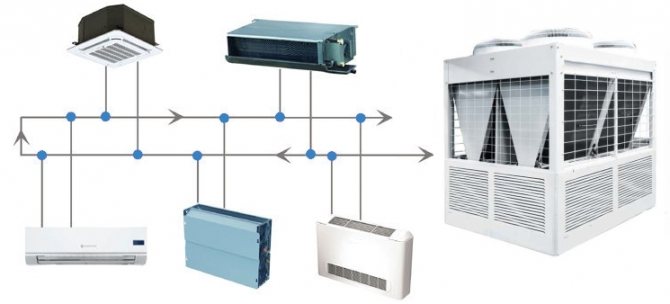

Household air conditioners cool (heat) the air locally in 1-2 rooms. Chiller-fan coil systems are designed to solve a wider range of tasks, for example, simultaneously maintain a microclimate in dozens of individual rooms. Moreover, the facade of an office building or a shopping center is not disfigured by the external blocks of "splits". A similar air conditioning scheme (ACC) can be implemented in a private cottage. We propose to understand what a fan coil is, describe the principle of operation and types of modern climatic units.

Fan coil design

The English name of the fan coil apparatus literally means "coil fan" and indicates a structural similarity with the long-known AVO heaters (air heating units). In appearance and device, fan coil units also resemble the internal blocks of a split system, only instead of freon, water or an anti-freeze liquid is used.

Reference. The working fluid in industrial air conditioning systems is traditionally the toxic antifreeze ethylene glycol. A safe analogue - propylene glycol - is 30-50% more expensive, therefore it is used less often.

On the left in the photo is the internal module of the split system, on the right is the AVO heating unit

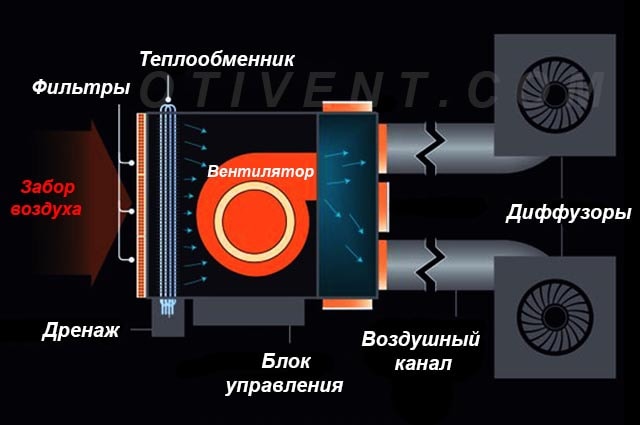

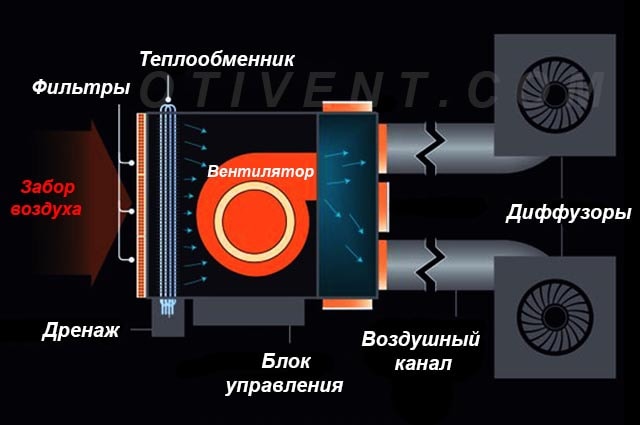

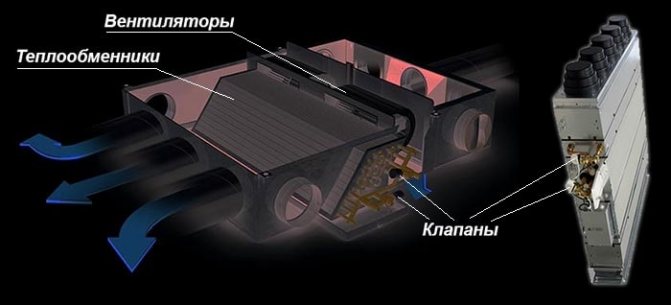

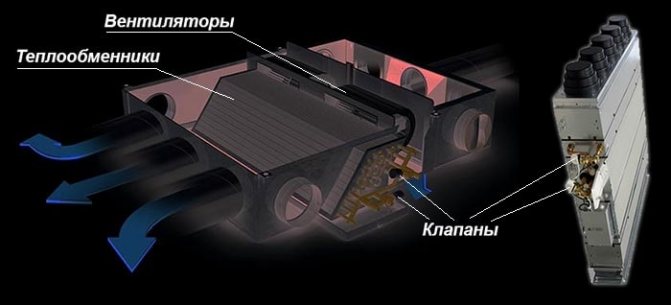

A fan coil unit consists of the following elements:

- a body equipped with air grilles or nozzles;

- heat exchanger - copper tube coil with multiple plates;

- fan, usually centrifugal;

- coarse air filter;

- solenoid valve - regulator of the fluid flow through the heat exchange radiator;

- manual air release valve;

- electronic control board.

A condensate collection tank is installed under the heat exchanger. The latter is discharged through a tube to the street or to a sewer receiver. If the unit is installed at a considerable distance from the discharge point, the condensate is pumped over by a drain pump.

Console fan coil device - sectional diagram

Operating principle

The device works on the principle of the aforementioned heater: antifreeze or water of a certain temperature flows through the pipes of the coil, the fan blows room air through the fins. Heat exchange takes place, the flow is heated or cooled. Hence the second name of the device is a fan coil.

Features of the fan coil unit:

- the unit is capable of operating in either heating or cooling mode, depending on the temperature of the incoming water;

- the main function is to transfer heat or cold produced by other installations to the air;

- the liquid flow is provided by an external pump, there is no own one;

- the sucked-in air flow is cleaned from dust by the filter;

- the fan coil unit normally processes indoor room air (full recirculation);

- some models integrated into the forced ventilation system are able to heat / cool the supply air;

- regulation of heating / cooling power is carried out in two ways - by changing the fan capacity and limiting the water flow by an electromagnetic two-way valve.

Note. The power is controlled by the electronic unit of the device - it opens / closes the valve and changes the speed of the impeller according to a signal from a temperature sensor or a room thermostat.

So, a fan coil is a component of a centralized climate system that maintains the air temperature in a specific room or in a specific area of a production workshop. Additional functions:

- drainage;

- ventilation (ventilation mode);

- mixing in fresh air - optional;

- control from the remote control;

- heating the flow with an electric heating element (also an option).

The difference between a fan coil unit and a split system lies in the principle of operation - there is no vapor compression cycle in it, the working fluid is water, which does not change the state of aggregation. Moreover, the heat energy comes to the radiator from the outside together with the liquid, as provided in the heaters.

Sources of cold / heat can be:

- Traditional boilers using various energy sources. It is clear that this equipment only provides heating of water or antifreeze.

- Heat pumps (HP) are of two types - geothermal and water. In winter, the unit heats up the coolant, in summer, on the contrary, it cools.

- Chillers are powerful air-cooled or water-cooled chillers.

Reference. Modern chillers operate in winter-summer mode and are equipped with inverters - frequency controllers of the compressor speed. Thanks to this, the refrigeration unit can heat the coolant (like the heat pump) at minus 15 ... 20 ° C outdoors, although the performance is noticeably reduced.

The most common connection is the chiller-fan coil system. This is the best option for the price of equipment, it will be more expensive to buy and install a heat pump of similar performance. We read below how the schema aggregates interact.

Inside the unit, a valve is provided for venting air after installation and filling the pipeline network with coolant

Benefits

A chiller-fan coil unit differs from similar systems in that it:

- Easy to maintain

... Filters are easy to clean and can be quickly changed - It is possible to serve a large number of consumers, that is, rooms in which fan coil units are installed. Their number is determined by the capacity of the unit, chiller.

- A device that heats or cools a heat carrier, a chiller, is installed in one place. This means that for its placement does not need a lot of space

. - If the pipes have high-quality thermal insulation, and the heat carrier has a high heat capacity, then the distance from the chiller to the rooms where the air-conditioning is carried out does not matter. You can install it at a significant distance

... In the case of using gas, this advantage disappears. - Low cost of installation work

... It is due to the use of conventional pipes, standard valves, simple automation in the system. - Environmentally friendly

... The heat carrier is water or ethylene glycol mixed with water. The latter, although toxic, can only be poisoned by prolonged inhalation of its vapors. But the first time it gets inside the body, it causes a painful cough and forces you to leave the room. The refrigerant, which poses a certain danger, circulates only in the chiller. And it is mounted either in the attic, or, if the device is made in the form of a monoblock, on the roof. - The system can be used together with ventilation

, preferably from the supply and exhaust type, and with heating. - Relatively low cost

the system itself.

Fan coil types

All existing fan coil units are divided into types according to the installation method:

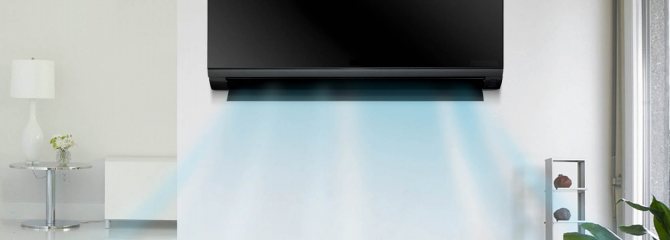

- Wall (otherwise - console) modules. Like the internal split block, they are attached to the wall in the upper area of the room or placed above the floors.

- Duct devices are often produced without decorative plastic lining, all parts are fixed on a metal frame. Open-frame models are built into the supply ventilation or recirculation duct.

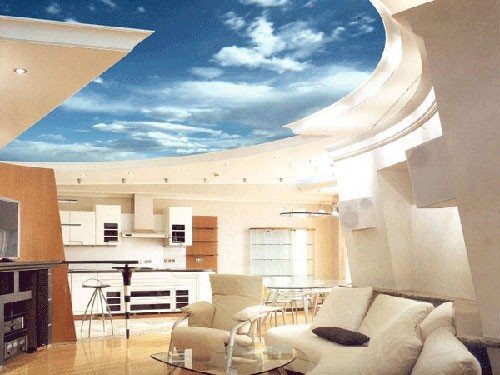

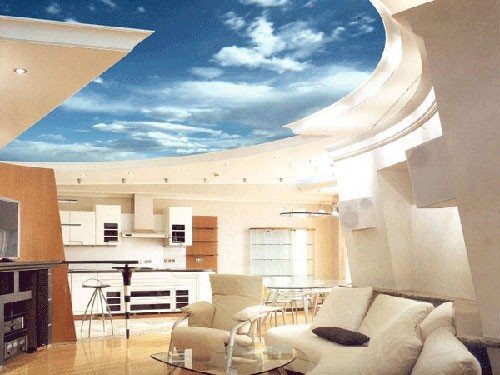

- Cassette ceiling fan coils are externally similar to similar blocks of split systems - they distribute the processed air in 2-4 directions and are equipped with rotary louvers on servos. These modules are designed for installation in false ceilings, with a decorative panel provided only at the bottom.

- Floor-standing column units, respectively, are placed on the floor. For the sake of saving useful space, the block is made in the form of a rectangular column, that is, it is elongated in height.

Note.In addition to the listed options, there are universal closers, for example, floor-to-ceiling. The module can be mounted in 2 positions - horizontal (fixing to the ceiling) and vertical (above the floor). Accordingly, 2 trays are provided for collecting condensate.

The left photo shows a columnar fan coil, the middle one - a cassette, on the right - a ceiling

As standard, fan coil units are equipped with 1 heat exchanger, which is connected to the mains in a two-pipe scheme. Cassette, floor and duct versions can be equipped with two separate radiators, connection - four-pipe.

The two-pipe units involved in a single network receive the heat carrier from one source - a water heating plant or a chiller. This means that all premises of the building will only be heated or cooled, users only adjust a comfortable temperature.

Closers with 2 heat exchangers are designed for multi-zone SCR. One radiator receives hot water from a boiler or other heater, the other receives cold water from a chiller. Users in adjacent rooms can simultaneously turn on their fan coil units in different modes - heating or cooling.

Four-pipe duct-type unit with 2 heat exchangers and fans

Installation features

Taking into account the complexity of fan coil-chiller systems, its installation and adjustment should be carried out by highly professional specialists. Only they will be able to perform high-quality installation of fan coil units by making competent:

- installation of the unit in the place where its work will be as efficient as possible;

- assembly of piping units by installing the necessary taps, valves, temperature and pressure control devices;

- laying and thermal insulation of pipes;

- installation of a condensate drainage system;

- work on connecting devices to the mains;

- pressure testing of the system and checking its tightness;

- media (water) feed.

They will also make all the necessary calculations before starting work, taking into account what functional load this or that fan coil will perform, as well as the features of each room in the structure.

After completing the installation work by experienced craftsmen, you will be able to use a system that will be safe, trouble-free and durable.

Thus, you were able to make sure not only that the fan coil-chiller systems are very effective, economical and reliable, but also that they require complex installation and commissioning operations. And this requires the involvement of employees of organizations specializing in the creation of such turnkey systems.

The device of chiller-fan coil units is often an integral part of the central air conditioning system of office buildings, shopping centers, public areas with high traffic, and other large objects. Installation of fan coil units allows you to provide cooling / heating of air in a large space. Design, installation of chillers and fan coil units, estimated estimates are carried out by specialists, depending on the modification of the device, the features of operation.

Chiller-fan coil circuit operation

First of all, we will consider how a single-zone SCR for 3 units + an inverter chiller, shown in the diagram below, works. The system maintains a comfortable temperature in summer and during the fall-spring transition period. Winter heating functions effectively at -5 ... -10 degrees below zero.

Clarification. A chiller is a unit that uses the Carnot vapor compression cycle to cool / heat the coolant. The unit is placed on the street, the working fluid is R410a or R407a freon. The heat exchanger-condenser is blown by air or cooled by liquid.

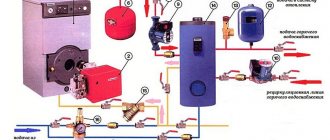

The working algorithm looks like this:

- In summer, the air-to-water chiller cools the heat carrier to a standard temperature of +7 ° C (if it is +35 degrees or less).

- The hydronic module directs cold water to a network of fan coil units connected in a two-pipe scheme (like radiators in a heating system).

- Using the remote control, the user sets the desired air temperature separately in each room.

- At first, the closers reach the set temperature, operating at maximum power. Then the controller, on a signal from the sensor, reduces the cooling intensity - it gradually reduces the fan speed (in total, there are from 3 to 8 steps, depending on the model).

- When the air reaches the set parameters, the two-way solenoid valve shuts off the coolant supply at the command of the electronics. Then the fan coil unit maintains the temperature.

- The water heated to 12 ° C (on average) returns to the evaporator heat exchanger of the chiller, the cycle repeats.

- In autumn, the outdoor temperature drops, the chiller receives a request for hot water from the fan coil units and switches to heating mode. Switching is performed manually or automatically - at the command of an additional controller.

Note. Well-known manufacturers of climatic equipment Gree and Carrier indicate the maximum operating ambient temperature plus 46 ° C. In such conditions, the water can be cooled to +18 degrees.

The hydraulic module providing the coolant supply consists of a pump, an expansion tank and an executive automation unit. Elements are included in the design of the chiller or are installed separately. Units of increased power are supplied with hydronic modules for 2-3 pumps.

In inexpensive fan coil units, the solenoid valve may not be available. Then the external piping of the closer is performed - an executive three-way valve, a servo drive and shut-off valves are installed. How it works, the master will tell in the video:

In order for the single-zone system to work fully in winter, a boiler is connected to the fan coil network. When the frost is below minus 10 ... 15 degrees, the chiller stops. The control valve switches the heating medium to the water heater line with a separate pump.

How a multi-zone system works:

- The required number of closers are simultaneously connected to the chiller and the boiler. A four-pipe scheme is used, more precisely, 2 two-pipe dead-end branches. The power of the heating equipment is determined by calculation.

- When the first user sets up the heating, the fan coil automation opens the flow through the "hot" heat exchanger, the second radiator is inactive. At the exit we get warm air.

- If the second user turns on the cooling, then the closer in the next room starts only the "cold" heat exchanger, and closes the "hot" one.

- Fan coil units of the same network operate independently of each other.

Simplified connection diagram of the elements of a multi-zone SCR, four-pipe closers are used

If, for some reason, the valves of all the closers close, the chiller will “understand” by the return water temperature that it is necessary to stop the cold supply and stop. The boiler automation will work in the same way.

Installation benefits

Above, we have already talked about the advantages of the system itself. We especially note once again that it is not difficult to mount it.

The cost of the components is low. It is easy to maintain and repair. In addition, it can be designed for any type of building.

Application area

Basically, devices of this type are used in:

- In office premises.

- Hospitals.

- Supermarkets and other retail outlets.

- Hotel complexes.

The cost

The price of the product depends on the cost of the components, that is, the chiller and the fan coil unit.

For example, let's take the cost of two products

Fan coil unit TRUST

- 12678 rubles.

Homo series

– 15609.

The fixtures are randomly selected.At the same time, the first unit also has higher productivity and serves a large area of the premises, but the price for it is lower than that of the second.

Hence the conclusion: the main factor that determines the price of the unit is the manufacturer.

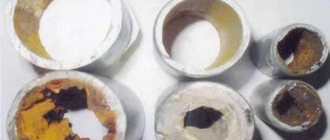

Features of operation

The main feature of servicing this type of unit is to charge the device with refrigerant.

In this case, you must strictly follow the instructions set out in the technical documentation of the device. In all other respects, the system is maintained in the same way as similar units.

The very definition of "fan coil" is inseparable from such concepts as a chiller and a hydronic module. Only in isolated cases can a fan coil unit be used separately and work with other climatic equipment.

Pros and cons of SCR with door closers

The obvious advantage of air conditioning with fan coil units is the precise maintenance of the desired temperature in different rooms. Multi-zone systems allow very wide regulation of microclimate parameters within one building. Other pluses compared to conventional air conditioners:

- the cost of equipment for 2-3 rooms will be clearly less than the price of a multi-split system of identical power;

- sources of heat and cold are located in a technical room or on the street, outdoor units do not clutter up the facade;

- fan coil units can be installed 50… 200 meters from the chiller;

- communications between the units are made of inexpensive plastic pipes - low pressure polyethylene or polypropylene (the latter must be soldered);

- in the event of an accident and leakage, it is easier to make repairs, replenish the system with purified water.

Comment. The distance from the chiller to the fan coil is limited only by considerations of expediency, since high heat (cold) losses occur on too long lines, plus the energy consumption of a powerful pump increases.

Do not think that the chiller-fan coil type SCR is applicable only in industrial buildings. Daikin, Carrier and Gree brands produce small two-fan chillers with a capacity of 3 ... 10 kW, which are quite suitable for private houses.

Disadvantages of fan coil units:

- SLE for 2 rooms is still more expensive than two separate split systems;

- decent size and weight of the chiller unit;

- qualified installation and start-up of equipment is required;

- the equipment will have to be serviced, the masters will have to be called annually.

On an industrial scale, the main competitors of water SCR are freon VRF systems operating on the "split" principle. Up to 50 indoor units can be connected to the external vapor compression module only. The cost of the equipment is about the same, but fan coil units benefit from the ease of laying highways and the lower price of plastic pipes compared to copper ones. A separate story is the leak of freon from a huge system, which is not easy to find and eliminate.

Improved planning houses

In our cities, more and more houses are being built with an improved layout, where the installation of a chiller-fan coil system is provided as an air conditioning system.

The developer company builds the house, lays down the necessary communications and installs one chiller for the whole house. And in each apartment, along with other communications, an air duct is supplied through which fresh air is supplied. Usually, little air is supplied, about 250 cubic meters per hour per apartment, and 2 pipes with cold water from the chiller for installing fan coil units.

The owner, the happy owner of such a home, is faced with the fact that the distribution of air throughout the apartment, and the installation of one or more fan coil units falls on his shoulders.

There are 3 tasks for air conditioning such an apartment:

- Install 1 or more fan coil units.

- Dilute the air supplied to the apartment in all rooms

- Drain drainage down the drain (since the solution that is used in most ordinary houses where drainage is released directly into the street is prohibited by the maintenance service in such houses)