Connecting to the network

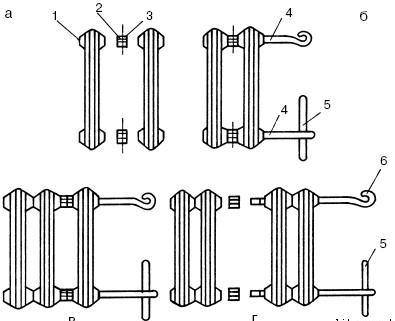

For self-connection to propylene pipes, you need to have a special soldering iron.

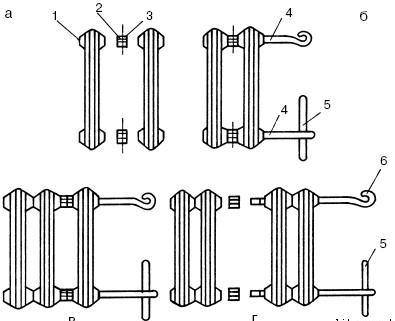

There are two connection options:

1. If the radiator valve is made of propylene, then its plastic branch pipe is connected by soldering directly to the liner. Then the metal end piece of the "American" is screwed from the tap and screwed into the radiator foot using a flax-paste winding or FUM tape for the tightness of the connection. After that, the "American" is again assembled and the union nut is tightened with a wrench.

2. If the radiator valve is metal, then a combined detachable coupling with an internal thread is used to connect to the plastic connection. By the principle of connection, such a coupling is similar to a metal "American", but the union nut is located on a plastic end switch for soldering. The plastic part of the coupling is soldered to the supply pipe through the connecting fitting. The clutch is disassembled, the reciprocal metal part is screwed onto the valve body with a winding and then assemble it again, tightening the union nut with a wrench.

1 - "American"; 2 - ball valve; 3 - combined split coupling; 4 - polypropylene coupling; 5 - polypropylene liner

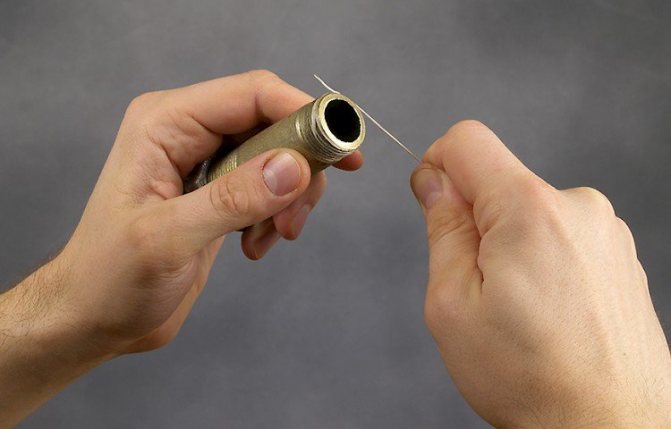

When connecting to a metal connection, you must first connect a ball valve or a thermostat to the pipe. Knowledge of welding skills is not necessary - the connection of valves to the pipe can be done using a threaded connection. To do this, it is necessary to cut a thread on the cut off part of the liner. This is done with the help of a klupp. A set of heads and mandrels with one or two handles is quite expensive, but you can buy only one die head of a specific size, and use a regular gas wrench as a mandrel with a handle. The sequence of work will look like this:

- the pipes of the liner are cut with a grinder to the desired size, trying to ensure that the plane of the cut is perpendicular to the axis of the pipe;

- clean the end of the pipe from rust and make a small chamfer with a file;

- grease is applied to the working section of the pipe and the klupp cutters;

- push the head onto the chamfer;

- center it relative to the pipe axis;

- holding the head with your hand, with the help of a gas wrench, begin to turn it clockwise.

As a result, it is necessary to obtain a section with a thread approximately equal to the long part of a standard squeegee (for example, for a 3/4 pipe - 45 mm).

Then a lock nut is screwed onto this section (for Dу 3/4 its thickness is 9 mm) and a coupling (for Dу 3/4 its length is 36 mm). Combine the inlet of the ball valve with the liner and drive the coupling from the liner to the thread of the valve body (of course, using flax or FUM tape winding). Then a winding is screwed onto the thread next to the coupling and the locknut is distilled.

1 - "American"; 2 - valve; 3 - clutch; 4 - lock nut; 5 - threaded liner

Important! The handle of the tap should be up or out of the wall for comfortable use. After the shut-off valve (or thermostat) is rigidly and hermetically connected to the liner, it is connected through the "American" to the radiator box

After the shut-off valve (or thermostat) is rigidly and hermetically connected to the piping, it is connected through the "American" to the radiator housing.

Hello dear forum users! I have a question for you: - how to determine on the radiators, where is the left and where is the right thread? How do they differ from each other? And can this be determined on batteries when the plug on the cast-iron radiator is already screwed on?

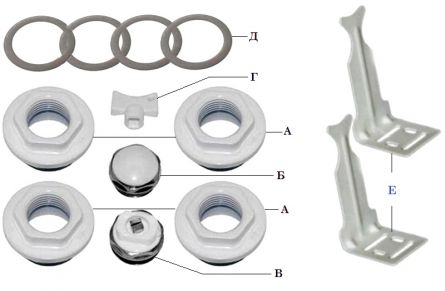

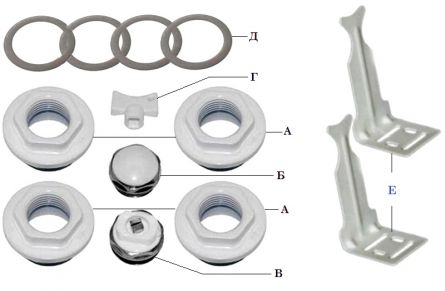

Kit for aluminum radiators

When buying heating radiators, I immediately bought standard kits at the rate of one kit for one radiator, for a total of 5 kits. The standard set includes: plug, air vent ("Mayevsky" valve), four sleeves and O-rings. The adapters must be sized according to the diameter of the pipes connected to the heating radiators.

The house has a heating system using polypropylene pipes 25x3.5 mm, so I bought kits with fittings for transition from the thread in the hole in the radiator section, the diameter of which is 1 "by ¾", this is the diameter of the thread for installing fittings and accessories that are necessary for connection radiators to the heating system.

Let's take a look at a standard set for aluminum radiators:

- A - transitional sleeves with ¾ ”internal thread.

- B - plug with ¾ ”external thread.

- В - air vent ("Mayevsky" valve) with ¾ ”external thread.

- G - the key to the air vent.

- D - O-rings (four seals for the fittings and two for the Mayevsky tap and the plug).

It is also necessary to purchase brackets for attaching heating radiators to the wall of the house. I bought corner brackets from the calculation - three brackets for one radiator, installed two at the top, one at the bottom in the center of the heating radiator.

Joint repair

To carry out repairs you will need:

- special radiator key;

- gas wrench No. 2 or No. 3.

We will assume that the radiator is removed. It must be laid on a flat surface. After that, the plugs and fittings (plugs with holes for pipes) are removed using a gas wrench.

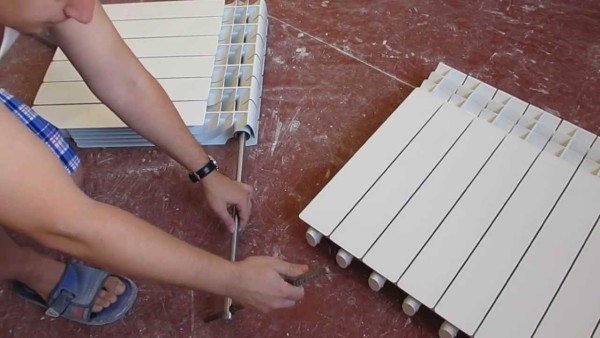

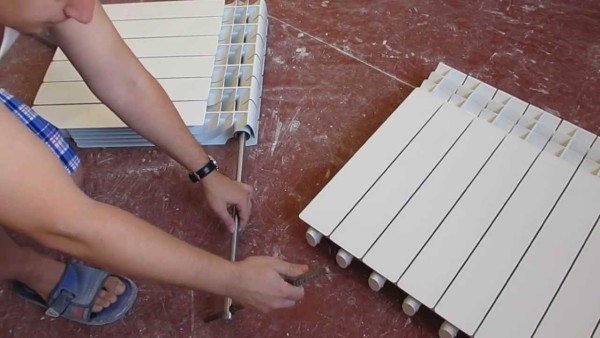

The radiator sections are interconnected by nipples. It is a short cast iron pipe with an external pipe thread (half right, half left) and an internal hole that has two projections.

It is these protrusions that are the place where the edges of the radiator key will abut. In fact, these are stops.

At this stage, you will need an assistant who will fix the heating device in a stationary position. The key is inserted into the hole of the section so that the edges of the tool rest against the protrusions of the nipple. Now you need to turn the key with effort at least a quarter of a turn.

The thing is that the long-term operation of cast-iron batteries, where a coolant with a high temperature is used, creates conditions under which the nipple and the section of the device are soldered together. The result is a monolith.

Therefore, great efforts will have to be made to break these ties. As soon as the nipple moves slightly off dead center, move to the second parallel element. It is impossible to untwist the sections on one side only, a skew will occur, which will complicate subsequent operations.

In this way, all sections are disassembled. Now you need to clean the joint surfaces with an iron brush and sandpaper. Only the rust needs to be removed.

Be sure to inspect the nipples, if their condition is in doubt, then it is better to replace them with new ones.

Pay particular attention to the threads

It is best to flush the battery sections at this stage. A hose jet and a pin (wood or metal) will do the job perfectly.

After that, you can proceed to the assembly, having previously prepared the gaskets. They can be made independently from heat-resistant paranite or rubber 1 mm thick. Currently, craftsmen suggest using a silicone sealant that can withstand high temperatures.

The battery is assembled in reverse order. Be careful when tightening the nipples

Here it is important not to twist, so as not to squeeze the gasket to a critical rate. She just might tear

As with disassembly, the two nipples must be screwed in alternately.

Often there are situations when the stops inside the nipple become covered with rust under the influence of long contact with the coolant. And under pressure from the radiator key, these stops are cut off. What to do in this case, because the sections simply cannot be promoted. Option one is to break the section on which the fistula appeared.

This can be done in two ways:

- Simply smash the battery section with a sledgehammer. Do this carefully so as not to break the good elements.

- Can be cut with a grinder. But the junction will still have to be smashed with a hammer.

Kit for aluminum radiators

When buying heating radiators, I immediately bought standard kits at the rate of one kit for one radiator, for a total of 5 kits. The standard set includes: plug, air vent ("Mayevsky" valve), four sleeves and O-rings. The adapters must be sized according to the diameter of the pipes connected to the heating radiators.

The house has a heating system using polypropylene pipes 25x3.5 mm, so I bought kits with fittings for transition from the thread in the hole of the radiator section, the diameter of which is 1 "by ¾", this is the thread diameter for installing fittings and accessories that are necessary for connection radiators to the heating system.

Let's take a look at a standard set for aluminum radiators:

- A - transitional sleeves with ¾ ”internal thread.

- B - plug with ¾ ”external thread.

- В - air vent ("Mayevsky" valve) with ¾ ”external thread.

- G - the key to the air vent.

- D - O-rings (four seals for the fittings and two for the Mayevsky tap and the plug).

It is also necessary to purchase brackets for attaching heating radiators to the wall of the house. I bought corner brackets from the calculation - three brackets for one radiator, installed two at the top, one at the bottom in the center of the heating radiator.

Dismantling cast iron radiators

To dismantle such heating devices with your own hands, you will need the following tool:

Dimensions of the cast iron battery.

- Pipe wrench number 3, for loosening the locknut and sleeve.

- A pipe cutter for cutting a pipe or a grinder.

- Hacksaw for metal.

- Chisel.

- Hammer and sledgehammer.

- Rust removal brush.

Dismantling of such heating devices, as a rule, is carried out in the summer, when the heating system is turned off. Before starting dismantling work, it is necessary to drain the water from the heating pipelines.

Then, with a pipe wrench, the locknuts on the water supply pipes are unscrewed, the sleeves are unscrewed and the radiator is removed from the brackets.

If it is impossible to unscrew the locknuts, the pipes supplying the coolant are cut off and the device is dismantled.

Installation and replacement

Under the cork

How to install a gasket under the radiator plug of an aluminum battery with your own hands?

- Lubricate the end of the section manifold and the plane of the plug with any neutral grease. Silicone plumbing grease, grease and even liquid soap are suitable.

- Place the gasket over the plug thread.

- Tighten the plug with an open-end wrench or adjustable wrench. Paronite shrinks until the moment when the effort becomes noticeable (but by no means insurmountable: you run the risk of ripping off the sections). The silicone is pulled together until the edges are visibly squeezed out from under the cork.

Intersectional

Instructions for eliminating intersectional leaks are somewhat more complicated.

- Close the heating riser and unscrew the plugs or open the vent valves. If there are valves on the connections to the battery, simply close them.

- Substituting a basin or other container with low walls under the lower blind radiator plug, unscrew the plug a few turns and let the remaining water drain off. Unscrew the plug completely; if necessary, use a stick or any other handy tool to free the lower manifold from dirt.

Attention: on blind plugs, in most cases, left-hand thread; they unscrew clockwise.

- Repeat the operation with the upper plug.

- Mark the distance from the edge of the battery to the nipple you need on the radiator key.

- Insert the key into any of the manifolds and, turning, push it into the radiator until it engages with the desired nipple.

- Unscrew one turn. The direction of rotation is the same as that of the plug.

- Repeat the operation with the nipple on the second manifold.

- Unscrew the nipples one turn at a time, one at a time. A misalignment caused by uneven unscrewing will jam or break the nipple.

- Remove the outer sections; Place new gaskets on the nipples and thread the nipples onto one thread.

- Install the end sections, press them against the nipples and screw them with a wrench until they engage securely.

- Reassemble the heater upside-down.

Preparation for disassembly

At this stage, you need to prepare all the necessary tools and dismantle the battery from the attachment point. For work, depending on the type and condition of the radiator, you may need the following tools:

- radiator (nipple) key;

- an adjustable wrench or a set of wrenches with different head sizes;

- autogen or grinder;

- construction hair dryer;

- hammer, sledgehammer;

- chisel.

Disassembly tools for radiators

The nipple wrench is an iron rod with a spatula-shaped head at one end and a hole or curved "ear" at the other. The tool purchased from the store has serifs, the distance between which is equal to the width of the heating radiator sections. They will help you find the location of the desired nipple nut.

After preparing the tools, it is necessary to equip a place for disassembling the radiator. A floor or a sturdy table will do. It should be borne in mind that dirty water will flow out of the battery, and do not forget to put a waterproof cloth under it.

How to disassemble an aluminum heating radiator with your own hands?

Removal of the aluminum battery occurs in the following cases:

- When the system changes completely.

- It is necessary to increase or remove the extra section.

- Eliminate the leak.

Before disassembling the aluminum radiator, you need to prepare a set of wrenches and a screwdriver.

Further actions are performed in the following sequence:

- The coolant is discharged from the system. If disassembly takes place during the heating season, then you should wait until the battery cools down.

- Using a wrench, unscrew the clutch... which connects the hose from the battery to the heating pipe.

- The disconnected radiator must be freed of water residues and put on a flat surface with the right side up.

- Remove the filter from the battery and rinse thoroughly. This must be done immediately, since the dirt accumulated in it can harden and then it will be extremely difficult to remove it.

- Further work is the analysis of the battery into sections. They are interconnected with special nipple nuts. To remove them, you need a key for disassembling aluminum radiators, turning it counterclockwise, they can be easily removed from the radiator. This must be done with extreme caution to avoid skewing.

After disassembly, the battery cells are washed and reassembled in the same sequence.

If it is necessary to eliminate the leak, then a special solution of epoxy resin with the addition of bronze powder is suitable for aluminum radiators. You need to work with this composition quickly, since it dries up in a matter of minutes, so the leakage must be cleaned up and prepared in advance.

If you decide to install aluminum radiators, it is important to know the following:

Features of mounting radiators

The most demanding for the strength of the fastening and base are cast iron radiators. In addition to the weight of the product itself, the internal volume of the section also plays a role.If the volume of the popular series of cast-iron radiators MC-140 can reach almost 1.5 liters, then for an aluminum radiator it is no more than 0.5 liters, and for bimetallic ones it is even less.

When calculating the number of brackets, they are guided by the provisions of clause 3.25 of SNiP 3.05.01–85 - one bracket per 1 sq. m of the heating area of the cast-iron battery (but there should be at least three of them). The heating area of one section depends on its type. For example, for the M-140 it is 0.254 sq. m, and for a battery of 12 sections, four brackets are already needed.

If the battery is mounted on three brackets, the mounting pattern looks like this: two points at the bottom, one in the middle at the top. The four brackets are installed in pairs on top of each other. And the bend of the bracket should wrap around the neck of the radiator (the junction of two adjacent sections).

Fastening of bimetallic and aluminum radiators follows the same scheme as cast iron. And the reason is no longer in the weight of the battery and the coolant, but in the thin walls of the steel liners of bimetallic products, in the low resistance to mechanical stress of aluminum and in the weak strength of the threaded connections of individual sections of both types of radiators. Therefore, they also need at least three points of support.

Cast iron radiators are installed on brackets with dowels fixed in concrete and brick walls. For bimetallic and aluminum radiators, the brackets can also be attached to wooden walls.

In other cases, for installation, you must use two floor stands with fixing to the wall of the upper part of the radiator. If the number of sections is more than ten, then three stands are needed.

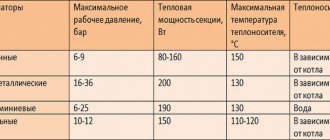

Recommendations for the selection of components

To begin with, let's consider what criteria you should pay attention to when choosing components for assembling a heating system, these recommendations will apply not only to the fittings, but also to all other necessary elements:

| Matching in size | If you do not know the parameters of the equipment, then it is unlikely that you will be able to purchase components, as a last resort, if you decide to do the work for the first time with your own hands, grab the documentation for the radiators and other equipment included in the system so that the seller can figure out what you need |

| Heating system plan | This is much more important than you think, so a sketch must be done, perfect accuracy is not required from you. The main thing is to clearly define the location of all nodes in the system and the peculiarities of their location relative to each other. This will greatly help in determining the exact amount of certain components, you will not miss important nuances |

| Thread matching | Another important factor, as the type of connection and its pitch may differ. Moreover, the differences can be both in the measurement system (inch or metric) and in the thread pitch. Of course, most manufacturers try to produce products according to certain standards, but nevertheless, some features are still encountered, and it is important to know about them in advance (again, the instructions attached to the equipment will help) |

| Product quality | It is possible to determine how well this or that product is made by eye - the carving inside and outside must be even without flaws and damage, other surfaces must be smooth and high-quality processed. When it comes to components for aluminum and bimetallic radiators, the products are most often painted white, since most radiators have exactly this color |

| Manufacturing material | The skylight for a cast-iron radiator should be made of the same material as the main element, as for bimetallic and aluminum radiators, then for them products made of galvanized steel are the best solution, they are quite reliable and durable, while their price is affordable |

| Checking items | It is best to check how well the element is screwed onto the threads, if you are purchasing many units, then check at least a few of them to choose from. The parts should be screwed in easily enough without any effort on your part. If resistance is felt, then the thread on one of the elements is damaged. |

Advice! We recommend purchasing components from the same company as the main components. In general, the easiest way is to buy everything you need in one store, then the specialists will complete the whole set for you, and you will save a lot of time, since you do not have to figure it out on your own, they will explain everything right on the spot.

When carrying out work, you may need a variety of components and components.

Step-by-step description of dismantling works

A few words about when you may need to disassemble the heating battery:

- In the case of replacing the old radiator with a new one with greater performance and better appearance.

- If you need to add additional sections for the battery.

- If it is necessary to replace a single section or gasket that has leaked.

The instruction begins with the preparation of the necessary tools:

Step # 1: preparing the tools

Photo of nipple wrench

Sample gas wrench

Advice: a nipple wrench, taking into account the fact that it is rarely needed on the farm, and its price is not the lowest, it is recommended not to buy, but to rent it. This will save the family budget.

Step # 2: disconnecting the battery

Before disassembling an aluminum or cast iron radiator, it is necessary to disconnect it from the heating system. To do this, it is imperative to turn off the heating and drain the water from the riser, otherwise you will simply flood the room and get burns.

Advice: it is recommended to cover the floor under the battery with a film, rags or at least newspapers before starting dismantling to avoid getting any residual liquid on it, which may end up in the circuit even after draining the riser.

Further, depending on the complexity, three situations can be distinguished:

- Polypropylene pipes. In this case, the sleeve joint, as a rule, is twisted with bare hands, without causing any difficulties.

- Steel new. With some effort, you will most likely be able to spin the battery inlet and outlet with a gas wrench.

Disconnecting new steel pipes

- Old steel or cast iron pipes. First, we try, removing the paint from the docking place with a blowtorch and a metal brush, we try to untwist the connection as described in the previous version. But in systems that have worked for a long time, most often this does not work, and then we simply cut off the drive with a "grinder" or autogenous.

Cutting old sills using a "grinder"

After disconnecting the battery from the pipes, remove it from the hooks and place it on a flat surface.

Step # 3: disassemble the radiator

Battery section disconnection diagram

A piece of pipe or crowbar

The battery can be cast iron, aluminum or bimetallic.

The most difficult option for parsing is the first of the listed ones, and we'll start with it:

- How to disassemble a cast-iron heating radiator on your own:

Carefully, we check the thread on the futures or plugs, which can be either left or right. We insert the nipple wrench inside, we increase its torque using a piece of pipe or a crowbar

We rip off the thread by scrolling the tool a quarter of a turn, first at the top and then at the bottom. Then we also alternately continue to unscrew the nipples so that the radiator does not warp. The main problem with old batteries is that the fuses can become stuck in the course of many years of use and not give in to the key. In this case, the junction must be warmed up in a circular motion with a blowtorch, and then again try to unscrew the nipple. We repeat the procedure until the thread gives in.If, however, nothing comes of it, then you have to cut it with an autogenous gun.

Disassembled old cast-iron heating battery

- Let's find out how to disassemble a bimetallic or aluminum radiator? The procedure is almost the same as above, but with a few differences:

- A smaller nipple wrench is used.

- It does not require as much effort when unscrewing the nipples.

- Plugs and futurocks are marked with the direction of the thread in the form of the letters S and D, where the first designates the left stroke, and the second - right.

- The metal gaskets between the sections are wiped, sanded and stored until the battery is reassembled.

Dismantling the aluminum battery

After completing the described tasks, you can replace the leaking part, add a section, or even install a new radiator in place of the old one.

Assembly and disassembly of aluminum heating radiators

For the first time, aluminum radiators appeared on the world markets for heating equipment in the 80s of the 20th century. Next to the heavy ribbed "monsters" of cast iron, they looked elegant and stylish.

Naturally, the demand for them was huge, but only a decade later, the first aluminum batteries showed their shortcomings.

To date, manufacturers have significantly improved the performance of aluminum batteries, so they now have much more positive qualities than before. The assembly of aluminum heating radiators has also been simplified and now they can be installed or disassembled without the involvement of specialists.

Marking for fastening

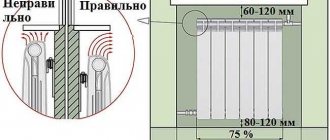

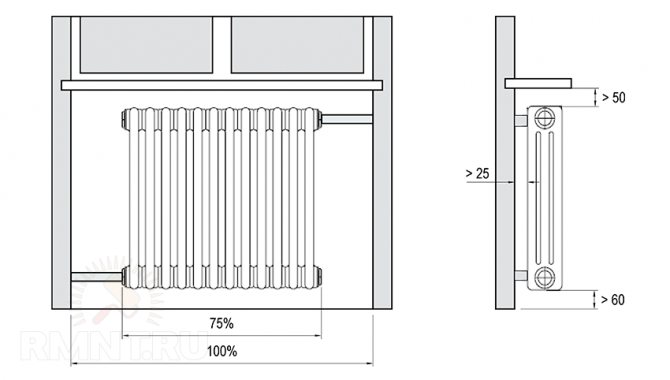

The standard location for the radiator is the wall under the window opening. According to SNiP 3.05.01–85 (p. 3.23), the battery on the side of the riser should not go beyond the border of the window opening, and the coincidence of their axes is not necessary. But in order for the battery to look harmonious in the interior, it must be located symmetrically relative to the vertical axis of the opening. Therefore, first, this axis is beaten off by level.

The second step is to beat the horizontal level of the battery position and ensure alignment when connecting the connections to the fittings.

But there is one feature - the horizontal channels of the radiator must be oriented strictly according to the level, and the pipes of the direct and return flow must have a slight slope relative to the flow of the coolant. These angles are needed to reduce the force of resistance to flow and to reduce the risk of airing the battery. The slope value is very small - 5–10 mm for a liner length of more than 50 cm (SNiP 3.05.01–85 p. 3.18), and steel liner pipes with a length of less than 1.5 m are not attached to the wall. And if a battery is replaced with reference to an existing wiring, then, for example, for a one-pipe system with a riser, an upward (or downward) shift in position can level the slope of the forward (or reverse) feed.

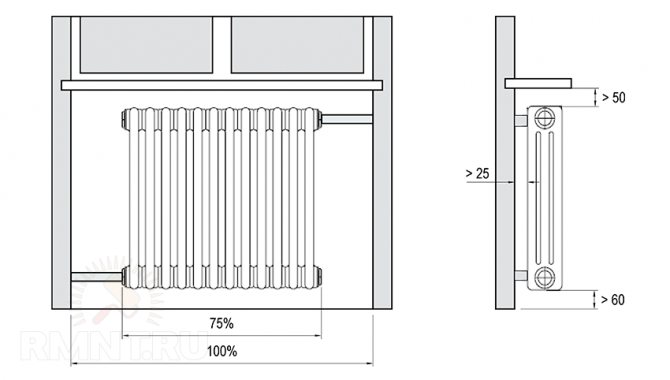

The very same position of the radiators must ensure that the following conditions are met:

- distance from the floor - more than 6 cm;

- distance from the windowsill - more than 5 cm;

- distance from the wall - more than 2.5 cm.

Self-assembly of sections

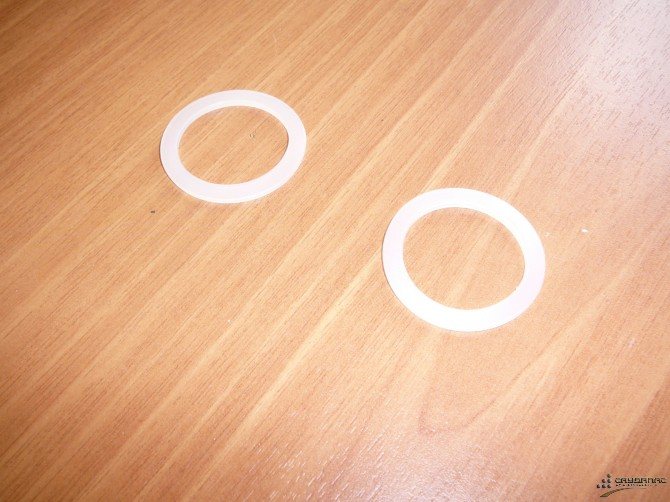

The gasket seals the nipple directly.

Why are gaskets used when installing heating devices? Which gaskets sold in plumbing stores are the best? Can you make them from scrap materials yourself? Finally, how do you install or replace them correctly? Let's figure it out.

Application

The products of interest to us are used in two ways:

- Radiator cross-section gasket

ensures tightness of connection of sections It is pulled together by a nipple — a short, counter-threaded tube — and is clamped between the cut planes of the upper and lower manifolds. - In addition, gaskets are used when installing radiator plugs on aluminum and bimetallic heaters.

But:

in the latter case, they can be replaced by a reel. It can be used as sanitary flax impregnated with silicone or paint, FUM tape or polymer thread sealant.

Varieties

Material

Gaskets for cast-iron heating radiators are made of paronite (heat-resistant hard rubber) in accordance with the requirements of GOST 15180-86. The standard regulates the main dimensions of products (by the way, not only paronite ones) and their mass in batches of 1000 units.

Paronite gasket for cast iron sections.

Gaskets for bimetallic radiators and aluminum batteries can be made from both paronite and heat-resistant silicone.

Which of the two materials is more preferable?

It is difficult to give a definite answer.

- paronite

due to its rigidity, it more effectively resists the internal pressure of the coolant; - silicone

on the other hand, it does not lose its elasticity over time and requires less pulling force to reliably seal the joint.

The photo shows a silicone product.

Dimensions and shape

A paronite gasket for a cast iron radiator is always in the form of a flat ring.

Products intended for aluminum and bimetallic batteries can be in the form of both a flat ring and a toroid (donut).

Observe:

toroidal silicone gaskets are used to seal annular groove sections. If you try to squeeze them between sections or between a plug and a flat section, you will find that the silicone will squeeze out.

The donut-shaped silicone gasket is installed only in radiators with an annular groove on the sections.

The diameter of the hole in the flat gasket is determined by the type of radiator and the diameter of the nipple. The nipple is supplied with the following thread sizes:

Self-production

The intersection gasket for any type of radiator can be made by yourself. Yes, the price of these products is not high; however, sometimes a long distance to a store, a weekend or a holiday can make you bother looking for alternatives.

The material will serve as a conventional tube for a pneumatic tire:

- automobile - for a cast iron battery;

- bicycle - for aluminum / bimetallic.

For cutting, ordinary scissors are used; the contour is preliminarily transferred to the camera cut along and laid out on a flat table with a ballpoint pen.

If you have an old camera and sharp scissors, you don't have to go to the store.

But:

if you need to make a large number of gaskets, it makes sense to speed up the procedure for their manufacture by making a punch from a section of the heating pipe of the appropriate size (DU32 or DU25) sharpened on one side.

Problems

The list of common problems with radiator gaskets is small:

- when installed under a plug, one-sided squeezing of paronite or silicone is possible. this happens especially often in cases where the thread axis of the plug or section has deviations from the perpendicular to the plane of the end of the manifold.

- Paronite, during long-term operation under conditions of strong heating, somewhat loses its elasticity. as a result, the intersection gaskets after several tens of heating-cooling cycles of the sections with the next cooling of the batteries are able to leak: a decrease in temperature leads to a slight change in the linear dimensions of the sections.

Leaking cast iron battery between sections.

Installation and replacement

Under the cork

How to install a gasket under the radiator plug of an aluminum battery with your own hands?

- Lubricate the end of the section manifold and the plane of the plug with any neutral grease. Silicone plumbing grease, grease and even liquid soap are suitable.

- Place the gasket over the plug thread.

- Tighten the plug with an open-end wrench or adjustable wrench.Paronite shrinks until the force becomes noticeable (but by no means insurmountable: you run the risk of stripping the pipe thread in the section header). The silicone is pulled together until the edges are visibly squeezed out from under the cork.

Intersectional

Instructions for eliminating intersectional leaks are somewhat more complicated.

The diagram will make it clear how the sections are connected.

- Close the heating riser and unscrew the plugs or open the vent valves. If there are valves on the connections to the battery, simply close them.

- Substituting a basin or other container with low walls under the lower blind radiator plug, unscrew the plug a few turns and let the remaining water drain off. Unscrew the plug completely; if necessary, use a stick or any other handy tool to free the lower manifold from dirt.

Attention:

on blind plugs, in most cases, left-hand thread; they unscrew clockwise.

- Repeat the operation with the upper plug.

- Mark the distance from the edge of the battery to the nipple you need on the radiator key.

- Insert the key into any of the manifolds and, turning, push it into the radiator until it engages with the desired nipple.

- Unscrew one turn. The direction of rotation is the same as that of the plug.

- Repeat the operation with the nipple on the second manifold.

- Unscrew the nipples one turn at a time, one at a time. A misalignment caused by uneven unscrewing will jam or break the nipple.

- Remove the outer sections; Place new gaskets on the nipples and thread the nipples onto one thread.

- Install the end sections, press them against the nipples and screw them with a wrench until they engage securely.

- Reassemble the heater upside-down.

Bulkhead cast iron battery.

Based on materials from "On Trubakh.ru".

The intersectional radiator gasket serves as a sealing element in these heaters. It prevents leaks at the joining points of the sections, thereby extending the battery life and improving the quality of heating.

These elements seal the joints of the sections in the heating radiators.

Radiator connection kit overview

Good afternoon, dear readers. Today we will consider a rather light, but no less important topic: "Review of the kit for connecting an aluminum radiator (futorki)"

I won't write anything in the introduction, and it's better to get down to business right away.

Before us is almost complete connection (except for taps).

- mountings for radiators with dowels

- a set of connection for 4 pcs., An air vent (Mayevsky's tap), a plug, a key for an air vent

Fastening a radiator with a dowel.

The mount is metal covered with white paint, which will not stand out against the background of the radiator. First, we drill a hole in the wall, hammer in the dowel, twist the mount into the dowel. The radiator lies in the recess of the fastening. To mount the radiator for better fixation, you will need 4 pcs. fastening.

Futorka (right)

The set includes 2 pcs. shorts with gaskets. They are also painted white to make them stand out. They are screwed onto the radiator without much difficulty. If you look closely, you can see the letter "D" on the footboard - this means which side the footboard is screwed on. in this case "right".

Futorka (left)

Everything is the same with the coating and application as the previous footwear, only here there is the letter "S" and, accordingly, the connection is "on the left".

Plug

The plug is screwed into the foot just to plug it if there is no connection on this side. The plug is screwed into absolutely all footwear, be it left or right foot. Plug color white, complete with gasket.

Air vent or Mayevsky crane

The function of the air vent is to remove the air that has formed in the heating system, or rather in the radiator. The air vent is mounted in such a way that the drain (small thin hole) is downward.When all the air is vented from the radiator, you need to drain a couple more liters of water and, accordingly, so that water does not splash in all directions, but strictly downward, the direction should be down

Note this mounting detail as the direction of the air vent hole. Air vent color white, gasket included

Airline key

You can open the air vent using a special key for this. If you do not have a key or you have lost it, you can use a regular flat screwdriver, just do not go to the construction markets specifically for it. There were such cases when this key was sold)))

Futorka with a plug assembly (left), a futorka with an air vent assembly (right)

This is how the assembled footwear looks like, whether it is a plug or a vent, or there is a continuation of the pipe suitable for the radiator.

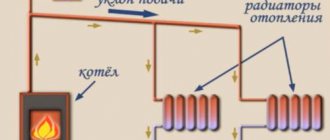

Connecting an aluminum or bimetallic radiator.

Here is a schematic illustration of how the radiator (battery) is connected. I think it is unnecessary to explain something. Everything is perfectly shown. We connect either a ball valve with an extension with a pipe, or a plug, or an air vent into the footboard. But in any case, we will have a supply pipe to the radiator, a return pipe from the radiator, an air vent (always put in the upper part of the radiator, a plug.

Cutaway upper part of aluminum radiator with foot

This is what a screwed-in case looks like into a radiator. As you can see, the futorka is screwed into the radiator well and deeply, which is quite reliable.

The box is screwed into the radiator (connection from the bottom)

Here we screwed the foot ("D" -right) into the one-piece aluminum radiator. to show how she looks from this side.

Fittings at first glance are very simple and insignificant, but choose even these parts wisely. And remember, it is always better to entrust the business to professionals, both in terms of sales and installation.

Thank you for your attention, we will soon prepare you more necessary and interesting articles.

Varieties

Material

Gaskets for cast-iron heating radiators are made of paronite (heat-resistant hard rubber) in accordance with the requirements of GOST 15180-86. The standard regulates the main dimensions of products (by the way, not only paronite ones) and their mass in batches of 1000 units.

Gaskets for bimetallic radiators and aluminum batteries can be made from both paronite and heat-resistant silicone.

Which of the two materials is more preferable?

It is difficult to give a definite answer.

- Paronite, due to its rigidity, more effectively resists the internal pressure of the coolant;

- Silicone, on the other hand, does not lose its elasticity over time and requires less pulling force to reliably seal the joint.

The photo shows a silicone product.

Dimensions and shape

A paronite gasket for a cast iron radiator is always in the form of a flat ring.

Products intended for aluminum and bimetallic batteries can be in the form of both a flat ring and a toroid (donut).

Note: Toroidal silicone gaskets are used to seal annular groove sections. If you try to squeeze them between sections or between a plug and a flat section, you will find that the silicone will squeeze out.

The diameter of the hole in the flat gasket is determined by the type of radiator and the diameter of the nipple. The nipple is supplied with the following thread sizes:

Dismantling of bimetallic and aluminum sectional products

To disconnect the radiator from the system and remove it from the mounting location, proceed as follows:

- Stop water circulation and relieve pressure.

- If the radiator is hot, you need to wait until it cools down and then disconnect from the system. To do this, unscrew the inlet and outlet couplings.

- Move the coupling away from the radiator along the pipe and remove the device from the brackets.

- Drain off remaining water and place the product face up in the disassembly area.

- Pull out and rinse the filter immediately so that dirt does not dry on it.

Dismantling of bimetallic and aluminum sectional products

In the next step, the radiator is disassembled into separate sections. To avoid damage during operation, you need to figure out which direction you need to turn the nipple-nut. This element is a ring nut with an external thread and grooves inside on both sides. In this case, one nut has both a right-hand and a left-hand thread. If you unscrew it, then the adjacent sections of the battery will move apart evenly, and when twisted, they will contract.

Typically, manufacturers make marks on the face of plugs and butts to indicate the thread direction. O stands for right-handed thread, "S" for left-handed thread. To accurately determine the direction of movement, it is recommended to take a loose nipple-nut and try to thread it onto the thread in the radiator. Having decided in which direction it is twisted, it will become clear where to turn the key in order to separate the sections.

Important! If the nipple-nut is turned in the wrong direction, you can easily break off the thread on it and on the radiator

Having decided on the direction of the thread, insert the nipple wrench into the radiator and slide it to the desired nut. The notches on the tool will help to do this. When it is in the grooves, insert the lever into the hole on the other side of it. Force is required to move the nut. Call an assistant to fix the radiator in one place.

Repair of bimetallic radiators

When the nut has advanced half a turn, go to the other side to unscrew the other, and follow the same procedure. After making sure that both nuts rotate without applying great physical force, gradually unscrew one or the other side, moving 5-7 mm.

Gasket between radiator sections

After disconnecting, take away the metal spacers that were between the sections. If they are in good condition, then they can be installed back during assembly, if in poor condition, then use them as a sample for buying new ones. Silicone gaskets must be changed.

Varieties of products

In most cases, all components are purchased with the purchase of the batteries themselves. In a hardware store, consultants are required to know which gaskets are required for bimetallic radiators, and which ones are needed for cast iron products. But often the buyer goes exclusively for spare parts. Therefore, it does not hurt to prepare in order to acquire what you need.

Paronite elements

Paronite is a modified rubber.

They are made from compressed rubber with the addition of asbestos fibers and powder substances.

This type of inter-sectional radiator gasket is most often used in apartments with central heating.

- Perfectly withstands temperature conditions of + 85-100º.

- The most popular is the product made according to GOST No. 15180-86. For production, paronite PMB, PON-B and PC, as well as reinforced paronite, are used.

- Products are made by cutting on a press or cutting with circular scissors, as well as a plotter.

General purpose paronite gaskets

- Such seals are effective for liquid and gaseous pipelines.

Note! Such gaskets for cast iron heating radiators are used in pipes with water, steam, various solutions, as well as oils. They do not react to inert gases, ammonia in different states, alcohol, nitrogen, oxygen.

- They are designed for temperatures from -50º to + 450º.

- They are supplied with PON-B and GOST markings No. 15180-86.

Oil-resistant analogs

- It is recommended for pipelines carrying oily liquids and gases.

- It is better to use them where the coolant passes, which is a technical oil, as well as oil products, hydrocarbons in a liquefied or gaseous state, molten wax, coke oven gas, nitrogen, oxygen.

- Temperature range from -50º to + 450º.

- Marked as PMB.

Acid Resistant Modified Rubber

- Keeps tightness in flange connections of pipelines carrying aggressive connections, for example, antifreeze.

- The gaskets work effectively in contact with acids and alkalis, organic solvents and various gases.

- Withstand from -50º to + 250º.

- Supplied with PC brand.

Reinforced products

This is how reinforced products look like.

- A gasket for a cast-iron radiator equipped with a reinforcing mesh is mounted in the intersection space of household batteries, including.

- The seal holds steam, water, various gases, oily substances.

- Temperature range -50º to + 450º.

- PA marked.

Manufacturing methods

By their shape, gaskets for cast iron batteries can be flat or convex. They are used for different types of structures.

In particular, flat sealing elements are made from sheet materials such as plastic, rubber, paronite or leather. In their production, methods such as punching or cutting with punching knives, as well as cutting with a laser or circular knives are used.

A convex gasket for a cast iron radiator and any other metal variety of batteries is produced by thermoforming from polyvinyl chloride, as well as by vulcanizing raw silicone or rubber.

Purpose and application

To organize long-term sealed joints in the middle of the heating battery sections, different types of gaskets are used. This is a small, but very important functional part of the heating device has a number of special qualities that ensure the safe operation of the system, a long period of operation in especially difficult conditions at high pressures and temperatures.

Intersectional gaskets for radiators guarantee the tightness of the connection of elementary heating units of the heater. It is fastened with a nipple - a short tube with threaded connections, pressed between the surfaces of the channel sections from above and below. Apart from this, spacers are used when securing plugs on batteries. In low-temperature environments in heat supply systems with natural circulation, where there are no high water pressures, a roll-up can be used - flax soaked in silicone or dye.

Cutting with circular knives

Only large round seals can be produced in this way. In the process of work, you will need rather cheap and high-performance equipment. Cutting is done with standard blades. Therefore, the production of gaskets of this type can be performed independently and in any volume. Often the cause of radiator leaks is a damaged gasket. And if you do not know what to do if the heating battery leaks, first of all you should pay attention to the gaskets.