With the onset of cold weather, car owners can often face a very unpleasant situation when, after turning on the stove, the interior does not begin to fill with warm air, although the regulator and the blowing force are set to maximum power. There are many reasons why it can happen that the stove does not heat up. To solve this problem, it is necessary to correctly diagnose the breakdown.

Check the health of the elements responsible for the temperature in the car to prevent it from freezing completely

The main causes of problems

Today, liquid cooling is the most common way to remove excess heat from the engine. The hot liquid passes through the pipes to the heating radiator.

An integrated fan draws in air from the outside and then passes it through the cooler and cabin filter. This is how the air in the car begins to warm up.

Remember to keep an eye on the coolant level in your car

There are two large groups of reasons why the stove does not heat up.:

- malfunction of the heating system;

- problems in the cooling of the car.

It is necessary to take into account the objective reasons due to which the stove does not heat well. In the cold season, when the temperature reaches -15 ° C, warm air will begin to flow into the cabin only after a while. The car needs about 15 minutes for the heat exchange fluid to warm up well (up to + 40 ... + 70 ° С). Only then will full heating begin.

Modern vehicles are often equipped with a climate control system, air conditioning, stoves, which start their work only after the antifreeze has completely warmed up.

The main reasons for a stove malfunction:

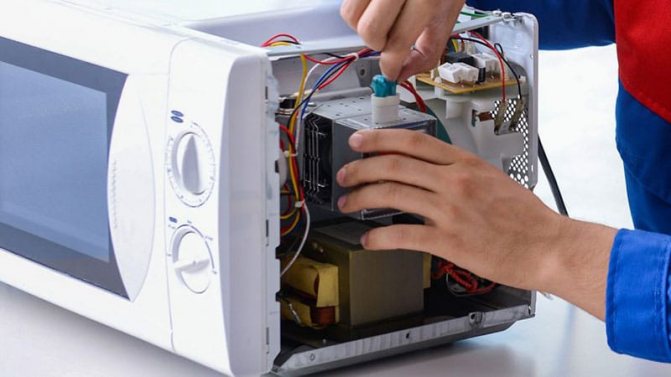

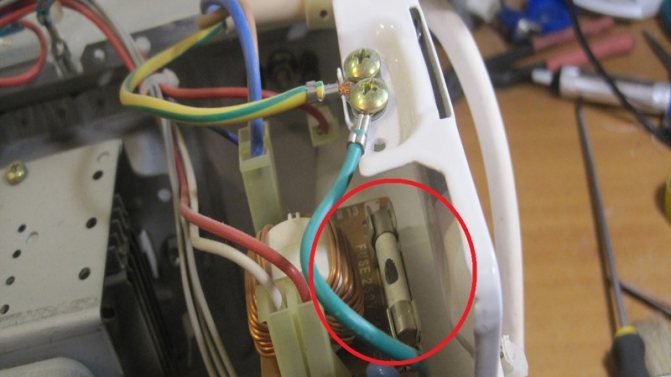

What to do if the microwave is heating dishes, not food

The principle of operation of a microwave oven is that microwaves emitted by a magnetron affect the water molecules contained in food. They begin to move erratically, and the food heats up evenly. Reheated food transfers heat to the dishes. If the food does not heat up when reheating, but the plate becomes hot, this indicates that the dishes are not suitable for the microwave oven.

For microwaves, special dishes are made, on which there is a sign that allows use in the oven. If there are no special dishes, the existing containers are tested. The plate is placed in the microwave, a mug of water is placed next to it and the appliance is turned on at full power for 1 minute. If the plate is not hot, then it is suitable for heating food.

Glassware is suitable for cooking and heating in the microwave. It practically does not heat up. Plates with thick walls made of porcelain, ceramics and faience also show themselves.

You should not use thin glass and crystal, porcelain cups with thin walls, ceramic dishes without glaze - these containers can crack under the influence of microwaves. Do not use gilded dishes.

Do not use in a microwave oven:

- metal dishes;

- utensils containing metal or having metallized coated;

- low-melting plastic;

- disposable containers;

- aluminum molds.

Cheap Chinese microwave containers are used with extreme caution. When heated, they can melt, releasing substances harmful to the body.

Important! Do not use dishes that cause sparks. This can cause a malfunction of the instrument.

In order for the microwave oven to work for a long time and without interruption, select the right dishes. If you use proven plates, and they heat up, but the food does not, this indicates a breakdown in the technique.For diagnostics and repairs, contact a workshop.

Fast diagnostics

There are many factors due to which the stove does not heat well. The reasons may be hidden, for example, in the thermostat. Air may enter the cooling system. It reduces the circulation performance of antifreeze, while creating a kind of plugs.

The main reasons why the stove does not heat well:

- Thermostat jammed.

- The liquid intended for cooling the engine does not circulate well in the stove radiator.

- Air pockets in the cooling system.

- The electric heater is out of order or there is no power supply. This problem can occur in vehicles that are equipped with electric heating.

Read the same: signs and causes of thermostat malfunction.

If you find a malfunction of the elements of the car, contact the master for help.

These are the most common reasons that the stove does not heat well. In reality, things can be much more complicated. For example, antifreeze will leak, which will lead to a decrease in the coolant level in the system. This happens when the cooling radiator or connecting pipes are damaged. Hot air may not pass well into the passenger compartment due to a malfunction of the air duct or ventilation valves.

10 reasons why the stove does not heat well:

Heating system

The main element of the car's heating system is the radiator. It has the function of heating the outside air. Diagnostics should start from this part.

Vehicle heating system: If you add antifreeze or antifreeze from another manufacturer to the coolant, this can lead to the formation of solid deposits. They begin to clog the channels that supply heat. You can solve the problem like this:

- Purchase a new heater.

- Flush the radiator. You can do this yourself. It is necessary to use a working solution: 50 g of citric acid is diluted in a liter of warm or hot water. If possible, pressurize during flushing.

- Swap the pipes. This often helps if a solid precipitate has formed. This procedure temporarily improves the quality of the heaters.

It may be that the radiator heats up well, but the stove does not work. The most common reason is a breakdown of the electric motor, which is necessary for the rotation of the fan. To solve this problem, it is necessary to replace the non-working element.

Diagnostics of the stove in the car: Another reason that the stove does not heat up may be a malfunction in the electronics or in the control system. Power buttons or temperature controls may break. You can solve the problem in the following ways:

- Buy a new part to replace the broken one.

- You can put the damper in the "open" mode.

- Set the temperature as high as possible, and then disconnect the terminal on the battery. Set the minimum value. Make sure that the adjustment works correctly.

The stove may not heat well due to a blockage in the cabin filter. The solution is to replace this part.

The main reasons why the stove does not heat up:

Cooling elements

The heating in the car may not work due to malfunctioning of the cooling system. Very often the thermostat is the problem. This is a device that ensures the correct movement of the heat transfer fluid in the system. If the thermostat breaks down, the antifreeze cannot heat the interior radiator in a short time. The solution can only be the replacement of the part.

The reason for the poor functioning of the oven can be a low level of heat exchange fluid. When there is not enough antifreeze in the system, little of the heated liquid enters the radiator. This causes poor air heating. To fix this breakdown, you need to find a place where the heat exchange fluid flows out.Then the leak is eliminated and the required amount of antifreeze is added to the system.

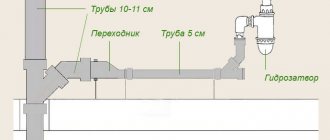

Reasons for poor functioning of the stove: The ingress of air into the system adversely affects the functioning of the stove. Ventilation can occur for a number of reasons: violation of the integrity of the gasket, leaks in the pipes, etc. To diagnose the problem, it is necessary to measure the amount of antifreeze in all elements of the heat exchanger. When the ignition is off, the fluid level should reach the maximum mark. There are two ways to solve this problem.:

- Open the radiator. Perform manual bleeding of the system. It is necessary to pump up the hoses until bubbles appear. Put the radiator cap back on, then start the engine. After a few minutes, the procedure is repeated.

- Raise the front of the car a few degrees (you can use a jack). Open the radiator and conservator caps. Then you need to start the engine and start rhythmically pressing the gas pedal. Do not forget to add antifreeze on time.

Both procedures are fairly straightforward. If you fear that you will not be able to cope on your own, it is better to seek help from specialists.

Stove in the car:

"Diseases" of stoves and their treatment

The material was found and prepared for publication by Grigory Luchansky

A source: L. Korobanov, engineer. "Diseases" of stoves and their treatment. "Rural Builder" No. 1, 1948

Every stove-maker competent in his field should be able not only to fold a new stove well, but also to straighten out the work of the old one. In this case, the stove-maker is like a doctor summoned to a patient. By external signs, he must quickly determine the "disease" of the furnace, understand its cause, and then take the necessary measures to correct the shortcomings.

Below are the main disadvantages in the operation of furnaces and ways to eliminate them.

I. Stoves smoke

The smoke of the veils occurs for the following reasons:

1. The gas ducts of the furnace and its chimney are clogged with ash in soot. Through the special cleanings available in the furnaces, it is necessary to clean the gas ducts at least once a season, and the chimneys twice a season.

However, it is impossible to completely clean the flue gas ducts of the furnaces from soot in this way. Therefore, it is very useful to heat the stove with dry aspen wood. They burn with a short flame and do not have resinous substances.

The gases of high temperature, obtained by burning dry aspen wood, passing through the chimneys of the stove, strongly heat up the layer of soot that has settled on the walls of the chimneys. Sublimation of resinous substances, which are impregnated with soot deposits, is learned. As a result of the evaporation of these substances, the soot layer becomes looser, the soot peels off from the walls and falls down into the gas collectors, from where it is easily removed through cleaning. Part of the soot in the first gas ducts burns out.

After burning with aspen wood, cleaning the furnace gas ducts is greatly simplified and accelerated, since loose sediments are easily brushed off with a broom. On the contrary, soot deposits impregnated with resinous substances are very densely deposited on the walls of gas ducts and it is very difficult to clean them off.

Sometimes in the fall, the stoves begin to smoke because of the nests that birds made in the chimneys in summer. Therefore, from the spring, it is useful to close the pipe openings with a mesh.

2. Collapse of bricks in gas ducts or blockage of gas ducts with pieces of mortar. This disadvantage is eliminated by viewing the gas ducts through cleaning and removing bricks and pieces of mortar. The solution usually enters the gas ducts after the furnace has been relocated or repaired.

It is necessary to ensure that when laying or repairing gas ducts, the stove-maker removes the excess solution protruding from the seams, and also does not rub the inner surfaces with clay, which, when dry, cracks and falls off.

It often happens that after removing the "blockage", the furnace starts to work much worse: it does not keep warm or does not warm up well.This indicates that the density of the partitions has been disturbed by the fallout of a brick or mortar, and gases along a direct path enter directly into the chimney. There are cases when there are up to ten such "falling" bricks; they are taken out, and the stove continues to be heated, without attaching serious importance to this phenomenon (if only it does not smoke!).

Instead of the dropped bricks, you need to put new ones in the appropriate places (from where they dropped out). After removing the blockage, it is necessary to carefully repair all cracks and leaks in the walls of the gas ducts and especially near the frames of the views and valves.

3. The flue gas ducts of the furnace are located below the grate level. In this case, most stoves have poor draft and smoke frequently. The flues should not be located below the grate, since then a significant traction force is required and the pipe must be increased in height.

4. Smoke from two adjacent stoves on the same floor are connected to one chimney and, moreover, on the same level. Stoves, as a rule, should have their own chimneys; for the above case, a vertical cut must be made in the chimney to a height of at least 0.7 meters, or the stoves must be connected at different levels in height (at least 1 meter).

5. Several stoves are heated in one room. In this case, it is necessary to open the vents or open the doors to adjacent rooms for air flow.

6. Air leaks through leaks (cracks, cracks) in furnaces and chimneys. This defect is eliminated by appropriate filling of cracks and coating of masonry seams.

7. Dampness of gas ducts. It happens during significant interruptions in the operation of the furnace or when moisture penetrates from the soil through a base that does not have appropriate waterproofing; the latter especially applies to chimneys from kitchen stoves and cooking kettles, the chimneys from which run a considerable distance in the floor.

In these cases, the draft of the pipe is increased by burning in a view door or by cleaning the pipe with dry wood or shavings.

8. The height of the pipe or its cross-section is insufficient. The chimney height (counting from the grate level) must be at least 5 meters. Clear pipe cross-sections for furnaces with dimensions in plan 0.5 sq. meters above, you must have 25x12 centimeters. For furnaces of smaller sizes, the cross section of the pipe can be different 19x12 centimeters and 12x12 centimeters.

If the height of the chimney is insufficient, it must be increased, which is most easily achieved by installing an additional metal pipe with an umbrella. If the chimney cross-section is insufficient, it must be shifted by increasing the cross-section, or, again, the chimney must be extended with an iron pipe. The last event will not, of course, give full results, but it will still significantly improve the operation of the furnace.

Deflector

Draft is often poor because the chimney is located next to or between standing tall buildings, walls, trees, etc. In this case, the pipe must be increased in height, making it at least 0.7-1 meter higher than the neighboring buildings. You can extend the pipe using an iron pipe.

In places subject to strong wind blowing, there is often "overturning" of the thrust, i.e. from time to time the smoke from the stove begins to pull into the room. To combat this, deflectors must be installed on the pipes (see figure).

II. The oven does not heat up well

1. The oven warms up unevenly on the sides. This disadvantage is often observed in older ovens such as the Dutch type. It is very difficult to even out the heating of the walls of such furnaces. Partially this can be achieved by a device, "holes" (holes) from the firebox into the gas ducts of the furnace, where the heating of the walls is weak. "Boreholes" are made with a cross section of no more than 7x7 centimeters, and then, judging by the heating of the furnace walls, they decrease or increase.

In general, at the first opportunity, it is better to shift such a stove again.

2.There are through holes or cracks from the firebox and the first gas duct directly into the chimney. As a result, a significant amount of hot gases, bypassing the rest of the furnace gas ducts, seeps into the chimney. This drawback can be eliminated by opening part of the section wall and sealing leaks.

3. Thick-walled oven. In old structures, it happens that the thickness of the walls of the stove, especially in the area of the firebox, reaches 1 brick (25 centimeters). Such stoves must be shifted with a device with a wall thickness of no more than 12 centimeters, and in the area of the firebox - 13 centimeters (half a brick plus lining on the edge). When removing smoke into the root pipe or channel in the wall for the central, western and southern regions of the USSR, it is generally recommended to make thin-walled stoves with walls l / 2 bricks (in an iron case or with a tile lining).

Very strong brickwork is also obtained on the edge when the frame is installed at the corners of the furnace made of corner iron, sealed with ends into the foundation of the furnace and tied from above with a belt of strip iron. In this case, the brick walls of the furnace need only plaster.

4. The amount of fuel spent on heating the furnace is insufficient. The stoves must always be heated with a full portion of fuel, regardless of the outside air temperature. If it is warm outside, it is better to heat the stove every other day, but it is always normal. With several stoves in the room - in warm weather it is better to heat only part of the stoves, but with a normal portion of heat.

This portion can be determined either by special counting, or in a practical way, by achieving such a heating of the oven so that its outer surfaces have a maximum temperature of about 30 degrees. Overheating of the furnace sections above 80 degrees on the outer surface should be considered unacceptable.

III. The ovens cool down quickly

1. The latch or view of the furnace does not close tightly. This often happens due to cracks in the masonry at the place where these devices are embedded. Therefore, such phenomena are possible when the furnaces are fired with closed views or valves.

After heating, such a stove cools down quickly, since cold air from the room seeps through leaks in the masonry and in the doors along the stove's gas ducts, takes away heat and carries it into the chimney.

2. The furnace is insufficient in terms of heat capacity. In this case, the stove must be heated normally 2 times a day, and even more in severe frosts. If this has to be done often (in the northern and northeastern regions of the USSR), then it is better to redo it, making it more heat capacity, for which the dimensions of the furnace are undoubtedly spinning to increase. The larger the dimensions of the furnace with the same internal filling with a brick nozzle, the higher the heat capacity of the furnace.

IV. Cracks in the oven masonry

Cracks occur mainly for the following reasons:

a) Uneven heating of individual sections of the furnace. This unevenness in some furnaces is very sharp, i.e. a hot section of the oven is followed by a slightly warm one. This disadvantage is caused exclusively by the design of the furnace and can only be eliminated by partial or complete re-laying of the furnace. It is possible to weaken this harmful phenomenon in an easier way, periodically smearing the cracks with clay mortar and leveling the heating of the walls with a cords device.

b) Thick seams of the oven masonry. The seams should not be thicker than 5 millimeters in the masonry of the walls of the stove and 3 millimeters in the masonry of the walls of the firebox. The thicker the seam, the more likely it is to crack, even in good furnace designs.

c) Ligation of the inner walls of the oven with the outer walls. This dressing should generally be avoided if possible. Such dressing is especially dangerous in furnace cavities exposed to high temperatures. The need for such a ligation (after 2 rows on the 3rd) is when laying the last collecting channel in order to create a tight conjugation of the channel walls and the furnace wall, as well as for vertical furnace channels with a channel system, gas distribution - dressing through 3 rows on the 4th ...

d) Settlement of the furnace foundation. This drawback can only be eliminated by correcting the foundation and base and then sealing the cracks in the furnace.

V. Carbon content of furnaces

The carbon content of the stove can be with leaks in the furnace and blower doors, as well as with through cracks located in the area of carbon monoxide accumulation. Burnout usually appears when the valves or views are closed prematurely, when the coals in the firebox still have blue lights.

An unpleasant smell from the stove usually occurs after the stove has been heated for a long time with damp wood. With such a firebox, water and tar vapors are deposited in the last gas ducts of the furnace and in the chimney. They soak through the brickwork and protrude outward in the form of dirty brown spots, emitting an unpleasant odor and spoiling the finish (coloring, etc.).

This disadvantage of the stove is eliminated by stoking the stove for a certain period with dry aspen wood and then cleaning the chimneys of the stove and chimney from soot.

Back to section

Preventive actions

In winter, the stove in the car performs an essential function. In order for it to function normally and not break, it is necessary to adhere to several recommendations.

Periodically check the serviceability of the car at the service station, this will allow you to find and eliminate problems in advance

Preventive measures:

- Keep the radiator clean. External dirt must be removed with a vacuum cleaner. For internal cleaning, the cooling system and oven radiator should be flushed regularly.

- It is worth pouring in high-quality antifreeze. It will be useful not only for the stove, but also for the engine as a whole. We must remember to replace the fluid in time.

- You should buy a new cabin filter as often as possible. If this element is clogged with dirt and dust, this negatively affects the functioning of the entire ventilation system of the car as a whole. An uncleaned filter can be dangerous to humans due to the appearance of various microorganisms.

If the outside temperature drops below -25 ° С, and the car stove heats the air in the cabin to + 15 ° С, then this means that the equipment is working normally. To avoid problems with the heating system of the machine, you need to take preventive measures on time, and also remember that the performance of the car's heating system directly depends on its age. The older the car, the more attention you need to pay to it.

What would the stove be better heated:

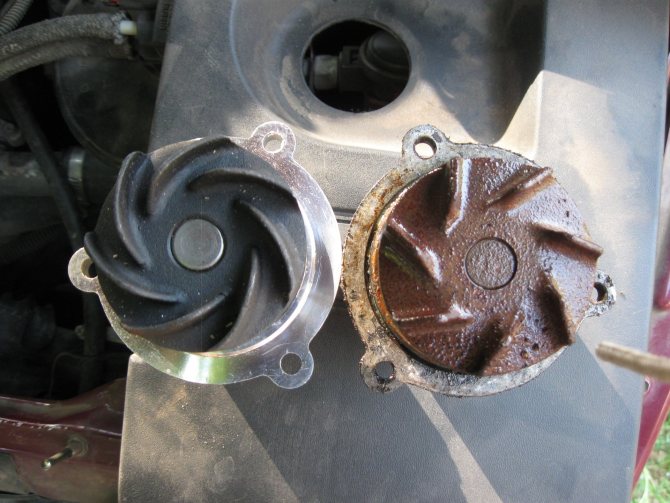

Pump impeller wear

A pump is a pump that pumps antifreeze from the engine, ensuring its continuous circulation throughout all components of the cooling system. It is quite difficult not to notice a breakdown of the pump: in this case, the engine will immediately overheat and boil.

When the impeller blades are worn out due to the aggressive effects of water or poor-quality antifreeze, the pump performance drops significantly. It is still enough for the coolant to somehow circulate and the engine does not overheat, but it is not enough to fully warm up the heater radiator.

What to do

As a rule, pumps are not repaired. Therefore, the problem is solved by replacing the faulty unit with a new one.

Fan problems

The cold in the cabin can be caused not only by insufficient heating of the heater radiator, but also by its weak blowing. This is already the fault of the fan, which does not provide the necessary air flow and heat removal from the radiator.

What to do

If the fan does not work at all, then everything is clear. More often than not, it rotates, but with insufficient speed. This is due to wear on the brushes of the electric motor or wedging of the bearings. In both cases, repairs by an auto electrician will be required.