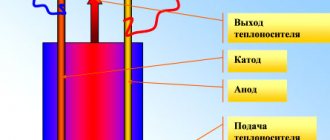

Principle of operation

The volume of the heating medium changes when the temperature in the heated room changes.

The bellows also changes its volume. It is because of this that the movement of the control spool begins. Its movement is proportionally related to how the temperature regime changes.

The thermostat has a special valve stem that moves due to a sensitive element that reacts to the environment.

About installation and its features

A thermostatic valve is installed on the supply part of the regulator pipeline. It is important to maintain a horizontal position for the head of the heating device. Exposure to direct sunlight, heat in large quantities is unacceptable.

Radiators cannot perform their functions normally if they are covered with curtains or covered with furniture. In such a situation, a zone appears with an almost complete lack of sensitivity. This means that there is no contact with the environment.

Otherwise

If it is impossible to install the heating system in another way, you will have to use remote control sensors, which have a sensitive patch element. The so-called mini-heating regulators are also intended for integration into niches.

Experts recommend installing a special shut-off valve on the return flow of the heating radiator. Then you do not have to disconnect the entire heating system from the riser, if you need to clean the battery, dismantle it.

The pump thermostat must be fully open when the heating season ends. After that, excess sediment will not form on the valve seat, the device itself simply turns counterclockwise.

There are several thermal modes with which different types of pump devices can work.

- summer - 28 ° C;

- bathroom - 24 ° C;

- living room - 20 ° C;

- bedroom - 16 ° C;

- inner corridor - 11 ° C;

- frost protection - 7 ° C.

It is imperative to set the thermostat for the pump before starting active operation. At this stage, additional hydraulic resistance is created. It is necessary to smoothly adjust the throttle mechanism in order to achieve the desired result of the pump operation.

The battery check valve and inlet valve are equally good at helping to do the same.

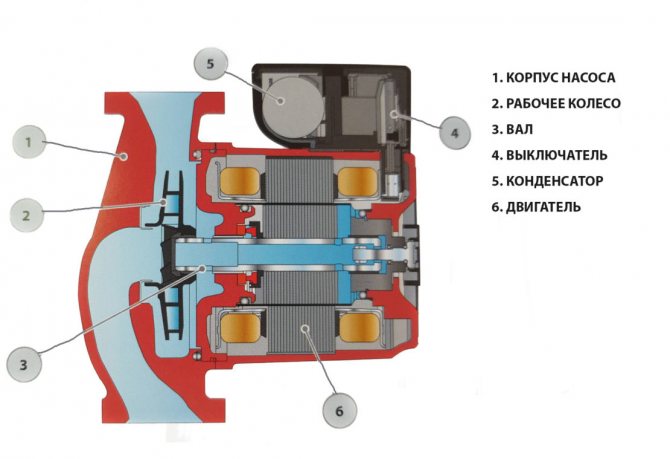

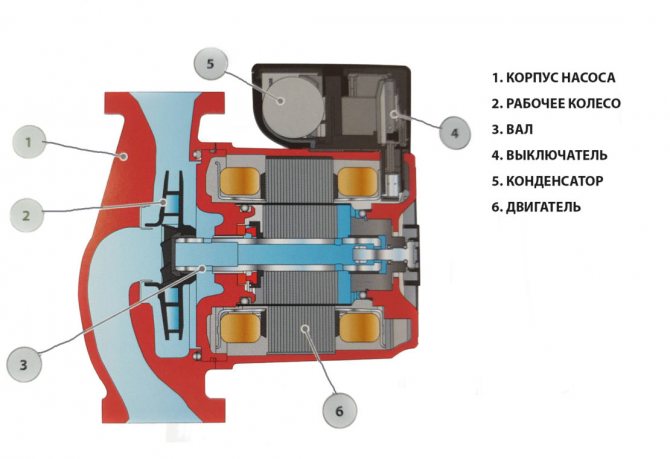

Materials used in the production of circulation pumps

This is a very important aspect that affects not only the quality of work, but also the cost of the unit. It is clear and without words that the contact of parts and assemblies of the pump with water brings a lot of trouble. Therefore, for the production of this type, high-strength materials are used that can withstand water at a sufficiently high temperature.

For example, today analogs are produced where the shaft, that is, the rotor, and the bearings are made of ceramics. Such parts have high strength and long service life. Moreover, ceramics are not afraid of water. Plus, such details work silently.

The average guaranteed service life of circulation pumps is at least ten years. Of course, the requirements of the manufacturers here must be strictly followed, otherwise there are no guarantees. What do manufacturers require? Correct selection, correct installation, prepared heat carrier, avoiding some negative indicators in the heating system, for example, the air inside.

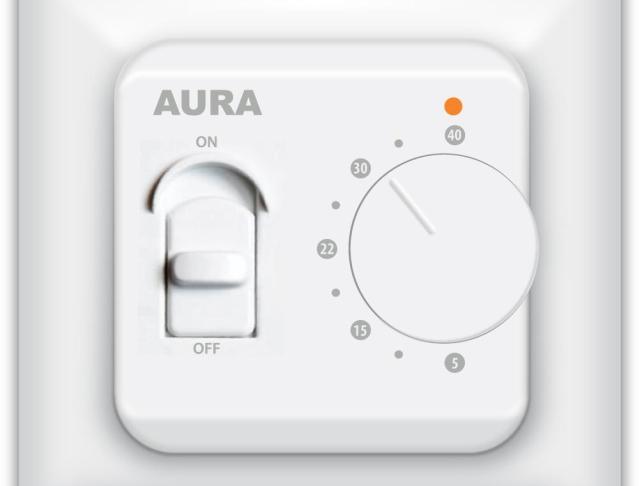

Electronic type models

They are also briefly referred to as ET. These are automatic devices that help maintain the set temperature. They can be used with any type of pump if required.

An electronic thermostat can automatically control system actuators such as valves and pumps, mixers, boilers.

How does it work?

The presence of an external or built-in thermal sensor in the design becomes mandatory. It is installed in a place free from direct influence of other heating devices. This part is used to adjust the device.

The thermal sensor gives the ET information about the temperature being maintained in the environment. Currently, digital and analog versions of ET are produced.

The first ones have more functionality, due to which they have become widespread.

In turn, digital type models are divided into two types:

- with open;

- or closed logic.

What is a circulation pump

This is a small unit that is installed in the heating pipeline system and distills the coolant along all branches of the heating system, that is, it circulates hot water. There is a wide variety of circulation pumps for heating systems. but for private houses, units with the so-called "wet rotor" are usually used. What is the design feature of this model?

The thing is that the moving parts of the pump, and this is mainly the rotor and the impeller, are cooled and simultaneously lubricated by the liquid flowing inside the pump, that is, the coolant. Hence the noiselessness of operation, and a high indicator of reliability, and the small dimensions of the unit itself. Add in durability, efficiency and economy.

Closed logic

The closed logic of the device for the circulation pump means that there is a rigid internal structure. The algorithm of work remains constant over time, does not change depending on the state of the environment.

For circulation pumping equipment, this is quite possible. There are only a small number of programmable parameters that can be changed.

Open logic

There are also freely programmable open logic instrument types. They are also often found in pumping products of the circulation type.Such devices can be easily configured for any environmental conditions and temperature conditions.

But it is rather difficult to manage them, special qualifications are required. Therefore, they have not become widespread, closed logic is most often found in circulating devices.

You should not save on the purchase of a thermostat for a heating system, because this product significantly increases productivity and efficiency.