Why is thermal insulation of the floor in wooden houses necessary?

A floor with illiterate thermal insulation does not retain heat, even if the house is built of solid wood. Installing a reliable heating system will not save the day. In the cold season, the temperature of the ground under the building decreases. With weak ground-based thermal insulation of the area under the house, the bottom of the walls and corners will certainly freeze.

It is necessary to install thermal insulation during the construction of the house, before installing the flooring. This will help save time, money and construction materials.

Insulating the floor in a wooden house will help prevent:

- Large daily temperature fluctuations during the heating season.

- Premature wear of the wooden parts of the structure.

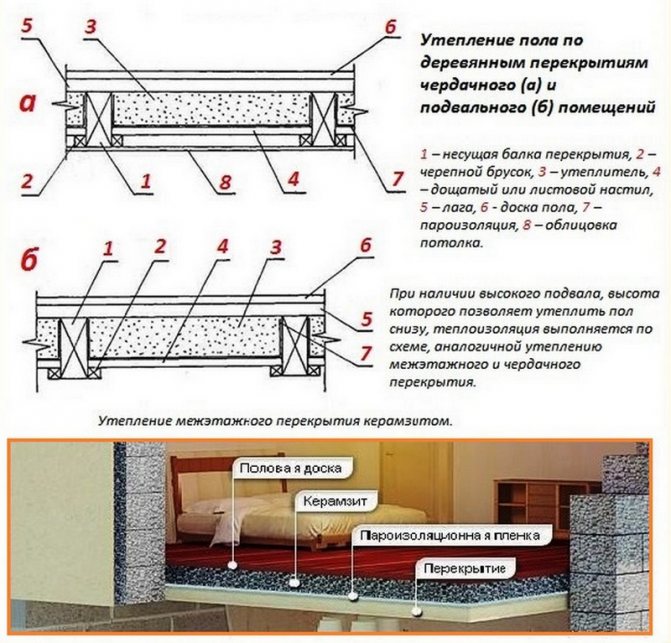

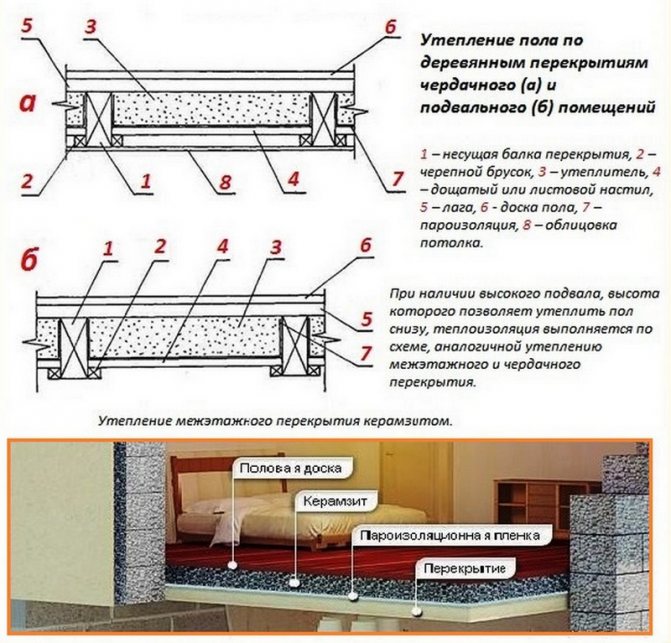

Insulate the floor if there is a basement or basement under the house. The building erected on piles also needs to be insulated. Insulated attic floors and overlapping of the second floor will save the wooden house from rapid cooling.

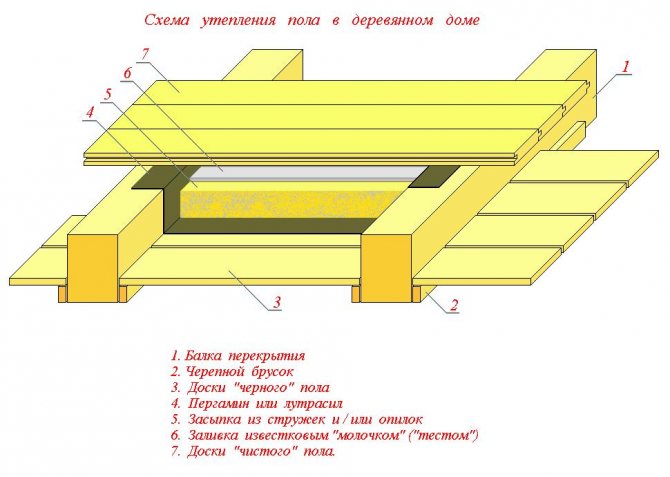

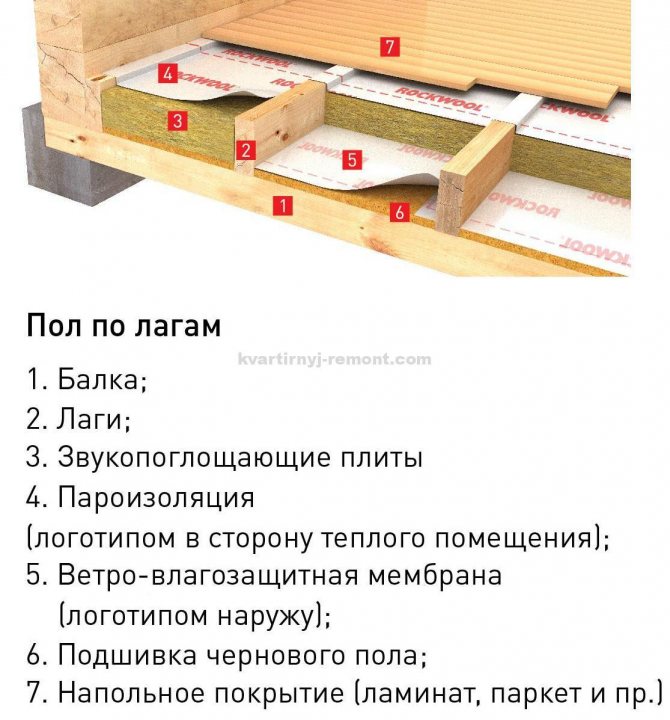

Insulation of the first floor slabs on wooden logs

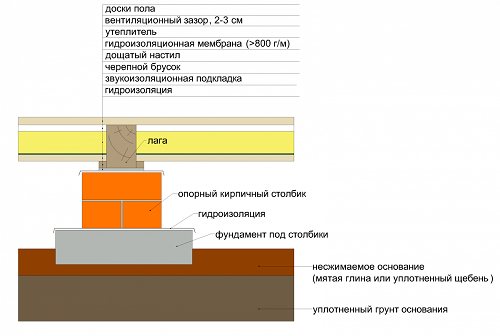

In a wooden house, it is especially important to monitor the waterproofing of the first floor above the foundation. Air must constantly flow to wood structures, so the ventilation ducts in the foundation cannot be blocked. For waterproofing the floor and wooden walls in the house, the insulation is carefully insulated on both sides.

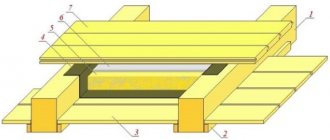

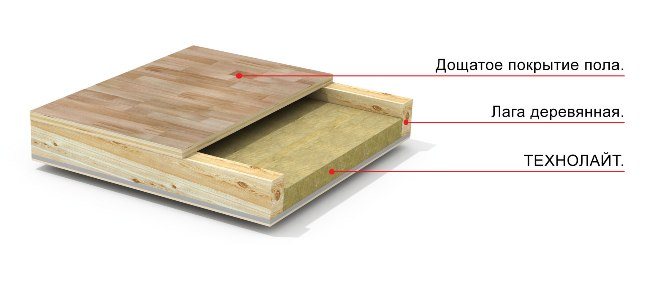

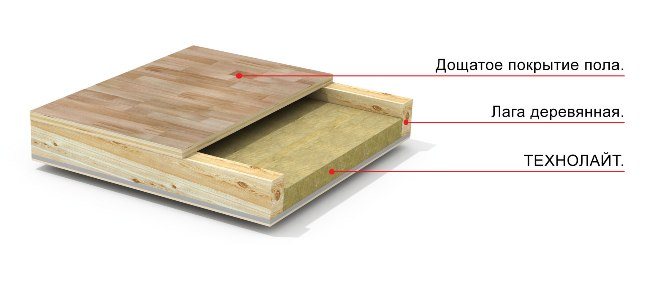

Logs are wooden blocks on which a floorboard or other covering is laid. Logs are also used for additional insulation of the cold floor. The double floor structure is quickly installed even by non-professional builders. It is distinguished by ease of installation and the absence of wet processes. In the same way, you can insulate the floors of the second and any other level of the building. A thinner layer of thermal insulation material will be required on floors in rooms above heated rooms.

Floor insulation scheme for logs.

For installation you will need:

- Thermal insulation boards of the selected insulation. Mineral wool should have a density of 35-75 kg / m and a thickness of 50 mm.

- Wooden logs of such height that thermal insulation can be placed between them.

- Waterproofing: polyethylene film, roofing felt, glassine, etc.

- Distribution boards: chipboard or fiberboard boards, special drywall.

- Floor covering: laminate, floor board, linoleum and more.

- Screws.

Actions to insulate the first floor after the foundation have the following order. Along the perimeter of the room, edge strips of insulation with a thickness of 2 cm are laid. Next, amortization strips are laid: these can be wooden slats or bars on which the logs are attached. A layer of vapor barrier is laid between the beams, the film is attached to the slats with a construction stapler. Between the lags, located at a distance of 50-90 cm from each other, a layer of heat-insulating plates is laid out. They are covered with a layer of waterproofing (polymer film).

As a tool for work, you will need the following:

- long level - 2-2.5 meters;

- drill and screwdriver;

- plane;

- saw or jigsaw;

- beat;

- construction mixer.

The structure is closed with chipboard or floorboards, which are screwed to the joists. This so-called sub-floor is made of rough planks that must fit snugly against the joists. It is necessary to ensure that there are no gaps left through which cold air will penetrate. At the end of the work, the selected flooring is laid.

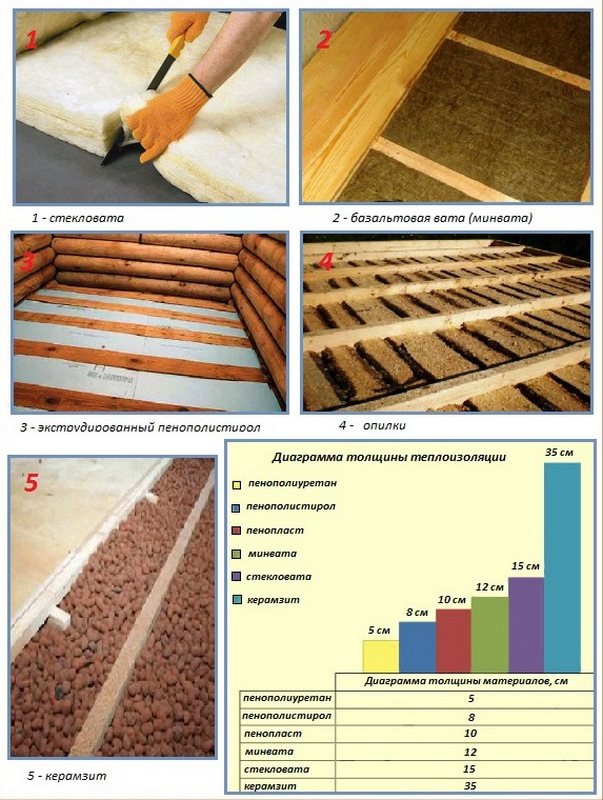

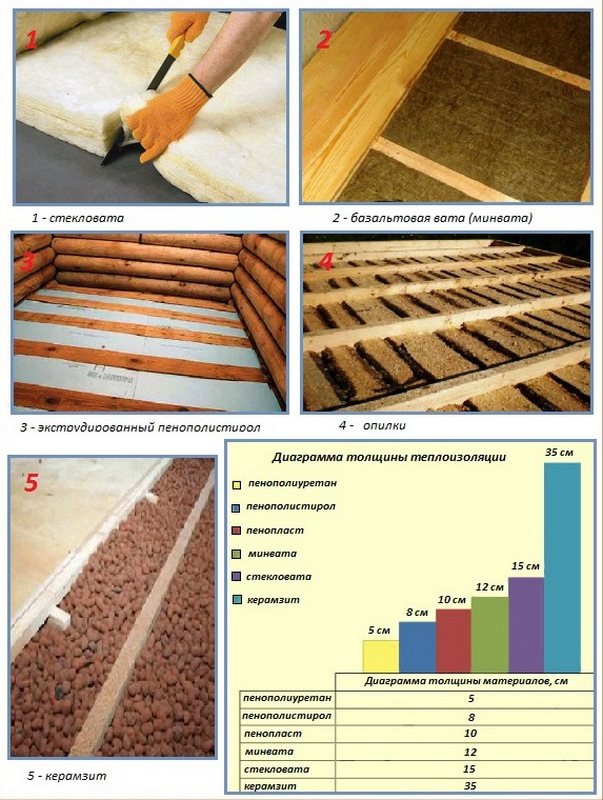

The choice of thermal insulation material

Before starting work, you will have to decide which of the materials on the market is best suited for thermal insulation of a floor in a wooden structure.

The choice of raw materials often determines the cost, but if you save on thermal insulation, you will have to spend money on heating your home. The heating method does not matter.

What to consider:

- drops in air temperature and humidity in the room;

- the expected load on the floor slab;

- the thickness of the insulation to be used.

Loose heaters, mats, canvases and slabs are suitable for insulating wooden floors on logs. The wooden floor and the thermal insulation used must breathe.

Moisture-resistant solid insulation is used for concrete floors. Polyurethane foam, polystyrene foam and polystyrene foam are very toxic during combustion, they are often used under concrete. You can combine materials.

Mineral wool is a commonly used thermal insulation agent

In a wooden structure, mineral wool is used more often than other materials. It comes in the form of hard slabs and flexible mats in rolls. One side of the slab is painted blue - this will be the top during installation. Rolled mineral wool on one side is covered with perforated paper, which is laid directly on the rough wooden flooring. Mineral wool is placed on the floor slab in one layer. Its advantages are as follows:

Floor insulation scheme with mineral wool.

- low cost;

- does not deform at high temperatures, does not burn;

- provides a "breathable" insulating layer, which is important in a wooden building for the first floor;

- retains its shape, installation is possible without assistance;

- eco-friendly material from molten rocks;

- good heat and sound insulation;

- not subject to decay and attack by microorganisms.

The main disadvantage of mineral wool is its ability to absorb moisture and get wet. To insulate the first floor or any other floor in the house with mineral wool, additional waterproofing is required.

Popular types of insulation materials

The construction market offers a huge selection of thermal insulation materials. The range will satisfy the most demanding builder. But remember that quality doesn't always translate into price.

When choosing a heater, proceed from the structural features of the building and the climatic conditions of the area.

Considered in demand:

- sawdust;

- expanded clay;

- mineral wool;

- ecowool;

- isolon;

- penofol;

- fibrolite.

The value for money of these raw materials has made them popular with home builders. The possibility of self-assembly when insulating, increases the demand for them.

Thermal insulation with sawdust

Ordinary sawdust is not inferior to the current insulation. The sawdust will help minimize heat leakage and prevent walls from freezing.

This junk material is free to get your hands on. The availability of sawdust is their main advantage.

Positive traits:

- Sawdust - natural, harmless to humans.

- This material can be obtained free of charge.

- Low degree of thermal conductivity.

Disadvantages of sawdust:

- Highly flammable material.

- Shrinkage and shrinkage.

- Good hygroscopicity.

- Sawdust is the home of rodents, insects, mold and fungi.

Insulating briquettes are prepared on the basis of sawdust. In proportions 1: 1, sawdust is mixed with clay, diluted with water. From the resulting mass, briquettes of the required size are formed and used for insulation.

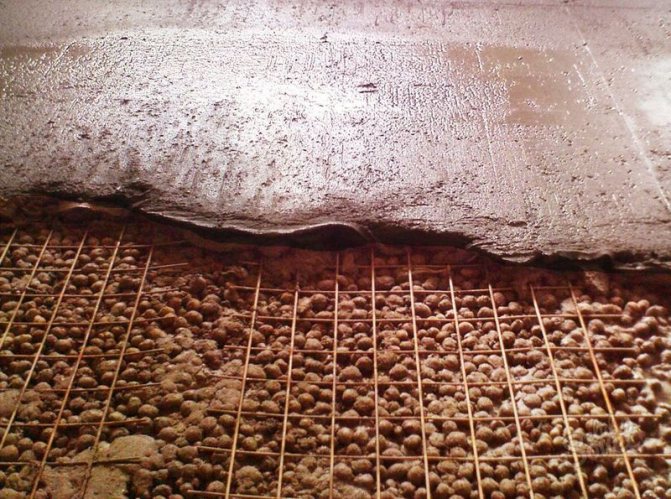

Thermal insulation with expanded clay

Expanded clay is a natural, environmentally friendly material. Lightweight, porous, resistant to temperature changes. Rounded granules - fired clay, mixed with the addition of shavings or peat. Sorted by fractions.

Pros:

- cheapness;

- environmental friendliness;

- chemical resistance;

- weight;

- thermal conductivity;

- long service life.

Minuses:

- ineffective in small quantities;

- high degree of hygroscopicity.

Good results are obtained by mixing two fractions of the material. This makes the backfill denser, which contributes to a decrease in thermal conductivity and noise insulation.

Thermal insulation with mineral wool

Popular insulation. It is used for floor, roof and wall insulation. Excellent raw material for heat and sound insulation.

Types of mineral wool:

- glass wool;

- basalt wool;

- slag.

Positive qualities of mineral wool:

- noise absorption;

- availability;

- resistance to chemical attack;

- moisture resistance;

- heat resistance.

Minvata contains toxic formaldehyde resins that can have harmful effects on the human body.

It is recommended to use cotton wool where it is possible to exclude its contact with the external environment.

Thermal insulation with ecowool

Ecowool - shredded waste paper mixed with boron and boric acid salts. Salts prevent harmful microflora from appearing in the insulation. Boron makes ecowool less flammable.

The ratio of substances in the insulation:

- waste paper 80%;

- boric acid salts - 20%.

The insulation "breathes" - it provides air circulation, and does not retain moisture, it keeps heat well.

Avoid dense stacking when installing horizontally. After filling the cotton wool between the floor logs, it is loosened and leveled, a thickness of 20-25 cm is considered sufficient.

Insulation with isolon

Izolon - foil-coated bubble polyethylene. Foil on one and two sides. The foam structure provides low thermal conductivity. Foil contributes to high moisture resistance and heat-saving ability.

On sale it is found in rolls and sheets. Izolon sheet is produced with a thickness of 15 mm.

Izolon comes in three varieties:

- one-sided foil;

- double-sided foil;

- one-sided foil with adhesive surface.

Low rate of heat loss, provided by the presence of foil - due to its reflectivity. The environmental friendliness of the isolon allows its use in any premises.

Izolon is a good sound insulator. It is inferior in thickness to many other insulating materials, but this does not make it less in demand. It does not absorb moisture and does not rot.

Penofol insulation

Penofol is a modern foil-clad material consisting of several polyethylene interlayers with different thickness, density and porosity. It is produced on the basis of polyethylene foam.

Penofol is produced in the following varieties:

- one-sided foil;

- double-sided foil;

- one-sided foil with an adhesive base;

- one-sided foil with laminated film;

- aerated.

Penofol is resistant to humidity and high temperature drops, combustion. These qualities make it possible to use it in private housing construction. The top coating can be laminate, carpet, linoleum.

With a thickness of several millimeters, it reflects about 95% of the heat energy. This is one of the best indicators among insulation materials.

Fiberboard insulation

A versatile material that is used for floor insulation, as well as wall formwork in concrete frame construction. All this speaks in favor of this heat-insulating material.

The boards are made of "wood wool" - thin, dense, ribbon-like wood chips, up to 50 cm long. The production technology is simple. The molds are filled with packing shavings and spilled with Portland cement mixed with mineralizing substances. This technology makes the structure of the slab quite strong.

Fiberboard insulation is appreciated for:

- high performance properties;

- reliability;

- ease of installation;

- low price.

This insulation is easy to install yourself. Plates can be used to insulate the sub floor. The gaps are filled with polyurethane foam.

How to insulate the floor

There are many materials for floor insulation: from sawdust and dry foliage used by our grandfathers to modern expensive heat-insulating materials. The choice of thermal insulation is most often based on the financial capabilities of the owner, but it is imperative to take into account the type of base and the intended method of laying the insulation.

If there are no restrictions on funds, then you can purchase modern, lightweight and easy-to-install materials offered by manufacturers. The developed floor insulation technologies and high-quality materials will help you quickly and easily cope with floor insulation on your own. If such materials are not affordable, then you will have to remember the proven folk methods.

Thermal insulation schemes for wooden floors

Budget heaters

Home craftsmen often use various improvised materials and production waste from their area for floor insulation. The following can be used as heat insulators:

- Dry sawdust... If there is a wood processing shop nearby, then such insulation will become a cheap alternative to expensive materials. It should be remembered that sawdust, like any tree, actively absorbs moisture, therefore, when insulating the floor in this way, it is very important to provide for high-quality waterproofing both from the ground and from the side of the room. An alternative to sawdust can be dry leaves.

- Sawdust granules... This is a more modern version of dry sawdust. Such granules are good because they are treated with a fire retardant and antiseptic. This protects the sawdust and therefore the floor from mold, mildew and rodents.

- Slag. A very cheap material that is formed in large production facilities. Most often it is used for floor insulation on the ground.

- Expanded clay. An excellent inexpensive heat insulator that is lightweight and environmentally friendly.

- Mineral wool. The material of the new-fashioned corrugated shells and foil layer has long been known to consumers and continues to be actively used for insulating various surfaces. It is lightweight, reliable and relatively inexpensive insulation.

- Fiberglass and slag wool... These materials are available in both rolls and mats. They are easy to install and produce good results.

- Styrofoam... A relatively new insulation that has found its fans among the owners of private houses and summer cottages. It is lightweight, does not absorb moisture and is easy to install, but requires protection from rodents. The main disadvantage of foam is its flammability and the formation of a large amount of corrosive smoke when burning.

All of these materials are inexpensive, but if you follow the rules of their installation, they will prevent the floor from losing heat. Unfortunately, most of them are labor intensive to install.

Insulation for a wooden floor of a private house

Modern high-tech heaters

If the consumer is not constrained in funds, then he can insulate the wooden floor in a private house with more modern heat insulators:

- Penoplex - produced in slabs. The material has increased strength and excellent waterproofing properties;

- Vermiculite - produced by processing hydrated mica. The material is distinguished not only by excellent thermal insulation properties, but also by its durability;

- Mats and slabs made of glass wool, expanded polystyrene and basalt with a superimposed foil side, which is designed to reflect heat rays. These are branded materials Termolayf, Ursa, Isovent, Isolight, Penofol.

- Ecowool and polyurethane foam will help to create a dense layer of insulation that does not allow moisture to pass through. The only drawback of these materials is that special equipment is needed to blow them in.

Upgraded floor insulation options

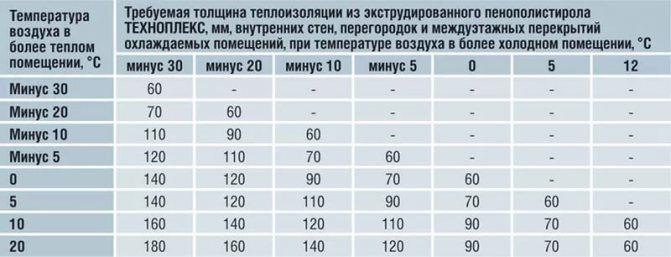

Calculation of the thickness of the insulation

Before proceeding with floor insulation and the choice of insulation, it is important to get acquainted with the method for calculating the thickness of the insulation layer. This is an important point in the construction phase.

Calculations take into account:

- structural features of the building;

- regional weather conditions;

- heat supply conditions of the building;

- type of insulation and its thermal conductivity coefficient.

The result will be a minimum performance requirement for a material that is recommended for use in the region as insulation.

Multiplying the coefficient of thermal conductivity of the insulation material by the thermal resistance of the structure, we get the thickness of the insulation. The required values can be found in SNIPs and instructions for heaters.

Selection of material and calculation of its required thickness

Before you buy a material for thermal insulation, carefully study the existing assortment. Of great importance here will be what it is made of, standard sizes, properties, brand-manufacturer. Keep in mind that the material in the mats will be more dense and resilient than in rolls. Consider the thermal conductivity of the material, its specific gravity, dimensional stability and vapor permeability. Many manufacturers place this information on their product packaging.

We'll have to apply several formulas. Calculation of the required thickness of thermal insulation = RxA. The values for the coefficient R (total thermal resistance of the building structure) can be found in the tables to the SNiP appendix "Thermal protection of buildings". Building codes are a set of basic regulatory requirements and regulations. There you can see all the values of interest. For example, the value of the thermal conductivity coefficient is A. The collection of all parameters should be carried out taking into account the requirements of SNiP. It is necessary to calculate the parameters of the permissible floor load. In the tables, you will also find values for calculating the so-called temporary loads (furniture, equipment, people and animals). The total height of the entire structure is calculated. The humidity and temperature inside the house are taken into account. You can also use an online calculator for the calculation.

The order of work

The process of floor insulation is simple. All installation work can be done independently.

Main steps:

- Sub-flooring.

- Laying insulation material.

- Laying a moisture-proof layer.

- Floor covering.

Subfloor is the basis for insulation. This is a frame that holds the insulation material in close proximity to the floor. Such a floor does not carry any load. For its construction, they use: not planed boards, bars, formwork material. The tree is impregnated with an antiseptic.

We put the selected insulation on the rough floor. For dense filling of the space, polyurethane foam is used. As a heater for the subfloor, it is possible to recommend a bedding made of expanded clay of a medium fraction.

Place a moisture-proof material on top of the insulation: polyethylene films, roofing felt, glassine. This will protect the insulation from moisture penetration and condensation.

A floor of boards is laid on top of the moisture-proof material. On top of the boards: a layer of soundproofing material, slabs, carpet or linoleum.

The main stages of floor insulation work

- Installation of a structure with wooden joists on a leveled floor surface

- Installation of waterproofing and rough flooring from boards or shields

- Laying insulation between the logs (filling the joints with polyurethane foam or sealant)

- Laying material that provides reliable vapor barrier

- Manufacturing of wood flooring on which the final finishing coat can then be mounted.

Can tiles be laid on linoleum?

A layer of insulation is “sewn up” between the layers of waterproofing and a vapor barrier. The vapor barrier will protect the thermal insulation from the formation of condensation and steam from the inside of the room.The material for the vapor barrier is a film that is additionally fixed with a special metal tape. There are the following types of film vapor barrier: polyethylene and polypropylene.

When used for wood floors, the film needs an air gap.

Features of the first floor thermal insulation

The floor of the first floor has direct contact with the ground, if there are no piles, an ordinary or screw cellar, a basement floor, underground premises (a feature of the lower floors). This requires additional measures to insulate the building.

The sequence of measures for insulation on the ground:

- Dismantle the old floor.

- Level the soil.

- Pour a layer of expanded clay 20-25 cm high.

- Spread a layer of coarse sand 5-7 cm.

- Make a concrete screed.

- Waterproofing concrete.

- Lay a layer of insulation.

- Flooring of floors.

This sequence of works on insulation is the most effective. The floor installed in this way will be warm and the house will be cozy.

Floor insulation in a house with a basement or basement has its own specifics. The material and organization of the insulation work depend on the purpose of the underground premises.

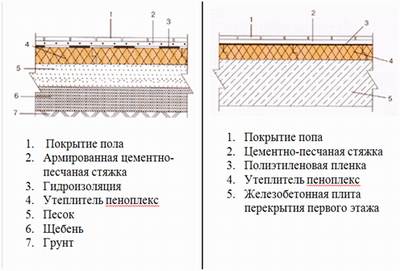

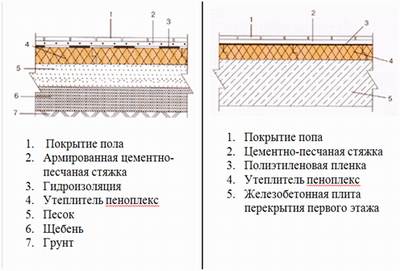

Insulation of a concrete base

Insulation of the floor on the first floor of a panel house, or a house with concrete ceilings remains relevant. Thermal insulation technology in this case will be significantly different compared to the previous version.

Instead of wooden logs, a cement-sand floor screed is used here, and denser types of insulation are used.

If you need to level, raise and insulate the base at the same time, you can use expanded clay

- Unevenness on the base must be filled with fine sand. If this is not done, the insulation may deform during loading. You can also use expanded clay for this. It simultaneously performs 3 functions: leveling, thermal insulation and filling to the desired height.

- Along the perimeter of the room, a damper tape is attached to a self-adhesive tape or self-tapping screws to maintain the temperature gap and increase sound insulation.

- A waterproofing film is laid on the floor with an overlap on the walls and on top of each other. Seams are hermetically glued with tape.

- For insulation of concrete, it is best to use extruded polystyrene foam, due to its high density and good thermal insulation characteristics. You can also use dense types of mineral wool and foam.

- Insulation sheets are stacked tightly to each other. It is not necessary to attach them to the base.

- To obtain a flat surface, beacon profiles are installed. They are leveled and fixed to mortar and screws.

- The screed solution is mixed with the addition of fiber and plasticizer.

- Then the solution is spread over the surface with a margin and leveled using the lighthouse rule.

The correct screed pie with insulation on the ground and on a concrete slab

Warm floor

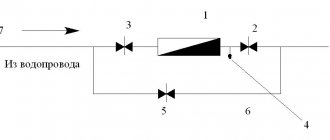

Installation of metal-plastic pipes in a screed

To make the room even warmer, the owners of private houses are increasingly installing a water-heated floor from the boiler. Residents of the southern regions can completely abandon the usual heating radiators, and heat the house only at the expense of the floor.

To do this, metal-plastic or polypropylene pipes are attached to the mounting mesh over the insulation with a snake or spiral. They are connected to the boiler through a manifold assembly.

If you live in an apartment building, you can use the electric type of floor heating. It can be installed both under the screed and directly into the tile adhesive during installation.

Features of thermal insulation of the second floor

Insulating the floor of the second floor of a wooden house means creating an insulating layer of a traditional structure. The differences in the insulation "pie" may be in the material, which is selected depending on the specific situation.

The order of work and structure of the overlap:

- Overlapping from a bar - a crate.

- Vapor barrier layer.

- Thermal insulation layer.

- Vapor barrier layer.

- Finishing floor with floor covering.

Any heat insulator loses some of its qualities due to getting wet. When insulating the floor of the second floor, it is necessary to pay attention to the upper vapor barrier layer. The moisture should be able to evaporate and not accumulate there.

This is an important condition for the correct operation of the thermal insulation layer of the second floor.

Mineral wool is another budget option

What is really good about mineral wool is an extremely successful combination of excellent thermal insulation properties of a heater with a low cost. In addition, mineral wool boasts such accompanying advantages as water resistance and sound insulation. The service life of mineral wool is practically unlimited. But only if during operation the material will not be subjected to strong mechanical stress. It is due to the air spaces in its structure that it retains heat. Under mechanical action, the structure of the mineral wool is deformed, the air gaps become smaller and the thermal insulation properties become much worse. So keep this in mind! Mineral wool slabs must be laid with the perforated side down.

Of course, the described methods have many variations and the device of the floors in each individual case will require an individual approach. For example, in addition to the listed materials, expanded clay can be used as a heat-insulating layer. Somewhere it may be necessary to make a double floor using a more complex technology. But for the overwhelming majority of cases, the described methods of floor insulation may be suitable. If you have little experience or have any problems that are difficult to cope with, be sure to seek competent advice from a specialist. Even if it is paid. This will really save you both time and money!

Expert advice and examples of successful designs

Tips on the main issues of installing heaters are as follows:

- You should not skimp on the quality of the insulation.

- When installing insulation material, take into account the nature of the structure and the quality of the insulation.

- Use the amount of insulation according to preliminary calculations.

- Distribute the insulation tightly, evenly, without gaps.

- It is imperative to install a waterproofing layer.

- A thoughtful combination of insulation will increase the quality of the work performed.

It is not difficult to insulate the floor in a wooden house. This work is done independently. The main thing is to take a responsible approach to the choice of insulating material and step by step follow a certain order of work.

Thermal insulation of a wooden floor - step by step instructions

Whatever material you choose as insulation, it is imperative to carry out preparatory work. And this will be the first stage in the entire process under consideration. It is better to perform it in the following sequence.:

- We remove the skirting board - we do it carefully, because at the end of the work, it will also be installed in place. If the wooden skirting board has become unusable, then immediately arrange for its replacement.

- We begin to lift the wooden floorboards - this is done with a nail puller (if the floorboards are connected with nails) or a screwdriver (in the case of using screws as fasteners).

Please note: when removing and folding the floorboards, be sure to number each of them - this will help you not to get confused in the process of rebuilding the floor covering. By the way, experts recommend removing floorboards from the window.

- The next step is to inspect the logs for rot or mold. If there are too damaged lags, then they will have to be completely replaced.As a last resort, you can treat each lag with a protective solution (the simplest is bituminous mastic).

- We clean the base under the logs - we sweep, we vacuum.

The preparation stage has been passed and you can safely start laying the insulation.

Important: do not forget to provide yourself with protection if you are going to work with mineral or stone wool - gloves, respirator, goggles.

In order for the insulation of a wooden floor with your own hands to be done really well, in your work, exactly follow the recommendations below.:

- Heat-insulating material is laid between the logs - all types of wool (mineral, eco-, stone) are realized in the form of small mats, they perfectly "fit" into the space between the logs. If you use expanded clay, then it is simply poured between the logs, and the layer of such insulation should be at least 10 cm.

- On top of the heat-insulating material, a layer of vapor barrier must be laid - it can also be an ordinary plastic film. The vapor barrier material is laid in strips overlapping each other, and the contact of the strips with each other should be at least 15 cm.

Please note: when using foam as a heat-insulating material, experts say that the vapor barrier layer can be excluded. But do not skimp on this - just one layer of plastic wrap can effectively protect the floorboards from the negative effects of moisture.

On this, in principle, the insulation of the wooden floor with your own hands is over - it remains only to return the floorboards back (do not forget to install them in the same order as they were removed - for this each was numbered) and install the plinth.

The above instructions for floor insulation are great if the base of the floor is cement, but in old private houses there is soil directly under the floors - what to do in this case?

Double floors

This term does not mean anything daunting - there is simply a technology for insulating wooden floors using an additional substrate. The essence of the process of arranging double floors - after laying all layers, immediately before the finishing stage of work, the subfloor should be laid. You can use unedged material (boards) for this, or you can make a substrate from fiberboards.

Care must be taken to ensure that the boards or slabs fit snugly against each other, there should not even be small gaps between them. If it is impossible to perfectly combine the fragments of the material (this mainly applies to unedged boards - it rarely has clear shapes), then the resulting cracks are sealed with putty.

Do-it-yourself insulation of wooden floors is quite easy and simple to perform. But after this work, you will personally feel the warmth and comfort in the house - the absence of drafts directly affects the comfort in the premises. Some people use ordinary carpet to insulate wooden floors - a special soft backing is laid directly on the existing floor covering, carpet is glued to it or fastened with small nails on top. In principle, such a solution will give a result - the floor will really become warmer. But the best solution to the problem of cold wooden floors with your own hands is the use of professional thermal insulation materials.

(53 voice., middle: 4,80 out of 5)

Laminate - types, advantages and disadvantages, installation rules

Diy two-level stretch ceiling