The gas boiler Hearth KGS is included in the line of a wide range of products. The Russian manufacturer produces gas burners, control units and gas burners. The Hearth KGS boiler is the result of the implementation of innovative strategies in combination with the technical experience accumulated by the largest specialized plant over the years. Just imagine, 63 types of boilers can be offered by this company!

Do not be alarmed, our review today will affect only the standard and premium version of the boiler equipment of the Ulyanovsk plant:

Gas boilers by Ochag

, which is the owner of the Ochag brand, is located in Ulyanovsk. The year 1993 is considered the beginning of its activity.

Today the company produces a wide range of heating equipment and individual units for it of its own design.... There are many standard sizes and designs of gas boilers in production, capable of heating rooms from 70 to 1000 volts. m.

The company carries out its work on the basis of the principles of simplicity and reliability, the stability of its equipment. The main advantage of Ochag boilers is their low cost, which makes them preferable and affordable for the mass buyer.

At the same time, the functionality and quality of the boilers are at a high level, which confirms the high demand and positive user ratings.

The boilers are non-volatile, which for the Russian user is a guarantee of the reliability and continuous operation of the heating system.

Reviews about the features and technical characteristics of the KSG-10 AT boiler

If you do not know which model to tilt your choice towards, then it is worth considering several options for gas heating equipment. Among other proposals, it is necessary to highlight KSG-10 AT. You can buy a gas boiler "Hearth" of this model for 11,000 rubles.

It has a floor-standing design and provides maximum consumer comfort. Buyers note a heating capacity that reaches 10 kW. The heated capacity is 100 m 2. Natural gas consumption per hour is 1.11 m 3. As for the liquefied gas, it can be used when replacing the burner nozzles, and its consumption will be 0.88 kg / h. Consumers especially emphasize the rather compact overall dimensions of the unit, they are equal to 250x470x750 mm.

It is impossible not to mention also the insignificant weight, it reaches 48 kg. The temperature control range of the heating medium is between 50 and 90 ° C. At the outlet of the boiler, the maximum temperature of the heating agent must not exceed 95 ° C. Buyers also like the rather impressive volume of water in the boiler, it is equivalent to 18 liters.

Views

Firm Ochag manufactures various types of construction boilers:

- Floor standing... They do not need specific installation, since they can be placed directly on the floor. This expands the installation options compared to wall-mounted models.

- Wall mounted... They need hinged installation on solid, preferably load-bearing walls. Temporary or plasterboard partitions are not suitable for this. The specificity of the installation requires a reduction in weight and a reduction in the size of the boiler, which affects the power and productivity.

- Parapet... They can be used both for operation as part of a heating circuit and as an independent heat source.

By functionality:

- Single-circuit... Designed only for hot water supply to the heating circuit.

- Double-circuit... They are capable of simultaneous heating of the coolant and preparation of hot water (DHW) for domestic needs.

By type of combustion chamber:

- Atmospheric (open)... Smoke is removed through a common building chimney using a furnace-type draft, and combustion air is taken directly from the room.

- Turbocharged (closed)... Fume extraction and air supply is carried out by a special turbocharger fan. Possible only on volatile models, but independent ones can be modified using an external turbo nozzle.

There are many options for the design of boilers Hearth, the user can choose the most suitable option for his purposes.

How to choose?

Options for the material for the manufacture of a heat exchanger - a container where the heat carrier is heated:

- Steel. Good ductility minimizing thermal stress cracking. Used in budget models. Service life is short - due to susceptibility to corrosion.

- Cast iron. Great weight. They are more expensive than steel ones. Minus - they react to temperature changes. They do not rust - a plus. They serve for about half a century.

- Copper. They weigh little. Resistant to corrosion. They are usually found in wall-mounted versions.

Series and models

Firm Ochag produces several model lines:

- Premium... The series is represented by single and double-circuit floor models AOGV and AKGV with power from 8 to 29 kW. There are models with different types of automation - Italian SIT or the company's own development.

- Standard... A series of floor-standing single and double-circuit gas boilers. The power of the models is in the range of 7-20 kW. Used automatic equipment EUROSIT or SABK-AT.

The most common models are KSG 7, 10 and 15.

They have a capacity of 7, 10 and 15 kW, respectively, which makes it possible to provide heat energy to rooms with an area of 70, 100 and 150 m2, which makes it possible to heat private houses of the most common sizes.

These are non-volatile floor standing boilers, designed in a modern compact style and perfectly fit into the interior of any room.... There is a possibility of conversion to liquefied gas.

A sturdy stainless steel burner was used.

IMPORTANT!

All models of boilers Hearth are manufactured in accordance with the requirements of the European standard ISO 9001-2011.

Gas boiler Hearth KGS, KSGV, AOGV, AKGV. Overview.

The gas boiler Hearth KGS is included in the line of a wide range of products. The Russian manufacturer produces gas burners, control units and gas burners. The Hearth KGS boiler is the result of the implementation of innovative strategies in combination with the technical experience accumulated by the largest specialized plant over the years. Just imagine, 63 types of boilers can be offered by this company!

Do not be alarmed, our review today will affect only the standard and premium version of the boiler equipment of the Ulyanovsk plant:

Boiler Hearth standard

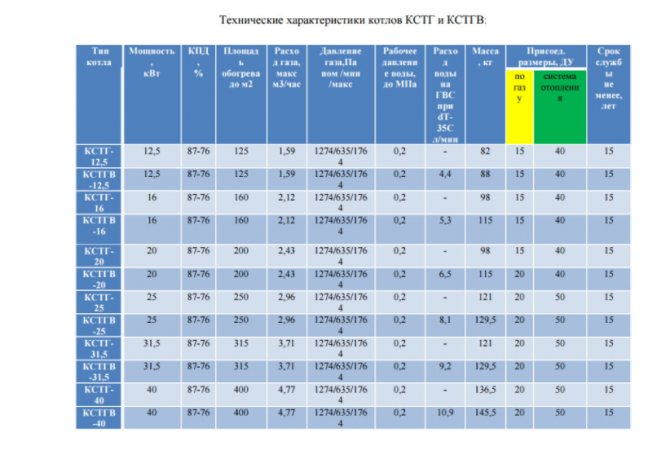

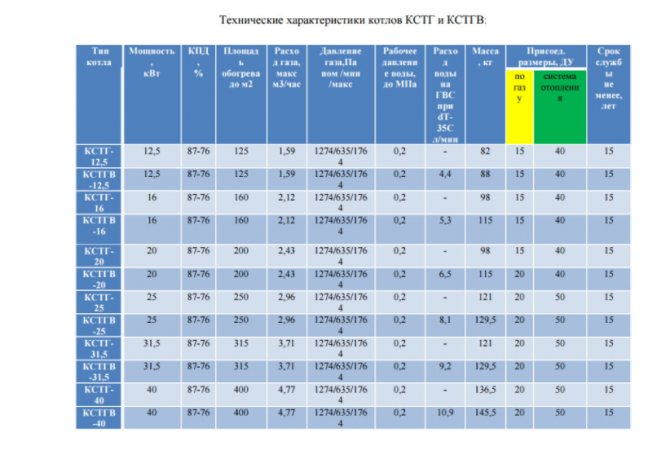

Specifications

| FLOOR BOILERS FOR FLOOR GAS SERIES KSG-STANDARD | |||

| Name | Heating area | Dimensions / Weight | Natural / liquefied gas consumption |

| Single-circuit heating only | |||

| KSG-7 C / E | 80 m2 | 244 * 470 * 710/46 kg. | 0.78 / 0.64 m³ / hour |

| KSG-10 C / E | 100 m2 | 244 * 470 * 710/46 kg. | 1.11 / 0.88 m³ / hour |

| KSG-12.5 C / E | 120 m2 | 300 * 470 * 710/49 kg. | 1.39 / 0.97 m³ / hour |

| KSG-16 C / E | 160 m2 | 300 * 470 * 710/49 kg. | 1.78 / 1.1 m³ / hour |

| KSG-20 C / E | 200 m2 | 376 * 470 * 710/60 kg. | 2.22 / 1.41 m³ / hour |

| Double-circuit with hot water supply | |||

| KSGV-12.5 C / E | 120 m2 | 300 * 470 * 710/50 kg. | 1.39 / 0.97 m³ / hour |

| KSGV-16 C / E | 160 m2 | 300 * 470 * 710/49 kg. | 1.78 / 1.1 m³ / hour |

| KSGV-20 C / E | 200 m2 | 376 * 470 * 710/61 kg. | 2.22 / 1.41 m³ / hour |

The gas boiler Hearth KSG is operated in automatic mode. Maintains the temperature of the heat carrier in the heating circuit set by the consumer at the same level. Provides multi-layered protection in the event of emergency situations. Among other things, a system of sensors monitors the attenuation of the flame on the pilot burner and monitors the occurrence of a situation of lack of draft - in each case, the gas supply is immediately blocked.

Boiler Hearth Benefits

- Laconic design;

- High efficiency up to 92%;

- Self-developed gas units of the ServiceGas concern;

- Completely non-volatile. No need to connect to the electrical network;

- Possibility of re-equipment for further operation on liquefied gas;

- Stable operation of the device in case of low gas pressure;

- Heat-resistant stainless steel burner.

- Stabilizer of gas pressure and draft is built into the boiler Hearth;

- Routine maintenance using easily removable turbulators in the gas passageways adds to the ease of use;

- Easy installation with a choice of one of two gas connection options.

- Thermocouples serve as additional protection against breakdowns during operation;

- Service maintenance due to the special fastening of the smoke collector does not interfere with the convenient work with the gas duct;

- Reduced installation costs are facilitated by small nozzle diameters = 1.5 inches;

- Service life is not less than 15 years;

- the warranty period from the manufacturer is 2 years.

The floor-standing gas boiler KSGV Hearth serves as a device for heating rooms with an area of up to 160 m2. Considering that the ceiling height does not exceed 2.7 m. Higher ceilings are likely to require a more accurate calculation of heating equipment. The two-circuit model provides the consumer with heat in combination with hot water supply, as indicated by the "B" index.

Explanation of the abbreviation KSGV S -12.5 AT

The letter designations that the Hearth boiler have are intuitive and do not make it difficult to decipher: "K" - boiler "C" - steel "G" - gas "V" - the possibility of supplying hot water (water heater coil is installed) "12.5" - boiler power in kilowatts "A" - a - possibility of operation as solid fuel "E" - EUROSIT automation

"S" - automatic equipment SABK-AT

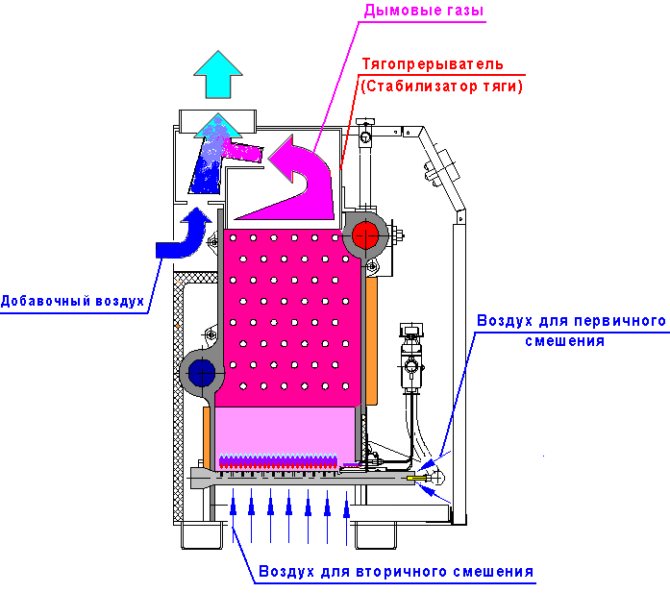

The unit uses a gas pressure regulator to regulate the mains pressure and ensure a uniform and stable flame on the main burners without changing the thermal performance. A new heat-resistant stainless steel burner, atmospheric type is used. It is installed at the bottom of the heat exchanger, maintaining a uniform heat zone in the combustion unit. The design has a uniform placement and does not allow zonal overheating of the heat exchanger and its failure.

The built-in draft stabilizer balances the pressure at the inlet to the ejector of the main burners and at the outlet from the slotted slots. Thus, constant discharge and stable combustion of the gas-air mixture in the furnace are ensured without additional regulation.

Boiler Hearth premium

Let's consider a series of Premium AOGV and AKGV. This line has a power from 10 to 35 kW, and serves as a heating device for a residential building up to 300 square meters. The devices are characterized by high performance and reliability. The manufacturer provides for the operability of the equipment from natural or liquefied gas. In the case of a planned connection to a liquefied gas cylinder, it will be necessary to purchase an additional set of nozzles with subsequent adjustment of the equipment.

Specifications

| FLOOR GAS BOILERS AOGV PREMIUM | |||

| Name | Heating area | Dimensions / Weight | Natural / liquefied gas consumption |

| Heating Gas Water Heating Unit, one circuit and works only for heating. | |||

| AOGV - 8 C / E | 80 m2 | 350 * 450 * 760/38 kg. | 0.81 / 0.63 m³ / hour |

| AOGV - 8 11.6 C / E | 100 m2 | 350 450 850/57 kg. | 1.18 / 0.91 m³ / hour |

| AOGV - 17.4 C / E | 160 m2 | 350 450 850/61 kg. | 1.76 / 1.36 m³ / hour |

| AOGV-23.2 C / EM | 210 m2 | 430 565 850/66 kg. | 2.35 / 1.82 m³ / hour |

| AOGV-29 S / EM | 260 m2 | 430 565 850/82 kg. | 2.95 / 2.28 m³ / hour |

| AOGV-35 S / EM | 320 m2 | 430 565 850/96 kg. | 3.6 / 2.79 m³ / hour |

| AOGV-45 C / EN | 400 m2 | 500 650 930/102 kg. | 4.6 / 3.54 m³ / hour |

| Combined Gas Water Heating Unit, two circuits, one for heating the room, the other for heating hot water. | |||

| AKGV - 11.6 C / E | 100 m2 | 350x450x850 / 57 kg. | 1.18 / 0.91 m³ / hour |

| AKGV - 17.4 C / E | 160 m2 | 350 450 850/62 kg. | 1.76 / 1.36 m³ / hour |

| AKGV - 23.2 С / ЕМ | 210 m2 | 430 565 850/68 kg. | 2.35 / 1.82 m³ / hour |

| AKGV - 23.2 С / ЕМ | 210 m2 | 430 565 850/68 kg. | 2.35 / 1.82 m³ / hour |

| AKGV - 29 С / ЕМ | 260 m2 | 430 565 850/86 kg. | 2.95 / 2.28 m³ / hour |

| AKGV - 35 С | 320 m2 | 500 640 930/96 kg. | 3.6 / 2.77 m³ / hour |

Boiler Hearth device:

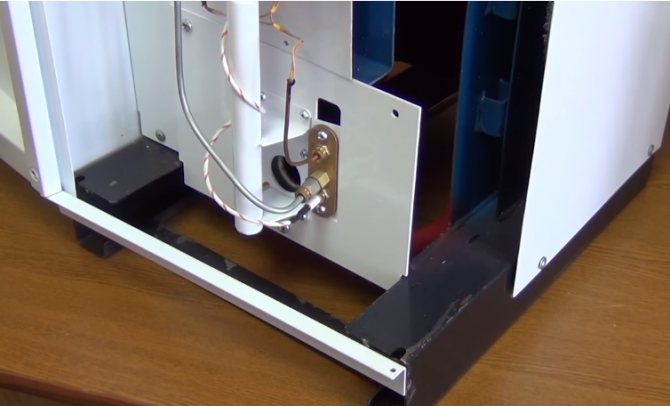

Structurally, the Hearth boiler is made in such a way that it can be fitted into any heating system. The front door can be re-hung as required and opens from either the left or right side. Two return lines, from the side and from the back, make it possible to supply the heating medium from the convenient installation side.

The Hearth boiler consists of:

- Boiler body

- Control automation

- Heat exchanger

- Second circuit (if the boiler is double-circuit)

- Safety system

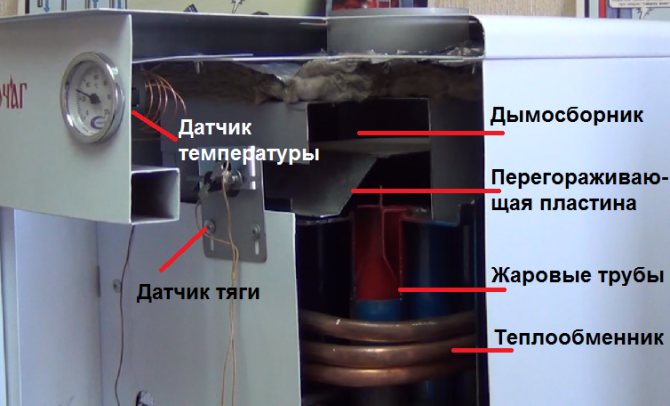

In the lower part of the body, there is a combustion chamber; it is closed from the side and back with sections of the water jacket. A heat exchanger is located above the combustion chamber. High efficiency of heat transfer and heat exchange between the exhaust gases and the coolant is carried out due to the developed convective part of the heat exchanger, consisting of “flame” tubes.

In the upper part of the heat exchanger there is a smoke collector with a built-in draft stabilizer. In the front part of the smoke collector there is a draft sensor, in the upper part of the smoke collector there is an outlet pipe of the boiler. When installing the boiler into the chimney, it is necessary to coordinate the diameter of the outlet pipe with the cross-section of the chimney. The technical parameters of the chimney must correspond to the technical parameters specified in the operating manual.

In the middle part of the smoke collector, there is a partition plate to ensure stable operation of the device regardless of weather conditions. The heat exchanger, complete with the smoke collector, ensures the efficient operation of the boiler without consumer intervention, and does not require manual adjustments. Stabilizer draft contributes to the stable operation of the boiler in case of unstable draft.

A gas burner device of Russian production by Service Gas company is installed in the combustion chamber of the apparatus. It consists of a front panel, burner pipes, safety sensors (flame sensor and draft sensor), and a SABK AT control unit.

Below, under the burner tubes, an easily removable distribution grid is mounted. Designed to supply secondary combustion air. It is very important to ensure free air access through the lower part of the boiler along the distribution grid to the burner pipes when installing the boiler in the room.

The boiler must be installed with a clearance to the height of the foot relative to the floor. Boiler The hearth is connected to the gas mains on both the left and right sides. This allows the design of the SABK AT unit. A temperature sensor is installed on the front panel, which indicates the temperature in the room.

Boiler Hearth how to light it up?

In order to ignite the Hearth boiler, it is necessary to turn the control knob clockwise until the point is opposite the pointer. Then press and hold the start button. Press until a characteristic click, the piezo ignition button. At this time, the pilot ignites. Keep the start button pressed while the thermocouple heats up. The gas block operates automatically on the igniter. Next, turn the knob counterclockwise to the required temperature.

The hearth gains high efficiency due to efficient combustion of fuel and high heat transfer from flue gases by means of “flame” pipes to the coolant and a developed firebox. The service life of the manufacturer is guaranteed for at least 15 years. The factory warranty for the product is 24 months.

We are watching a video on how to light a gas boiler with Eurosit630 automation

teplogalaxy.ru

Specifications

Consider the parameters of gas boilers Hearth:

| Parameters | The values | ||

| KSG-7AT | KSTG-16 | AMG 24 | |

| Boiler type | Gas heating convection | ||

| Fuel type | Natural gas convertible to LPG | Natural gas with the possibility of using solid fuels | Natural gas convertible to LPG |

| Functions | Heating | Heating | Heating and hot water supply |

| Mounting method | Floor | Floor | Wall |

| Efficiency | 85 % | 75 % | 90 % |

| Power | 7 kW | 16 kWt | 24 kWt |

| Power supply | Absent | Absent | 220V 50Hz |

| Life time | 15 years | ||

| Guarantee | 36 months | ||

Models and their characteristics

Let's note the technical characteristics of the most popular models of gas boilers Ochag.

KSG-7AT

This volatile single-circuit unit has an affordable price. The approximate cost is 10,000 rubles. The material used for manufacturing is steel. Available in floor-standing design, the device is very simple and convenient to use.

Gas boiler Hearth KSG-7 AT

This gas boiler Hearth uses fuel economically, the device is able to efficiently heat a room with an area of 80 m². Specifications:

- power is 7 kW;

- high efficiency - 85%;

- water pressure - 0.1 MPa.

The unit operates without interruptions and malfunctions even with minimal pipeline pressure. The package includes a gas block, built-in pressure and draft stabilizer, compact steel heat exchanger. The burner is made of high temperature resistant stainless steel. It is simple and convenient to maintain - the lining can be easily removed, the gas is connected on both sides. There is a device that collects condensate.

Users note that this model has good characteristics. If you replace the burner nozzles, then liquefied gas can be used as fuel.

AMG 24

Outbreak KNG-24

The approximate price for such equipment is 25,000 rubles. It is double-circuit, wall-mounted, small in size. Differs in stylish design.

In operation, the device is absolutely silent - you can mount it right in the room, it will not create discomfort.

On the front panel there is a liquid crystal display, which shows the current parameters. The boiler can be used for heating rooms that are equipped with a water heating system, as well as for heating water.

Technical indicators:

- high productivity, efficiency reaches 90%;

- efficiently heats rooms up to 220 m²;

- the maximum heating power is 24 kW;

- auto ignition is present;

- gas consumption is 2.6 m³ / hour.

Such units can be connected to a floor heating system. The combustion chamber is closed, it can operate on natural or liquefied gas. There are several stages of automatic protection. The weight of the boiler Hearth KNG 24 is 36 kg.

KSG-11

KSG-11 is a floor-standing gas boiler Hearth, designed for heating premises for various purposes.

Installation is simple and convenient, because gas can be connected from any side. The door can be mounted on any side convenient for the user.

There is a device for collecting condensate, the heat exchanger is made of steel, the thermal insulation is 30 mm. The type of combustion is low-flame; during operation, the device does not emit any noise.

Technical specifications:

- heating capacity is 11 kW;

- the maximum area that the unit can heat is 125 m²;

- Efficiency - 85-90%;

- gas consumption is 1.34 m³ / hour;

- weight - 48 kg.

KSTG-16

Combined single-circuit boiler, maximum power is 16 kW. The device operates on gas and coal. Designed to supply heat to premises up to 160 m². Floor-standing installation, without auto-ignition and flame modulation. The efficiency is 75%.

KSG 10-AT

The unit is floor-standing, with a heating capacity of 10 kW, and heats a room with an area of up to 100 m².

Gas boiler Hearth KSG-7 AT

The fuel consumption is 1.11 m³ / hour. The cost of the device is 11,000 rubles.

If you replace the burner nozzles, then liquefied gas can be used as fuel. The unit has a compact size, dimensions - 25x47x75 cm. Weight - 48 kg. Tank capacity - 18 liters.

KSG-7 E

Floor-standing single-circuit gas boiler Hearth KSG-7 E, which is characterized by stable operation at reduced pressure in the gas supply pipes. It is small in size, has an attractive design, is fuel efficient, and efficiently heats houses up to 80 m² in size. The weight of the device is 37 kg.

The combustion chamber is open, there is no auto-ignition, and there is also no flame modulation. This model is inexpensive, but its functionality is also very narrow.

Summing up all of the above, it is worth noting that the Ochag gas boilers occupy a worthy place in the domestic market among the variety of heating devices. A wide range of models in terms of technical characteristics, appearance and price allows each user to choose the most optimal option. Owner reviews of the Hearth boilers are mostly positive. Their efficiency and ease of use are noted.

You can also pay attention to German, Japanese, Korean, Czech and Ukrainian gas boilers.

Advantages and disadvantages

The advantages include:

- Strength, reliability, stability of the boilers.

- A wide range of models, allowing you to obtain the optimal design and boiler capacity.

- The energy independence of the units ensures the uninterrupted operation of the heating system in all situations.

- High performance of boilers.

- Simplicity of design, ease of management and maintenance.

- Low fuel consumption.

- Attractive appearance, compact size.

- Low price.

The disadvantages of boilers are considered:

- The complexity of the ignition.

- The need to ensure the slope of the system, which ensures the circulation of the coolant.

- For more stable operation, the use of external devices is required - a circulation pump and a turbo nozzle.

For non-volatile boilers, these disadvantages are quite typical and are, rather, design features.

The best floor standing gas heating boilers

They are much more powerful than wall-mounted models, but at the same time they weigh two or even four times more. Among the disadvantages are the high price, the need to mount a chimney, very large dimensions and high gas consumption. The main advantage is the ability to heat even large houses.

Lemax Premium-12,5N

This is a convection gas heating boiler with one circuit and an open type of combustion chamber. This can be a problem in small, poorly ventilated areas. Among the advantages, it is worth highlighting the simple regulation of the room temperature due to the possibility of connecting a room thermostat. The soft start system prevents equipment from overheating. A power of 12 kW is enough to heat an area of up to 125 sq. m. The level of efficiency here is lower than that of analogues (90%). Mechanical control and operation on only one type of fuel - natural gas - can cause inconvenience. A rather large weight (62 kg) cannot be called an advantage either.

Advantages:

- Ignition does not depend on electricity;

- Three-year warranty;

- Advanced security system;

- Low cost;

- High-quality assembly;

- Does not heat up;

- Moderate fuel consumption.

Disadvantages:

- Low corrosion resistance;

- External control must be connected separately;

- Low power.

average price - 18,000 rubles.

Lemax Premium-12,5N is the best gas-fired heating boiler from the inexpensive and most affordable options.

Protherm Bear 40 KLZ

This is a floor-standing gas boiler for heating large areas, up to 350 sq. m. High operating efficiency is confirmed by an efficiency of 90-92%. The equipment is protected from overheating and in the event of a critical rise in temperature, it turns off on its own.The expansion tank holds up to 10 liters of coolant, this figure is more than that of competitors. There is a special system to control the electric ignition and the strength of the flame. Thermal power is not bad - 24.5-35 kW, but the noise level is upsetting - up to 55 dB. The device requires natural or liquefied gas to operate.

Advantages:

- Simple ignition;

- Spacious;

- Powerful;

- Has a built-in 90 l boiler;

- No condensation accumulation.

Disadvantages:

- Too big;

- Very heavy;

- Complex installation;

- Works noisily;

- Quite expensive.

Read the operating instructions for the boiler here. Protherm Bear 40 KLZ.

average price - 65,000 rubles.

Protherm Bear 40 KLZ is one of the most expensive outdoor models.

Baxi SLIM 1.400 iN

This is a very powerful single-circuit boiler for floor installation with an efficiency of 90%. Easy operation, intuitive electronic control and a high level of protection against low temperatures and overheating helped him enter the rating. It needs liquefied or natural gas to work, which makes it versatile. In case of malfunctions, a self-diagnosis system is triggered. A plus is the ability to connect an external outdoor temperature sensor. Electric ignition is carried out smoothly, as well as flame modulation, which eliminates the risk of overheating of the device.

Advantages:

- No smell;

- It is not noisy;

- Heats the air quickly;

- Doesn't crash;

- Does not turn off at low temperatures.

- Heats up slightly;

- Powerful (40 kW).

Disadvantages:

- Requires the involvement of professionals to connect;

- Not available everywhere, pre-order required;

- Large weight (158 kg);

- Dear;

- Weak ignition block.

Here is a detailed instruction manual for the operation of the gas heating boiler Baxi SLIM 1.400 iN.

average price - 64,000 rubles.

Operation and setup

Operation of gas boilers The hearth occurs practically without human intervention, in automatic mode.

The owner is required only:

- Filling and draining water from the system.

- Switching the boiler to summer / winter mode.

- Periodic cleaning of the case from dust and dirt.

The operating mode is configured during installation and initial start-up. Boilers are sold already tuned and adjusted.

At startup, only adjustments are made to the factory settings for the most efficient operation in the given conditions.

The adjustment must be carried out by a specialist from the service center, who has the appropriate admission and qualifications.

Any independent intervention in the boiler design automatically terminates the warranty agreement.... In addition, an inexperienced user can permanently disable the boiler by his actions.

Best Wall Hung Gas Heating Boilers

This is an ideal solution for small spaces, because the equipment does not take up much space. It is compact, looks neat and fits easily into any interior. But, unlike floor-standing models, the power is slightly less.

Buderus Logamax U072-24K

This is a wall-mounted gas boiler, in which the attention is paid primarily to stable combustion thanks to the impulse tube. Reviews indicate that it maintains a comfortable temperature, regardless of the gas pressure level (from 9 to 30 mbar). It is convenient to adjust the rate of room heating by choosing one of three pump operation modes. There is practically no noise even at the highest noise level (the threshold does not exceed 39 dB). The user will always be aware of the current state of the system through the backlit display. The electrical connection is thought out as much as possible. The water also heats up to 60 ° C.

Advantages:

- Silent;

- Convenient display;

- Optimization for the Russian market;

- Economical;

- Easy to operate;

- Compliance of the actual efficiency with the declared one;

- Frost protection.

Disadvantages:

- In severe frosts, it can malfunction.

- There is a defect in the control board;

- Great weight.

average price - 38 thousand rubles.

Buderus Logamax U072-24K equipment is designed for use in rooms up to 350 sq. m.

Leberg Flamme 24 ASD

This is a fairly powerful heater (22.5 kW), it is capable of heating an area up to 178 m2. The type is double-circuit, so it can be used not only to raise the air temperature from 40 to 80 ° С, but also to heat water up to 65 ° С. A rather large expansion tank of 6 liters allows you to avoid a catastrophic increase in pressure in the system. The device has a powerful pump for underfloor heating. Here, a safety system is well thought out in case of a pressure drop, at which gas simply ceases to be supplied to the burner. Critical water overheating is also excluded thanks to the temperature sensor.

Advantages:

- Self-diagnosis;

- Possibility to work from butane or propane;

- Two modes - for summer and winter;

- Good anti-freeze system;

- Can be used in "warm floor" mode;

- Room thermostat compatible;

- Intuitive control panel.

Disadvantages:

- Often freezes without responding to any actions;

- The front panel is difficult to remove;

- Sometimes it turns off and gives an error;

- Overheating of the coolant is possible.

average price - 28 600 rubles.

Bosch Gaz 6000 W WBN 6000-24 С

This is another popular double-circuit wall-mounted convection type heating boiler. As a fuel, it needs liquefied or natural gas, it works stably at a power of 7-24 kW even with pressure drops in the water supply. The tank here is larger than in the Leberg Flamme 24 ASD, its volume is 8 liters. The control is completely electronic, the ignition is automatic, which makes operation easier. The autodiagnostics mode allows you to do without a specialist in case of minor breakdowns. The thermometer notifies about the warming up of the air in the room. The weight, as for the wall-mounted model, is average - 32 kg. The model is adapted to Russian operating conditions.

Advantages:

- Works fast;

- Simple setup;

- Small size;

- Quiet work;

- Good selection of capacities;

- High efficiency.

How to light a boiler

The procedure for firing up a gas boiler with SABK-AT automation:

- Open the gas cock.

- Put the handle of the gas block in the “Ignition” position.

- Press the "Start" button, hold it for about 10 seconds, then press the piezo ignition button 2-3 times until it clicks (ignition is possible through the viewing window using a burning match).

- Hold the "Start" button for another 20-30 seconds to warm up the thermocouple. The gas valve can then be held open by a magnetic plug.

- Turn the knob on the gas block to position 5 and check that the burner flame is stable.

- Set the required temperature on the gas block.

To ignite the burner of boilers with EUROSIT automatics, perform the same actions, only in step 5 the knob must be turned to position 7.

Download instruction

Download the instruction for the gas boiler Ochag.

Boiler marking Hearth

The boiler brand has letter designations, which are deciphered as follows:

- K - boiler;

- C - material of the heat exchanger steel, C - cast iron;

- T - used to work on solid fuel;

- Г - equipped with gas burners;

- B - has a water heater in the design;

- M - heating elements and an extended firebox can be mounted to it;

- the figure indicates the power of the boiler, the first figure is for solid fuel operation, the second for gas.

For example: KSG-7AT is a boiler with a steel heat exchanger, equipped with a 7 kW gas burner, with SABK-AT automation. Modification of KCHTG-16: a boiler with a cast-iron heat exchanger operates on gas and solid fuels, with a capacity of 16 kW without installing automation.

Why does the gas boiler go out?

The fading of the flame of a gas boiler can be caused by external or internal reasons.

External reasons include:

- Reverse thrust... The most difficult case, almost impossible to eliminate by conventional means.Sometimes it helps to eliminate drafts, to open or close some doors or windows.

- Strong gust of wind outside... Cases of flame blowout by the wind are frequent, they are the result of an unsuccessfully located chimney or a low height above the roof surface.

- Drafts indoors... This situation is quite solvable, the main thing is to determine the source of the draft and close it.

Internal problems can be:

- Cut off the gas supply to the mains.

- Gas valve failure, problems with gas equipment.

- Burner nozzles clogged with soot and combustion products.

In case of such problems, you should call the gas service and clarify the reasons for the lack of gas. The fuel supply valve must be closed before this.

Call a specialist from the service center and entrust him with the repair of gas equipment.

It is forbidden to try to repair the gas block on your own; this can cause very dangerous and even fatal consequences.

Owner reviews

The most reliable and truthful information can be considered only information received from people who directly handle gas boilers Ochag.

The reviews of these people are not aimed at obtaining material or reputational benefits, they simply reflect their experience in operating the units.

Solid fuel and gas boilers Ochag in an assortment of more than 40 models are produced at the GazStroy enterprise. Among them you can find products suitable for heating any space, from small apartments to large production facilities. Read reviews about solid fuel boilers Ochag. The most popular are combined boilers that can operate simultaneously on gas and solid fuel. All products of this brand are unpretentious and durable, reviews of Ochag boilers will help you learn about their disadvantages and advantages.

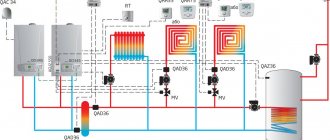

The house is large, with an area of 300 sq. M., Water-heated floors are installed on the entire ground floor. Batteries are naturally on both floors. They are heated by the manufacturer's boiler Hearth 31.5. In addition to batteries and underfloor heating, the boiler also works to heat the water in the house. Problems with the boiler began immediately, I really could not light it up. Even with a full load of briquettes and with two heating elements, the maximum temperature that could be reached when heating the water is 40.

And he never put everything at the same time, he only turned on, for example, water and floor or batteries and water. I am not a builder and far from all these matters, so I could not immediately figure out what the problem was. But in the end I realized that the whole problem turned out to be in the chimney, the builders set the pipe diameter to 110 for me. But as it turned out, this was not enough for such a boiler, the boiler burned quite a bit and the smell was bitter-sour during combustion. I expanded the chimney by 200 and the problem disappeared. True, the boiler still had to be cleaned of the tar that had previously flowed out of the furnace.

Maintaining an acceptable temperature in the room during the cold season is not only a guarantee of a comfortable stay in it, but also a guarantee of the longevity of the house. It is expensive to be heated with electricity, wood is not very convenient, it remains to choose the best gas heating boiler, which has been proven over the years, and with its help create optimal living conditions. There are so many of this equipment on the market and it is not cheap, so it is important to decide in advance on the choice that will help make our rating.

Major malfunctions

The main malfunctions of gas boilers The hearth is problems with the burner - a weak flame, attenuation after a few seconds of burning, frequent flame outages for unknown reasons.

There can be many reasons for a malfunction of gas equipment; to eliminate possible problems, knowledge of the design and features of the equipment operation is required.

All work must be carried out by service technicians authorized to work with gas equipment.

The only possible independent procedure may be to clean the burner nozzles from soot.

The device and operation of gas-wood boilers

A universal gas-wood boiler for home heating, available in three different modifications, differing in design and functionality:

- Module, with the possibility of converting to gas.

- A boiler that has two combustion chambers at once, separately for firewood and gas.

- Heat generator with built-in electric heating element.

Combined boilers of mixed type, for gas and firewood, have built-in automation that fully automates the combustion process. After the firewood burns out in the firebox, the module automatically switches to gas or electricity. For hot water supply, water is heated by an electric heater.

Bi-fuel wood-gas boilers

Combined gas-firewood boilers are widely used in domestic conditions. The design includes the following units:

- Combustion chamber - made of steel or cast iron. One or two fireboxes are installed in the design. Modification with two combustion chambers, more convenient. A gas burner is installed in the lower furnace. In the upper chamber there are grate bars for burning firewood.

- Heating and DHW circuits - manufacturers produce models designed exclusively for heating (with the possibility of subsequent connection to an indirect heating boiler), as well as for receiving hot water and heating rooms. The latter are completed with two circuits. DHW is heated in a flowing manner.

Heating water for hot water supply, depending on the capacity of the boiler TT, reaches 700 l / h. There are modifications with a built-in storage tank for 40-120 liters of water.

Electric-gas-wood boilers

Combined heating boilers, gas, wood and electricity, have a device that resembles that of dual-fuel units. The main difference is the installed electric heating element. The principle of operation of combined boilers, gas, firewood, electricity, is as follows:

- Firewood is considered the main type of fuel. After the wood has burned, the gas burner is automatically turned on. The heating process continues without interruption.

- The heating element is used to maintain the minimum temperature of the coolant after the gas and firewood have run out. Operation in anti-freezing mode is allowed. The electric heating element maintains a minimum temperature in the heating system, preventing freezing of the water circuit.

Some universal heating boilers - gas, firewood, electricity, use the principle of gas generation in their work, which increases the autonomous operation time to 6-12 hours, from one bookmark of logs.

Price range

Average prices of boilers Ochag are in the conventional range of 12-20 thousand rubles. Before buying, you should clarify what additional devices and devices will be needed for the normal operation of the boiler itself and the entire system as a whole.

In addition, you will need to conclude a warranty agreement in order to be able to urgently restore the system to work.

Boiler device

In general, he arranged in the same way as usual... But there are some peculiarities associated with the use of multiple resources.

Boiler included in the hot water heating system... Solid or liquid fuels are burned by heating the water in the heat exchanger. It moves through the pipes to the radiators, where it gives off heat. Then the cooled liquid returns to the heat exchanger.

Photo 2. Internal structure of a combi boiler: the possibility of heating with wood or gas is shown.

With electricity the heating principle is slightly different. Used heating elementthat heats the water in the tank.

What elements are included in the design and how do they interact?

The main parts of the boiler are as follows:

- firebox;

- burner;

- Heating element;

- heat exchanger;

- automation;

- body;

- outlet branch pipe.

Sometimes there is one combustion chamber capable of providing combustion two types of raw materials... In other cases, two are installed at once, for solid and liquid species.

Heat exchangeris usually done from pipes... Then, with the same volume, the surface area is larger, and the liquid heats up faster. It is located next to the fireboxusually top or bottom. And if there are two, the coil is between them. The pipes for connecting the piping system are connected to the heat exchanger.

Automatic control much makes it easy to use boiler. Maintaining the set temperature occurs without human intervention. It is measured by sensors. If necessary, the damper opens more or less. In this way, the flow of oxygen and the intensity of combustion are regulated. The heating power is also regulated by the heating element. If one of the raw materials is not available, the device will switch to another. The parameters are configured on the control panel. Some models have and Remote Control.

Housing boiler is manufactured made of steel or cast iron. For thermal insulation, it is made double. In more expensive models, noise insulation is also present.

Design features

The specificity of the boiler device is associated with the use of various heat sources and depends on the types of fuel. The following options are possible:

- Two combustion chambers instead of one.

- Combination furnaces and heating elements.

- Removable pellet hopper and an automatic feeding mechanism.

These features and lead to an increase in size boiler.

general information

Modern boilers operating on solid fuels have gone far from their "progenitors". Today, a boiler is a device that ensures long-term combustion of fuel by using the pyrolysis effect. Thanks to this, it was possible to significantly increase the efficiency of fuel technology.

In addition, modern boilers are equipped with a device for adjusting the heating power and combustion intensity. Thanks to this, the owners have the opportunity to choose the optimal temperature regime in the house, saving fuel.

Principle of operation

The boiler is divided into two parts:

- the upper compartment is used for stowing fuel (coal or firewood);

- the lower compartment is a combustion chamber into which air and gaseous products of the pyrolysis reaction are fed, passing in the upper chamber.

Fuel combustion takes place at extremely high temperatures, this process ensures the release of gas from the fossil fuel, as well as a large amount of heat.

Advantages of a solid fuel boiler Hearth KS-TV 20 m

1. Highly efficient steel heat exchanger to achieve high efficiency. 2. The set includes cast iron grates, which significantly increase the service life of the boiler. 3. Independently from external sources of electricity. 4. The heating boiler does not require adjustment in case of atmospheric changes, all gas combustion processes are automated. 5. Equipped with a double-chamber combustion chamber. 6. Possibility of manual adjustment of the intensity of the combustion process. 7. Easy to clean. 8. Compact dimensions of the boiler make it possible to place it in almost any room. 9. Ease of maintenance and operation. 10. Complete set with Italian EUROSIT automatics. 11. The temperature indicator is located on the top cover of the boiler, which makes it easy to control the boiler heating. 12. Two mounting holes for heating elements. 13. Elongated firebox. 14. Water heating (coil) included.