Did you like the article? Stay tuned for new ideas and useful auto tips in our channel. Subscribe to us on Yandex.Dzen. Subscribe.

The radiator is a technically complex unit, on which the efficiency and uninterrupted operation of the engine depend. Considering this, it is not recommended to carry out diagnostics and repair work on your own.

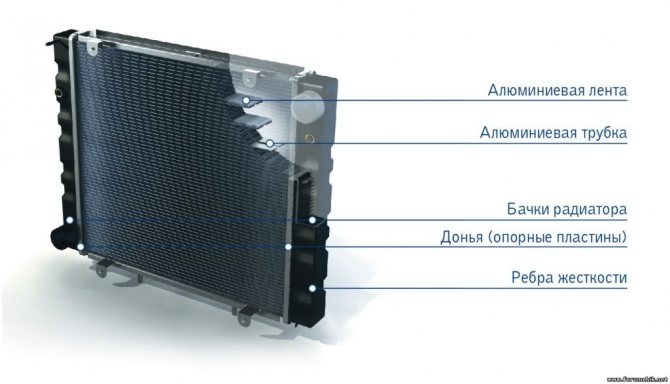

Types of radiators

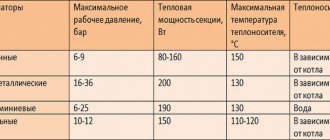

Radiators may differ in assembly method, material of manufacture and optional components. They can be divided into the following options:

- Prefabricated radiators. In them, the connection of the components was carried out mechanically. Such an assembly is notable for its affordable cost, the joints of such models needed sealing gaskets, which are resistant to antifreeze and temperature extremes;

- Copper radiators. They are more expensive, but damage to them can be easily repaired by sealing;

- Aluminum radiators. Such products are more durable and reliable, but aluminum gives off heat worse than copper.

Antifreeze as a coolant for aluminum radiators

As a coolant, you can use not only ordinary water, but also a specially produced antifreeze. Such mixtures do not freeze even at low temperatures, without changing their qualities at all. Each variety is designed for its own limits, this must be taken into account when choosing.

Antifreeze contains special additives that inhibit corrosion and various mineral deposits.

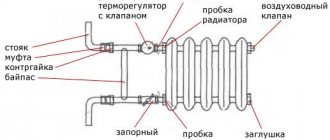

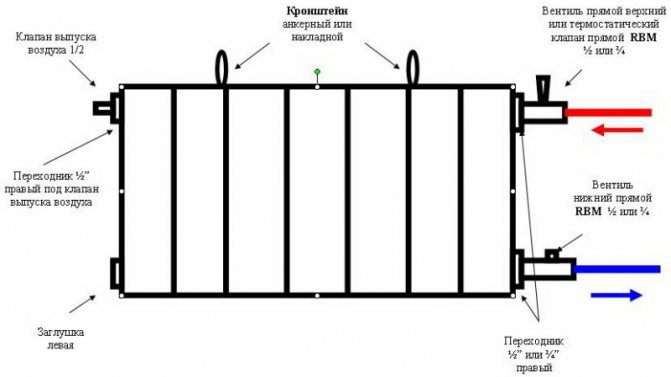

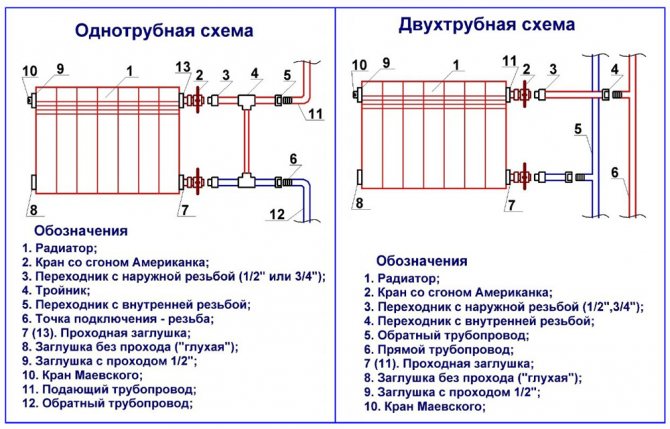

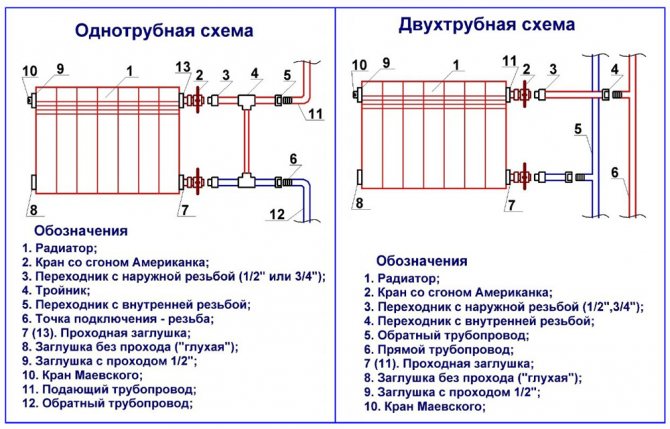

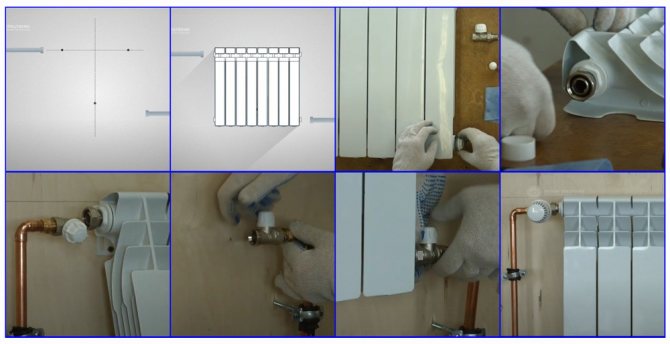

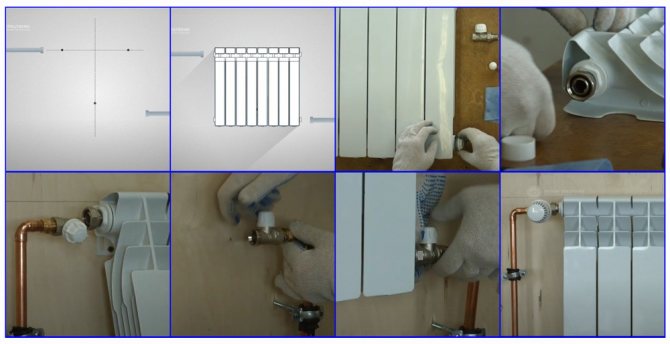

Installation diagram of an aluminum radiator.

But when buying, you should choose exactly those compositions that are suitable specifically for aluminum heating radiators. But such coolants also have their drawbacks:

- heat capacity is fifteen percent lower than that of water;

- high viscosity, that is, a pump is needed to ensure circulation in the system;

- strong expansion is observed when heated;

- fluidity is 50 percent higher than that of water, that is, high demands are placed on sealed joints;

- ethylene glycol antifreezes are poisonous, they can only be used for single-circuit boilers.

Radiator and corrosion

When the cooling system stops functioning, it is necessary to carefully examine it to determine the defect. Spent refrigerant can cause corrosion on the radiator surface. It begins to ionize almost immediately after refueling. In this case, the liquid begins to destroy surfaces of metal, to which it can come into contact, moving through the system.

Old ionized refrigerant can cause damage after just a few weeks of operation. When the radiator starts to leak, it can be due to mechanical damage or corrosion. It can occur for many reasons, including poor quality coolant, the presence of salts in the water, or damage to the protective coating of the device. Timely elimination of the defect will help prolong the performance of the automotive part.

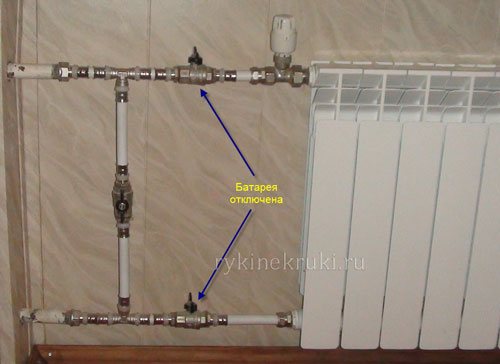

How to regulate heat in batteries

Suppose you put a battery of 10 knees in the room, and you feel good with it when it is -20 degrees outside the window. But now, the cold has passed and now it has been -2 degrees for several days. Hot water, as is often the case with us, of the same temperature continues to flow in a powerful stream through our pipes and a gas chamber is formed in the room, from which there is no escape. In this case, the temperature regulator comes to the rescue. There are many of them in nature. In the picture below you can see one of them.

What brand the thermostat should be is a topic for a separate article. And now it is important for us to understand the principle. The figure shows one of the simplest thermostats. It has a knob on top that you can rotate and set values from 0 to 5:

5 - means that the entire flow of hot water will pass through the battery; 4, 3, 2, 1 - means that the regulator will reduce the diameter of the flow pipe, providing less hot water flow through the battery per unit of time. Thus, a 4 battery will be colder, a 3 even colder, and so on.

If you want to disconnect the battery at all, then you can set "*" - the water flow will be very small. Practically it will not be:

Or you can simply shut off the ball valves on the battery. The effect will be approximately the same:

If you have 2 windows in the room and 2 heating batteries under them, then even during installation it is advisable to install them wisely. For example, you need 20 sections for the whole room. Then it is better to put, for example, 12 sections on one battery, and 8 sections on the other. In this case, in addition to the regulator on each of the batteries, you can completely turn off or turn on 8, 12 or all 20 sections at the same time.

Elimination of radiator defects

The condition of the radiator should be checked regularly. This is especially important before a long trip. When a leak appears in the radiator due to corrosion, it is necessary to use special sealants or cold welding. Small leaks in the cooling system will help fix the seals. For these purposes, the sealant is poured into the tank of the cooling system. In contact with air, such substances solidify, forming a polymer film that reliably closes the leak. Cold welding is a more difficult type of repair. It is used in the presence of large cracks.

Heat-resistant adhesive sealants that resemble plasticine are applied to the damaged surface. The sealant sets within a few minutes, but full hardening may occur much later. Sometimes this takes a whole day. These remedies are, in fact, emergency. In the near future it will be necessary to contact a car service for more substantial repairs, otherwise the radiator will have to be replaced with a new one. Even if "cold welding" can last for several years, it is still not worth the risk.

Ethyl alcohol based antifreeze

You can make your own radiator mix. To do this, you need: distilled water and 40% ethyl alcohol.

To use antifreeze in the heating system, it is not always possible to fill in ready-made purchased mixtures. In this case, you can use a coolant that is easy to prepare with your own hands. How is this possible, you ask? Everything is very simple, such a coolant is an antifreeze mixture of distilled water and forty percent ethyl alcohol. A similar antifreeze, prepared by hand for a heating system, has the following characteristics:

- the viscosity of the liquid is slightly higher than that of water, but much lower than that of purchased antifreezes;

- fluidity is less than antifreeze, which makes it possible to somewhat reduce the requirements for the tightness of the circuit connections. Rubber seals are not damaged when using just such a liquid;

- Alcohol-based blends have another advantage, making them an excellent choice for metal radiators. The fact is that alcohol prevents the development of corrosion, and this is important for systems, the destruction of which can lead to a variety of troubles;

- in this case, it is recommended to use hard water for the heating system, which, together with alcohol, prevents the formation of scale on the inner surfaces. The precipitate is formed in a solid form, with preventive flushing it is very easily removed from the system;

- when the alcohol content in the mixture is from 30 percent, it does not evaporate separately;

- the boiling point of the alcohol heat carrier is approximately equal to the value for ordinary water. That is, when the temperature rises to 85 degrees Celsius, it does not boil with the formation of large masses of steam;

- alcohol in the coolant reduces thermal expansion, that is, heating pipes and other elements are not damaged during freezing.

Related article: Convenient finishing of slopes with pvc f profile

If you have to choose between water and an alcohol mixture, then many experts recommend giving preference to the second option (if the boiler design allows it). The proportions of such a composition are calculated based on what temperature values are planned:

If for some reason the boiler is turned off, it is imperative to drain the hot water from the radiator, otherwise the pipes may rupture.

- when the temperature drops to minus 10.6 degrees, the alcohol content should be 20.3 percent;

- with a decrease to a value of minus 23.6 degrees, the alcohol content is 33.8 percent;

- when freezing to minus 28.7 degrees - the alcohol content should be 39 percent;

- with a decrease to minus 33.9 percent, the alcohol content is 46.3 percent.

When preparing a coolant for aluminum radiators, the volume must be calculated based on the fact that one liter of 96% ethyl alcohol contains 960 ml of anhydrous alcohol. To get a 33% alcohol solution, you need to divide 96 by 33, which will give a volume equal to 2.9 liters. When water is added to one liter of alcohol in an amount of 2.9 liters, we get a 33% alcohol solution, which is an excellent coolant poured into an aluminum radiator for a heating system. The resulting solution will not freeze even at temperatures down to minus 22.5 degrees.

When should antifreeze not be used? But it is not always possible to use such a convenient and effective coolant as antifreeze for a heating system. If you are still choosing which one to use, consider the following factors:

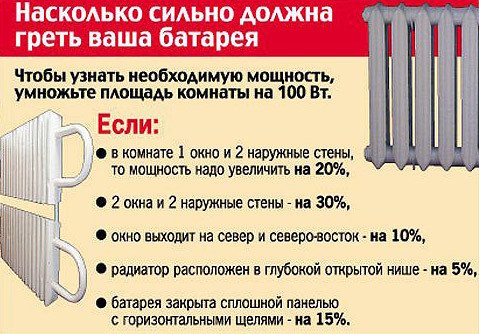

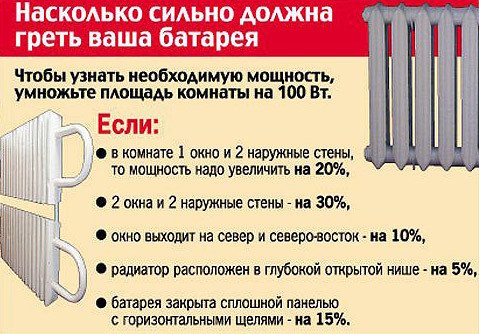

Calculation of the required power of the radiator.

- it is categorically impossible to take antifreeze if ion (electrolysis) boilers are used. In them, heating is carried out by passing current through the entire volume of the boiler tank, and this is unacceptable for antifreeze. When designing a home heating system, make sure that it can be used with a certain type of heat carrier;

- antifreeze must not be used in an open system. But in this case, such a prohibition applies only to those mixtures that are produced on the basis of poisonous ethylene glycol, the rest can be used in open circuits, if there is a manufacturer's indication for this;

- the temperature must not be reduced more than to minus 20 degrees. This can seriously reduce the characteristics of the additives included in the composition, that is, corrosion foci will appear inside the system, scale will appear;

- when making sealed joints, it is not recommended to use linen roll, which is covered with ordinary oil paint on top. When using antifreeze in heating aluminum radiators, it is allowed to use linen winding only with sealants, since oil paint is easily corroded by antifreeze, and this leads to a complete loss of tightness;

- antifreeze must not be used when galvanized fittings and pipes are used for the heating circuit;

- when the boiler heats the coolant to a temperature above 70 degrees Celsius, it is no longer possible to use antifreeze. This value is the limit for most of these mixtures, which have the highest thermal expansion at higher heating.

Related article: Making an arch in an apartment with your own hands: a photo and an option for decorating with decorative stone and wallpaper

How does corrosion in pipes appear and what does it lead to?

As the water temperature rises for every 10 ° C, its ability to cause corrosion doubles and the ability to dissolve CaCO3 and CaSO4 salts decreases, which leads to accelerated scale formation.

However, it is not only reactions between different chemical elements that harm heating systems. Substances that are dissolved in any water have the ability to settle and attach to the walls of streams.

These chemical processes contribute to the formation of rust and scale in the heating system, which reduces pipe clearance and heat transfer.

A corrosion inhibitor is used to prevent or slow down corrosion processes in heating systems. Various additives and reagents are used to reduce the formation of scale.

Installation and connection of heating radiators

Before carrying out work, they purchase accessories - adapters with hooks; dowels with screws are often included in a typical kit. They also buy a thermostat and two valve or ball valves.

To drill the holes, you will need a screwdriver or drill with a suitable drill for the dowel. You also need to have a building level, a tape measure and a pencil, an adjustable plumbing wrench.

Before carrying out work, determine the location and dimensions of the battery according to the following rules:

- the heat exchanger is positioned symmetrically about the central axis of the window;

- it should be suspended at a distance of 100 - 120 mm from the bottom surface of the window sill;

- the distance between the floor and the battery should not exceed the range of 80 - 120 mm;

- the optimal clearance between the battery and the wall is 30 - 50 mm;

- the total length of the battery is 70 - 80% of the width of the window under which it is fixed.

For hanging bimetallic radiators, at least three brackets are used - two at the top and one at the bottom.

When connecting bimetallic heating radiators, you may need information about: Pipes for heating - what are the types of modern pipes, as well as what is better to choose when installing a heating system in a private house or apartment

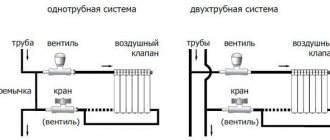

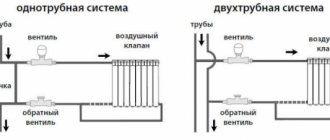

Fig. 13 Diagrams for connecting radiators to a vertical riser in communal apartments

Diagonal connection of a bimetallic radiator with a thermostat with pre-drawn pipes is carried out in the following sequence:

Attaching the retaining hooks

- First, markings are carried out on the wall. Outline the central vertical line, then symmetrically apply the radiator to the wall (you will need the help of a second worker) and make marks with a pencil through its edges.

- Two points under the horizontal section of the section are placed at the top and one point at the bottom near the center line.

- Next, drill holes of the required diameter and install the radiator mounts on the dowels with screws.

- They hang the battery and check the correctness of its installation - it must firmly rest on all brackets without gaps.

Connection of fittings

- Use a wrench to screw in four 1-inch and 3/4-inch radiator adapters that have sealing gaskets. In theory, they can be screwed in without any additional winding, but it is better to use flax. The fact is that when aluminum and steel threads come into contact, their partial destruction occurs over time, lime deposits settle in the free cavities and after a certain time the adapter sticks and cannot be unscrewed with an adjustable wrench.

Flax prevents the formation of deposits by blocking free channels, which greatly facilitates further dismantling of the fittings and disassembly of the battery.

- At the top of the radiator, a connecting sleeve (American) is screwed to connect the thermostatic head, from below, diagonally, the same American is installed at the battery outlet.

- A plug is installed on the free exit at the bottom, flax is used to wind up the parts. Opposite the thermostat, the Mayevsky tap is screwed into the adapter with an adjustable wrench.

- Next, a thermostatic head with a regulator turned towards the room is screwed onto the upper inlet pipe.

- A shut-off valve (ball valve) is screwed onto the diagonal outlet pipe from below.

- After that, the radiator is hung on the brackets and connects its inlet and outlet with the thermostatic head at the top and the shut-off valve at the bottom, using the cap nuts of the American women.

Fig. 14 Connecting bimetallic heating radiators - basic steps

Bimetallic radiators are one of the latest technological developments of the world's leading manufacturers, which can be effectively used both in communal and individual heating systems. The methods and options by which the connection of bimetallic heating radiators is made is no different from the connection of popular aluminum radiator heat exchangers.

Important nuances of installing radiators

Important nuances of installing radiators

All other things being equal, diagonal connection of radiators is the best option. This method is especially well suited in situations where batteries from multiple sections are connected.

Practice shows that it is better to install 2 batteries next to 6 sections, rather than one to 12.

The lateral connection option does not significantly differ from the diagonal technology if an assembly is being installed, consisting of a relatively small number of sections. The diagonal connection begins to surpass all other options in cases where the unit consists of more than 6-8 sections.

Special attention should be paid to the paint and varnish composition, which was used to finish the bimetallic battery. During the installation of the unit, be careful not to spoil the coating, otherwise it will peel off very quickly in the future.

All scratches and other damage must be covered with a similar paint and varnish composition as soon as possible in order to prevent further expansion of the damage. It is better to buy a suitable finish in advance, so as not to waste time looking for it later, because self-assembly of the battery rarely takes place without damage.

It is highly recommended that you arm yourself with the support and help of an experienced technician who will make sure that nothing is damaged during the battery connection process. In the absence of such an opportunity, be extremely careful.

It is recommended to remove the cellophane with which such products are wrapped only after the installation is complete and the unit is connected.