Views

According to the material of manufacture, water reducers are divided into those that are made of:

- Brass;

- Plastic;

- Polyamide.

It should be noted that brass is copper and zinc, that is, an alloy of these metals, this material is often used for the manufacture of plumbing devices. Plastic assemblies (fig. 1) are durable and practical. Polyamide is a material that is very similar in composition to plastic, but its durability can be attributed to the presence of fiberglass in the composition.

Fig. one

Membrane type plastic water assembly

The operation of this device in a gas water heater is no different from other gas water heaters. That is, the main difference lies in the material of manufacture.

Diaphragm reducers for a gas water heater can withstand sufficiently high pressure, as for household appliances. Namely, it is from 0.5 to 3 m3 / hour.

Design and types of water block

The material for the manufacture of a water reducer is different, therefore it is divided into several types:

- Brass. Alloy of copper and zinc.

- Plastic. The practical device does not corrode.

- Polyamide. Reliable device with fiberglass composition.

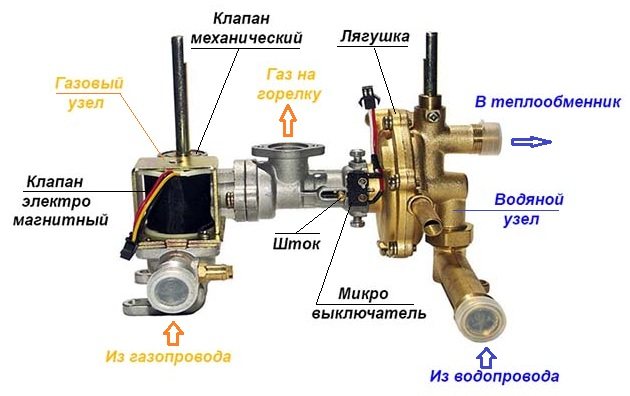

The column regulator or "frog", as the unit is also called, has protective functions. It serves to automatically turn on the device when water is supplied. Also protects against overheating when the line pressure drops.

How the reducer works:

- Bolted base and cover.

- Rubber diaphragm with disc on the stem.

- Flow device.

- Temperature switch.

- Flow sensor.

- Venturi tube.

- Filtering device for hot water.

See diagram:

The cover of the water pressure regulator can be secured with steel screws or plugs. Since the parts are not in contact with water, there is no risk of corrosion. By unscrewing the screws, you will remove the cover, behind which the membrane is located. The device is quite simple.

When the water is turned on, pressure is created on the membrane. It pushes the stem, which actuates the gas valve. Fuel is supplied to the burner and heating starts. When the mixer closes, the pressure drops - the parts return to their original position.

An important part of the gas-water unit is the Venturi nozzle. What is it for? For example, in the technique of the company "Neva" the tube is at the bottom. The location in the columns "Oasis", "Astra" may vary. The part serves to reduce the pressure of the working medium. This is how the gas supply is regulated.

When you close the faucet, the tube aligns the readings, so that the diaphragm fitting returns to its place. After that, the device turns off.

The water part is also prone to breakdowns, so we will list the main faults and ways to repair yourself.

Principle of operation and design

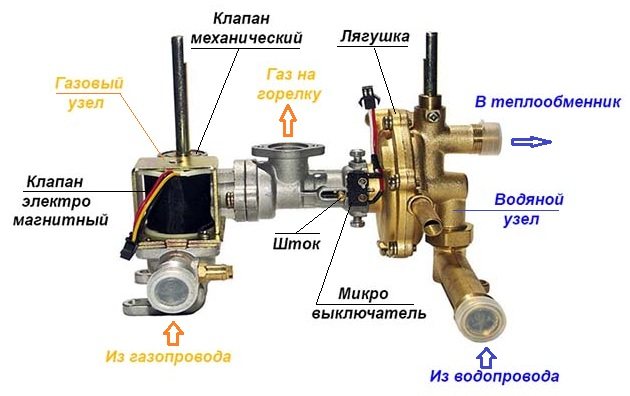

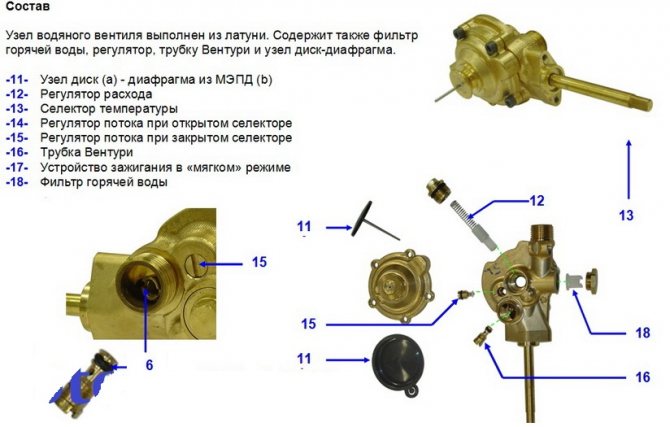

The device of the reducer of the gas column made of brass consists in the presence of the following components (Fig. 2):

- The diaphragm and disc appear as a single unit;

- Flow regulator;

- Temperature selector;

- Water flow regulators with open and closed selector;

- Venturi tube;

- Hot water filter.

Fig. 2

A reducer for a gas water heater has the main task - it is to start and ensure normal operation after opening the water tap. Also, thanks to this unit, it is possible to regulate the flow of water that enters the gas column. The reducer also performs a protective function, since with a poor pressure, it does not allow the column to overheat.

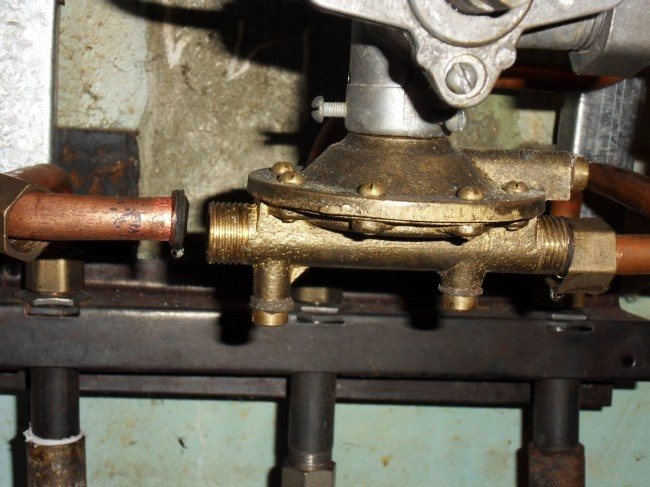

The principle of operation of the water unit of the column is the effect of the water flow on its parts. Namely, when water passes through the reducer, it presses on the membrane (diaphragm) (Fig. 3) and the so-called fungus (disc). This fungus changes its location, rising up to the level of the valve. The rod of the fungus, in turn, directly acts on the gas unit, that is, on its valve. And as a result, gas begins to flow into the burner of the device.

Fig. 3

Membrane for the water unit of the gas column

When the water tap closes and water stops flowing into the gas water heater, the indicator of water pressure on the fungus decreases. The gas valve in the unit begins to affect the fungus, which means that the gas is shut off and the gas appliance is turned off. When the gas water heater is off, the reducer does not function.

Why the gas water heater does not work

There are several common reasons why the gas water heater does not work. You can find and fix them yourself.

Lack of traction

Any gas water heater has a function that controls the presence of traction. If there is a shortage of it, then the gas is automatically shut off and the ignition on the gas column does not work.

It is very easy to check the presence of traction yourself. You need to bring the match to the ventilation hole or chimney. If the flame burns evenly, then there is no thrust. If the fire draws into the hole, then the chimney is working correctly. It happens that back draft occurs, and then the air flow blows out the fire in the burner.

If there is no thrust, then it is necessary to determine the reason for this. Most likely, a blockage has appeared in the ventilation or pipe, which must be removed.

Batteries are low

In an automatic gas water heater, the cause of a malfunction is often dead batteries. They spark when ignited. Basically, the batteries are enough for 7-15 months of operation.

In this case, the problem is very simple to solve - by replacing old batteries with new ones.

Insufficient water pressure

Each gas water heater works only at a certain value of water pressure in the line. There are models that are capable of heating water only at 0.2 or 0.3 bar. In the case when the pressure is lower, the device will not work.

After detecting low pressure in the line, it is necessary to find out the cause and eliminate it:

- If the pressure has dropped throughout the water supply network, then you need to call the utility service and report the problem.

- Sometimes a clogged pipe or filter is the cause of the pressure drop. It is recommended to check the filter and clean it if necessary.

Note! If a drop in water pressure in your line is not uncommon, then you can correct the situation by installing a pump that will increase the water pressure or replace the device with another one that can operate at 0.1-0.15 bar

Gas burner clogged

Most often, the piezoelectric element in the gas column does not work due to a clogged burner. If it is clogged with soot and soot, it is necessary to disassemble the structure and thoroughly clean each of its elements. Then you should collect all the parts and try to ignite the column again.

No gas supply

Usually, when you turn on the speaker, you can hear the sound of incoming gas and smell it slightly. If neither one nor the other is present, then fuel is not supplied. This is one of the reasons why the ignition of the gas column does not work.

If gas does not flow, it is recommended to first check if the gas filter is clogged. If so, the filter is cleaned of the blockage. In other cases, you need to call the gas service and find out what is the reason for the lack of fuel.

Note! If there is a gas leak and you smell it in the room, then you cannot turn on the gas water heater. Call a gas specialist immediately

Problems in the water unit

After 3-4 years of intensive use, the membrane of the column water unit gradually loses its elasticity and may even break. If this happens, the device will not be able to work.

To check the membrane, it is necessary to remove the body of the device and unscrew the bolts that hold the assembly. Then remove the cover of the water block and inspect the membrane. If it is damaged, then replace it with a new one. It is better to purchase an item made on the basis of silicone. This membrane will last longer.

Replacing the elements of the water unit should be carried out only if you are confident in your abilities and have the skills to repair such devices.

If you cannot identify the reason why the gas water heater does not work when turned on, call a specialist. He will quickly figure out what the matter is and fix the problem.

Malfunctions

Qualified experts say that in 8 out of 10 cases of breakdowns of gas columns, the problem lies in the water unit. Typically, this is contamination or deformation of the membrane in the assembly. Namely, the deposition of various clogs and salts occurs, as well as the formation of cracks in the housing, etc.

You should be aware that a damaged node cannot perform its functions to the fullest. If the membrane is damaged, then it cannot stretch so as to open access to gas.

There are models of gas water heaters, the membrane in which you need to change regularly. According to reviews, this is a device from the manufacturer Neva. In order to prevent damage from time to time, you need to disassemble the gearbox in order to clean it. Then you can notice the deformation of the membrane in time. Filters in the water unit are often clogged.

Gearbox wear is due to frequent switching on / off, this is strongly reflected on the membrane in the unit, seals, etc. When the seal wears out, water begins to ooze from the gearbox.

We can conclude that the reducer for the gas water heater is an important part that needs to be serviced, which means that it must be in such a position so that there is constant access to it. Such maintenance of the gas water heater or, if necessary, repairs can be carried out independently, since these manipulations are not difficult. No special skills are required to replace or clean the gearbox.

Fig. four

Column water assembly with 8-bolt housing

Repair and maintenance of the water block

In order to carry out any manipulations with the gearbox, or to understand or the problem lies in this particular part, you need to unscrew it from the copper pipes, that is, the nuts are unscrewed. Next, you need to unscrew the reducer from the gas unit. Typically, it is located under the gas valve and is screwed in with three screws. Often in newer models, the gearbox is secured with a single bolt. During the unscrewing process, the device must be held so that it does not fall.

To open the gearbox, unscrew the bolts that hold the two body parts, usually 8 pieces (fig. 4). They are located in a circle. Next, you should check the integrity of the rubber membrane in the middle, the integrity of the case. If the membrane is clogged, it must be cleaned and reinserted, and if it is deformed, a new one should be purchased. The new membrane is inserted in place of the previous one. Membranes of different quality are sold today, you should not buy too thin, as it can break through in the near future. There are good quality silicone membranes, just don't be lazy, but you should go to several stores and find one.

Fig. five

To install the gearbox back, it is important to determine which branch pipe connects to where. If you look closely, the inlet and outlet pipes are different in diameter. The hole through which water is supplied to the reducer for the geyser is larger than the one through which water leaves the device. If you install the gearbox incorrectly, then there will be problems with the membrane and, in general, with the operation of the entire unit.

Next, the two parts of the body are twisted with bolts and screwed to the inlet and outlet pipes. The nuts that screw the assembly to the nipples are fitted with rubber gaskets for sealing. When installing the water unit, you need to carefully check them. Sometimes you also need to replace them. Next, you should test the water unit by running the column.

The internal structure of the gas water heater is quite complex and is represented by many details. One of them is the water block, which is also called the water reducer, water unit, water regulator or "frog". It is located inside the column in front of the heat exchanger and is responsible for regulating the operation of the column depending on the flow of water into the apparatus.

Repair and maintenance of the gas-water unit

Hard water, constant thermal stress and other factors destroy the structural components of the column over time. Any gas consuming equipment needs to be serviced regularly. And if defects are detected, carry out immediate repairs.

The design of the water reducer of the gas column has a simple internal structure. Everything is easy to understand. If desired, you can repair the gas water heater frog or carry out preventive maintenance without calling the master.

How to remove a frog from a gas water heater

First you need to shut off the water and gas supply. After this, work is carried out in the following order:

- water is drained from the heat exchanger - for this purpose it is better to use a tap or mixer located significantly below the water heater;

- disconnect the gas and water supply pipelines (an adjustable wrench is required);

- now you can remove the water assembly of the gas column, if everything is done correctly, the frog should be easily dismantled.

The design of the reducer may vary depending on the flow column model. In order for the removal of the water block to be successful, it is necessary to detach all parts and pipes that fit the main structure. The case can be removed easily, no physical effort is required.

Cleaning the water unit of the gas water heater

Held at least every year. There are several fixing bolts on the frog's cover. When unscrewing, care must be taken not to spoil the folds. After removing the cover, or disassembling the gearbox into two parts (depending on the column model), the internal space is cleaned and the structural parts are serviced:

- while cleaning the gearbox, scale and solid residues that have settled on the bottom of the unit are removed, at the same time they clean the coarse mesh on the inlet pipe;

- the stem can be lubricated with castor oil or grease;

- the gasket can also be smeared if it feels rough and has lost its elasticity to the touch.

Regular maintenance of the frog will prolong the life of the tankless gas boiler and keep it running smoothly.

What components should be replaced

There are several elements in the gearbox that are constantly exposed to mechanical pressure and poor-quality water. At each service, the operability is checked and the following components are replaced:

- stem seal - gland replacement is required on average every 3 years to protect the gas valve from moisture ingress;

- membrane - replacement of the gasket is needed when it breaks, as well as when microcracks appear;

Views

Depending on the material of manufacture, the water block is:

- Brass, that is, made of an alloy of copper and zinc. Brass is often used to create plumbing fixtures.

- Plastic. Such a site is very practical and has a long service life.

- Polyamide. Additional durability of such a block is provided by the fiberglass present in its composition.

Brass Water Knot

Plastic water unit

Polyamide water assembly

Principle of operation

The main task of the water unit in a gas heater is to start the column after opening the tap, and also to ensure its normal operation while the tap is open. Also, this node is important for regulating the flow of incoming water. If the water pressure is insufficient, the reducer will also perform a protective function, preventing the column from overheating.

The operation of the water unit is based on the effect of the water flow on the parts of the reducer. The water entering the column acts on the diaphragm, as well as on the disk (it is also called a fungus). A change in their location affects the stem, which activates the valve of the gas unit, due to which gas begins to flow to the burner.

As soon as the hot water tap closes, the pressure acting on the diaphragm and the fungus decreases. This reduces the impact on the gas valve, which leads to the blocking of gas access and the shutdown of the device. When the gas water heater is not turned on, the water unit does not function.

Typical malfunctions

A breakdown of a water block is considered one of the most common malfunctions in gas water heaters. The most common cause of block failure is membrane deformation or contamination. Salts can be deposited on it, and cracks can also form. With such damage, the unit ceases to function, which prevents gas from entering the column.

Also, a fairly common problem is clogging of the filters of the water reducer, and due to the frequent switching on and off of the device, the unit wears out, which leads to leaks at the locations of the seals.

You definitely need to check the water unit if:

- The water pressure is normal, and the column does not turn on (the membrane is damaged or the stem is dirty).

- The cold water pressure is normal, and the hot water comes with a very weak pressure (a blockage has formed).

- The hot water tap is open, and the column began to work only after a while (a problem with the flow regulator).

- The hot water tap is closed, but the column is still running for some time (problem with the flow regulator).

- The column turns off during operation or does not gain the required power (the membrane is damaged).

Repair and service

In order for the gas water heater to function properly, the water unit should be periodically disassembled and cleaned, as well as inspected for the timely detection of deformation areas and small cracks. Replacing the diaphragm in the water reducer is recommended even with the slightest deformation of this part.

Having disconnected the column from the water and gas supply, you need to open the hot water tap to relieve pressure. After that, it is necessary to remove the casing of the apparatus and find a water reducer on the cold water pipe. The regulator can be removed by unscrewing the nuts fixing the part to the pipes and the screws fixing the reducer to the gas unit.

To open it, the bolts located in a circle are unscrewed, which hold it in two parts (usually there are eight). After inspecting the membrane and housing, perform the required manipulations (cleaning, replacement), after which the assembly is assembled and mounted in its place inside the column. In this case, it is important not to confuse the connection of the branch pipes (the diameter of the inlet must be larger). You should also make sure that all connections are properly sealed.

Geysers occupy a leading place in popularity among water heating equipment. This is due to their efficiency and fuel availability. One of the nodes that are responsible for the correct operation of a gas water heater is a water (water intake) unit. What the assembly consists of, what the principle of its operation is based on, and what, the most common, breakdowns can affect the element - read below.

Gas water columns: principle of operation, malfunctions

The water geyser refers to flow-through water heaters.This means that the water, through the water intake unit, enters the column, passes through the tubes of the heat exchanger, heats up and leaves, heading through the pipeline to the points of water intake.

So, one of the important elements in the design of a gas water heater, which affects the efficiency of its operation, is a water block or "frog".

Like any complex equipment, the gas water heater can fail (stop turning on, igniting and extinguishing, etc.). This may be due to both external factors (pressure of water, gas, quality of ventilation draft), and breakdowns of internal components of the equipment.

It is necessary to check the water intake block of the column if:

- The column does not ignite at a working water pressure of 3-4 bars;

- Hot water flows poorly, while the pressure of cold water is strong enough;

- The column lights up some time after opening the hot water supply tap, and not immediately;

- The column remains in working condition after closing the hot water supply tap;

- The column does not gain the required power, it turns off during operation.

Some of the above breakdowns can be eliminated on your own, while others require a call from a specialist.

The principle of operation of the column water block

Instantaneous water heaters turn on immediately after opening the water supply tap and turn off after closing it. The working process regulates the water block of the gas column.

The hollow frog device is divided into two parts by a rubber membrane. One half of the reducer is connected to the cold water supply, the second is a stem connected to the gas valve. On the metal rod of automatic water heaters there are “wings” connected to the electric ignition unit.

The principle of operation of the gas-water unit of the gas column is as follows:

- when the cold water tap is opened, one of the cavities is filled with water;

- under the pressure of water, pressure is exerted on the membrane of the water unit;

- the diaphragm under pressure bends and presses on the rod located in the second cavity;

- a metal rod presses on the valve, opening the gas supply;

- in the automatic dispensers on the rod there are ears connected to the ignition unit;

- a spark is supplied to the burner, igniting the flame;

- after closing the hot water tap, the structure and internal parts of the unit return to motion;

- the stem returns to its original position thanks to the spring and closes the gas supply.

The device of the gas water heater reducer may differ depending on the model of the gas water heater, but the general principle of operation of the unit remains unchanged. Any malfunctions are reflected in equipment malfunctions. A breakdown can be determined by several characteristic features.

How does a reducer for a gas water heater work: design

The main task of the gas water heater's reducer is to pass water into the equipment and take care of turning the heater on and off when opening and, accordingly, closing the tap. The node located in the gearbox is responsible for changing the water flow. Arranged "frog" is quite difficult.

So, the water-gas reducer of a gas water heater consists of:

- Membrane and disc (fungus);

- Flow regulator;

- Temperature regulator;

- Water supply regulator with open and closed mixer;

- Venturi nozzle;

- Hot water filter.

The scheme of the structure of the node in each individual model remains unchanged. Differences can only be in the material of the assembly: the gas-water block is made of brass, plastic, polyamide.

The operation of the water-gas unit of a flow-through heater is based on the principle of the mechanical effect of a water flow on its parts.

So, water entering the column affects the diaphragm and disc (fungus). The parts change their location, which causes the valve stem to activate the gas unit, and fuel begins to flow to the burner. As soon as the valve closes, the pressure in the system decreases, the parts return to their places and the burner goes out.

Gas water reducer

A modern gas water heater is a very convenient device for heating water, which can be used both at home and at work. Usually it is installed in non-residential premises, according to the project. The water reducer (or block) is installed in the apparatus in front of the heat exchanger and is connected to it using copper pipes, while the gas block is attached to the upper part of the reducer with screws.

The principle of operation of the water block

The functions that the water unit performs are almost the same for all gas-fired water heaters, regardless of the model, the difference can only be in the material. Quite a variety of materials are used to make a column water reducer:

- Plastic is a durable and practical modern material.

- Brass is an alloy of copper and zinc traditionally used for plumbing.

- Polyamide is a plastic-like product that is reinforced with fiberglass.

Regardless of the material from which this part is made, the main task of the unit is to start the column into operation at the moment the hot water tap is opened.

The unit located in the device is designed so that you can change the flow of water entering the device. The node diagram provides the following operating procedure:

The water flow, passing through the unit, affects the reducer membrane and with its help the fungus in the upper chamber rises up. Having reached the upper level, the rod of the fungus begins to act on the valve of the gas block and thus gas access to the burner opens.

At the moment when water stops flowing into the system, the pressure in the lower chamber drops, and the valve of the gas block presses the gearbox fungus, thereby blocking the flow of gas to the burner and the column turns off. Thus, at this moment, the function of the water unit ends.

Reasons for the speaker malfunction and how to fix them

A water heater, like any home device, sometimes fails and it is very important to correctly determine the cause of the breakdown. Quite often, consumers complain that the device starts to heat the water very weakly or does not heat it at all. In this case, the first step is to inspect the water unit, in which, most likely, the membrane is clogged or deformed. Defects can be as follows:

- Clogging.

- Cracks.

- Salt deposits.

In any case, the damaged membrane of the water reducer cannot function correctly and react to the pressure difference in the water supply system. Insufficient stretching of the membrane from the pressure of water prevents the gas valve from opening the required amount. In order to solve this problem, you must:

- Disconnect the device from the gas supply.

- Clean the block.

- Check the quality of the membrane.

- Replace the membrane if necessary.

- Additionally clean the filter and unit cavities.

- It is recommended to use a silicone membrane, which is much more reliable and durable.

The next reason for the inoperative state of the device may be insufficiently strong water pressure, as a result of which there is a lack of traction. To make sure of this, you need to check the hot and cold water taps and if they have an equally weak pressure, then the reason most likely lies in the plumbing system. But in the case when cold water pours with a higher pressure than hot water, then the problem again lies in the functioning of the water reducer.

As in the first case, in order to establish the full-fledged operation of the gas column, you need to know how its circuit is arranged, and first of all, check the membrane, as a part of the block. To troubleshoot in this case, it is worth disassembling the gearbox and cleaning it. In the event that the membrane is deformed and becomes unusable, it must be replaced.Another cause of breakdown can be both clogging of filters in the unit and clogging of pipes through which hot water flows. As a preventive measure, it is recommended to clean the device from soot once a year by first removing the housing and cleaning the burner and heat exchanger with a vacuum cleaner.

A device for heating water, better known as a gas water heater, only at first glance does not represent anything complicated. On closer examination, the diagram of this device contains many interesting technical points. For example, a water regulator of a gas column, which is designed to ensure the safety of the column. It serves to automatically regulate the on (when hot water is turned on) and off (when the water intake is turned off). If the pressure is too low, the device will protect the device from overheating. Quite often there are regulators that have plugs and screws made of steel, but this does not affect their durability at all, since these parts are not exposed to water and, accordingly, do not rust.

When operating a gas water heater, it is worth remembering that constant switching on and off provokes severe wear of the membrane, microswitch, stem seal and plate with stem. The seal in this case is responsible for the tightness of the part and when it wears out, water begins to drip from the device. But the main load goes, first of all, to the water unit, therefore this part of the unit requires constant attention and control. It is necessary that all parts of the device are within reach for their repair and replacement.

So, from all of the above, we can conclude that the main malfunctions in the operation of the gas column can be quite easily eliminated, even without special skills.

Venturi nozzle: working principle

One of the important elements of the water unit is the Venturi nozzle (Venturi tube) - a device that regulates the gas supply. Most often, in a gas column, the nozzle occupies the lower part of the column, and is located in the right branch pipe (as, for example, in the Neva column).

The main components of the venturi are the inlet, with an annular chamber and a pressure tapping hole.

When the hot water supply tap is closed, the tube equalizes the pressure under and above the membrane, the stem responsible for the gas supply moves to its original position: the supply stops and the burner goes out.

Water block of the gas column: typical malfunctions

Deterioration and failure of elements of the water intake block of the water column are common malfunctions that can affect any gas water heating equipment. This is due to the quality of tap water, drops in hydraulic pressure in the pipes.

Specialists in the maintenance of gas water heating equipment say that 80 out of 100% of the failure of gas water heaters is associated with problems in the gas-water unit.

It is possible to eliminate most of the faults in the water block without the help of a specialist. The main thing is to know which breakdowns are most typical for a particular part.

So, the most frequent malfunctions of the water block of a gas water heater are:

- Diaphragm is dirty or deformed. A worn diaphragm cannot stretch enough to open up gas. Because of this, the column may not light up. The membrane should be changed if the part is stretched, skewed to one side, has breaks, etc. There are columns in which the filter needs to be changed regularly (for example, Neva). A planned replacement of the part is carried out, depending on the quality of the water, every 12-36 months. At the same time, it is better to install a silicone part, the service life of which is longer than that of a rubber one.

- Clogged or mechanical damage to the water filter. The filter becomes clogged during the entire operation of the column with lime, fine sand particles in water, and rust.The element can be cleaned with a high pressure of water. If the filter is badly worn out, then it is usually replaced with a new one.

In addition, incorrect operation of the gearbox can be associated with cracks in the element body, leaks in the connecting pipes (for example, the cold water supply to the water-gas unit can leak), clogged stem or malfunction of the pressure regulator.

Possible malfunctions of the water unit

There are malfunctions and malfunctions in the operation of the instantaneous water heater, which clearly indicate the failure of the structural elements of the gearbox. These include:

- refusal to turn on the column;

- the flame is not ignited the first time;

- there is a water leak from the reducer;

- after closing the DHW tap, the flame does not extinguish.

Malfunctions indicate the following probable breakdowns and malfunctions in the "frog":

- Diaphragm ruptured - the average service life of the diaphragm is 5-7 years. Over time, due to constant mechanical stress and hard water, rubber breaks through. A sign of membrane failure is that water is dripping from the gearbox.

- The membrane has become coarse - the quality of the water unit of the gas column depends on the elasticity of the diaphragm. For operation, it is important that the membrane is sensitive to any changes in the water pressure. If the gasket is hardened, the column will be triggered with a delay. After closing the DHW tap, the gas burner continues to work for some time.

- Plugged stem - when the membrane breaks through, water enters the metal surface of the stem, causing it to corrode. Rust interferes with normal needle movement. Symptoms of malfunction: it is difficult to start the column. The flame is ignited only under strong water pressure. After closing the DHW tap, the burner does not go out.

- The coarse filter is clogged - a mesh is located at the entrance to the gearbox, which quickly clogs, especially if the connection conditions were violated and the piping scheme was completed with errors. Malfunction symptom: difference in pressure at the inlet and outlet of the water heater.

Damage to the device and the principle of operation of the gas water block (video)

One of the main units responsible for the correct operation of gas water heating equipment is the water intake unit. Due to its location and purpose, it is prone to wear and tear. That is why every owner of a gas water heater should know the device of a water intake gas unit. This will allow him to quickly repair equipment, eliminate breakdowns that block the operation of the column. And the above overview of the most common malfunctions will help to correctly identify the breakdown.

Attention, only TODAY!

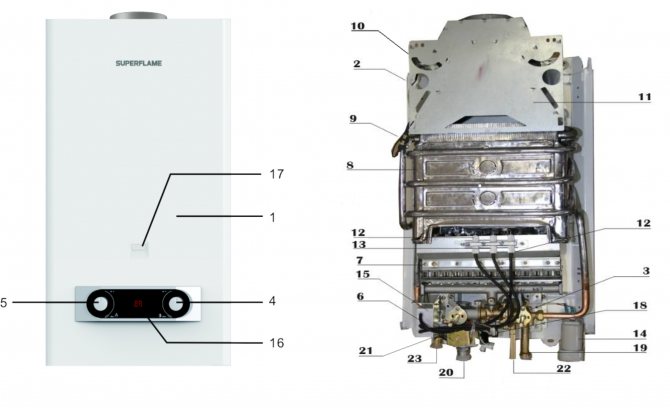

How does a gas water heater work, and what elements does it consist of? If you are interested in this issue, I propose to consider in detail the device of the gas water heater. I am sure that this will help beginners understand the principle of operation of the heater and, in the event of a malfunction, diagnose it in a timely manner.

Gas water heater device: detailed inspection

Metal equipment, similar to a cabinet, is a box with two pipes connected. One tap, the second supplies gas. The main parts are the heat exchanger and both burners (main and pilot).

A more detailed geyser device is as follows:

- Water node.

- Gas unit.

- Water flow regulator.

- Diaphragm valve.

- Chimney connection.

- Exhaust hood.

- Power control.

- Switch.

- Rear panel.

- Heat exchanger.

- Ignition.

It is important to know that this equipment differs in the way of ignition. The methods are as follows - electronic, manual and ignition with a piezoelectric element. These devices function in different ways.

Column device

General information

The geyser for water is an instantaneous heater. Unlike a boiler, where a container with water is heated, the water in the columns has time to heat up as it flows through the pipes.Accordingly, they have no storage capacity.

Flowing gas water heaters were invented at the beginning of the last century. During their existence, they, of course, have improved significantly. However, in general, the design and principle of operation of the geyser have not changed.

Main elements

All existing instantaneous gas water heaters consist of the following main elements:

- Igniter and ignition system.

Provides ignition of the burner; - Combustion chamber and burner.

An important element that provides the column with thermal energy; - Water block

... Responsible for the gas supply when the water is turned on, and closes it when the hot water tap is closed; - Heat exchanger.

It transfers heat from the combustion chamber to the coil in which the water is heated;

- Coil.

It is a spiral tube located around the heat exchanger; - Water and gas pipes.

Provide connection of the column to the gas pipeline and pipeline; - Chimney connection pipe.

Provides connection of the column with the chimney, through which the combustion products are removed to the outside; - Control block.

Allows you to change the heating temperature, etc.

Modern speakers are equipped with some safety features, such as:

- Chimney draft sensor - blocks the operation of the column in the absence of draft;

- Gas valve - shuts off the gas in the event of a drop in gas pressure in the pipeline;

- Flame presence sensor - cuts off the gas if the column, for some reason, does not light up within a few seconds.

I must say that all columns differ in the combustion chamber. Depending on its type, they are divided into two types:

- With an open combustion chamber

... The name speaks for itself; - With a closed combustion chamber

... In this case, air is supplied to the burner by means of a fan. As a rule, such devices are equipped with an electronic unit that controls the operation of the heater.

Loudspeakers equipped with electronic control units most often run on batteries, which ensures their autonomy. True, there are also models that operate on the network.

Principle of operation

In general, the principle of operation of gas water heaters is quite simple:

- When the gas burns, heat energy is released;

- Thermal energy heats up the heat exchanger. The latter, as a rule, is made of copper or special alloys with high thermal conductivity;

- Around the heat exchanger there is a coil, also made of metal with high thermal conductivity, as a result of which it also quickly heats up itself and heats up the water;

- From the coil, hot water is supplied to the pipeline;

- Combustion products leave the combustion chamber and are discharged outside through the chimney.

Design and operation of a gas water block

... Separately, the device and the principle of operation of the gas water block should be considered. As I said above, the water block reacts to the water supply and ensures that the column starts up.

The main element of the water block is a reducer, which is called a "frog". Inside it is a diaphragm with a stem. In modern dispensers, the water unit works as follows:

- When the tap is opened, the water flow passes through the reducer;

- In one of the chambers of the reducer, an increased pressure forms, as a result of which the membrane (position 2 in the diagram above) bends and pushes the plate out. The poppet, in turn, pushes the stem (position 1). It must be said that the rod pressure is about 50 kg;

- The water rod pushes the rod of the gas module, which is located opposite;

- The pusher, which is in communication with the rod, acts on the switch plate, as a result of which electricity from the battery section enters the electronic control module section, and then to the ignition burner, where a spark is generated;

- At the same time, the stem presses the mechanical gas valve and gas begins to flow into the ignition system and the burner.At the same time, an additional solenoid valve is also triggered, which also provides free gas passage;

- When a spark appears, the gas is ignited in the igniter, after which the main burner ignites. In this case, the flame presence sensor sends a signal to the control unit, as a result of which the spark plug that generates a spark is turned off;

- When hot water is turned off, the pressure in the two chambers of the reducer is equalized, as a result of which the stem is squeezed out. Accordingly, the gas valves are triggered and the gas supply to the burner is abruptly stopped.

Modern dispensers also have a water temperature sensor. When the water heats up above the set temperature, it sends a signal to the control unit, which in turn shuts off the gas supply system. When the water cools down, the sensor is triggered again, and the burner is ignited.

In simpler models, many sensors are absent, but in any case, the gas supply opens only after the water pressure in one of the reducer chambers rises. Therefore, if there is insufficient water pressure, the column will not turn on.

If the pressure of the hot water supply is weak and the column does not ignite, but the pressure in the water supply is good, then the reducer channels are most likely clogged. In this case, you can disassemble it yourself and rinse it thoroughly.

Ignition method.

Currently, there are the following types of column ignition:

- Manual.

In this case, to ignite, you need to turn the handle of the column until it stops, without pressing it, and then light the igniter with your own hands, for example, with the help of matches. After igniting the igniter, push the knob and turn it clockwise to turn on the gas supply to the burner. In this case, the igniter will ignite the burner;

- With piezo ignition.

In such columns, as in manual ones, gas is first supplied to the igniter. To ignite it, you need to press a special button, as a result of which a spark will appear. After igniting the igniter, you can open the gas supply to the burner. During the day, the igniter can not be extinguished, respectively, the next time the column is turned on, you do not need to press the button.

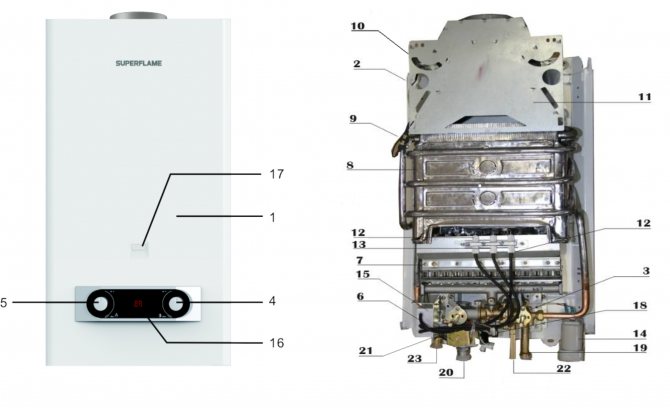

Tula Gas Equipment Plant

The device consists of: 1 - facing *; 2 - frame; 3 - water-gas unit; 4 - handle of the water unit regulator; 5- gas unit regulator knob; 6- solenoid valve; 7- burner with manifold; 8- heat exchanger; 9- water overheating sensor; 10- thrust sensor; 11- gas outlet device (GOU); 12- electrode for electronic ignition of the burner; 13- ionization flame control electrode; 14- battery compartment; 15- electronic control unit; 16- indicator of digital temperature of hot water; 17- viewing window; 18- microswitch; 19 - water block inlet pipe (water supply) with filter; 20 - gas block inlet (gas supply) with filter; 21- water outlet; 22- safety valve, 23- hot water temperature sensor

* - the appearance of the cladding differs depending on the model.

The purpose of the main nodes.

The device uses an automatic electronic ignition system, powered by two 1.5 V LR20 batteries located in the battery compartment 14. The convenience of using the device is achieved by turning on the water heater by simply opening the hot water tap.

Water-gas unit 3 is designed to turn on the device and ensure the regulation of water temperature and gas flow. The assembly consists of two regulators: water and gas, as well as a mechanical gas valve.

The design of the water regulator opens the mechanical gas valve and supplies gas to the burner only when there is a water flow, while simultaneously ensuring the opening of the solenoid valve 6.

The design of the gas regulator is part of the gas fittings that regulate the gas supply to the burner.

Burner with manifold 7 is intended for combustion of the air-gas mixture supplied to the combustion chamber.

Heat exchanger 8 (heat exchange system: hot combustion products - cold water) is part of the water fittings in which heat exchange takes place between the hot combustion products of the burner and the water flowing through the heat exchanger pipes. The heat exchanger has a shell that forms a combustion chamber and a special coating that provides additional protection against oxidation, which significantly extends its service life. Heat exchanger material - copper.

Water overheating sensor 9 ensures that the water heater is turned off when the water is heated above 80 ° C, thereby preventing the formation of scale in the heat exchanger tubes, which increases the service life of the water heater.

Traction sensor 10 is designed to turn off the device in the absence of draft in the chimney.

Gas venting device 11 is designed to remove combustion products into the chimney and serves as a place for installing the sensor 10.

Electrode for electronic ignition of the burner 12, forming spark discharges for 5 s when the device is turned on (when passing water through the device), ignites the burner.

Flame control ionisation electrode 13 provides control of the burner flame and automatic shutdown of the gas supply to the burner when it goes out.

Hot water temperature sensor 23, which is a thermistor whose resistance value changes depending on the degree of heating of the sensor.

Digital indicator 16 displays the temperature of water heating at the outlet of the water heater.

safety valve 22 is designed to drain water from the water heater without disconnecting it from the pipelines (by turning the valve) and relieving pressure in the event of a sharp increase in water pressure in the system.

Most common breakdowns

Finally, I will give a few of the most common breakdowns of gas water heaters. Most often, the following problems can be observed in the operation of heaters:

- Scale clogging the coil

... If the pressure in the hot water tap is low, while cleaning the gearbox did not solve the problem, then the coil is clogged. In this case, it must be rinsed with a remover such as Anti-Scale;

To prevent the formation of scale, make sure that the water temperature does not rise more than 60-65 degrees. In addition, the heater should not operate in the ignited pilot mode for a long time.

- Flow.

This problem is usually faced by owners of old speakers. As a rule, a leak occurs due to wear of the seals, respectively, they just need to be replaced. In rare cases, the leak occurs due to the depressurization of the coil. You can repair it by soldering;

- Does not ignite.

There are several reasons why the column may not light up: low water pressure; - there is no draft in the chimney - a foreign object may have got into the chimney;

- batteries are discharged (applies to speakers with automatic ignition);

If the column does not ignite due to low water pressure, the filter located at the inlet may be clogged.

- Heats water poorly

... There may be several reasons: blockage of gas equipment; - the need to adjust the burner - modern dispensers have a tap that allows you to adjust the gas supply to the burner.

These are all the most common malfunctions of gas water heaters that you can fix yourself. The service manual, which usually comes with the passport, will help with this.

If you are not sure that you can fix the breakdown yourself, it is better to seek help from specialists. The repair price starts from 300 rubles excluding the cost of parts.

Performing serious operations, such as soldering a radiator, costs 1000-1200 rubles. Prices are valid in spring 2020.