Most insulation materials have a porous or fibrous structure. Basically, this means that inside the material there are many small voids filled with air. Due to this, such materials have a high coefficient of resistance to heat transfer. With improper installation, builders' mistakes, it happens that the insulation gets wet, and the voids inside it are filled with water. If this happens, the thermal insulation material loses its properties, because its resistance to heat transfer is seriously reduced.

Roof insulation got wet, what should I do? With a decrease in temperature and frost, instead of a heater, there is just a layer of ice. This leads to a strong increase in the heat loss of the room. If the building has an autonomous heating system, fuel consumption and money costs increase significantly. With centralized heating and the inability to increase the heating power, the temperature in the building drops significantly. Excess moisture in the roof space creates dampness, the wooden elements of the roof suffer, and the metal parts of the structure corrode. As a result, wet insulation turns out to be the cause of a whole heap of related problems.

Possible causes of moisture accumulation in thermal insulation

The problem when the thermal insulation material under the roof gets wet requires an immediate solution. This can happen for many reasons. Here are the main ones:

- During installation, the waterproofing material between the roof and the insulation was damaged. This is usually a film or superdiffusion membrane. The workers may have punched it when they were assembling the roof. This often happens when the waterproofing is attached by over-stretching, which is a mistake. Installation must be carried out so that the waterproofing sags a little and does not create excessive stress on the material. Also, moisture from possible condensation can collect and drain off in places where the film sags.

- The joints of the waterproofing sheet were not carefully glued. In this case, condensate moisture can penetrate through the cracks in the joints.

- Poor installation of waterproofing in places of passage of a chimney or ventilation shafts. Here it is necessary to bend the edges of the waterproofing upwards and fix them to the pipe walls with a clamping bar or a clamp.

- A low-quality waterproofing material was used, a cheap superdiffusion membrane is moisture permeable.

Expert opinion

Konstantin Alexandrovich

In addition to possible reasons with waterproofing, moisture can penetrate into the insulation due to improper installation of the vapor barrier layer, which should protect the insulation from vapors from the interior. Even with good ventilation, steam is always present and with warm air accumulates at the top of the roof. Therefore, a vapor barrier is always installed in front of the insulation layer. If it is installed incorrectly or damaged, moisture will penetrate into the insulation.

What if the insulation is already wet?

First, it is necessary to determine the degree of wetting of the thermal insulation, regardless of whether the insulation in the floor or roof has suffered. If it is saturated with moisture through and through, then the only thing that remains is to throw it away, since it will not work to dry the insulation in the roof. However, many modern thermal insulation materials are made with protection from getting wet, for example, mineral wool fibers are impregnated with special hydrophobic substances that prevent the fibers from being impregnated with water. And if the insulation is not very wet, then you can try to dry it. How to do it? It is necessary to create a draft so that the moisture gradually evaporates from the insulation layer.To do this, you can use a heat gun. If the weather permits, it is better to remove the roof or facade coating material and dry the thermal insulation.

If the insulation gets wet, then, most likely, the weather is not ideal, and there may be a problem with the drying of the insulation. After all, the speed of its drying under the material of the roof or facade will in any case be low, even if you manage to create a good draft.

The best solution would still be to remove the wet thermal insulation and install a new one instead, avoiding mistakes during installation again. After all, not completely dried heat-insulating material definitely has the worst coefficient of resistance to heat transfer, which entails increased heat loss and heating costs. In addition, high humidity has a bad effect on wooden supporting structures, which threatens the need for their early repair. And these are costs of a different order than just replacing the insulation, and the savings can go sideways.

Properties and application features of the material

The main property that determines the effectiveness of a particular insulation is the thermal conductivity coefficient.

It characterizes the heat loss occurring through a layer of material 1 m thick on an area of 1 m2 for 1 hour with a temperature difference on opposite surfaces of 10 ° C.

For various forms of release of mineral wool, this figure is 0.03 - 0.045 W / (m * K).

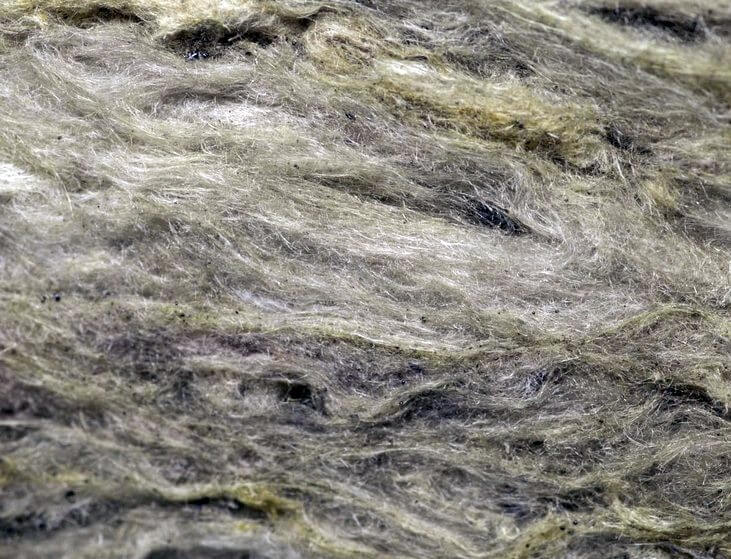

A distinctive feature of fiber insulation is the dependence of their thermal insulation properties on moisture content.

When wet, water droplets envelop the fibers and gradually penetrate into the bulk structure, gradually displacing air from there.

An increase in the amount of water inside, between the fibers, leads to a sharp drop in thermal insulation characteristics. The situation is aggravated by the fact that water that has got inside is extremely difficult to get out.

Insulation can take up to 70% of its mass of water. Naturally, under these conditions, the efficiency of his work will tend to zero.

Despite the criticality to wetting, the scope of mineral wool is extremely wide. When building a house, its use is possible almost everywhere where direct contact with water is excluded:

- Hollow walls (frame and brick, made using well masonry technology);

- The outer surface of wood or brick walls;

- Internal partitions;

- Floors;

- Interfloor ceilings;

- Roof.

Insulation ventilation

Poor ventilation of the under-roof space is a common cause of high humidity in the thermal insulation layer. Ideally, with good ventilation, air always circulates between the roof covering and the insulation, which prevents condensation from collecting. That is why it is so important to have proper ventilation not only in living quarters, but also under the roof.

Important! When installing roof ventilation, it is important to ensure air exchange in the space between the roof covering and thermal insulation. To do this, you can install special aerators in the ridge or directly in the cover. If you do not have any, it will not be superfluous to install them.

With insufficient thermal insulation between the living quarters and the attic on the roof from the inside, there is an increased formation of condensation. This can be dealt with by regular ventilation, then the condensation will dry out quickly and no drops will form. But this is called dealing with the consequences. does not correct the cause or solve the problem. In such cases, it is better to invite specialists with a thermal imager to inspect the building and identify the places of greatest heat loss.

Protection of cotton wool from rain before installation

To prevent the basalt insulation from getting wet during installation, it is worth protecting the installation site from rain. For this purpose, it is very convenient to use inventory forests. And on these scaffoldings, on the upper rungs of the upper row, lay boards and stretch the film.

It will turn out cheap and cheerful. Not only building materials will be dry, but also the installers themselves who work on the walls.

To drain rainwater from the film roofs on the scaffolding, it is easiest to use 3-4 drain pipes with a diameter of 110 mm, into which the water accumulating on the film will drain. This will allow you not to get wet under an unexpected "waterfall", when the water, which has no drain, bends the film and gushes down in the "unfortunate" place.

We store the finished cotton wool in bales right next to the walls, preferably indoors. At the same time, it can be served for wall mounting in the windows of the first or second floor, as it is more convenient.

Further, if the wall is deaf, we make a temporary canopy next to it from boards and film. Nothing global is needed, the main thing is that the water flows to the ground, and not to cotton wool. Although it is packed in plastic bales, it is not protection from heavy rain.

Further, we understand that in heavy rain, especially during a prolonged autumn storm, all the water under our feet, the earth does not have time to absorb such an amount of water. We do not put cotton wool in bales and sheets on the ground, even under a canopy. It is best to use the most common wooden pallets. Their height, 15 cm, is enough to prevent cotton wool from getting wet from the ground.

A vapor barrier enters the scene

You should get the first one. For this, a vapor barrier is arranged. It was invented precisely in order not to turn frame walls into equipment for air dehumidification. Moreover, mind you, and this is again extremely important, we protect our walls from warm air, and not from cold air, in which there is very little moisture! This means that especially careful insulation must be inside the room, so that this very air is not allowed into the walls.

And the insulation of the outer walls? Yes, she seems to be even harmful! Indeed, why do we need to keep moisture inside the walls? Let it come out! Do you feel sorry for her or what? Therefore, I usually advise against insulating outside walls. I wrote a special article about this. However, in our case, and indeed in frame construction, we use exterior finishing materials, which in themselves are moisture-proof. Simply by virtue of its original properties. Here is the OSB, for example. These are epoxy impregnated shavings. Of course, it does not allow moisture to pass through!

Knowing about these properties of frame houses, vapor barrier is given the utmost importance and it is done extremely carefully. And in the outer walls, ventilation openings should be provided that would allow the inner space of the walls to dry out. And why should they dry out if we made a vapor barrier and received a complete analogue of a sealed bag of cotton wool?

What causes condensation and where can it occur?

Condensation occurs on cold surfaces when they come into contact with warmer, more humid air. What does humid air mean? Do we have a bath or something? Not! It's just that warm air is able to contain significantly, several times, if not tens of times more moisture (by mass) than cold air. Therefore, it is in comparison with cold air that our warm air is humid.

If the house is not completed, then one way or another, warm air cannot be isolated from cold surfaces, and in this case, the fact that condensation falls on them is normal.

If the house is completed, the condensation situation that we described at the very beginning is completely abnormal. I'll try to explain my position in a fun and simple way.

Entertaining physics

Let's imagine that we took a polyethylene bag, which definitely has no holes, and put a sheet of glass wool in it. Yes Yes! The one that heaps in our frame walls. The bag was sealed on top. Thus, the cotton wool turned out to be strictly in the bag. Moreover, we packed this cotton wool in a warm room and did not dry the air. What follows from this? From this it follows that inside our bag there are the following things:

- cotton wool (most)

- air (also decent)

- steam (the one in the air)

Lots of steam? Well, if you count in grams, then very little. Well. let's say. 10 grams of water.

Now we take our bag and, as it is, carry it out into the cold. What's going to happen? Our 10 grams of water will fall out of the air. Where will they be located? In cotton wool and on other surfaces inside the bag. You can even see them. These will be drops of water or even “drops of ice”, if I may say so.

What will happen if we bring our bag back into the heat? The air in it will warm up and the condensate will go back into the air. Everything will look and feel dry again.

But that's not all the reasoning! The most important thing will be now.

We agreed that 10 grams of water would fall out of the air in our bag in the cold. Is this constant? Yes! Absolutely constant. Since we have a closed system and we do not have access to air inside the bag, there will always be the same amount of water in it, forever and ever, until we open it. Either it will be in the form of steam or in the form of condensation.

And what will happen if we make an ingenious system that will remove cold air from our bag and introduce warm air there (the bag, as you understand, is in the cold)? We will have a device for dehumidification of air. In this case, dry air will come out of the bag, and water will form in the bag. A lot of water, even a lot. She will pour out of him. At the same time, and note, this is important to understand, all moisture will form inside the bag, and outside it will be dry.

If you understand the whole line of reasoning, then now try to define it yourself. What are our walls? A certain volume, in which a constant and not very large amount of steam, or did we have equipment for air dehumidification?

Preparing walls for insulation

If you think that mineral wool, the characteristics of which are suitable for your home, is a good insulation, then you must first prepare the walls for finishing. If the walls have plaster, it is necessary to remove it to brick, wood, concrete or stone, depending on what the walls of the house are made of.

If there are level differences on the walls by more than two centimeters, then they must be eliminated. After cleaning the walls from dust and dirt, you can cover the prepared walls with a primer.

You will need two types of mineral wool, which will differ in density. The soft board is placed against the wall, as such wool can fill all the unevenness of the wall. Place a hard board on a soft board, so you form a smooth surface of the walls outside. The total width of the insulation should not be more than 10 centimeters.

Insulation work begins from the bottom, the plates are glued with a special glue.

When insulating a wall, you will have to adhere to the following sequence: wall, insulation, reinforcing mesh on dowels and facade plaster.

You can also insulate your house by making a ventilated facade. This will help prevent the formation of wet condensation, which is harmful to the mineral wool. Even in spite of their high moisture resistance, they let water vapor pass through themselves through their thickness, which can spoil both mineral wool, deforming and stratifying it, and the walls of the house.

What is the harm caused by condensation?

Condensation on the roof seriously damages a variety of insulation materials such as mineral wool. From moisture, it not only turns into lumps, but also loses its properties. Wet cotton wool will not last more than two years, although in dry conditions it will not have to be changed after 20 years.

Roof repairs are quite expensive. Due to moisture, supporting structures can suffer, for example, logs and the roof will sag, begin to leak or collapse. That is why it is necessary to deal with condensation immediately after its detection, without postponing the solution of the problem until later.