Fan coil units of cassette type are climatic equipment for hidden installation. They have some similarities with cassette split systems, but such devices differ in the way they are placed. They are installed in rooms with a false ceiling, which allows you to hide the working unit with a fan and communication elements. After installation, only the decorative panel remains outside. The appearance of the decorative grille may differ depending on the model of the appliance.

Cassette fan coil units are an ergonomic solution for air conditioning smaller and more spacious rooms. This is one of the best solutions for banks, offices and other objects with open space organization. This zoning method has many advantages, but at the same time it also has a significant drawback. Since there are many partitions in such rooms, they create an obstacle to the movement of air. When fresh air enters through the through-holes of the ceiling panel, it first enters the pre-ceiling space, and then moves along the walls and floor. The flow is evenly distributed over the entire area of the object, without creating drafts.

Design features

A duct fan coil unit can have various design features, but most often the models consist of a filter element, a heat exchanger, a fan, an electric heating element and an equipment control panel. As for the filter, it is able to protect the system from the ingress of foreign particles that can penetrate along with air masses. The heat exchanger allows you to effectively cool or heat the air, which will depend on the set operating mode of the equipment at a certain moment. The fan provides air flow that is blown through the heat exchanger.

Ballu machine

Description

The latest developments and sophisticated design solutions have resulted in an innovative 6-segment cassette fan coil heat exchanger. Thanks to the new design of the heat exchanger, the capacity of the fan coil has increased by 15% with the same overall dimensions.

Housing

The cassette fan coil unit is made of high-strength sheet steel, making it resistant to corrosion, chemicals, solvents, hydrocarbons and alcohols. Thanks to internal heat and sound insulation, a low noise level is achieved.

Decorative panel

The elegant design of the outer panel of the unit matches perfectly with any type of false ceiling. The fan coil unit is equipped with a standard size 950x950mm panel.

A huge advantage of the cassette fan coil unit over other types of fan coil units is the ability to distribute the air flow in four different directions, which helps to quickly and evenly achieve the desired temperature throughout the room.

Heat exchanger

Thanks to the use of an innovative 6-segment high-efficiency copper-aluminum heat exchanger, there is an efficient removal of excess heat in the room. The heat exchangers are pressure tested at 30 bar and are designed to operate with water up to 15 bar. The CHARM series fan coil unit is available in two-pipe design.

Fan section

The fan coil unit is equipped with an axial fan, which ensures a high air flow rate. The fan impeller is statically and dynamically balanced for low noise levels.

Air filter

The fan coil unit is equipped with a regenerable air filter. For ease of maintenance, the filter can be easily removed, it can be washed with water, blown out, cleaned with a vacuum cleaner.

Drainage pump

The built-in drainage pump is included in the basic package and provides a head up to 800 mm of water. Art. The pump is switched on and off automatically. The drain pan is insulated to prevent condensation from forming on the outer surface of the pan. The pan is also equipped with a drainage pipe, which is located as standard on one side with the connections of the heat exchanger, which ensures convenient installation and drainage of condensate.

Remote Control

The remote control is supplied in the kit, it allows you to set the operating mode, temperature and fan speed. Simple and easy to use.

Three-way valve RCVA with on / off actuator (option)

It is used to regulate water flow and bypass water in the system when the fan is off.

Specifications

| BMFC-720 | ||

| Cooling capacity (full / explicit) | kw | 7,2/5,9 |

| Heating power | kw | 10,8 |

| Water consumption | m³ / h | 1,40 |

| Pressure drop | kPa | 34 |

| Air consumption | m³ / h | 1360 |

| Noise level, high / medium / low | dB (A) | 45/42/38 |

| Power consumption | W | 131 |

| Working current | BUT | 0,75 |

| Block dimensions, LxHxG | mm | 835x240x835 |

| Unit weight | Kg | 25 |

| Decorative panel dimensions | mm | 950x55x950 |

| Decorative panel weight | Kg | 5 |

| Recommended 3-way valve | RCVA 3/4 ″ (2.5) -230 | |

| Power supply | V / Hz / ph. | 220-240/50/1 |

| Join. dimensions of pipelines | 3/4″ | |

| Join. drainage size | DN20 |

Specifications are given for conditions:

- Cooling capacity: incoming air temperature 27 ° C dry bulb, 19 ° C wet bulb, water inlet / outlet temperature 7/12 ° C.

- Heating capacity: incoming air temperature 20 ° C dry bulb temperature, inlet water temperature 50 ° C, flow rate as in summer mode.

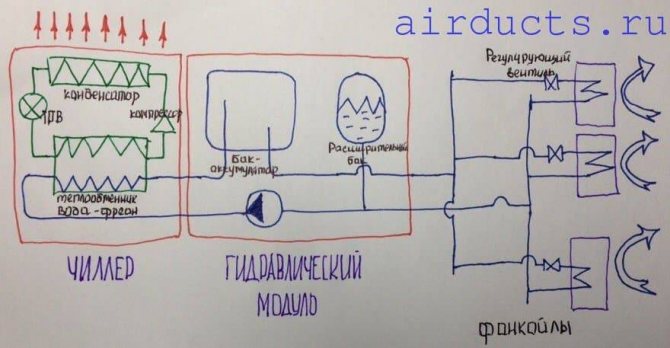

Principle of operation

If you decide to purchase a duct fan coil, you must first familiarize yourself with the principle of its operation, which is that the air is cooled and heated, depending on the selected operating mode. Air masses are driven by a fan through the heat exchanger. In this case, the air flow is created not from the air masses that are present in the room, but from the fresh air that is supplied from the chiller. The last element acts as a central component in the creation of an air conditioning system. The air masses enter the chiller from the air supply unit, which draws in air from the outside.

Main advantages of the system

The duct fan coil unit has a lot of advantages, among them it is possible to highlight the provision of complete cooling or heating of the room within five minutes after starting the system. This capability is guaranteed by the simultaneous installation of a fan coil unit and a chiller. Among other things, the system allows you to create a comfortable microclimate in the rooms where the fan coil unit is installed. The owners of an apartment, house or building will be able to save energy.

Additional features include the ability to connect a different number of fan coil units to the chiller. But the step of the route from the chiller to the most distant fan coil unit cannot be more than six hundred meters. A channel-type fan coil unit allows you to save money that is required to create pipe routes when choosing water as a carrier.

Modifications of the Electrolux series Cassette fan coil units CARRYROUND

| Model | Cooling capacity | Discounts up to 30%! Make a request. | |

| Fan coil unit cassette two-pipe EFR-300 (without panel) | 3.5kw | RUB 28,285 | Buy |

| Fan coil unit cassette two-pipe EFR-400 (without panel) | 4.1kw | RUB 29 692 | Buy |

| Fan coil unit cassette two-pipe EFR-450 (without panel) | 4.5kw | RUB 31,036 | Buy |

| Fan coil unit cassette two-pipe EFR-500 (without panel) | 5 kW | RUB 32,571 | Buy |

| Fan coil unit cassette two-pipe EFR-600R (without panel) | 6.3kw | RUB 32,700 | Buy |

| Fan coil unit cassette two-pipe EFR-750R (without panel) | 7.7kw | 34 299 rub. | Buy |

| Fan coil unit cassette two-pipe EFR-850R (without panel) | 8 kW | RUB 41,723 | Buy |

| Fan coil unit cassette two-pipe EFR-950R (without panel) | 9 kWt | RUB 43 130 | Buy |

| Fan coil unit cassette two-pipe EFR-1200R (without panel) | 11.4kw | RUB 44,730 | Buy |

| Fan coil unit cassette two-pipe EFR-1500R (without panel) | 14.2kw | RUB 46,521 | Buy |

See all Electrolux models of the series "Cassette fan coil units CARRYROUND"

…

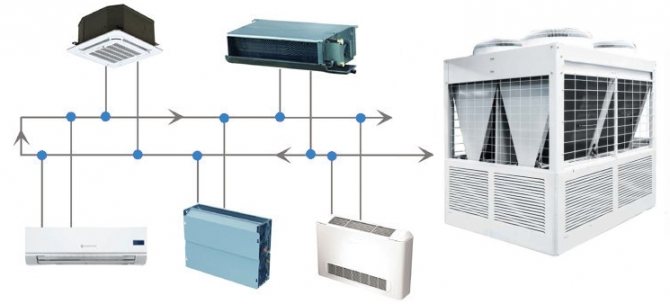

Choosing a type of fan coil before installation work

If you decide to install a channel-type fan coil in a building, you must decide on what classification the system should have. There are four types of structures on the market today, namely: console type, cassette type, horizontal type, and cantilever type enclosed in a case. Each of these heat exchanger systems can be installed indoors using different technologies: the elements can be hung on the wall, built into the ventilation system of the building, installed on the floor or suspended from the ceiling. The main features of the fan coil unit, which influence the choice of a particular device, are the overall air capacity, as well as the cold air capacity.

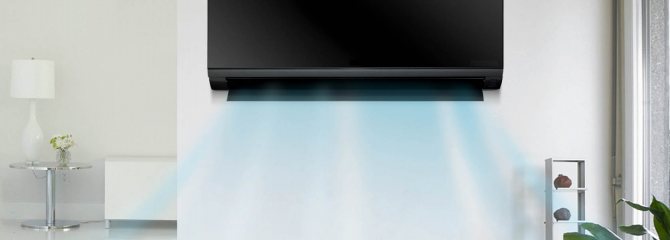

Floor-ceiling fan coil unit

Conventionally, this type of fan coil unit can be divided into two subspecies - floor and ceiling, although many models are universal. They are made as a separate unit, which is mounted on the wall or ceiling of the room.

Floor-standing options are often installed under windows - warm air cuts off the cold from the window and creates a thermal curtain. Due to the peculiarities of convection, such fan coils work better for heating.

Ceiling fan coil units are installed similarly to floor units, but in a horizontal plane. This installation option provides air convection in the room, its uniform heating or cooling. Since cold air is heavier than heated air, these models work better for cooling.

The modern ceiling fan coil looks aesthetically pleasing and provides good airflow to the room.

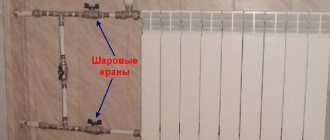

Characteristics of two-pipe and four-pipe heat exchanger systems

Before you install a duct fan coil unit, you need to decide whether a two-pipe or four-pipe heat exchanger system that uses water as a carrier will be used. The simplest piping scheme is possessed by a two-pipe system, which is why it is so common. With it, you can cool the air inside the room, and the cost of the device will be relatively low.

For the winter period, the two-pipe fan coil unit can be switched to heating mode, but for this it will be necessary to disconnect the pipes from the chiller, and then connect them to the central heating. This function can be carried out using a special valve, which is manually adjusted.

The four-pipe system has two heat exchangers, one of them is connected to the system with a hot medium, while the other is connected to the chiller. Such a piping scheme is characterized by more complex design features, this affects the increase in the price of a fan coil, which is why consumers quite often refuse to purchase this equipment.

The four-pipe duct fan coil unit can cool or heat the air in the room, while you do not have to make particularly difficult pipe switching, you just need to select a certain mode using the equipment control panel. This is very convenient, according to the assurances of users who have been using a similar system for heating or cooling air for a long time.

Characteristics

| Cooling capacity, kW | 6.3 |

| Heating power, kW | 11 |

| Power consumption | 125 watts |

| Pressure loss | 23.8 kPa |

| Air consumption | 1000 m3 / h |

| Water consumption for 1 hour | 984 l |

| Noise level | 33 dBA |

| Appliance dimensions | 230х840х840 mm |

| Net weight | 25 Kg |

| Guarantee | 24 months |

| Net weight, kg | 30 |

| Gross weight, kg | 30 |

| Volume of packaging of goods, m3 | 0,203228 |

| Product packaging length, m | 0,94 |

| Product packaging width, m | 0,94 |

| Product packaging height, m | 0,23 |

Table of characteristics of the whole series Cassette fan coil units CARRYROUND

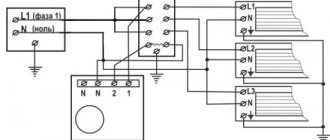

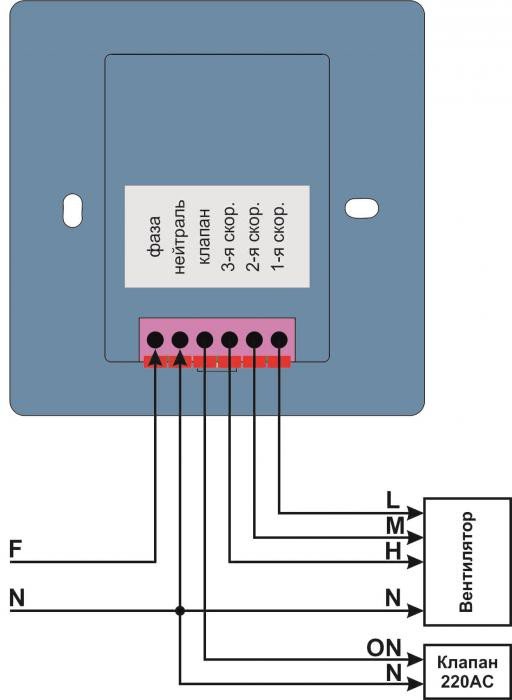

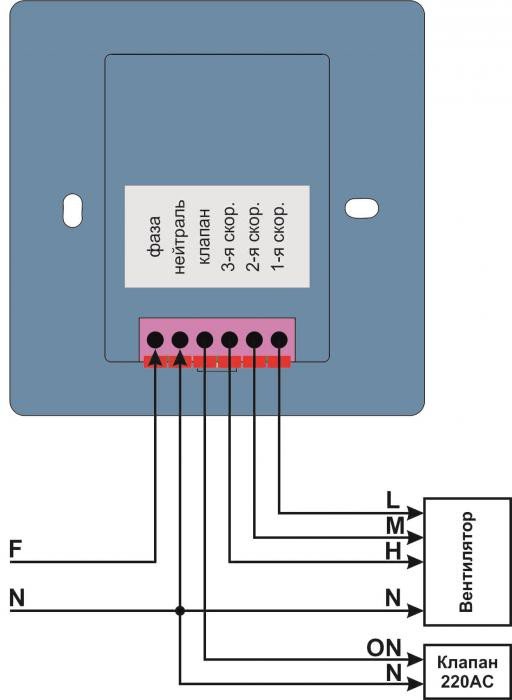

Installation technology

Before starting work, you must definitely consider the connection diagram of the channel fan coil, this will eliminate errors, which is especially true for inexperienced novice craftsmen who have not previously encountered solving such problems. Due to the fact that the system, in which the chiller and fan coil are present, is distinguished by rather complex design features, it is best to entrust installation work and adjustment to highly professional specialists. They will be able to complete the installation by correctly installing the equipment in the place where its work will be most effective. In this case, you can take advantage of the warranty and service. Most often, supplying companies guarantee full service in case of breakdowns within 24 hours.

If you yourself plan to deal with these manipulations, then at the next stage it will be necessary to assemble the piping units, and this can be done after installing the necessary valves, taps and pressure and temperature control devices, which is a very important task. The next step will be the installation and insulation of the pipe, as well as the installation of a condensate drainage system, which will protect the system from premature failure even before the end of the warranty period. When a high-pressure channel fan coil is installed, manipulations will have to be made to connect the devices to the power supply network. The system must be pressurized and its tightness checked.

The last stage is the supply of water, which acts as a carrier in the system. Before determining the maintenance side of the Clint duct fan coil, it is worth considering whether you can carry out all the necessary calculations that are needed to carry out the work. They will allow you to take into account the functional load that will be on a particular fan coil. Among other things, experts will help determine the characteristics of each room in the building, which allows you to choose the right equipment for the most efficient work.

Views

There are universal models, they can be fixed both on the wall and on the ceiling. According to the method of installation, fan coils are wall-mounted, floor-mounted, and also ceiling-mounted. You can also choose according to their appearance: there are case-based (console) and open-frame systems (vertical systems are often used). Frameless systems are cheaper, and they are almost always hidden behind special panels or even behind suspended ceiling systems.

Fan coil units are classified according to the number of heat exchangers.

- Two-pipe. Two pipes go from the heat exchanger: one by one, the liquid goes to the closer, and the other - the liquid goes back. Such varieties are almost always used strictly for refrigeration. Heating air is realistic in theory, but you will be forced to heat water in an auxiliary heat exchanger, and also apply pumping force.

- Four-pipe. In this case, there are two heat exchangers, and two pipes emanate from each of them. It turns out that in one heat exchanger the water is cold, and in the second it is hot. Such a climate gadget perfectly cools and warms the air.

There can be cassette and channel fan coils. The former are usually designed where there are suspended ceilings. More often, such devices are made frameless, because most of them are hidden, and only the decorative panel is revealed to everyone's attention. Such a closer does not actually make noise, it is not particularly difficult to install, it manages to evenly distribute the air inside the building.

Ducted fan coil units are more often used for large objects such as shopping centers.They are fixed inside the ventilation system behind false walls and a suspended ceiling structure. They either supply fresh air or purify the one that is. There are also column closers - they are installed against the wall, because their main purpose is to service rooms where it is impossible to organize a pipeline supply to the ceiling space. These are high-performance devices that are not used very often.

Why choose a fan coil unit?

If you decide to install a fan coil unit indoors, you will find a heat exchanger with a fan inside. All of the above components are enclosed in one compact housing, which looks very aesthetically pleasing and does not take up much space, in particular when mounting on the ceiling. That is why experts advise resorting to such a solution. By installing this system, you can simultaneously solve the issue of air conditioning and ventilation, which saves money on the purchase of appropriate equipment. The equipment operates with minimal noise and does not involve complex maintenance, which is undoubtedly an undeniable advantage.