A wide variety of heating means makes it possible to choose the most optimal samples from them. So not all boiler devices have the same performance, and, consequently, fuel consumption. Therefore, before buying this or that model, it is worth making the necessary calculations.

If you have correctly calculated the fuel consumption, the diesel boiler will work efficiently and will be able to maintain the required temperature in the room. Otherwise, various nuances in the operation of the device and the system as a whole are possible.

Liquid fuel equipment and its features

Devices fueled by kerosene, diesel fuel or diesel fuel can be used to heat industrial and residential premises.

Fuel for such boilers is contained in a special tank, which can be located in any place convenient for the consumer:

- In the boiler room

- On the street

- Underground

This feature is one of the main advantages of liquid fuel devices.

The most effective is the use of this heating equipment in non-gasified settlements, since the fuel consumption of a diesel boiler is not very high. The principle of its operation has insignificant differences from devices operating on other types of energy carriers.

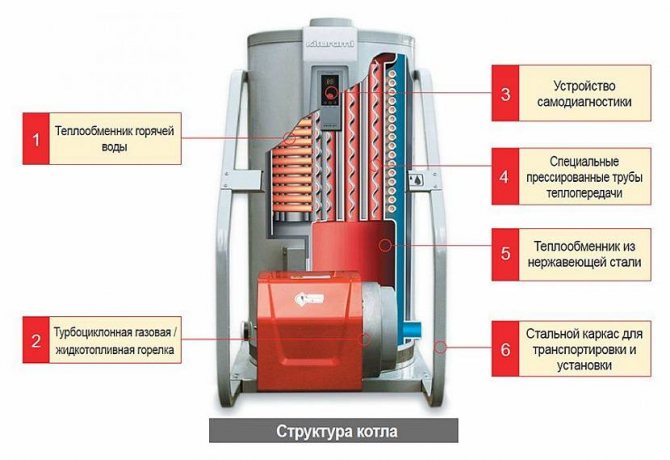

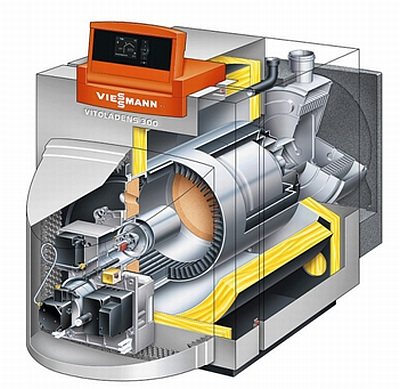

It has a combustion chamber in which a burner is located, which is necessary for burning diesel fuel. In the course of its operation, the coolant is heated, which is then supplied to the heating system. Combustion products are removed from the apparatus through the chimney. At the same time, they pass through the heat exchanger, partially giving off heat to it, which helps to increase the efficiency of the device.

Diesel fuel boilers most often have a steel body, which is practically not subject to corrosion.

Under it are located control and automation units that control the operation of the equipment. Heat exchangers in diesel boilers are made of steel or cast iron so that they can withstand prolonged exposure to high temperatures.

To reduce heat losses during operation, as well as to make the diesel heating boiler consume less fuel, a heat-insulating gasket is placed under the outer casing of the device, which also protects users from burns.

All about diesel fuel

The consumption rates of diesel fuel, as well as other types of fuels, as well as lubricants for all brands of cars produced and sold in Russia, are established by the Ministry of Transport of the Russian Federation and fixed by the order of the Ministry in special methodological instructions. Normalized fuel consumption values for different vehicles provide:

- Planning the total fuel consumption for a specific type of work performed using a given vehicle.

- Calculation of the cost of goods and services that need transportation.

- Economical use of money and fuel resources.

The base rate of diesel fuel consumption is calculated per 100 km of run, measured in liters and includes only resource costs for carrying out transport activities, excluding garage, economic and technical needs, as well as the mass of passengers transported. The nominal load of passengers and cargo is taken into account when calculating the transport fuel consumption rate based on the base.

Fuel consumption rationing provides for a possible increase in the rate due to engine operation in the winter season (up to 20% depending on the region), in mountainous areas (up to 20% at altitudes above 3000 m above sea level), in settlements with a high population density (up to 25%),and also in the presence of additional non-motorized heavy equipment (for example, a trailer), in extreme climatic conditions, with constant operation of the air conditioner, etc.

Car brands for which certain values of consumption rates are set are ranked by purpose. For each type, in this case, the base rate of diesel fuel consumption is calculated according to a strictly established formula.

- For passenger cars, the calculation formula for the standard fuel consumption Qн is:

Qн = 0.01 * Hs * (0.01 * D + 1) * S

where Hs is the base rate of diesel fuel consumption established by the Ministry of Transport of the Russian Federation, l / 100 km;

D - correction factor;

% S - mileage, km.

- For buses, the calculation is made according to an identical formula with the addition of the base rate of fuel consumption for heating.

- The standard fuel consumption of tractors and flatbed trucks is calculated as:

Qн = 0.01 * [0.01 * D + 1] * [Hs * S + Hw * W]

where Hs is the fuel consumption rate for a loaded vehicle;

Hw - transport consumption rate, l / 100 t km

W - the amount of transport work, depending on the weight of the cargo and the mileage of the vehicle with the cargo)

Similar formulas also exist for dump trucks, medical vehicles, vans and specialized vehicles. The formulas are spelled out in the guidelines for the consumption rates of various types of fuels and lubricants.

More interesting on the topic:

- Reducing diesel fuel consumption

- Fuel cards

- The rate of loss of petroleum products

- Fuel card accounting

- Fuel cards for legal entities

- Lukoil Likard cards

What does fuel consumption depend on?

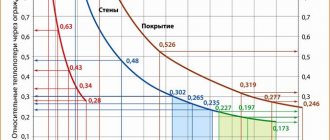

The heating system is affected by a large number of different factors and loads.

It:

- Thermal insulation of the room

- House area

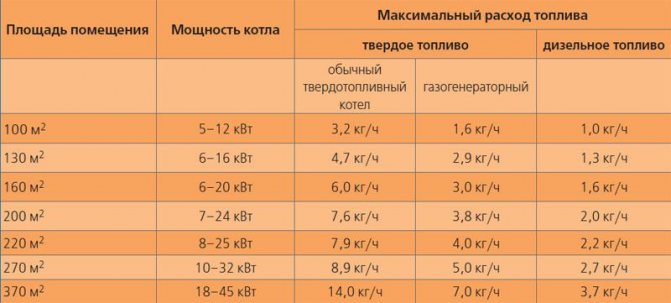

Naturally, the larger your home, the higher the consumption of a diesel heating boiler will be. The efficiency of devices, such devices, ranges from 90 to 95%. But such a result can be obtained only at the maximum speed of the device. Therefore, when purchasing heating equipment, you should not choose it with a margin. This will help to avoid unnecessary costs, since in this case, oil-fired heating boilers will consume less fuel.

Types of diesel boilers

This type of device operates on three types of fuel:

- Diesel fuel.

- Fuel oil.

- On two fuels: fuel oil and gas, diesel and gas.

All liquid diesel equipment is powered by electricity. It is needed by the burner, the pump, and the autonomous system. On average, it uses 300W during the heating season and 100W during the warm season.

An oil-fired boiler has a burner design, which is much more complicated than a solar boiler. This substance is quite astringent, so the unit is endowed with a complex heating oil heating system, which is powered by electricity. A fuel oil boiler needs about 1000 W of electricity in winter and 200 W in summer, but it is much cheaper than a solar boiler. And diesel boilers on diesel fuel, which is easier to heat up, require less energy consumption, but their cost on the market is much higher.

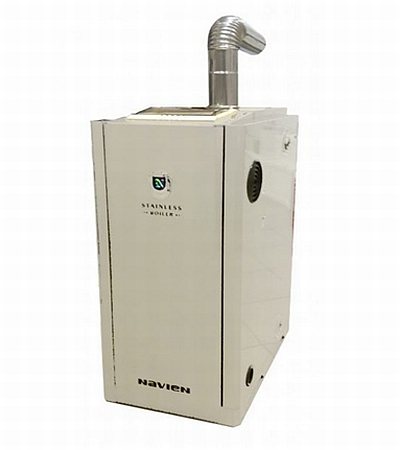

Fig. 3 Floor standing diesel appliance

The combined oil and gas fueled device is very economical and easy to operate. Such devices are endowed with an excellent security system, an autonomous process. They are universal, because if, for example, solid fuel burns out, then the device automatically switches to another mixture. Also, such devices involve the installation of a boiler, the work takes place continuously.

The boilers are made of cast iron and steel. Cast iron is a durable material that is not afraid of corrosion. The unit has several sections that can be replaced. But the minus of this type of equipment is the intolerance of temperature jumps. Steel devices are much lighter than cast iron ones, they are stronger and cheaper.

Diesel fuel contains a lot of sulfur, which, when burned, interacts with air to form corrosive condensation. It affects the metal, corrodes it, causing corrosion. Therefore, a cast iron device is more durable in this regard, since its walls are much thicker than steel walls. Also, boilers are both wall-mounted and floor-standing (Figure 2). But wall-mounted in the CIS countries are rarely found on the market, since they are not easy enough to operate.

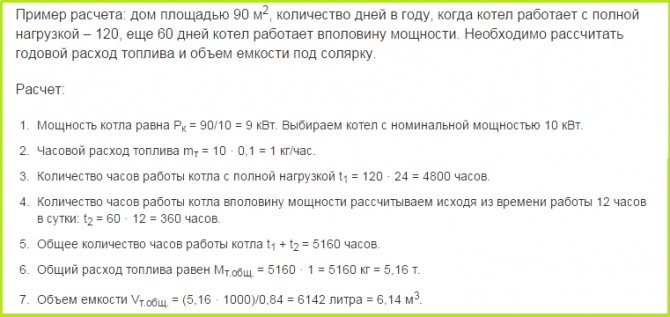

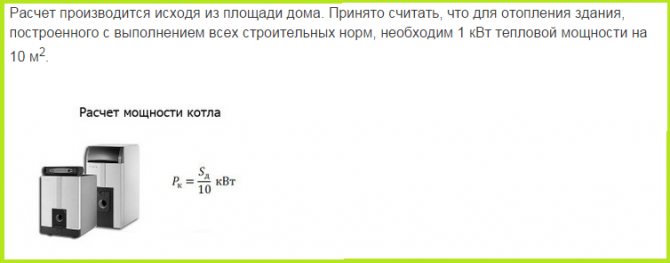

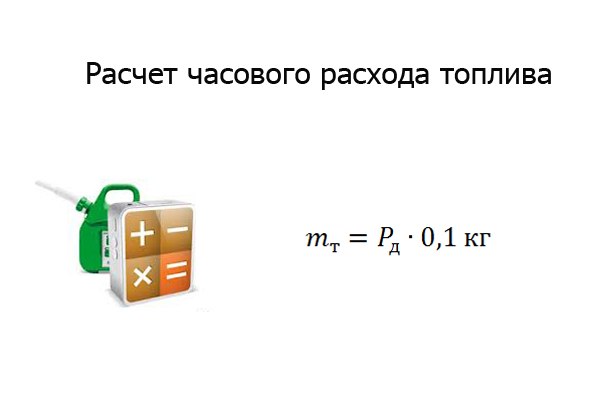

What formula should be used to calculate

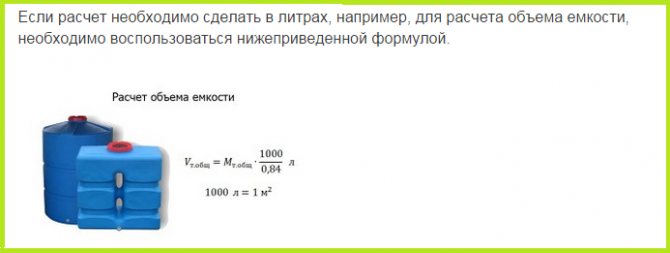

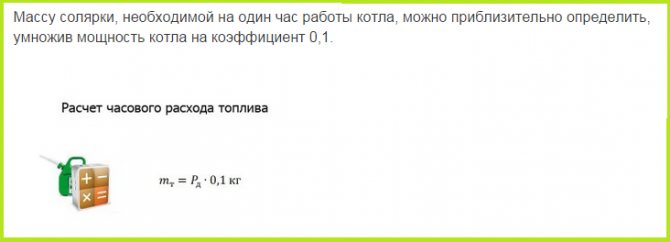

To calculate the fuel consumption of a diesel boiler for a particular room, you can use approximate calculations. For example, in the average statistical case, to obtain a power of 10 kW, you will need to consume 1 kg of diesel fuel per hour.

There is another option, it is based on the burner power readings, which must be multiplied by a factor of 0.1. The result is the amount of fuel for 1 hour of equipment operation.

Knowing these indicators, you can calculate the approximate figures that a diesel boiler consumes to heat a room with a certain area. For example, to heat your house of 150 m², you need a 15 kW boiler. Then multiplying this value by 0.1, we get 1.5 kg / h.

This means that when operating at full speed, your device will burn 36 kg (1.5x24) per day. And if we take 100 days at full load as the average operating time and the same amount at half load, then it turns out: 100x36 + 100x18 = 5200 kg. As you can see, more than 5 tons of diesel fuel will be spent to heat your premises in the autumn-winter period.

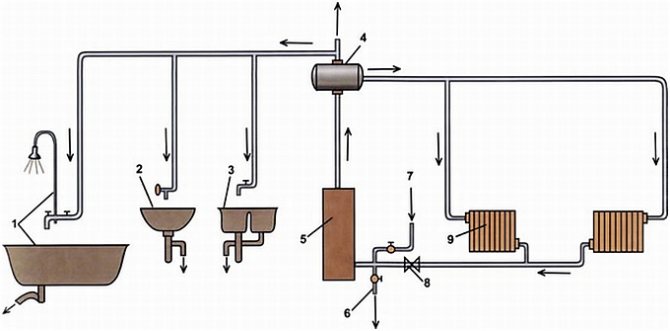

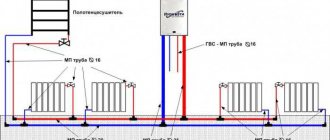

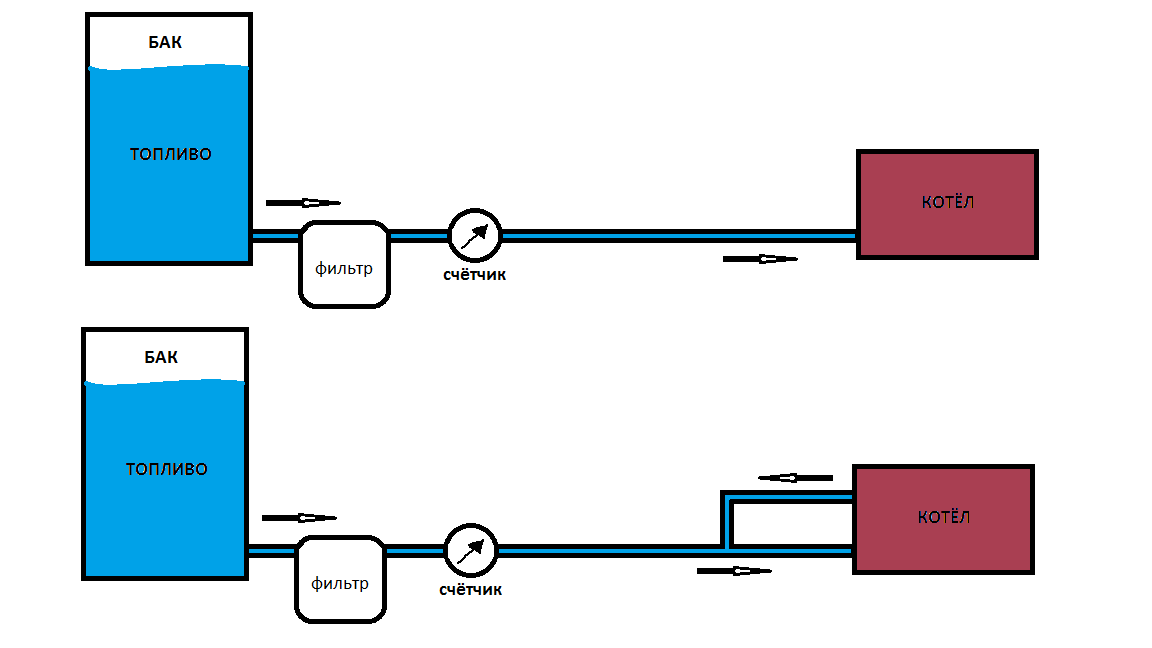

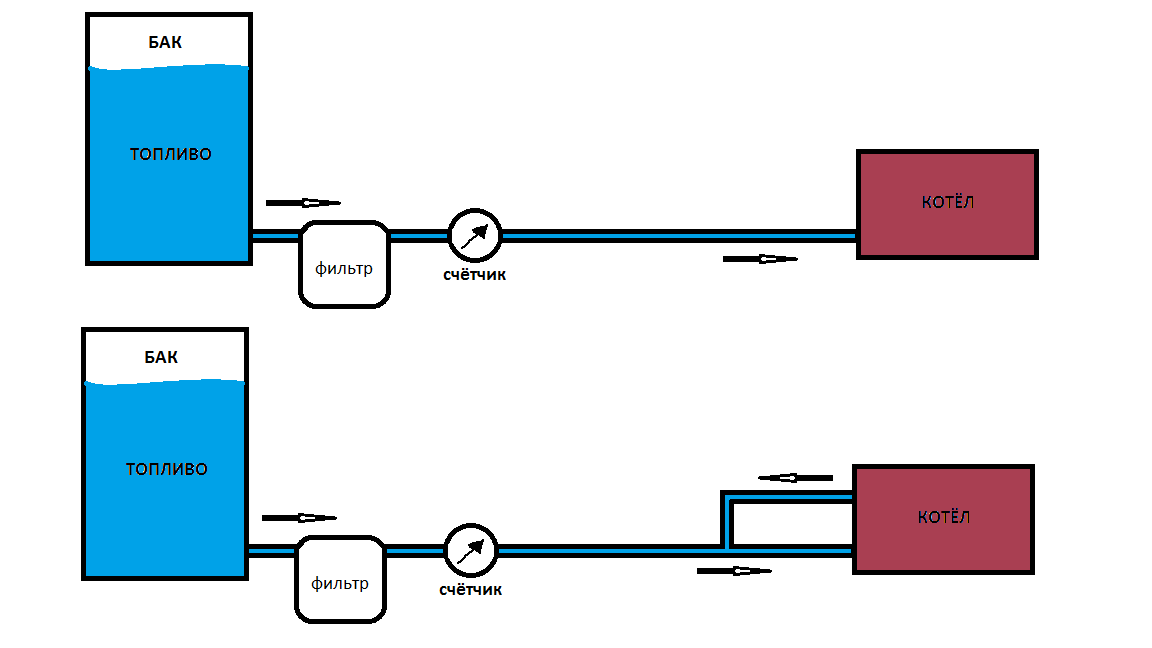

One-pipe systems

For a one-pipe system, it is enough to install one fuel flow sensor, for a two-pipe system, you have to use two sensors or one differential fuel meter. It is clear that in a one-pipe system, the entire accounted flow passing through the fuel line of the boiler room or boiler will be consumed by the boiler, and the error in determining the fuel consumption is determined by the error of the measuring device.

How to save fuel? And which device to choose?

Liquid fuel devices can be either one or two-circuit. Naturally, the latter will require a higher diesel consumption for work, which will lead to increased costs. Therefore, for such models, the best solution is to reduce the amount of hot water, which will save on fuel.

One more advice from experts. They recommend setting a lower temperature for the coolant, which also affects the diesel consumption.

And the last way is to install a thermostat in the warmest room.

Using these tips, you can reduce the amount of fuel needed to operate your heater and save money.

Very often a question is asked on forums. Which boiler equipment is more profitable - electric or diesel? Diesel heating boiler, what fuel consumption does it have?

The answer to it depends on various factors, such as the thermal insulation of the premises, the area of the house, the number of residents, the climatic zone and, of course, fuel prices. Knowing them, you can always calculate the approximate consumption of diesel and electricity, and compare the costs of them.

How to save diesel fuel

This is not an idle question. It is asked by everyone - from ordinary people to experienced craftsmen. There are no special recommendations, and all of them have been known for a long time. Let's just list them:

- When installing a double-circuit unit, it is recommended to reduce the consumption of hot water for domestic needs.

- Set the reduced coolant temperature. In this case, you will have to consider a more efficient heating system. For example, a manifold option for piping with the installation of control valves.

- Use the latest control blocks.It should be noted here that the temperature sensors are installed indoors or better outdoors.

How much fuel does a diesel generator consume - fuel consumption in a diesel generator set

Autonomous power supply of country houses can hardly be called a whim. In most cases, the purchase of a diesel generator is due to an urgent need and cannot be considered a waste of money. When choosing a mini power station for home, most buyers prefer to purchase diesel generators as the most economical and affordable equipment. The cost of DGS is not great and is more than compensated by the advantages obtained from its acquisition. Diesel generators are characterized by high performance, designed for long-term operation, and are easy to maintain. Most modern models are quite economical in terms of fuel consumption. In addition, diesel fuel has a lower cost than gasoline. These advantages led to the great popularity of diesel generators among consumers.

How much fuel does a diesel generator consume?

The fuel consumption of the diesel generator set depends on the degree of workload of the installation and the power for which it is designed. Generators are classified according to the amount of power they generate. There are low-power, medium and powerful diesel generators. Less powerful models are the most economical. The degree of loading directly depends on the number of consumers connected to it. In any case, diesel models consume almost half the fuel than gasoline power plants. In addition, there are certain conditions, the observance of which allows you to achieve maximum savings.

How to make the fuel consumption of a diesel generator set to a minimum

The basic rule is not to let the generator run dry. This happens when consumers consume less than 35% of the electricity generated by the power plant. In this case, a significant decrease in efficiency is observed. Subsequent engine wear will lead to a significant increase in fuel consumption. An important factor is the quality of the fuel used. Low-quality fuel is consumed faster. Along the way, clogging oil and fuel filters, which in turn leads to uneconomical consumption.

Heavy loads not only increase the consumption of fuel consumed, but also lead to premature wear of the mechanisms. Limit loads are considered to be more than 75% of the rated power. In practice, this means that with a rated power of a power plant of 6 kW, the total power of consumers connected to it should not exceed 4.5 kW.

First of all, it is necessary to determine the rated power of all devices that are planned to be powered from the power plant. The power ratings of the devices are indicated in their technical data sheets. In order to find out the total power of the connected load, add all the values. The environment also affects the fuel consumption of the generator. At low temperatures, it becomes more viscous and does not completely burn out, which in turn leads to a decrease in efficiency. It is important to choose the right place for the diesel power plant. The room must be heated and well ventilated. This rule applies to all generators, regardless of what capacity they are.

Fuel consumption figures for diesel generators

Evaluation of the efficiency of a diesel unit is made on the basis of how much fuel is needed to generate one kilowatt of electricity per hour. This rating system is adopted in the countries of Europe, Russia and in most of the countries of Asia. It makes no sense to compare one brand with another and draw conclusions about their efficiency based on this comparison, since, as already mentioned above, many factors affect the performance of diesel generators. If used improperly, any generator will consume a lot of fuel.

How to calculate fuel

Empirically, it was found that the production of one kilowatt of electricity consumes about 200 grams of fuel (in this case, diesel fuel). In order to determine the fuel consumption, multiply the value of the generator power by the mass of the consumed fuel. For example, for a diesel generator set with a power of 6 kW, the calculations will look as follows: 6 × 0.2 = 1.2. Consequently, 1200 grams of diesel fuel or fuel oil will be consumed in one hour.

Diesel fuel types

Residual and distillate fuels are used to power diesel power plants. Distillate types include diesel fuel and gas turbine. Diesel is subdivided into:

- Summer (L);

- winter (W);

- arctic (A).

Residual or heavy varieties are used for refueling diesel generators with a built-in fuel preparation system, which includes heating and separation. Heavy types (fuel oil) are used in powerful diesel generators installed as a source of backup power supply at industrial enterprises and for powering facilities classified in the first category of consumers.

In order for the diesel generator to operate without fuel oil, the fuel must be preheated. This type of fuel is used only in high-power installations. Fuel oil is not used in low-power power plants. Low-power diesel generators use light fuel - diesel fuel.

Benefits of diesel boilers

Low equipment cost and installation

In terms of installation, this is the cheapest option available today. Even buying a gas appliance with minimal capabilities will cost more. An electrical appliance will be even cheaper, but it is necessary to pull electrical wires over, at times, very long distances.

No chimney

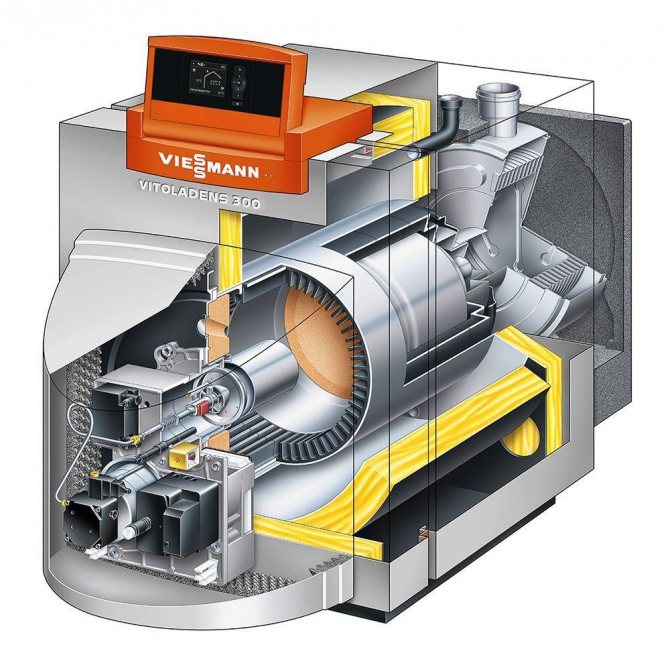

Most models are used without a chimney, provided that the device is installed in a room not in contact with living rooms. But in the wall, they still make a hole into which the pipe is brought out in the form of a sandwich. This is necessary so that the wall does not catch fire. This is where it all ends, because the turbine, which is in the structure (Figure 3), pushes the air itself. All this works perfectly without the presence of smoke in the apparatus.

Fig. 4 Diesel boiler design

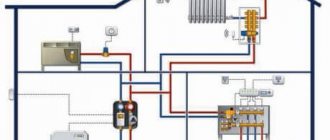

Autonomous operation of the unit

The boiler automatically maintains a stable water temperature in the heating system. When the water is cooled, the burner turns on independently, and when the desired temperature is reached, it turns off. The operation of the heating system is provided with protection in several stages. Comfort at the level of city heating is possible thanks to a properly organized system and correct wiring of heating pipes of a single-circuit diesel boiler.

Light fuel use

Diesel boilers also run on light heating oil, which is diesel fuel with additives. Cars are prohibited from using it, so it is sold without taxes and many fees. Accordingly, the requirements for this type of fuel are too low. Therefore, its cost is much lower than the automobile one.

Where does diesel heating begin?

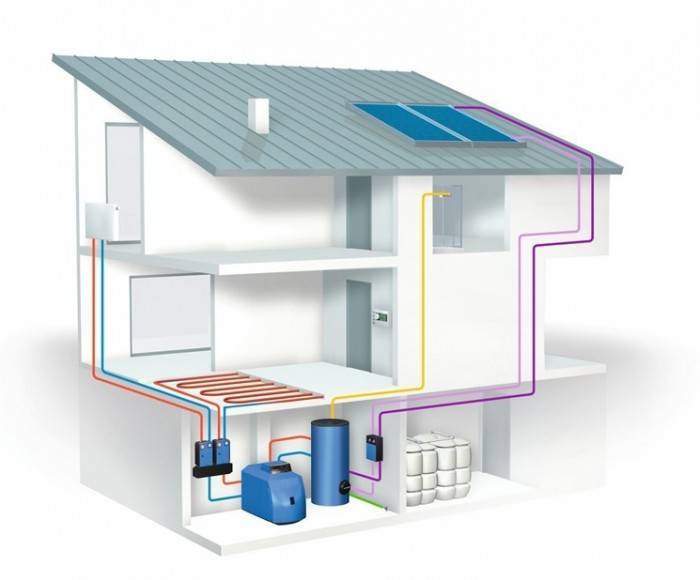

Today, diesel heating in a country house is not a problem. After all, you can find many companies that offer diesel boilers. The efficiency of such boilers is 75-85%. It all depends on what design features the boiler has and what kind of appearance it has. Double-circuit boilers can not only heat the house, but also be used to supply hot water.

Boiler room of a private house

Of course, first of all, even when choosing a heating system, all home owners have a question - what will be the consumption of diesel fuel for heating a house? Based on statistics, fuel consumption with constant operation is 0.9 liters per hour. Average rates are 0.5-0.7 liters per hour.However, such indicators can be ensured only if your house is very well insulated.

In this case, you can focus on the requirements for gas boiler houses: area from 4 sq. M for each boiler; ceiling height from 2.2 m; doorway from 80 cm; a window of 10 cubic meters by 0.3 square meters of a window; supply ventilation 8 sq. cm per one kW of the rated power of the boiler or 30 sq. cm per 1 kW with air inflow from the internal premises; chimney cross-section not less than the boiler outlet; ground loop bus; channel of natural supply ventilation 30 cm from the ceiling; power supply on a separate machine; diesel fuel for heating - no more than 800 liters in the boiler room.

Heating system with a diesel oil boiler

When you equip a diesel boiler room, you need to pay attention to the fact that you do not need to equip a complex special chimney to work with a turbocharged burner. You can just buy a coaxial chimney and draw it out through the wall

Thanks to such a pipe, combustion products will be efficiently removed, and clean air will be taken inside.