Liquid fuel boilers make it possible to make the heating of the house completely autonomous from the central gas pipeline. They are used for both space heating and water heating. There are many models, so before buying, you need to understand the specifics of their installation and operation.

Heat your home with liquid fuel boilers

Equipment advantages and disadvantages

Heating boilers for liquid fuel make the house completely autonomous in terms of heating and hot water supply. They have their pros and cons to be aware of. The main benefits include the following:

- ease of installation;

- ease of operation and maintenance;

- automatic fuel supply;

- no need to obtain a special permit for installation;

- high power and efficiency;

- the ability to use for heating both residential and industrial premises;

- boilers are fully automated.

In this video, we will consider boilers for liquid fuel:

If necessary, the type of fuel can be changed by replacing the nozzle. The devices are characterized by a high level of efficiency. The main disadvantages are as follows:

- noise during operation;

- the need to create a separate room for the boiler and fuel storage;

- availability of uninterrupted power supply;

- the need to install a chimney.

More details: do-it-yourself chimney.

The cost of liquid fuel is quite high. Despite all the shortcomings, such boilers are in demand.

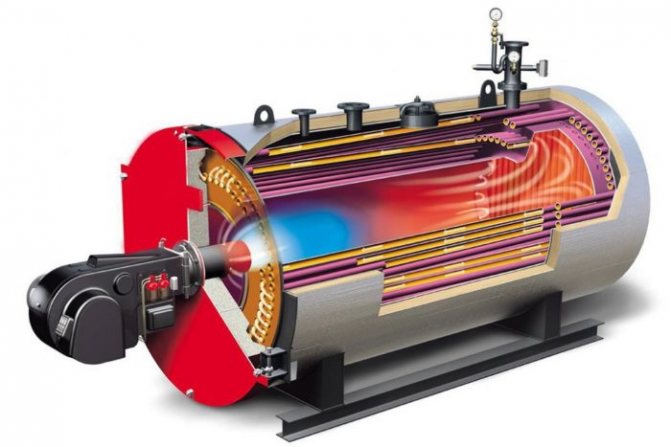

The principle of operation and the device of the liquid fuel boiler

The main element of the liquid fuel heater is the burner

From the name it is already clear that the main difference between long-burning liquid fuel boilers is the very fuel on which they work. Since this is a liquid, the problem arises of how it is dosed to burn. Accordingly, in the device of a liquid fuel boiler, some kind of device must be provided that will be responsible for this process. In addition to the main elements of the unit, which are no different from the standard set of any boiler, the burner plays a key role. This is, one might say, the heart of the device. It was invented by Robert Babington and patented at the end of the twentieth century, more precisely, in 1979. The device was named after him.

It is clear that the principle of operation of a long-burning liquid fuel boiler is to heat the coolant by means of an open flame. The heating medium flows through the heat exchanger, which in turn is exposed to heat from the fire. There are no subtleties in this.

Considering the principle of operation of a liquid fuel heater, it would be more correct to imply the principle of operation of a Babington burner.

Let's start with the construction:

- air supply pipe;

- fuel supply pipe;

- fine bore nozzle.

It would seem such a simple scheme, but in fact there are many nuances that we will consider a little later, talking about how to make it yourself. The design of the unit largely depends on how much fuel it will burn over a certain period of time. Almost the main question asked about a liquid fuel boiler is fuel consumption per hour. And this is not surprising, because the "selfish" question, nevertheless, has a significant meaning.

How to choose the right diameter of polypropylene pipes for heating: table and calculation.

About what adapters for heating pipes are and how to work with them is described in detail here.

Principle of operation and device

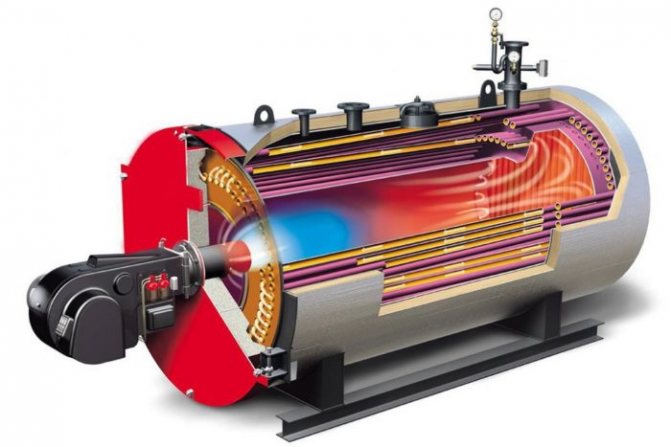

Liquid fuel devices work on the same principle as gas ones.The main difference lies in the use of a nozzle (fan burner). The boiler has the following structural elements:

- common building;

- burner;

- Control block;

- the combustion chamber;

- chimney;

- heat exchanger.

The package also includes a pump, which is responsible for supplying fuel to a special tank. To improve efficiency, some manufacturers complete the device with heat exchange plates and chimneys.

The control unit is fully automatic. The body is completely insulated. This increases the efficiency of the device and also minimizes heat loss. The outside of the boiler is covered with a special film, which remains cold even when the unit is heated, so there is no risk of getting burned.

Varieties of boilers

All models can be divided into several groups depending on the principle of operation and the fuel used. There are two principles of fuel combustion:

- Evaporation of liquid fuel occurs from the surface of the bowl. The fuel itself burns slowly, so the volume of vapors is quite large. Most often, this principle of action is found in homemade devices.

- A flare burner is used. The fuel, like in the first method, goes through pyrolysis. However, the mixture is prepared, vaporized and burned directly in the torch flame.

Flare boilers are more versatile. Most often they are used for heating country houses. They can work for:

- fuel oil;

- diesel;

- reduced gas;

- working off.

It is interesting: how to make a waste oil boiler.

Devices that have pre-evaporation cannot burn diesel fuel and gas. Heating units can also be divided into factory and homemade ones. The former are safer and more effective.

Mounting method

Theoretically, all hot water boilers can be mounted (wall-mounted) or floor-standing.

As you might guess, the former have less weight than the latter, as well as less power and performance. Simply put, wall-mounted boilers are more compact and convenient, but the area heated by them is limited, as a rule, to 300–350 m2. Nevertheless, wall-mounted diesel boilers, unlike gas ones, are not on sale. Perhaps this is due to the fact that liquid-fueled units are generally less popular than gas-fueled ones.

- 1 of 1

On the picture:

Wall mounted steel heating boiler.

Device selection criteria

Domestic liquid fuel boilers are manufactured by both European and domestic companies. When choosing, you should pay attention to the main characteristics of the device. You need to consider:

- power;

- price;

- functionality;

- availability of additional functions.

The optimal power of the device must be calculated by a specialist. The functionality of the units is manifested in the fact that single-circuit models are aimed only at heating. Double-circuit can not only heat, but also be connected to hot water supply.

Prices for liquid fuel devices are different. German-made models are the most expensive, most of them belong to the premium class. The middle price category is represented by devices from Korea. They are multi-layered and fully automated. The most accessible are models of domestic production.

An important factor when choosing a heater is the manufacturer's brand itself. The most popular products are from the following manufacturers:

- Gecko;

- 5Energy;

- Viessmann;

- De Dietrich;

- Navien;

- Kiturami.

Read more: korean cauldron Kiturami.

The choice of a specific device depends directly on the budget and the wishes of the owner. Domestic models are in no way inferior to European ones. They are not whimsical to raw materials and are equipped with automatic control.

Burner type

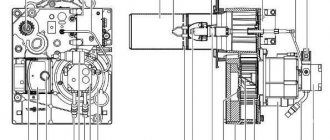

Burners for oil fired boilers can be built-in or mounted.

- Built-in burners the unit is rigidly "tied" to one type of fuel - usually diesel fuel.

Fuel oil and other alternative fuels are practically not used due to low efficiency and environmental damage. Many manufacturers do not even consider fuel oil as their intended fuel and do not produce equipment that could run on it.

- 1 of 3

On the picture:

In appearance, the liquid fuel boiler resembles a miniature refrigerator.

Which burner?

There are two types of boiler burners: atmospheric and blast. However, in diesel boilers, burners can only be blown (pressurized), that is, with forced air supply using fans. In their work, atmospheric burners use the natural flow of air due to the vacuum created in the furnace. In oil boilers, atmospheric burners are not installed.

Photo: Sun G oil burner from Ferroli factory.

- Mounted burners make the heating boiler universal: since it is no different from gas, then you can switch from diesel fuel to main or liquefied gas and vice versa, if necessary, simply by changing the burner equipment. This is done easily and quickly and does not require significant cash costs - apart from, of course, the fact that you will have to buy not one, but two burners. However, the ability to work on three types of fuel at once is an undoubted advantage of such a device.

Liquid fuels

The list of types of liquid fuel is quite extensive. The choice of a specific type depends on the boiler model. Most often used:

- fuel oil;

- diesel fuel;

- kerosene;

- waste oil.

It is interesting: selection of a diesel boiler for a private house.

Fuel oil and diesel fuel are fairly light fuels. They are easy to transport and store. Due to the low viscosity of the fuel, it burns as efficiently as possible. The minimum amount of ash and sulfur in the composition ensures the safety of equipment and minimizes emissions into the environment.

When choosing a fuel for a liquid fuel boiler, you should pay attention to the viscosity and the amount of sulfur in the composition. The price of a low sulfur product is higher, but its use has advantages:

- economical consumption;

- low costs for maintenance and repair of equipment;

- minimum amount of harmful emissions into the atmosphere.

You cannot save on fuel. Otherwise, you will have to constantly change the injectors, the fuel filter and clean the tanks from sediments.

Fuel for liquid fuel heating boilers

For equipment such as liquid fuel boilers, it is not only diesel fuel that can be used.

Currently, different types of fluid are used for the operation of such heating units:

- Kerosene. It is desirable that the provisions of GOST 305 are used in its production.

- Waste oils: transmission, motor and others. Mineral or synthetic based ATF grease is permitted. The presence of water and abrasive particles in the fuel is not allowed.

- A mixture of used oils and diesel fuel in different proportions.

Features of operation

In order for liquid fuel heating boilers to work efficiently and properly, it is necessary to adhere to the basic recommendations for operation. It is necessary to constantly monitor the amount of fuel in the boiler.

Technical inspection and maintenance of the device is carried out periodically. It is recommended to carry out cleaning and detailed inspection for damage at least 2 times a year. The first inspection is carried out before the start of the heating season, and the second immediately after its end.

An important nuance is the use of only high-quality fuel and the installation of a special filter to clean it.Periodically, it is necessary to check the integrity of the containers in which liquid fuel is stored.

Long burning liquid fuel boilers, if properly operated, can serve for a long period. It is important to carry out technical inspection and troubleshoot on time. Only in this case the operation of the device will be not only efficient, but also safe.

Device

As the name implies, liquid fuel heating boilers are units that do not use gas, coal or firewood for their work. The main type of fuel is diesel fuel.

The main problem that the boiler designers had to solve is the organization of the dosed supply of liquid fuel to the combustion chamber. The fuel is supplied through a burner that was created and patented by Robert Babington.

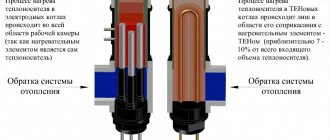

Otherwise, a liquid fuel boiler is no different from units that use gas as fuel. The general principle of operation of heating equipment:

- burning, the fuel provides heat generation;

- in this case, the heating agent is heated, which circulates through the tubes of the heat exchanger;

- hot coolant enters the heating system of the house, giving off heat;

- the cooled heat carrier returns back and is reheated in the heat exchanger.

Advice! If industrial heating boilers, most often, are single-circuit, ensuring the operation of the heating system, then for a residential building it is more convenient to use double-circuit water heating units, which are also used for hot water supply.