What is the principle of the gravitational heating system

Gravitational heating is also called natural circulation system. It has been used for heating houses since the middle of the last century. At first, the common population did not trust this method, but seeing its safety and practicality, they gradually began to replace brick stoves with water heating.

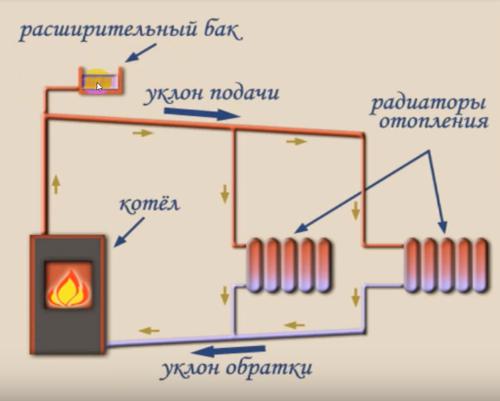

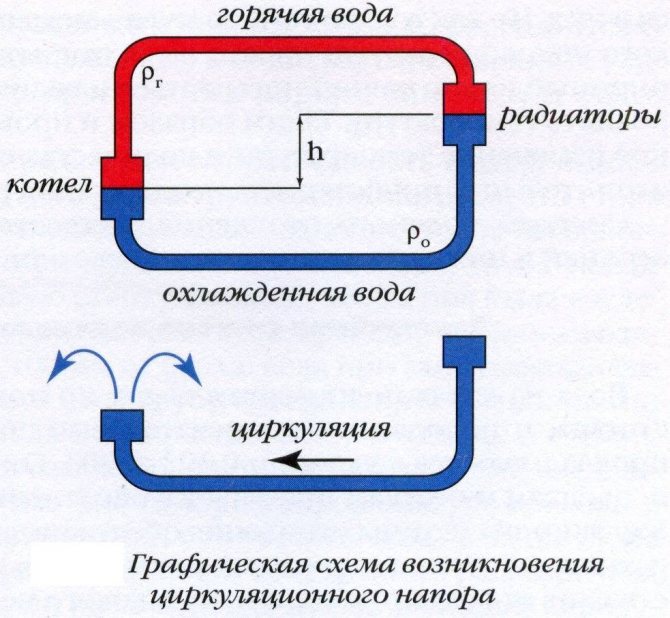

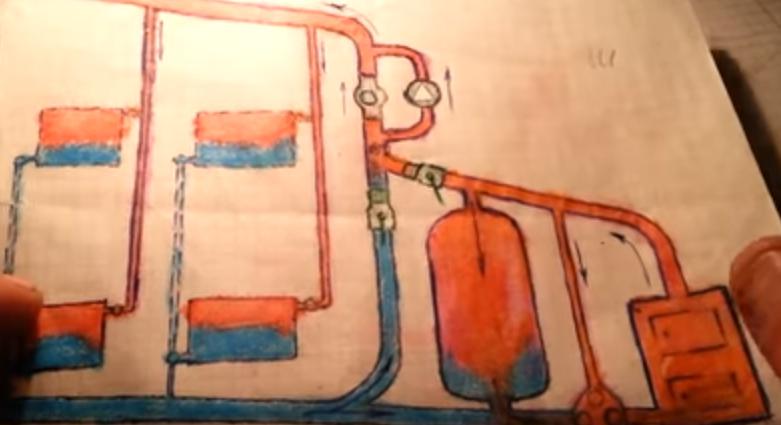

Then, with the advent of solid fuel boilers, the need for bulky furnaces disappeared altogether. The gravitational heating system works on a simple principle. The water in the boiler heats up and its specific gravity becomes less cold. As a result, it rises along the vertical riser to the top of the system. After that, the cooling water begins its downward movement, and the more it cools down, the greater the speed of its movement. This creates a flow in the pipe towards the lowest point. This point is the return pipe installed in the boiler.

As it moves from top to bottom, water passes through the radiators, leaving some of its heat in the room. The circulation pump does not participate in the movement of the coolant, making this system independent. Therefore, she is not afraid of a power outage.

The calculation of the gravitational heating system is done taking into account the heat loss of the house. The required power of the heating devices is calculated, and on this basis the boiler is selected. It should have a power reserve of one and a half times.

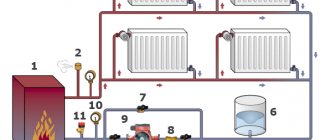

Natural circulation heating circuit

Heating schemes with natural circulation of the coolant are not particularly popular today due to their "morally old age", low efficiency, bulkiness, high cost of materials and installation, the impossibility of differentiated temperature control in individual radiators, etc.

But they are indispensable in those houses where there is no electricity, since such systems equipped with a solid fuel boiler can work autonomously (with the periodic presence of a person, of course).

The principle of operation of a heating system with natural circulation (it is also called gravity) is to create a temperature difference between the coolant at the outlet from the boiler and its inlet. Due to the different density of the coolant at different temperatures, it moves through the pipes by gravity, without using a circulation pump, that is, warm water rises up, and already cooled water "comes" from the return pipe in its place. As it passes through the radiators, the coolant lowers its temperature, giving off heat to the environment, and after a “full circle” and returning to the boiler heat exchanger, it heats up again, and the cycle repeats.

The volume of the coolant in such systems is quite large and depends on the diameter of the pipes and the length of the system. On average, the volume of water will be 3 times more in a natural circulation system than in a forced circulation system. And this is with an equal area of heated rooms.

A large amount of coolant in the system increases its inertia. There is also a positive point in this, if the boiler "goes out", the heat in the system will remain for some time. And in the case of using antifreeze in the heating system, you simply pay for additional tens of liters of this substance.

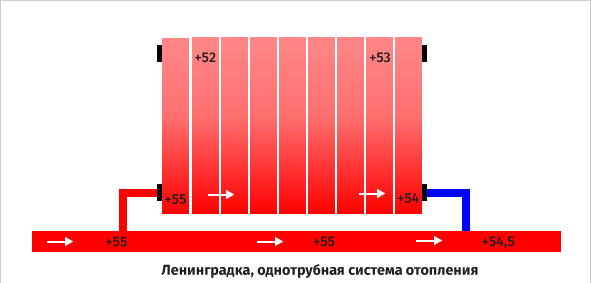

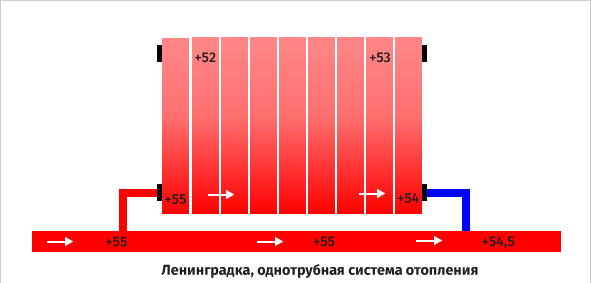

The sequential passage of the coolant through the heating radiators leads to its cooling.Thus, those radiators located at the beginning of the system (from the central riser) will heat up more than those located at the end of the heating main (in front of the boiler). It is practically impossible to regulate the degree of heating of radiators with such a connection.

Another feature of such a system is its "picky" to the material of the pipes used. Without fail, they must be metal - usually steel. Polymer pipes simply cannot withstand the high temperatures that can arise in the system when the coolant in the boiler overheats. The consequences of such a "limitation" in the choice of materials are the low efficiency of the entire system as a whole, the high cost of installation and the nullification of the aesthetics of modern heating devices with a large diameter of steel pipes and the cumbersomeness of the entire system as a whole.

An obligatory element of such a heating system is, which must be at the top of the system. Its volume should be approximately 1/10 of the volume of the coolant in the system. For example, if the volume of the coolant in the system is 200 liters, the capacity of the tank should be 15-20 liters. The open tank type assumes that the system is constantly in contact with atmospheric pressure. This is also a prerequisite for the existence of the system.

Summing up the results.

Gravity flow has the following advantages:

- the possibility of autonomous use;

- sufficiently high thermal inertia.

Disadvantages:

- a large volume of coolant (antifreeze);

- unaesthetic "bulkiness";

- low efficiency;

- expensive (difficult for self-execution) installation;

- quite high cost;

- lack of the ability to adjust the temperature.

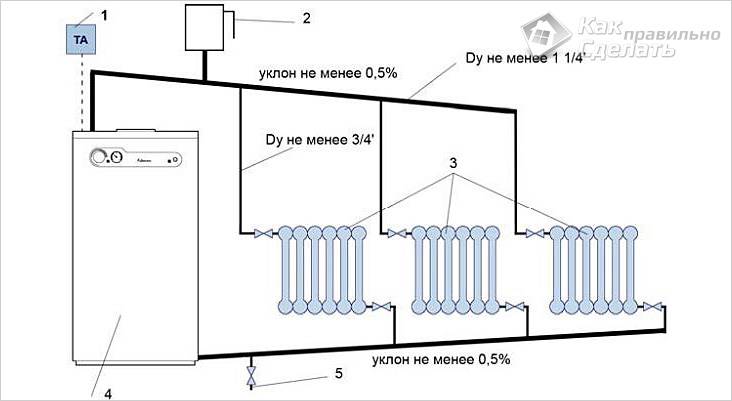

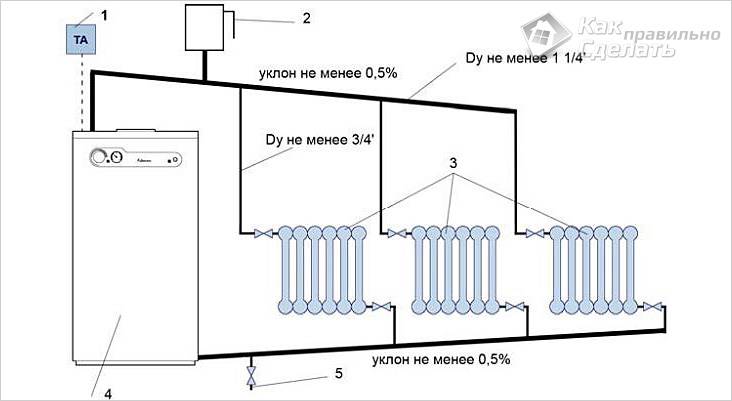

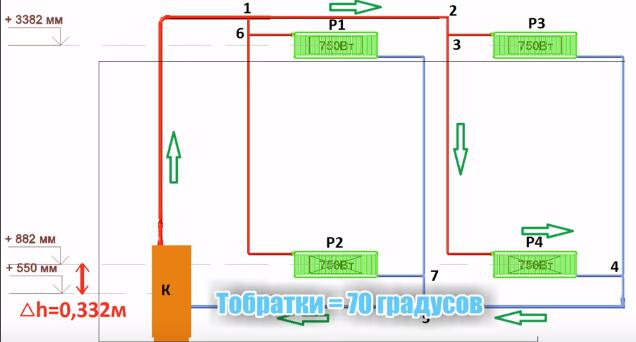

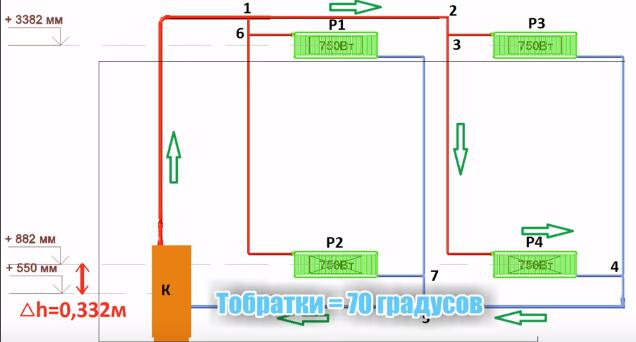

Parallel two-pipe version of the heating system of a private house

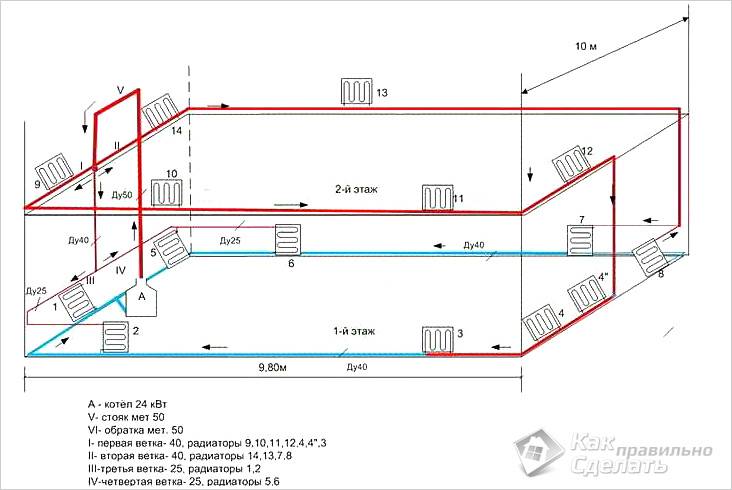

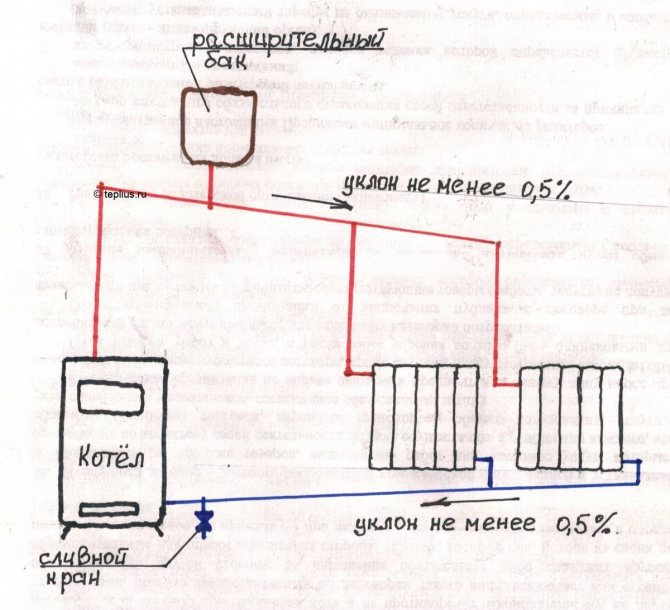

In the system, the diagram of which is shown in the figure, the temperature of individual radiators will no longer strongly depend on the location, it is already possible to regulate the temperature of individual radiators, but not all! The slope of horizontal pipes (risers) and their sufficiently large diameter are also required.

Let's move on to the next diagram of the heating system.

Description of the circuit

In order for such heating to work, the ratios of pipes, their diameters and angles of inclination must be correctly selected. In addition, some types of radiators are not used in this system.

Consider what elements the entire structure consists of:

- Solid fuel boiler. The entry of water into it should be at the lowest point of the system. Theoretically, the boiler can also be electric or gas, but in practice they are not used for such systems.

- Vertical riser. Its bottom is connected to the boiler feed, and the top forks. One part is connected to the supply pipe, and the other is connected to the expansion tank.

- Expansion tank. Excess water is poured into it, which is formed during expansion from heating.

- Supply pipeline. In order for the gravitational hot water heating system to work effectively, the pipeline must have a lower slope. Its value is 1-3%. That is, for 1 meter of pipe, the difference should be 1-3 centimeters. In addition, the diameter of the pipeline should decrease with distance from the boiler. For this, pipes of different sections are used.

- Heating devices. Either large-diameter pipes or cast-iron radiators M 140 are installed as them. Modern bimetallic and aluminum radiators are not recommended to be installed. They have a small flow area. And since the pressure in the gravitational heating system is low, it is more difficult to push the coolant through such heating devices. The flow rate will decrease.

- Return pipeline. Just like the supply pipe, it has a slope that allows water to flow freely towards the boiler.

- Taps for drainage and water intake.The drain cock is installed at the lowest point, directly next to the boiler. The tap for water intake is made wherever it is convenient. Most often this is a place close to the pipeline that connects to the system.

Types of systems

Gravity system

As already mentioned, there should be no height differences in a gravity heating system, otherwise it simply will not work. For this reason, multiple contours can be made.

Single-circuit

Connection diagram with natural circulation

Everything is very clear here - one pipe goes from the boiler, and the other to it, and batteries are connected between them. The presented diagram will help you figure it out.

A single-circuit system can be a single-pipe system, only in this case it is necessary to take into account the factor that each subsequent battery in a gravity system will be sensitively colder than the previous one.

Double-circuit

Dual-circuit system

Double-circuit systems may differ in the direction of movement of the coolant:

- With oncoming traffic.

- With passing traffic.

The choice of the method for installing pipes, taking into account the direction of movement of the coolant, mainly depends on where the doors are located in the room or there are other nuances due to which the installation of the return pipe in this place is impossible.

Regardless of the system selected, the slope angle of the pipes does not change.

disadvantages

Proponents of closed systems cite a lot of disadvantages of gravitational heating. Many of them look far-fetched, but still we list them:

- Ugly appearance. Large diameter supply pipes run under the ceiling, disrupting the aesthetics of the room.

- Difficulty in installation. Here we are talking about the fact that the supply and return pipes change their diameter stepwise depending on the number of heating devices. In addition, the gravitational heating system of a private house is made of steel pipes, and they are more difficult to install.

- Low efficiency. It is believed that closed heating is more economical, however, there are well-designed natural circulation systems that work no worse.

- Limited heating area. The gravity system works well in areas up to 200 sq. meters.

- Limited number of storeys. Such heating is not installed in houses higher than two floors.

In addition to the above, gravitational heat supply has a maximum of 2 circuits, while in modern houses several circuits are often made.

Two-pipe heating system

There are two options for connecting radiators to the heating system:

The only plus of a one-pipe system is savings on pipes. But the minus is significant - the radiator closest to the boiler is the hottest, and the farthest one is the coldest. And it is also problematic to turn off some kind of radiator - they are all in the same circuit. If this is not critical, why not use this option? This is a perfectly normal scheme.

The two-pipe scheme is more flexible:

- All radiators are in almost equal conditions. Water is supplied to each of the same temperature;

- You can set your own temperature on each radiator by regulating the flow of water through it;

- You can painlessly shut off the water supply to any radiator, for example, when it is hot or you need to flush the radiator;

- More convenient for increasing the number of radiators.

For the sake of fairness, it must be said that in the two-pipe version, the last radiator is somewhat "offended", it gets less heat. The reason is that the pressure difference between supply and return on it is practically zero and the water flow is minimal.

So what choice did I make?

That's all for today. In the following articles I will bring to your attention a gas heating system, underfloor heating, infrared heating. Comment, ask questions. Thanks, see you!

The centralized heating system does not always cope with the tasks assigned to it.Therefore, many are striving for energy independence and are worried about the device of autonomous heating. This is especially in demand in private houses, where there is often simply no centralized heating system. There are various heating schemes for a private house, but you just need to choose the one that suits the specific conditions of your home.

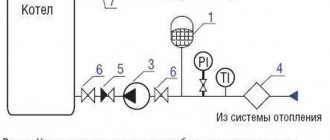

Differences in the operation of a solid fuel boiler

The heart of any heating system is the boiler. Although it is possible to install the same models, operation with different types of heating will differ. For normal boiler operation, the temperature of the water jacket must be at least 55 ° C. If the temperature is lower, then in this case the boiler inside will be covered with tar and soot, as a result of which its efficiency will decrease. It will need to be constantly cleaned.

To prevent this from happening, in a closed system, a three-way valve is installed at the outlet of the boiler, which drives the coolant in a small circle, bypassing the heating devices, until the boiler heats up. If the temperature begins to exceed 55 ° C, then in this case the valve opens and water is added to the large circle.

A three-way valve is not required for a gravity heating system. The fact is that here the circulation does not occur due to the pump, but due to the heating of the water, and until it heats up to a high temperature, the movement does not begin. In this case, the boiler furnace remains constantly clean. The three-way valve is not required, which makes the system cheaper and simpler and adds pluses to its merits.

The essence of the system

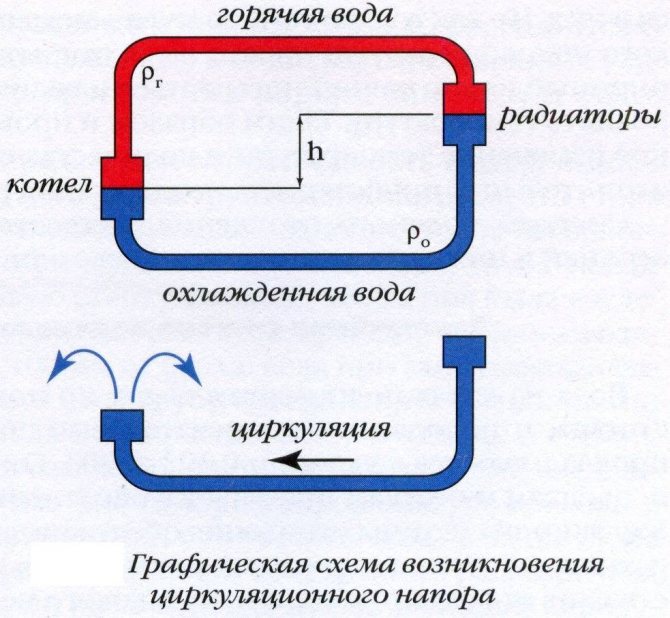

How does circulating pressure arise?

The flow movement through the pipes of the heat-carrying fluid is due to the fact that with a decrease and increase in its temperature, it changes its density and mass.

The change in the temperature of the coolant occurs due to the heating of the boiler.

In the heating pipes there is a colder liquid that has given up its heat to the radiators, therefore its density and mass is greater. Under the influence of gravitational forces in the radiator, the cold coolant is replaced by the hot one.

In other words, having reached the top point, hot water (it can be antifreeze) begins to be evenly distributed over the radiators, displacing cold water from them. The cooled liquid begins to descend into the lower part of the battery, after which it completely goes through the pipes into the boiler (it is displaced by the hot water coming from the boiler).

As soon as the hot coolant enters the radiator, the process of heat transfer begins. The walls of the radiator gradually heat up and then transfer heat to the room itself.

The coolant will circulate in the system as long as the boiler is running.

Heating safety

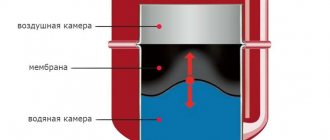

As mentioned above, the pressure in a closed system is greater than in a gravitational one. Therefore, they take a different approach to security. In closed heating, the expansion of the heating medium is compensated for in an expansion vessel with a membrane.

It is completely sealed and adjustable. After exceeding the maximum permissible pressure in the system, the excess coolant, overcoming the resistance of the membrane, goes into the tank.

Gravitational heating is called open because of a leaky expansion tank. You can install a membrane-type tank and make a closed gravitational heating system, but its efficiency will be much lower, because the hydraulic resistance will increase.

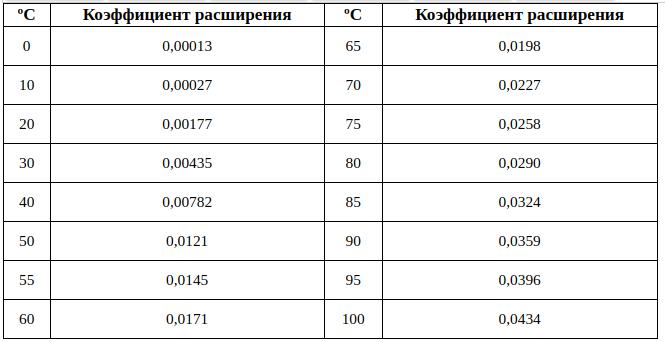

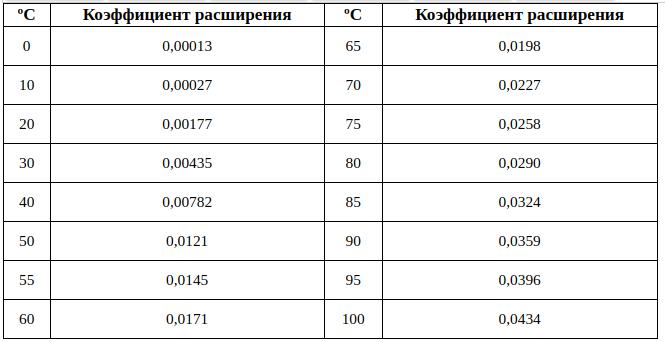

The volume of the expansion tank depends on the amount of water. For the calculation, its volume is taken and multiplied by the expansion coefficient, which depends on the temperature. Add 30% to the result.

The coefficient is selected according to the maximum temperature that the water reaches.

Features of design and installation

The main nodes of the gravitational system include:

- a heating boiler in which water or antifreeze is heated;

- pipeline (double or single);

- heating batteries;

- expansion tank.

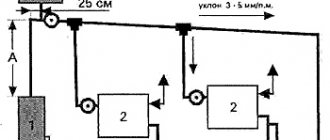

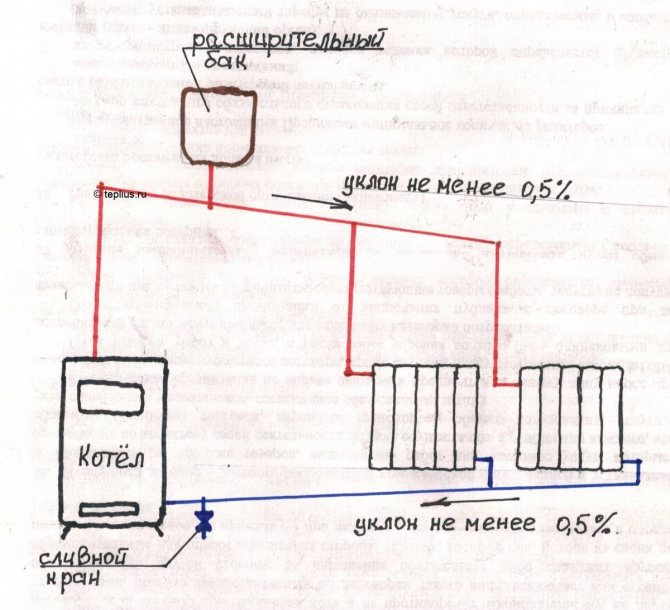

When designing, as well as directly during the installation of the system, it is very important to observe one prerequisite: the pipe along which the coolant will move must be inclined towards the heating boiler. The slope must be at least 0.005 m

one meter running pipe.

In general, if the boiler and radiator are located on the same floor, then the entrance to the radiator pipe should be slightly higher.

Diagram of a gravity system with a slope of pipes

The presence of this bias is explained by the following factors:

- the cold coolant will enter the boiler faster through the inclined pipe;

- the presence of a slope is also necessary in order for the air bubbles that appeared during the heating of the coolant to rise more efficiently into the expansion tank, from which they evaporate into the atmosphere.

The expansion tank creates additional pressure, which has a beneficial effect on the speed of movement of water through the pipes.

The speed of movement of the working fluid directly depends on the difference in quantities such as mass, density and volume of the coolant in the cold and hot state. The flow rate is also affected by the level of the radiators relative to the boiler.

The gravitational pressure in the heating system is consumed to some extent in order to overcome the resistance of the pipeline. Turns and branches in the system, additional radiators act as additional obstacles.

Therefore, in order to maximize heating of the room, when designing a gravitational system, it is necessary to ensure that such obstacles are as few as possible.

Traffic jams and how to deal with them

For normal operation of heating, it is necessary that the system is completely filled with a coolant. The presence of air is strictly not allowed. It can create a blockage that prevents the passage of water. In this case, the temperature of the boiler water jacket will be very different from the temperature of the heaters. To remove air, air valves and Mayevsky taps are installed. They are installed at the top of the heaters as well as at the top of the system.

However, if the gravitational heating has the correct slopes of the supply and return pipes, then no valves are required. The air in the inclined pipeline will freely rise to the top point of the system, and there, as you know, there is an open expansion tank. It also adds the advantage of open heating by cutting down on unnecessary elements.

Is it possible to mount a system of polypropylene pipes

People who make heating on their own often think about whether it is possible to make a gravitational heating system from polypropylene. After all, plastic pipes are easier to install. There are no expensive welding jobs or steel pipes here, and polypropylene can withstand high temperatures. You can answer that such heating will work. At least for a while. Then the efficiency will start to decline. What is the reason? The point is in the slopes of the supply and outlet pipes, which ensure the gravity of water.

Polypropylene has greater linear expansion than steel pipe. After repeated cycles of heating with hot water, the plastic pipes will begin to sag, breaking the required slope. As a result of this, the flow rate, if not stopped, will significantly decrease, and you will have to think about installing a circulation pump.

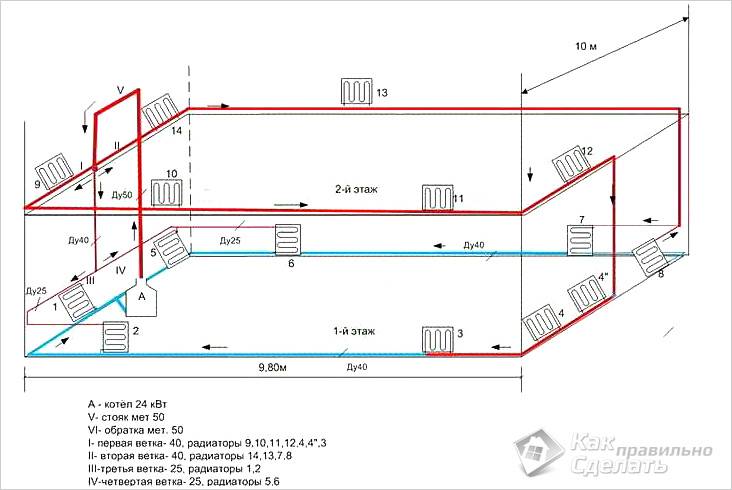

Difficulties in installing a gravity system in a two-story house

The gravity heating system of a two-story house can also work efficiently. But its installation is much more difficult than for a one-story one. This is due to the fact that roofs of the attic type are not always made.If the second floor is an attic, then the question arises: what to do with the expansion tank, because it should be at the very top?

The second problem that will have to be faced is that the windows of the first and second floors are not always on the same axis, therefore, the upper batteries cannot be connected to the lower ones by laying pipes in the shortest way. This means that you will have to make additional turns and bends, which will increase the hydraulic resistance in the system.

The third problem is roof curvature, which may make it difficult to maintain correct slopes.

Basic schemes for heating systems of houses

Private house heating system

Despite the fact that heating systems differ in the type of energy source used, they have only two main schemes. The correct measurements of the house and the surrounding area will help to determine the choice of heating scheme. The size of the building is the main indicator that determines the choice of the scheme. Consider these schemes:

- Scheme using the gravity of the coolant;

- A circuit working with forced circulation of the coolant.

What are the fundamental differences between these schemes - we will try to figure it out. It should be noted right away that both heating schemes can have a single-pipe and two-pipe design. Regarding gravity systems, we can say that they have a number of disadvantages, and therefore they are used much less often than heating systems with forced circulation. These are the disadvantages:

- High cost of the system. Taking into account the fact that the supply line is far from the cooled water return line, and everything happens under the influence of the gravity of the coolant, it is necessary to have a pipeline with a sufficient length.

- The complexity of installation associated with the need to strictly adhere to the values of the slope angle to ensure the natural flow of the coolant in both directions.

- Not aesthetic appearance of the system, due to the fact that it is not always possible to use modern materials, since the temperature of the water in the system can reach rather high temperatures, up to the boiling point.

- The complexity of regulating the temperature of individual heating devices.

- Low efficiency due to large losses arising from the long length of the system.

- Large volume of heat carrier used.

Among the advantages of a gravity heating scheme, two facts can be noted. Firstly, such a system can work without power supply, although it is rare now to find an area where there is still no electricity. Secondly, the system has a high inertia, that is, heat spreads evenly and external factors have little effect on the state of the coolant.

Tips for installing gravity heating in a two-story house

Most of these problems can be solved during the design phase of the house. There is also a little secret on how to increase the heating efficiency of a two-story house. It is necessary to connect the outlet pipes of the radiators installed on the second floor directly to the return pipe of the first floor, and not do the return pipe on the second.

Another trick is to make the supply and return pipelines from large diameter pipes. Not less than 50 mm.

Is a pump needed in a gravity heating system?

Sometimes an option arises when the heating was incorrectly installed, and the difference between the temperature of the boiler jacket and the return is very large. The hot coolant, not having enough pressure in the pipes, cools down before reaching the last heating devices. Redoing everything is a laborious job. How to solve the problem with minimal costs? Installation of a circulation pump in a gravitational heating system can help. For these purposes, a bypass is made, into which a low-power pump is built.

High power is not required, since with an open system, an additional head is created in the riser leaving the boiler.The bypass is needed in order to leave the possibility of working without electricity. It is installed on the return line in front of the boiler.

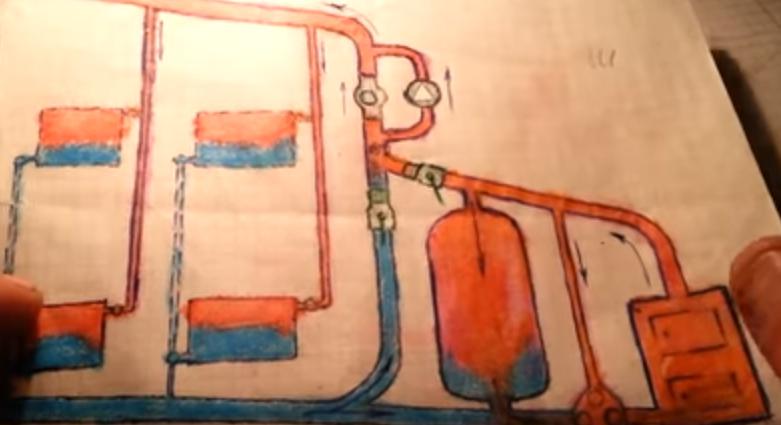

Heating battery wiring option

The radiator wiring diagram, which is relatively simple and reliable, can be as follows:

- At the end of the acceleration collector, an expansion tank is installed in the attic room, from which, in turn, the filling with a diameter of 40 to 50 mm, proceeding at a constant slope, should begin.

- The return loop is located around the entire perimeter of the floor on the ground floor. Despite the fact that for greater efficiency of the equipment, experts recommend installing the bottom filling in the basement, nevertheless, this should be done only when it is known for sure that the temperature in this place does not fall below 0 °, even if the boiler is not working. However, if the coolant contains elements such as, for example, antifreeze or antifreeze, then there is nothing to worry about.

- If there is a real opportunity to determine the spills in the attic and in the basement, then this will definitely meet the norms of aesthetics, since, as you know, a massive and thick pipe is unlikely to be able to decorate a home and harmoniously fit into its interior.

Thus, we can say that the installation of a gravitational heat supply system does not involve excessive difficulties and can well be done on our own.

However, in the event of problems or to perform a power calculation, it is still recommended to seek advice from specialists who can provide the necessary assistance in the repair of equipment, as well as provide various photos of samples of the device of such systems and detailed videos on their correct connection.

An example of a gravitational heating system device in the video:

How to further improve efficiency

It would seem that a system with natural circulation has already been brought to perfection, and it is impossible to come up with anything that increases efficiency, but this is not so. The convenience of its use can be significantly improved by increasing the time between boiler furnaces. To do this, you need to install a boiler with a higher power than is required for heating, and remove the excess heat into a heat accumulator.

This method works even without using a circulation pump. After all, the hot coolant can also rise up the riser from the heat accumulator, at a time when the firewood in the boiler burned out.