All of these and a few other questions will be answered on this page. We will consider heating units on wood, pellets and coal.

Types of solid fuel boilers

A solid fuel boiler is one of the most economical options for heating a private house. Heating a room with gas or electricity is not always cheap. And also in the absence of the possibility of connecting gas, the acquisition of a solid fuel boiler remains practically the only profitable option. This heating equipment is divided into several types:

- Heating boilers, into which you need to load fuel yourself. They are divided into 3 types: top-burning pyrolysis boilers, classic boilers and long-burning boilers.

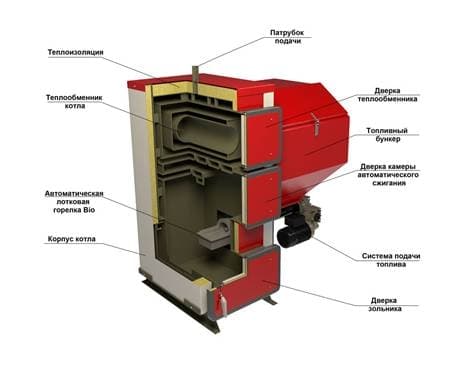

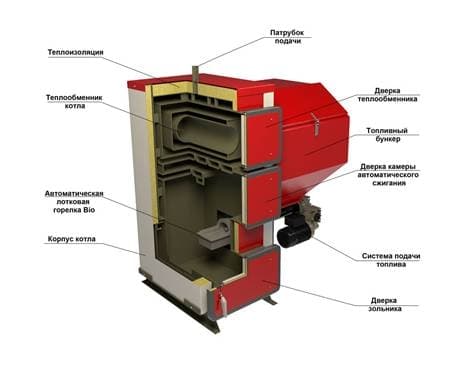

- Pellet boilers. They are also called boilers with automatic fuel supply. In such equipment, fuel is supplied automatically. The boiler operates on solid granular fuel.

Choose solid fuel heating boilers according to the main parameters:

- The type of fuel on which the equipment will work properly;

- The time during which the fuel will burn with one load.

And also when buying a heating boiler, you should pay attention to the following nuances:

Unfortunately, solid fuel heating boilers are only of floor type. Wall-mounted boilers of this type are not produced. Perhaps this factor is a disadvantage of such equipment, since it will take up a lot of free space in the room.

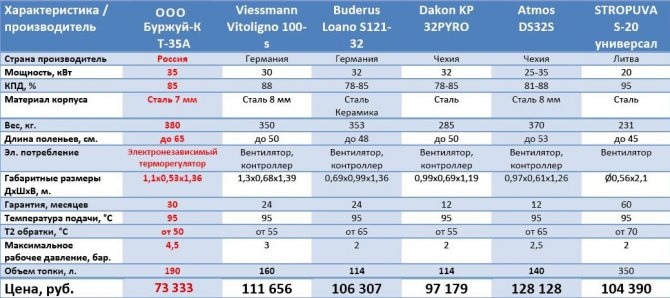

Heat price

Any boilers, regardless of the type of fuel, are divided into two classes: economy and luxury. First-class boilers are cheaper, since cheaper materials and components are used for their production, their design is simpler, and repair is also not a big problem. At the same time, their efficiency and power are lower and the service life is limited. Luxury boilers are modern, high-tech devices made of resistant anti-corrosion materials, equipped with a large number of electronics, allowing for more fine tuning. Their power is high, while they use fuel efficiently and economically. In addition, the luxury boilers are distinguished by their modern design, which makes them a source of special pride for the owners. Such boilers are much more reliable, require less maintenance and have a long service life.

Depending on many parameters, the cost of boilers ranges from several thousand to several hundred thousand rubles. The price depends on the manufacturer, materials, and such technical characteristics, in addition to the availability of automation, such as power, efficiency percentage, number of circuits, non-volatility, mechanical or electronic control, frost protection, built-in boiler availability, the ability to use 2-3 types of fuel and many others. ... And that's just the boiler itself. If you approach the issue of heating thoroughly, and are going to install a heat accumulator, install heating pipes in the house, then the cost of such large-scale structures increases significantly.

As already noted, the most expensive in the series of solid fuel boilers are pellet boilers. The cheapest are simple manual coal boilers.

The Baltic boilers Stropuva are very popular with us.They have earned the recognition of buyers for their quality and a wide range of models for every wallet. In addition, boilers of domestic manufacturers, such as Teplodar, TRAYAN, are widespread in Russia.

The subsequent costs cannot be ignored. In our difficult time, when energy prices rise every season, solid fuel boilers become, in fact, a guarantee of your independence from energy suppliers. Gas and electric boilers in this sense are noticeably inferior to coal and biomass boilers. In case of some unforeseen circumstances, the user of a solid fuel boiler can always switch to cheaper fuel, while the prices for gas and electricity are only growing. In addition, using a solid fuel boiler protects you from power or gas outages.

Pyrolysis boilers

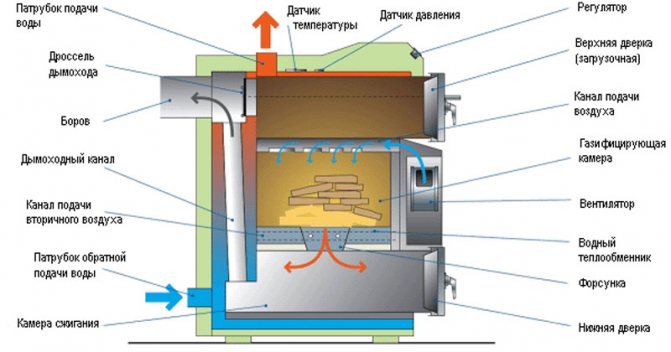

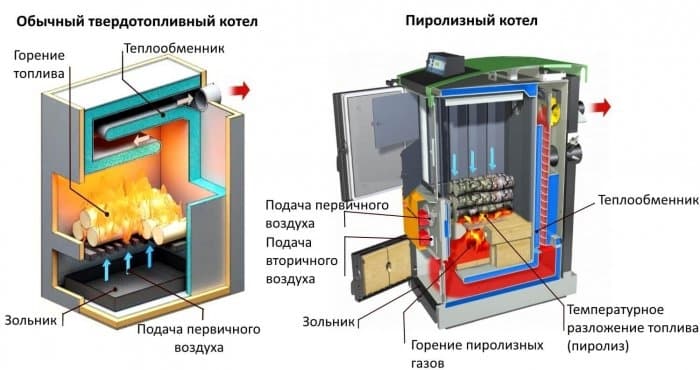

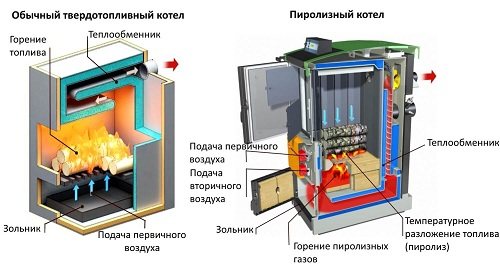

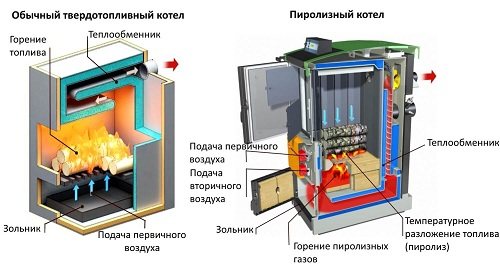

This type of solid fuel boiler runs on gas, which is obtained by burning fuel and lack of oxygen. The device is equipped with two chambers, which are separated by grates. An upper combustion chamber and a lower chamber in which gas is burned. The upper chamber is used to load fuel. After it ignites, and then the fan automatically starts to work.

Under the influence of high temperature, the tree begins to burn and release gas. It, in turn, moves down through the nozzles, and then mixes with air. As a result, the mixture once again heats up the fuel in the upper chamber. Due to the lack of air, the fuel is gasified and decomposed.

Pyrolysis solid fuel boilers are complex devices. To increase the burning time, a tree with a thickness of less than 10 cm is used. In order not to disrupt the operation of the device, it is necessary to load it with a power of 50 to 100%. It is recommended to use other heating devices during the off-season.

In pyrolysis boilers, some features are distinguished:

- The burning time of the fuel of one load is equal to 10 hours.

- Full boiler load is required.

- The wood must be dry.

- High price.

- High efficiency. It can be as high as 90%.

- Environmental friendliness of the equipment.

The pyrolysis boiler includes: controller, smoke exhauster and electronic control.

Principle of operation

The basic principle, regardless of the operating model, is to burn the contents of the furnace and heat the coolant, through the circulation of which the room is heated.

In long-burning models, the combustion process is from top to bottom. Depending on the amount of fuel, one bookmark can be enough for more than a day of continuous operation.

The pyrolysis models use two chambers. In the first, the fuel combustion process takes place in conditions of a lack of oxygen, after which the pyrolysis gases enter the second chamber, where they are completely burned. As a result, one fuel load lasts much longer than for the operation of a standard solid fuel boiler.

The range of long-burning boilers is small - this technique is still one of the novelties of the domestic market.

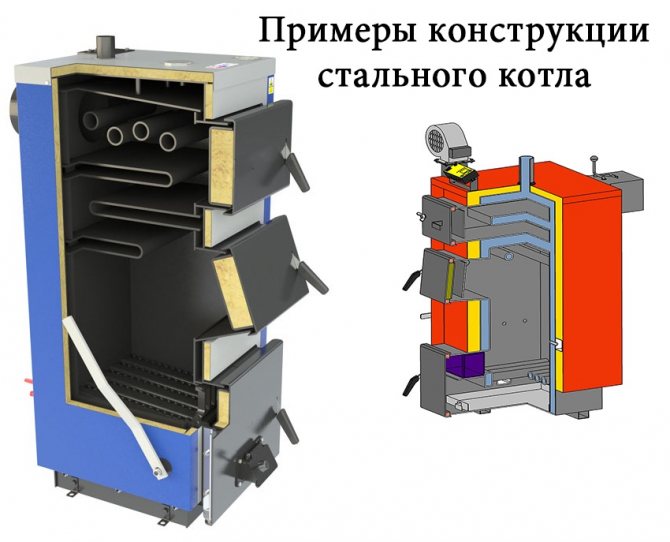

Classic boilers

The most popular type of solid fuel boilers is considered to be classic. Heat is spread by burning solid fuels. Such boilers are made of steel or cast iron. Moreover, heat-resistant steel is used. Classic boilers can heat the house and heat the water. This boiler can operate on wood, coal, pellets or peat. The most profitable option is coal heating. Since when using firewood as fuel, the combustion process will be much faster. The boiler with one load can work from 2 to 6 hours.

Using a temperature sensor, you can maintain a certain temperature regime and adjust the air damper. If the temperature drops, the damper will open with the help of the sensor.On the contrary, if the price rises, an opening will occur. Classic boilers are independent of gas and electricity.

For more efficient heating, some models have a built-in fan, control panel and an electronic temperature control sensor.

The advantages of this solid fuel boiler include:

- Large selection of manufacturers, models.

- Low cost of equipment.

- High-quality manufacturing technology.

- Easy to operate.

- Low fuel costs.

- Large selection of fuels.

- No electrical connection required.

But there are also several disadvantages:

- Self-loading fuel.

- Fuel delivery and preparation.

- Frequent loading of fuel.

- Availability of a place where fuel will be stored.

- The inertia of fuel combustion.

Despite some shortcomings of this model, it is the most demanded due to its high efficiency and low cost.

Stove evolution

Each village has a stove. The Russian stove is the heart of the house, its foundation. It provides heat, completely unlike the heat from radiators in apartments. This is a living, breathing warmth, from which the soul becomes calm. But progress cannot be stopped, and now the brick hearth is being replaced by a high-tech device - a solid fuel boiler. We can heat it with wood, or coal, or modern types of biofuels, but the meaning remains the same: what gives your home warmth gives life itself. And the choice of such an assistant should be approached with all responsibility. Let him take the place of a Russian stove in your house, and become your reliable friend and ally in the long winter months.

Long burning boilers

Long-burning boilers can operate on different types of fuel: wood, sawdust, drill, coal, etc. But there are models that are designed to work on wood. They differ from other boilers in the material from which the combustion chamber is made, as well as in the air supply system.

One load can be 50 kg of fuel, and the burning time of firewood varies from 12 to 48 hours. If coal is used as fuel, then it will burn from 4 to 7 days. If you decrease the fuel combustion rate, the boiler output will decrease. This option is suitable for light frosts.

The fuel burns from top to bottom. Therefore, these boilers work for a long time with one load.

Long burning boilers have the following advantages:

- Low cost of the boiler in comparison with pyrolysis ones.

- Long fuel combustion.

- They do not depend on the power supply.

- Ash does not need to be removed more often 2-3 times a month.

- The power regulation is deep, in contrast to the classic boiler.

The disadvantages include:

- Low efficiency.

- Installation of a circulation pump.

- The boiler operates in a full cycle. This means that it is impossible to add fuel to the equipment.

When changing the burner, you can easily switch to another type of fuel. To do this, it is necessary to change the burner, and then reconfigure the automation.

Boilers with automatic fuel supply

Such boilers are quite popular for heating private houses. With the help of a screw or transport bunker, the fuel is automatically fed. Fuel burns with one load from 3 to 10 days. Boilers with automatic fuel supply are highly efficient. It can be 85%.

For safe operation, it is necessary to install the boiler in a separate room and install a fireproof ash collector. This boiler has a high cost, and is also dependent on the power grid. The fuel can be used: wood or other pellets of combustible materials and granular coal. Such fuel is more expensive than others.

In order to prevent overheating of the boiler, it is necessary to fill the firebox with firewood gradually.Since they quickly ignite, and this leads to the release of a large amount of heat. If you use coal as a heat carrier, then it burns slowly and gradually. Therefore, the temperature in the furnace will be the same throughout the entire combustion.

What is important to know before buying

It should be borne in mind that not all boilers are suitable for your conditions. Pay attention to how the fuel is loaded into the combustion chamber. As a rule, in cast iron boilers, the loading of firewood or coal is carried out from the side. At the same time, there are many top loading models.

If the boiler room is located directly inside the house, then this can create some inconvenience, due to the fact that when the door of the heater is opened, smoke will enter the room.

To prevent smoke from entering living quarters, top-loading boilers are best placed in a separate boiler room.