Any node role. Therefore, the correspondence of the parts of the structure must be carried out correctly. The heating system includes, batteries, a connection system, thermostats, fasteners, an expansion tank, collectors, air boiler, pipes, pressure increasing pumps. On the open resource tab, we will try to find and select the necessary parts of the system for the cottage. The heating design of the apartment has some elements.

The use of boilers for heating and heating water is becoming increasingly popular today. The use of the cheapest type of fuel - gas and ease of operation guarantee this equipment demand at any time of the year.

Main types

In addition to single-circuit and double-circuit boilers, columns. a distinction is also made between models with natural draft and with a closed combustion chamber. The first type, during operation, uses a chimney, which must be present in the room. In products of the second type, combustion products are removed using a fan, for which common ventilation systems of apartment and private houses can be used. Therefore, such boilers are widespread not only in private DOSs, but in multi-storey buildings. The water-indicating boiler of the column maintains the optimal water level. Also in our market, models are being actively promoted not only with the flow-through principle of heating water, but also with a built-in battery. Condensing boilers have a high percentage of efficiency and, at the same time, guarantee economical operation even at high power levels.

If the traction is weak

The thrust of the apparatus weakens, the thrust indicator reacts, and the gas is automatically blocked. All this happens when the chimney is clogged. These can be soot formation or accidentally dropped objects, as well as cracks.

In this case, the wick of the gas column usually does not ignite.

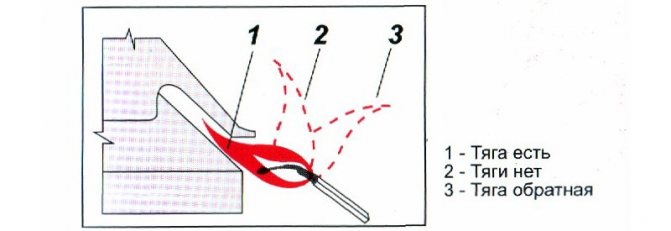

You can even carry out a draft test: a window opens, a paper sheet is leaning against the chimney hole, or an ignited match is brought up.

In the presence of traction, the piece of paper will be attracted, and the flame of the match will tilt to the side.

If the traction is weak, this will not happen. Then it is necessary to clean the chimney. You should not do this by your own efforts. After all, you need to work from the roof of the house.

Where to go if the gas water heater does not work for this reason? Your local management company can help here. Go there and they will refer you to a chimney cleaning specialist.

You can contact a private licensed company.

The analysis of the work front is free of charge. And the cleaning itself goes in three stages:

- Vacuum equipment is used. A special vacuum cleaner pulls out the dirt.

- Mechanical cleaning. A special cable with a ruff at the end is used.

- Repetition of item 1.

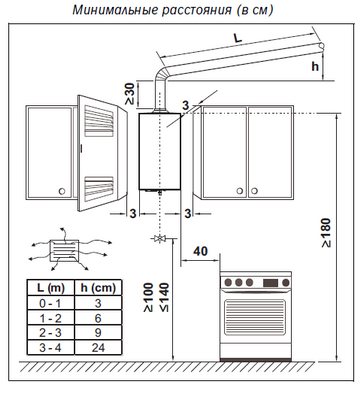

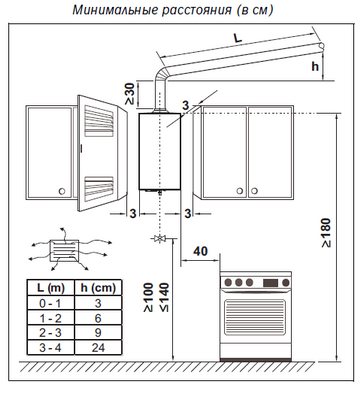

Column boiler installation

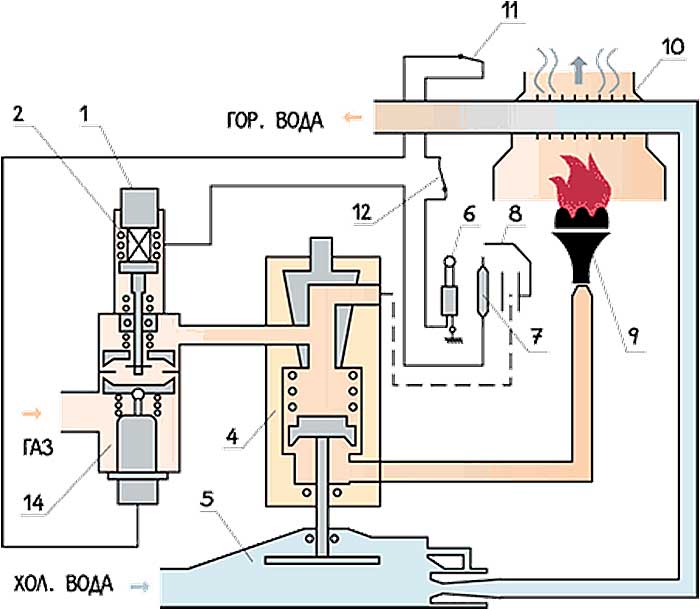

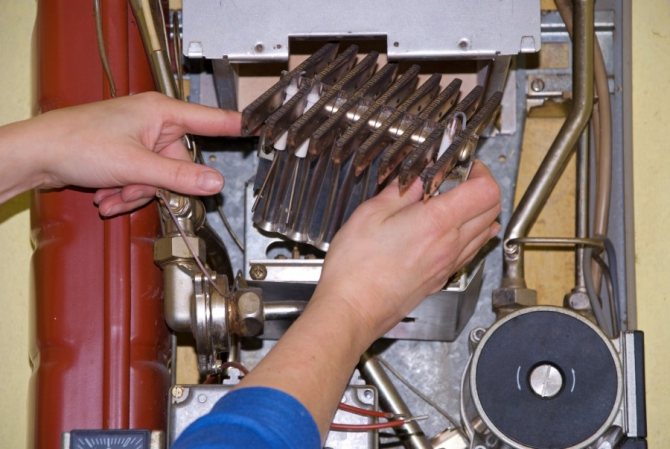

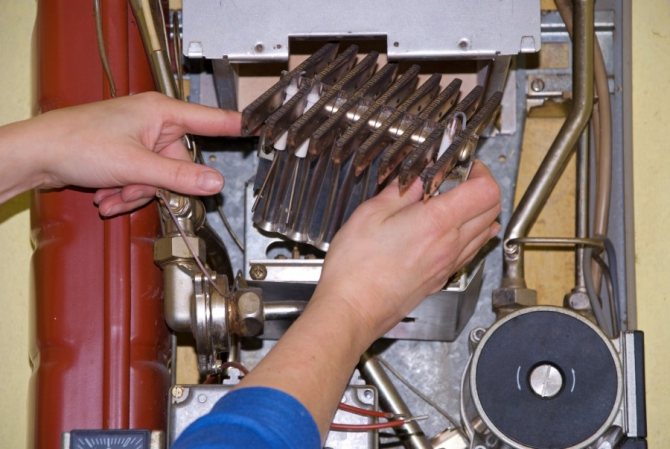

The gas boiler with the help of the burner heats the water, which is supplied by the pump to the heating circuit. The main characteristics of such a product are the power and volume of water required for the functioning of the system. Accordingly, the larger the area that needs to be heated, the more the power of the corresponding equipment should be. The main advantage of modern products is reliability. Safety systems, including ionization control, allow boilers to be used with maximum benefit and with minimal risk of malfunctions and possible damage.

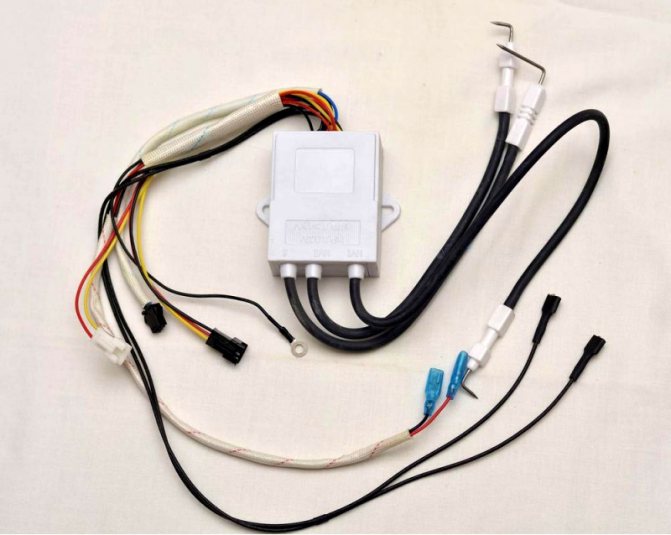

The installation of the column boiler must be coordinated with the gas service. The wall-mounted boiler is attached to the wall with large self-tapping screws. The wiring is mounted at the bottom. The cold water pipe must be fitted with thermal insulation to avoid condensation.To protect against limescale, it is best to use a magnetic transducer, which is placed at the input of the column. The long service life of such a device guarantees comfort in using the boiler. To connect the gas, you need to purchase a special hose, and to relieve pressure in the system - a safety valve. The final step is connecting the boiler to the mains.

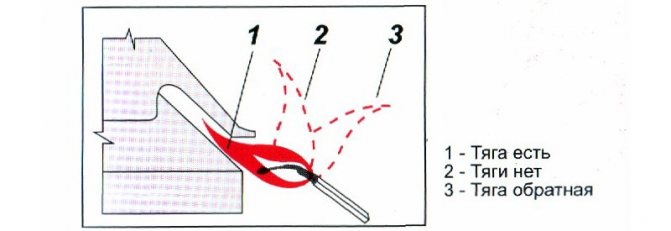

How to check the thrust in the gas column

First of all, if there are problems with the water heater, check the draft. To do this, a lighted match or a piece of paper is brought to the exhaust hole:

- if the flame is still, then there is a problem in the chimney or exhaust system. To do this, you can simply remove the accumulated dirt;

- if the flame draws inward, then the system is working perfectly;

- if the flame deviates in the opposite direction, this means the appearance of a reverse draft, which is extremely dangerous, for this you should check it in the ventilation shaft, having previously disconnected the chimney from it. If the ventilation duct works normally, the flame on the match deflects inward, which means that there are problems in the heat exchanger.

It is important! Checking the draft with a match should be discarded if there is a risk of gas leakage.

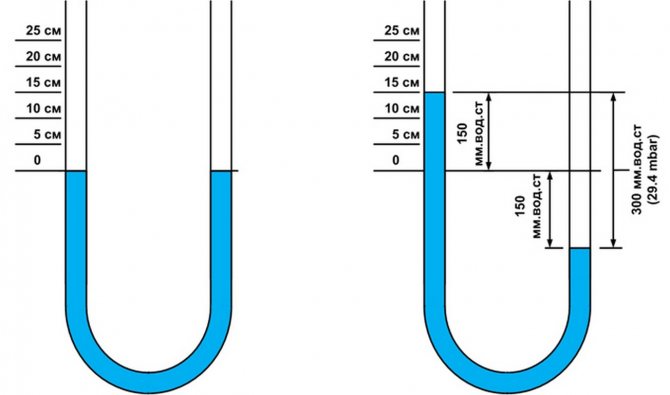

Column thrust check

Modern market of manufacturers

The most popular are the products of such manufacturers as:

Their cost varies depending on the volume, configuration and brand awareness. For example, a novelty - a Baxi column boiler with a digital control panel, an updated traction control system and a power of 14 kW can be purchased for $ 500. The models are characterized by increased power and, therefore, their price is approaching the $ 1000 mark. A wide variety of models allows you to make the best choice.

A gas boiler costs 20 thousand rubles - while it is not a fact that a circulation pump will be installed in it, so add a couple more thousand more. Gas water heater - 4 thousand. The temptation to save 15 thousand was very great for me, because, as I said earlier, a rogue, and I decided to use a gas water heater instead of a heating boiler.

My fears - the column will not withstand the load, the chimney will burn out, the column will overheat, the gas hose will burn out because of this - none of this happened. Everything works, I'm happy to the ass that everything worked out. The problem got out in another place - water began to run into the house, which condensed on the walls of the chimney. I hadn’t come across chimneys before, so it was an unpleasant discovery for me. They say that it is necessary to insulate the chimney pipe, but I just stuck the corrugation inside the chimney and now water drips from the chimney onto the street.

What is on my system. Expansion tank for 10 liters - 700 rubles. Underfloor heating pipes 16 mm polyethylene - 300 meters - 25 rubles. per meter. Batteries - 24 sections - 300 rubles. per section .. Battery pipes - 20 mm polypropylene 50 meters (a neighbor gave). Two pairs of collectors, 650 + 250 rubles each = 1800 rubles. All sorts of accessories such as bolts, nuts, valves, adapters, fittings, etc. - countless numbers, the feeling that most of the money went there. Three gas cylinders - 500 rubles each. Gas reducer with oxygen hose - 300 rubles. And you also need to install cylinders on the street - while it's at home. Scary. A neighbor passed gas from a cylinder through a polypropylene pipe - I will also do it. I forgot to count the chimney pipe - corrugation 200 rubles. for 3 meters. Galvanized pipes 8 pieces, 120 rubles. per piece (1 meter). Mounting bolts - 200 rubles. Fungus on the pipe from the rain - 240 rubles.

And here's what happened. I had an electric boiler. But he got me, because last winter, heating costs 10 thousand rubles a month. According to my calculations, about 3 thousand rubles will be spent on gas. per month

The system works like this. There are two circulation pumps (without a hydraulic arrow). One in front of the gas water heater, the second after the batteries in front of the underfloor heating.They are turned on by a thermostat, which I took out of the electric boiler and tied it directly to the manifold with electrical tape. Circulating pumps are turned on, they draw water - the water flow turns on the gas water heater. After five to ten minutes, the thermostat turns off the pumps and the gas in the column goes out. Everything works like a clock.

Disadvantage - a lot of heat is lost through the chimney. Therefore, next year I will try to get money for a normal gas boiler with a coaxial chimney and a closed combustion chamber. But for now, for the time being, you can use a water heater, its power (20 kcal) will be enough for a 50-60 meter house.

This sheet is written for those who doubt whether it is possible. You can, I did it. Most of all, I was afraid that the water pressure generated by the circus pump would not be enough to turn on the water heater. Enough. In those characteristics of the column it is said that the minimum water pressure is 0.02 MPa.

Seek and find.

P.S. In addition to the indicated 25 thousand, another 5 centimeter concrete layer is needed, in which 300 meters of pipes are recessed. (3 cubes, 4 thousand rubles each). Reinforcement mesh that holds these pipes. Extruded polystyrene foam 5 cm thick (250 rubles per meter, 65 meters = 17 thousand with delivery). Lighthouses - 10 pcs for 200 rubles. (reused). And for something else you need to buy food during work. Total in the region of 60 thousand only net costs. It is clear that I will not pull a normal boiler right away, so I have to be perverted with a gas water heater.

And if you remember, my first step was a conversation with a heating engineer, who asked for 40 thousand for installing a chimney and five batteries. For work on a warm floor, they would have charged me 50 thousand more. Thus, with my hard work and indispensable health, I saved it, which means I earned 90 thousand rubles. Time was spent on everything about everything without straining about two months.

Boilers are subdivided according to the type of installation: wall-mounted and floor-standing. The first type is used for rooms of small dimensions and therefore the appearance is very compact and with less power.

The second type is installed both in a separate room and next to the heating system. Floor standing boilers differ in capacity, mainly models are produced, more than 30 kW. The disadvantage of the second option is massiveness.

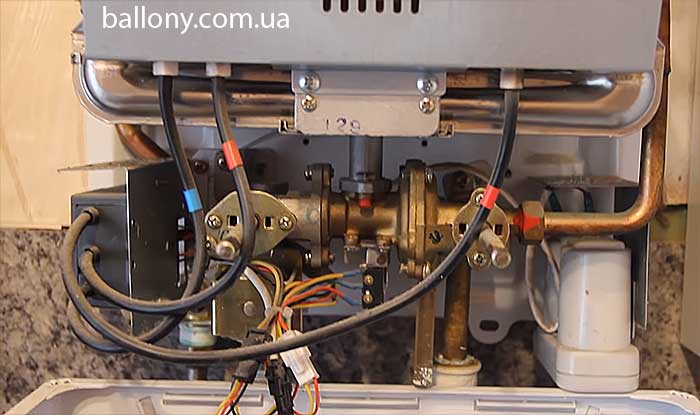

The speakers we are repairing

Specialists serve the most common brands of gas water heaters. Our specialists have extensive practical experience, and also undergo training in the relevant companies, confirmed by certificates for carrying out repair work. The maximum volume of our services is for repairs gas water heaters Bosch (Bosch) and repair of gas water heaters Neva (4510, 4511, etc.): the equipment of these brands is widely popular and is installed in many apartments and houses in Moscow and the Moscow region. We also carry out repair of gas water heaters of brands:

- Junkers

- Electrolux

- Ariston

- Vaillant

- Mora

- Beretta (Beretta) and others.

For a specific call, a certified repairman for a gas water heater of the specified brand is sent. We work in all districts of Moscow and the near Moscow region, providing a prompt visit of the master to the house.

Top manufacturers

Geyser Baxi Slim 2300 Fi

The market is saturated with models of domestic and foreign manufacturers:

- AOGV and AKGV brands.

Single-circuit products and double-circuit products are produced by Zhukovskiy machine-building plant ZhMZ. Location - Moscow region. - Konorod plant.

Has a wide range of gas boilers and other designs. - Navien brand.

Korean manufacturer. - Buderus, Viessmann, Vaillant brands.

Products from Germany. - Ariston (Italy).

- Protherm (Slovakia).

The best Italian-made floor standing gas boiler is the Baxi Slim 2300 FI

... His rating is ten out of ten. A boiler is built into the structure, which is a very convenient part, with a closed combustion chamber, which brings safety. Ideal for Russian gas supply systems. Copes with its functions with a reduced gas supply.

A complete set of automatic control and protection devices is available. Has an additional option for connecting a timer and remote control.With a maximum thermal useful power of 29.7 kW, a minimum of 14.9 kW, the presence of a closed combustion chamber, a circular pump.

Weight 177 kg, powered by 170/230 V. Dimensions - 85x65x60 cm.

pros

:

- Elegant appearance.

- Possibility of reconfiguring to liquefied gas.

- Can be used under the underfloor heating system.

- Burner material - stainless steel.

- Full set of protection.

- Ability to work at a pressure of 5 bar.

- The device is equipped with a diagnostic system.

Minuses

:

- High price.

Nuances of checking sensors and possible malfunctions

In order for the sensors to work properly, it is necessary to constantly monitor them. So, the main reasons for breakdowns and failure of sensors can be:

- The sensor is dirty with dust, soot or scale. Each of the contaminants adversely affects the performance of the protection system. This can be fixed by trivial cleaning.

- The sensor may have melted or has reached the end of its expiration date. Only a complete change of the protection system will help here.

- Weather conditions can interfere with the operation of the sensors. For example, heavy snow or heavy rain can flood the throttle sensor, which is responsible for the gas supply.

Geyser sensors may fail due to dust contamination

There are two ways to test sensors for faults. Both of them are quite simple, but at the same time effective and they can be carried out without special devices.

In the first case, you need to use a mirror. Attach it next to the sensor. If it doesn't fog up, it works fine. Otherwise, it is worth contacting the gas service.

The second method is to cover up the cravings. The sensor should "feel" this and stop the gas supply to the wick.

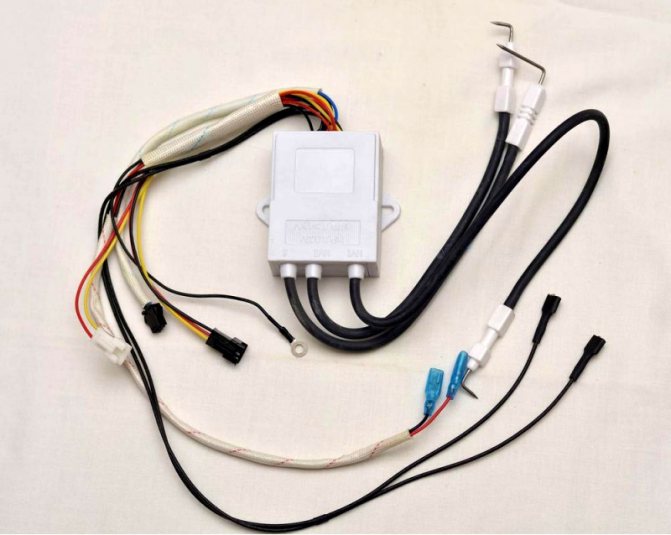

If, after checking all this, experiments show that the sensors are in good order, then the point is in the controlling element. It is best to replace the element, since most often it turns out to be defective.

Many owners of a gas water heater, when the boiler is constantly turned off, because of a malfunction they do not understand or because the sensors are constantly blocking the operation of the column, they just simply turn them off. This directly violates all safety regulations.

Thus, you expose yourself, loved ones and others to danger, which can be fraught with further consequences. However, with such a way out of the situation, the column works smoothly, but it is unsafe for you.

Advantages and disadvantages

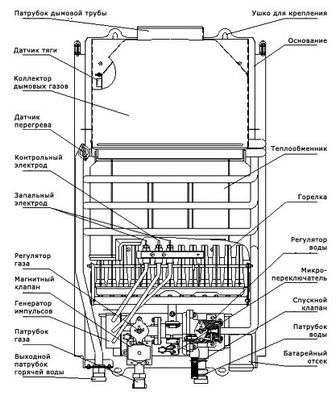

Device

Pros:

- Safety.

- Long service life.

- Ease of maintenance.

- Profitability.

Minuses:

- There is no possibility of heating water

(single-circuit models). - Stopping heating

during water supply (double-circuit products). - Costly installation.

- Mandatory presence of a chimney.

- Sufficient gas pressure

and water.

Selection criteria for a private house / apartment:

- Manufacturer's brand.

- Price.

- Power.

- Ignition type.

- Burner type.

- Combustion products removal method.

- Safety.

- Installation method.

- The number of contours.

- Type of fuel.

- Material.

Each company has its disadvantages and advantages. Therefore, preference when choosing equipment should be given to well-known manufacturers.

Consumers treat the cost with particular scrupulousness. Sometimes a product with lower prices may turn out to be of high quality with excellent characteristics.

Gas smell is felt during heater operation

We turned on the column and felt a sharp and unpleasant smell of gas, immediately turn off the device and turn off the gas supply with a tap, ventilate the room and call the gas service.

Taking any action on your own is dangerous, you do not have the appropriate qualifications for this.

Power, type of ignition and burner

Piezo ignition

The most important parameter of the device is power.

It is she who determines the minimum energy costs and the future comfort of housing.You can calculate it yourself, given that with an area of 10 sq. m and a ceiling height of 3 meters, one kilowatt of power will be required.

There are several ignition options: from a hydraulic turbine, electric and piezo ignition.

The first type (turbine generator) is widely used in expensive modifications. As soon as the hot water tap opens, the burner automatically ignites. The high cost is the only drawback of the device.

Electric ignition also occurs when the hot water tap is opened. For the device to function, it must be provided with a power supply unit (batteries), which must be replaced periodically.

In the piezo ignition device there is an element from which a spark comes, when the gas opens, the automation is triggered and thereby the igniter is connected.

The task of the burner is to combine gas and air in certain proportions, as a result, the gas is completely burned, which increases the efficiency of the equipment.

By the method of transmission, the following options can be distinguished:

atmospheric, ventilatory and diffusion-kinetic. Also, burners are divided into several types of fire control, namely: two-stage, simulated, single-stage. The most commonly used is the modulated option.

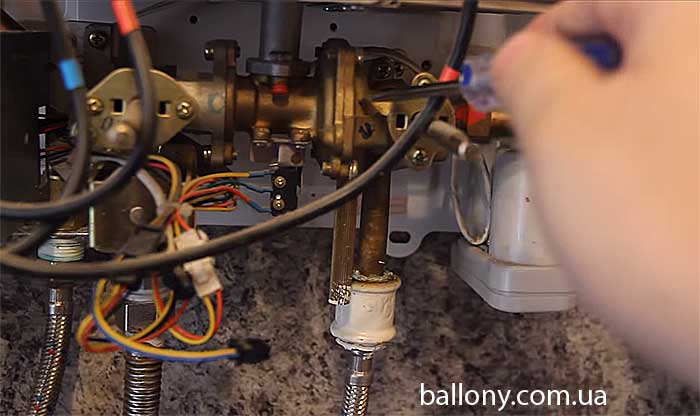

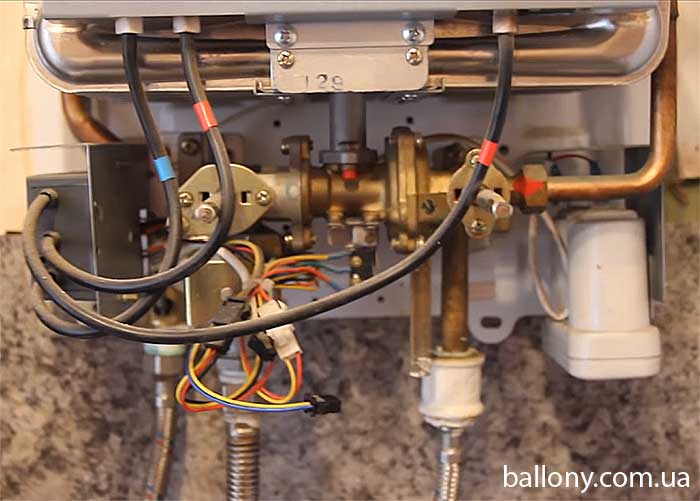

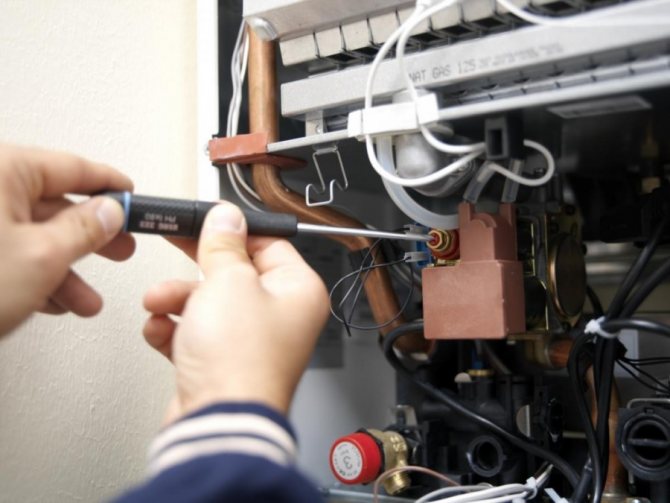

Repair of gas water heaters of popular brands at home

Repair of major breakdowns of all gas water heaters is similar to each other, since the principle of operation is similar for all devices. However, different manufacturers have hardware weaknesses that are most common.

It is important! If the gas water heater is under warranty service, it is not recommended to make repairs yourself. In the future, the service department can withdraw it from the warranty.

Only minor breakdowns can be eliminated on your own.

Features repair of gas water heaters "Bosch"

The weak point in the models of the Japanese manufacturer is a thermocouple, after a couple of years of operation, problems with ignition and combustion may arise, the gas column may not turn on when the water is turned on or go out spontaneously. You can clean the thermocouple yourself, but this will only temporarily eliminate the cause. The part will have to be replaced soon. Another problem is that the igniter tube is not rigidly fixed, and therefore, its displacement may occur. To fix such a problem, you just need to put it back in place.

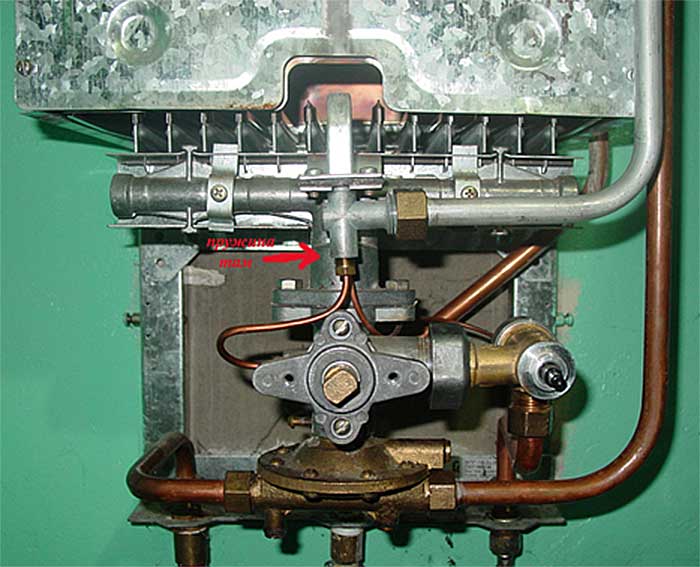

Gas water heater thermocouple

The nuances of DIY repair of the Junkers gas water heater

The weak point in the models is the ignition system. Over time, the burner or wick may go out, in this regard, the problem of heating the water arises. To eliminate it, you need to check the performance of the node.

Ignition unit for water heater

Brief instructions for the repair of the gas water heater "Oasis"

The equipment of the German manufacturer is characterized by a very high quality assembly. No problems characteristic of this particular brand have been identified, and to eliminate ordinary breakdowns of the Oasis gas water heater, you should familiarize yourself with the installation diagram and our repair instructions using the above methods.

Gas water heater "Oasis"

Features of the repair of the gas column "Vector"

According to experts, all the malfunctions of the speakers of this manufacturer are in the use of spare parts of poor quality and improper assembly. The main problem, why the "Vector" gas column does not light up, is that the contacts in the power supply unit have oxidized. In this case, even replacing the batteries will not bring the desired result, you must carefully clean the contacts. Another possible nuisance: the rod hangs on the water valve.

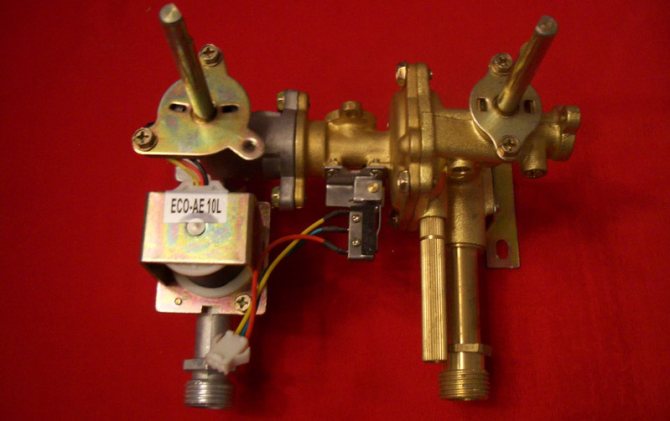

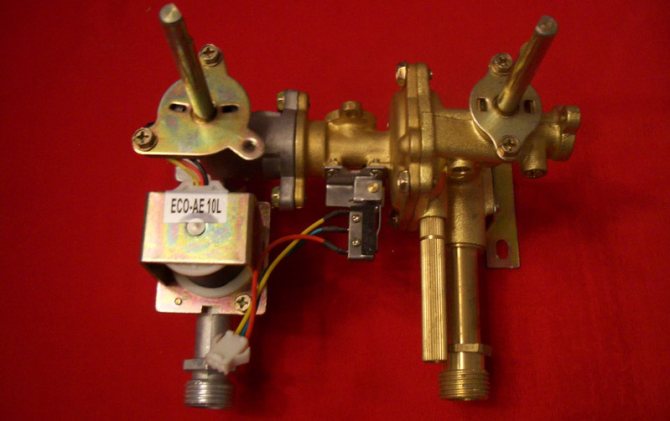

Gas-water block of a water heater

Related article:

Column gas "Neva". In the publication we will consider the principle of operation and features, technical characteristics, model range, where to find spare parts and how to repair equipment. Causes of emerging breakdowns.

Purpose of the draft sensor

To better understand how the speaker works and why it turns off, you need to study the principle of its components. One of the main parts of such a device is the thrust sensor.

A draft sensor or thermal relay detects the draft force in the gas boiler. It is he who gives the signal that the column thrust has crossed the permissible limits.

Normal draft in a gas boiler ensures that combustion products are released not into the room, but into the street. If this process is violated, combustion products begin to accumulate in the apartment, which has a negative effect on your health.

In addition to the function of ensuring the removal of combustion products outside, the thrust is also responsible for the normal combustion of gas. If the gas in the column does not burn, then an expensive device may break down.

Insufficient draft can cause the column to fade, so if you have such a problem, first of all, check the draft in the boiler. It is this indicator that is the most common reason for the malfunctioning of the column.

It is the draft sensor that helps to choose the wrong operation of the boiler in time and eliminate its causes. Without this element, the safety of the functioning of such a device will not be complete.