What is a boiler stabilizer for?

Gas-fired boilers in modern heat supply systems are complex installations with electrical components that are susceptible to consumer quality of voltage, namely: control boards and safety automation, heating medium circulation pumps, fuel ignition systems and switching on the ventilation unit.

It is better to take the choice seriously. Photo source: rusthermo.ru

For this reason, when purchasing an expensive boiler, you need to worry in advance about the special protection of its digital cards from network violations. That is why in Russia in general, there is no question of whether a voltage stabilizer is needed for heating equipment, all consumers understand what is needed.

Russian power grids do not guarantee the consumer quality of electricity required for the proper functioning of heating systems, which is very important when using imported gas units, expensive “contents” that require strict power supply parameters.

The use of stabilizers protects expensive equipment from damage, which is also important for equipment that is under warranty.

All defects of the gas units resulting from power surges are not covered by the warranty, therefore the restoration work is paid by the owner of the unit at his own expense.

Model range of inverter stabilizers "Shtil" for gas boilers

When choosing a stabilizer for working with a heating boiler, it is necessary to proceed primarily from the electrical power of the boiler, which consists of the capacities of the circulation pump, fan, ignition system, as well as display and automation elements. The thermal power of the boiler should not be confused with the electric one - these are different physical quantities! The first is measured in kW and is designated in the technical documentation as "power", the second is usually called "electrical power", "connection power" or "power supply" and is measured in W (50-200 W for gas boilers of domestic heating systems).

To avoid overloads, the power of the stabilizer should be selected with a margin of 20-30% relative to the electric power of the boiler. Therefore, for most boilers used in everyday life, a stabilizer with a capacity of 250-500 watts is sufficient. From the line of inverter stabilizers "Shtil" this criterion corresponds to the models InStab IS350 and InStab IS550.

Check out the full range of inverter voltage stabilizers for gas boilers.

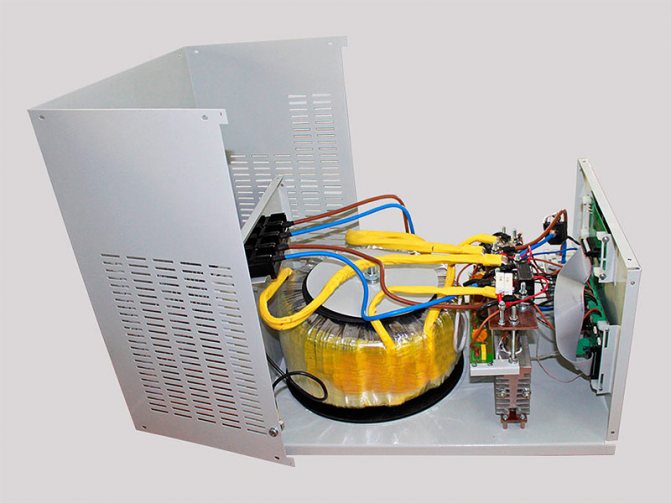

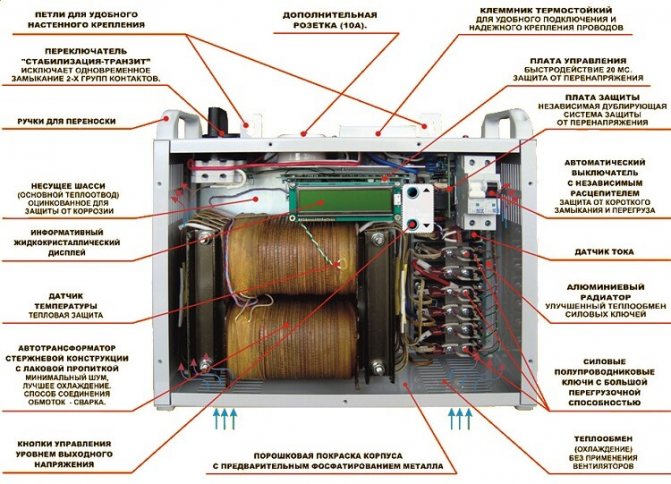

Voltage stabilizer device

The basics of the operation of such equipment must be known before choosing a voltage stabilizer for a gas boiler.

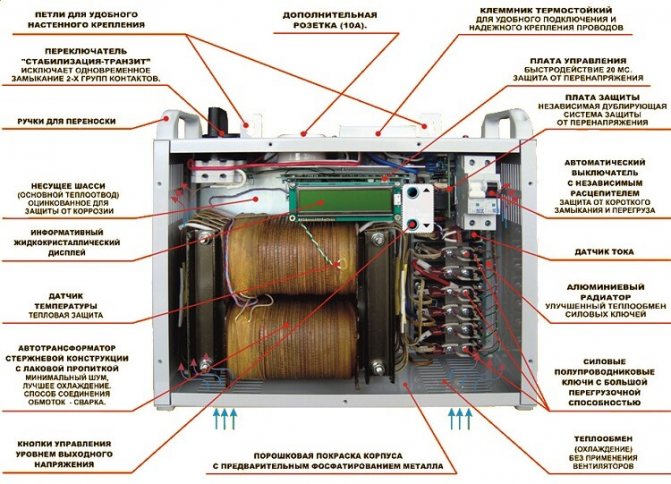

The main components of the voltage regulator

The device is made of the following structural units:

- An autotransformer with various windings, it is responsible for the compliance of the output indicators with the generally established characteristics.

- A monitoring device that determines the configuration of the incoming voltage.

- Fuses that turn off the device when the characteristics of the electrical network go beyond the permissible values.

- Control automation that changes the direction of current flow through the windings.

- Batteries that feed the device in the absence of electricity.

For relay voltage stabilizers for a gas boiler with a 10% working scale, the voltage changes around 220 V, fluctuating by 10% in different directions from the base.

This is why the stabilizer clicks when relays are frequently triggered due to poor power quality.Technologically, the stabilization effect is obtained in various ways, depending on the modification of the device.

Stabilizer types

The period of maintenance-free operation of a gas boiler with a pump and ignition from the mains depends on a stable and constant voltage. Therefore, the inclusion of a stabilizer in the boiler operation scheme, if not necessary, is highly desirable. Modern stabilizers are divided into three types:

- Relay type - the cheapest, but not the most durable devices. Burning contacts forces the owner to change the device every 3-4 years. The accuracy of the stabilization amplitude also leaves much to be desired.

- Stabilizers on servo motors can smoothly equalize the output voltage, but they run more slowly, which increases the risk of an accident.

- Electronic circuits based on controlled thyristors (triacs) and microprocessors are durable, have high stabilization accuracy, are quiet in operation and instantly react to voltage surges in the network.

According to other parameters, stabilizers are divided into DC or AC devices, floor or wall structures, single-phase or three-phase devices. The table shows the technical characteristics of the most popular stabilizer models in 2014. Analysis shows that an electronic device can work in any conditions, with any voltage fluctuations. The electronic stabilizer does not distort the voltage waveform, which means that the gas boiler will work stably and reliably.

A mechanical or servo-driven stabilizer has a longer response time when input voltage and current fluctuations. That is, when the amplitude jumps, the mechanical device does not have time to equalize the amplitude and the voltage fluctuations go to the electronic and electrical devices of the boiler. Swings are rare but often cause breakdowns in the load electronics.

Therefore, the question of which voltage stabilizer for a gas boiler is better can only be answered by the owner of the unit. The cost of the device and the requirements for it, and even the dimensions of the stabilizer, play a role. Since a gas boiler is expensive, it makes sense to put a more expensive but high-quality stabilizer on its maintenance, and not save on trifles.

How to choose a stabilizer

When buying, start from the main parameters:

- The power of the stabilizer is determined by the total power of the loads - pump, control panel, gas burner and other automation elements. The standard power of the stabilizer is 150-350 watts.

- The range of the output voltage of the device.

- Mains voltage. To determine the voltage difference at different times of the day, measurements should be taken periodically, and then the arithmetic mean should be taken.

Requirements for a quality stabilizer for a gas boiler:

- Aesthetic appearance.

- Small size and sufficient power.

- Possibility of wall or floor placement.

- Simplicity and reliability.

- Quiet operation and reliable thermal operation.

- Electronic execution.

- The price of the stabilizer should be justified by its technical characteristics.

In terms of price, the miser pays twice. Choose a stabilizer with increased characteristics relative to the requirements - situations are different. If you have an expensive boiler installed, then the protection must match. Therefore, buy a stabilizer from a branded manufacturer, preferably with recommendations from friends, from consultants or gas experts.

Electronic and mechanical stabilizer manufacturers

Popular models of stabilizers of foreign and domestic production:

| Specifications \ Model | SNAP-500 | VEGA-50-25 | RESANTA ASN-2000 | Shteel-1000 |

| Stabilizer | Mechanical | Electronic | ||

| Power | 500 watts | 500 watts | 2000 watts | 1000 watts |

| Adjustment speed, sec | 1,0 | 0,3 | 0,5-0,7 | 0,2 |

| Input voltage | 150-250V | 172-288V | 140-260V | 132-260V |

| Voltage accuracy at the output of the stabilizer,% | 1 | 0,5 | 1,5 | 2,5 |

| Protection | Not | there is | there is | there is |

| Working temperature | -5 / + 40 ° С | -25 / + 45 ° C | 0 / + 45 ° C | + 5 / + 40 ° C |

| Lifetime | 1-3 years | 7-15 years old | 5-10 years | 10-20 years |

| Dimensions (edit) | 175x190x140 mm | 275x425x260 mm | 100x183x240 mm | 240x170x120 mm |

| Weight | 4 Kg | 16 Kg | 4.2 kg | 6 Kg |

| Service warranty period | 1 year | 5 years | 2 years | 5 years |

| Manufacturer | PRC | Italy | Russia | Ukraine |

| The cost | 30 $ | 600 $ | 700 $ | 140 $ |

As you can see, the cheapest are Chinese mechanical devices. Russian stabilizers are the most expensive in their range of capacities and other technical characteristics. However, the cost always justifies itself. Therefore, advice from the pros: do not pursue savings - it can turn out dearly for you.

Mandatory requirements for the stabilizer

Power is a basic parameter, the performance of the device depends on it. This value is taken into account when choosing a voltage stabilizer for a gas boiler.

The more electricity the boiler uses, the more stabilization power is needed. On the electrical equipment market, modifications from 0.50 to 3.50 kW are produced.

An equally important parameter for the selection of a device is the speed of response, which characterizes the response to voltage transformation.

The earlier the device detects a failure, the weaker the current curve will bend. So in inverter devices, stabilization occurs instantly in 2 stages, so the boiler is completely protected from network failure.

When choosing a protective device, attention must be paid to the safety levels. All double-conversion protective complexes protect against short-circuit, wrong connection, polarity reversal and battery overcharging.

Types and functional features

The voltage stabilizer for a gas boiler includes simple and intuitive functions. During mains voltage drops within a certain interval of possibilities, the device must supply power to the system with properties that correspond to normal values, or are closest to them. If the voltage surges are very large and go beyond the limits of the stabilizer's capabilities, then its system must completely disconnect the power circuit until the input indicators return to a certain interval.

This method creates the correct operation of all equipment connected to the device, and its malfunction is not allowed with large voltage surges.

For consumers, a large assortment of devices of this method of operation is given, in various designs and a wide range of operational capabilities. If a safety relay is most often responsible for the emergency shutdown option of the device, which performs a similar action, then the accuracy of voltage stabilization can be carried out in different ways. Voltage stabilizers for gas boilers are divided into types according to the principle of action on electromechanical, relay and electronic.

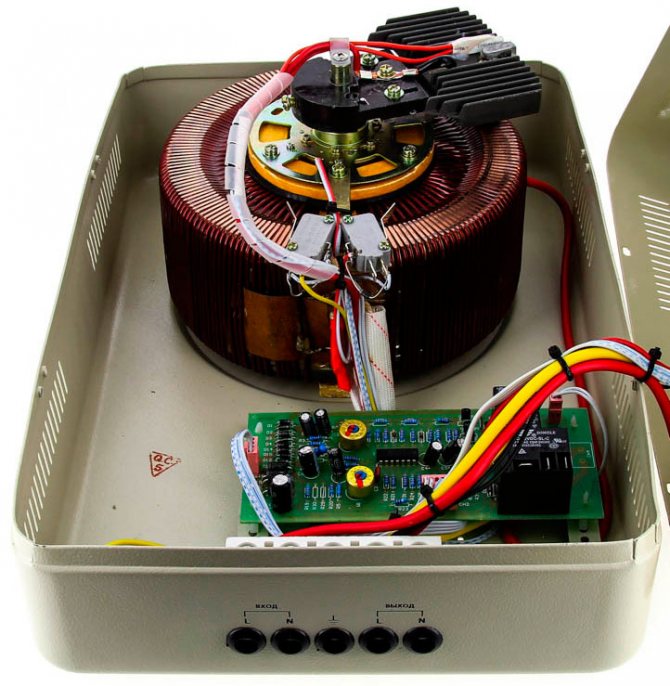

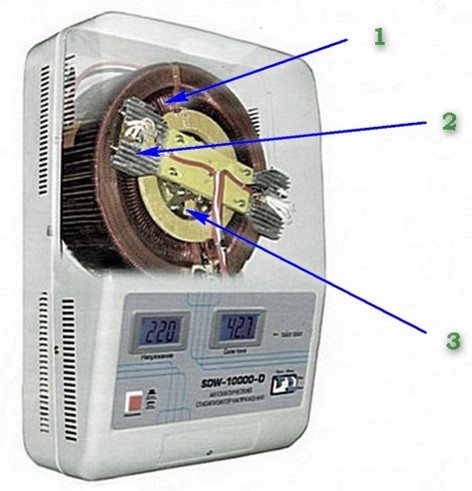

Electromechanical stabilizers

In such versions of devices, the voltage is equalized to the desired value by moving the carbon current-collecting brushes along the winding of the automatic transformer. The movable part is moved using the built-in servo drive.

1 - turns of the autotransformer.

2 - carbon collector brush.

3 - servo drive.

This scheme has shown itself well - it has a difference in increased stabilization accuracy, its cost is low. Electromechanical stabilizers have their own characteristics that limit their use with gas equipment.

Sparking occurs between the collector and the carbon brush, which increases with wear on the assembly. Electrical appliances with sparking effect must not be used in the boiler room for safety reasons. The stabilizer can be taken to another room, but its action is accompanied by noise, and many people do not like this.The performance of such a stabilizer model is low, the total response time to a voltage surge is up to 2 seconds. This is a large value for the sensitive electronic system of a gas boiler.

Also, similar devices are short-lived due to friction units and kinematics. From this we can conclude that it is better to refuse to use the electromechanical model of the stabilizer together with a gas boiler, or use it with extreme caution.

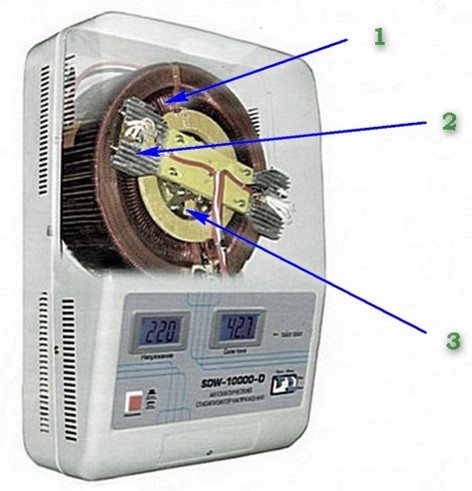

Relay stabilizers

Such devices have a different design. Switching between the windings is carried out using a relay. There is no arcing of contacts in these devices, since the relay is placed in a sealed case.

1 - Leads of the coils.

2 - a group of relays for switching outputs.

The models of such devices have drawbacks, one of which can be called step regulation and low accuracy of stabilization of the output voltage (8%). This is sufficient for many devices.

Relay-type stabilizers quickly respond to changes in the power supply network, can easily carry heavy loads, and have a wide input voltage range. These devices function reliably and for a long time, have a low cost. The disadvantages include a little noise from the operation of the relay contacts. However, if there is a lot of noise in the boiler room, such noise from the contacts is unlikely to be heard. Today, such relay stabilizers can be attributed to the most popular models.

Electronic stabilizers

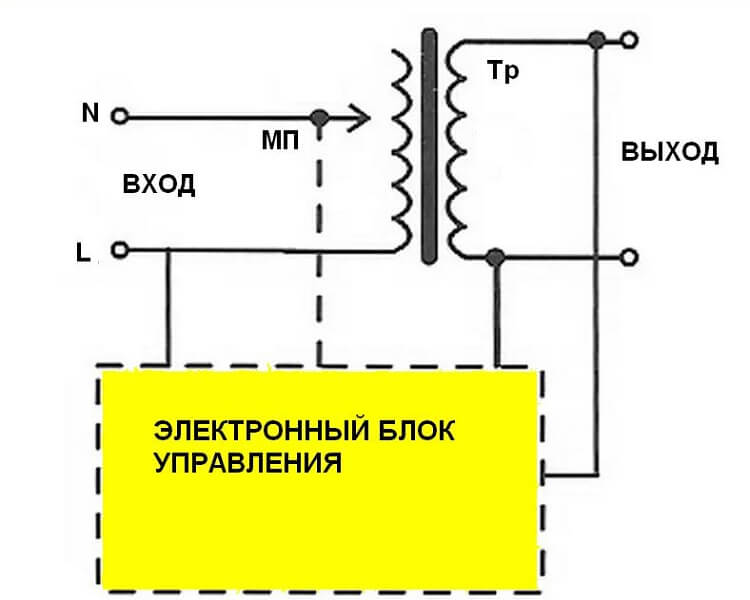

The development of voltage stabilizers with electronic components was a significant step forward. The role of switches for switching between the windings is played by semiconductor elements (thyristors and triacs). This creates the highest speed of the device, above the relay circuit.

The electronics accelerate the stabilization action and increase the service life of the device. compared to other species. The degree of accuracy of the stabilizer directly depends on the number of adjustment steps. This is analogous to the relay type of devices. Electronic stabilizers are more compact, do not create noise, and are unpretentious to the external environment.

Such a stabilizer will be the best choice for any working conditions, since there are no serious drawbacks, like other types of devices, in it. The main reason for refusing to purchase this type of device is the increased cost of the device.

There are other types of regulators, with a double inverter converter, perfect equalization of the output voltage. But for the equipment of the boiler room, similar devices will be too expensive, and their purchase is impractical.

What type is suitable for the boiler

Today's electrical digital equipment market presents a large selection of protective devices, with a variety of operating principles. Before choosing a voltage stabilizer for a gas boiler, you need to understand the basics of their functioning.

Inverter

These are devices for two-system transformation. Primary when converting alternating current to direct current. Secondary - on the contrary, in connection with which another name of them appeared: inverter.

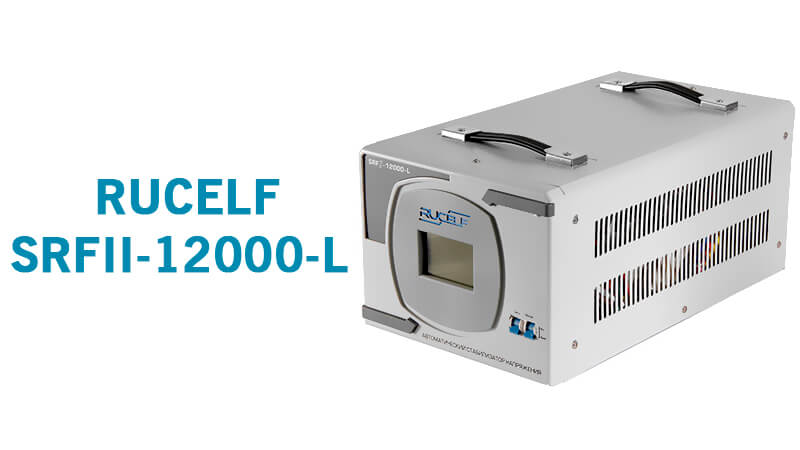

Inverter stabilizer SHTIL. Photo source: shop.ecoteco.ru

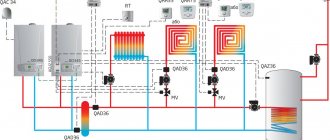

The initially unstable current from the network enters the rectifier and power corrector of the apparatus, where the filtration and stabilization processes take place. After that, energy is accumulated on the plates of a huge number of capacitors.

For stable and long-term operation of the boiler, the mains parameters with correct sinusoidal qualities are required.

This type of protection creates a perfect sine wave due to the use of an inverter. The charge from the capacitors, after the completion of the 1st stage of the conversion, is transferred to the second part of the device, where it is again transformed - inversely with stable output sinusoidal parameters.

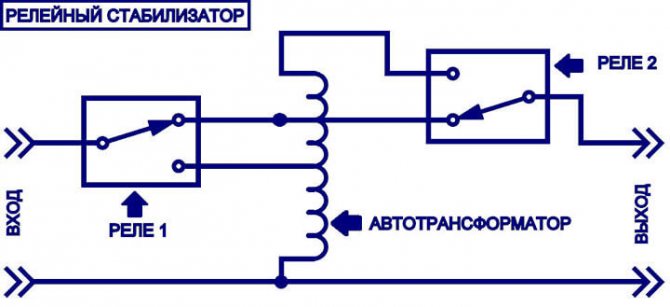

Relay

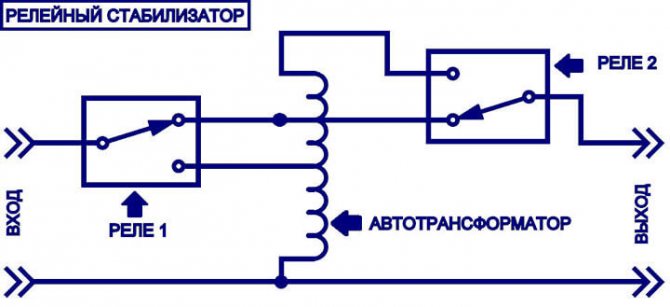

Relay devices have an automated transformer and specialized electronic circuitry that controls the transformer. They differ - they are relays, which is why they got their name.

With the support of this small device, a current transition is made between various windings. Initially, such 220 V voltage regulators were produced in the booster format.

Relay stabilizer circuit

Later, changes were made to the device, which made it possible to use them both to increase and decrease the voltage.

It should be recognized that these modifications sold on the market cannot demonstrate good quality. Some manufacturers, mainly from Asia, reduce the cost of the stabilizer by using not very high-quality components, which affects the low service life of the devices.

Electronic

This type is often referred to as triacs, today they are considered the best with good technological and operating parameters. The principle of operation of the device is based on the automatic method of switching the converter with the support of digital keys - triacs, which are the primary cause of the instantaneous response of the device to all kinds of deformations of the network characteristics.

Only one drawback is the decent cost of the device. In this group of devices, the ratings are headed by the voltage stabilizer for the gas boiler Shtil.

Electromechanical

This type belongs to very simple, but super-quality devices, the method of operation is based on the sliding of the slider along the secondary winding of the drive. The slider moves the brushes, decreasing or increasing the number of turns that are energized.

Of course, the slider will not be able to move spontaneously. This is done by an electric motor or, as it is called, a servo drive.

Electromechanical stabilizer

The engine is directly under the control of the processor, which controls the stress strain. When the network characteristics change, the microprocessor will send a signal to the electric motor, which starts and initiates the direction of the slider along the windings, in one direction or the opposite direction, on the basis of which the network parameters have decreased or increased.

Types of stabilizers

Let's consider the types according to the principle of operation.

Relay or electronic... They are connected to a network with a range of 135-315 V. One of the cheapest devices. The pluses of the relay type include:

- Good response speed (100ms).

- Compactness and light weight.

- Stable sine wave. The accuracy of the output current is 7.5%.

Minuses:

- Quite noisy operation (clicks are heard).

- When switching the windings, the light may flash.

- Short service life.

Electromechanical or servo driven... The voltage is regulated by a brush that moves around the motor.

Benefits:

- High accuracy (3%).

- Work in a wide range.

- Smooth adjustment of the output frequency.

- Low cost.

Disadvantages:

- After three to four years, the adjustment brush will have to be replaced.

- The appliance will not function in a cold room.

- Slow response.

- Due to the principle of operation, it can openly spark.

Triac or thyristor... This is the best device for today, although its cost is higher than that of the previous two. High actuation accuracy of 2–3% due to the large number of windings. Take-off run - 214-226 V.

Pros:

- High speed (10–20 ms) and accuracy.

- Stable and quiet operation.

Minuses:

- High price.

Double conversion (inventory). A separate type of protection that can be called the most reliable. Initially, the device converts alternating current to direct current, and then back to alternating current with a pure sine wave. The operating range is 120-300 V. It immediately responds to a surge or undervoltage.

The disadvantages include the high cost of the device.

Pulse width (PWM). The device is based on the triggering of a pulse generator. It provides accurate output current. Allows you to fully synchronize with the gas boiler. Recommended for connecting to a low frequency network.

Which device is better to choose depends also on the number of phases. You can choose a device with a built-in rechargeable battery that will keep working in the event of a power outage.

Number of phases

The choice of the number of phases depends on the parameters of the network. If it is single-phase, then the same type of protective device is needed.

Single phase... Suitable for wall and floor heating equipment. It is often installed in houses and apartments with 220 V network values. Serves to straighten power up to 135 kVA.

Three-phase... It is used more for industrial purposes for connection in boiler rooms. The power range is 380-400 V. It can also be used in domestic conditions if the connection parameters correspond to the declared ones.

What to consider when choosing

To choose the best model, pay attention to the following parameters:

- Boiler power. Electric models of different brands "Buderus", "Visman", "Ariston", "Bosch" have a different operating range - maybe 10 or 24 kW. This must be taken into account when choosing.

- Response time. Specified in milliseconds (ms). The parameter will tell you how long it takes for the stabilizer to equalize the voltage during a jump.

- Input voltage. Recommended range 140-260 W.

- Output correction accuracy. So you will find out how well your boiler is "feeding".

- Working temperature. This refers to the ambient temperature at which the equipment operates normally. Usually it is +5 - +40 degrees.

- Placement method. Wall-mounted options are lighter and more compact, take up a minimum of space. Floor-standing ones are more often used for industrial purposes for high-power equipment.

To calculate the power of the stabilizer, add up the power of all devices that are connected to it. Multiply the resulting number by 1.3 (jump at start).

How to choose the power of the stabilizer

The protective device must have good power in order to ensure the performance of absolutely all elements connected to the boiler unit: the unit control unit, the coolant circulation pump and the fan.

Therefore, first of all, it is necessary to clarify how many nodes for the consumption of electric current will be connected through the stabilizer.

Power data are registered in the passports. In addition, it must be taken into account that current consumers, for example, such as a pump, have increased starting power characteristics. Therefore, the calculated value needs to be increased by 1.3.

Which to choose

The choice of the stabilizer is determined by the design features of the boiler, the type of burner, the type of fuel and other features of the installation. You should immediately abandon the use of electro-mechanical (lateral) devices.

During operation, they spark strongly, which is unacceptable in rooms (especially in separate chambers) with gas appliances.

Consider which stabilizers are good for individual series and models of Baksi boilers:

SLim series

The selection of stabilizers should be based on the calculation of the amount of power consumption. For boilers of the SLim series, a number of tests were carried out, according to the results of which the stabilizers and "Calm" showed the best performance.

They offer a wide selection of devices for various tasks, including for normalizing the operating voltage of Baksi Slim boilers.

The devices have good characteristics, small error and a high input voltage range, which makes it possible to successfully work with powerful floor-standing installations of the Slim series.

Baxi Luna Series

For boilers of the Luna series of the Luna 3 or Luna Comfort series, various devices from several manufacturers have been tested.Tested indicators of power, speed, stabilization accuracy.

Experts note that almost all domestic stabilizers demonstrate equally stable indicators that are optimal for boilers of these lines.... The leader according to the test results was the products whose products were able to show the best results.

They have a very reasonable cost with wide possibilities and high quality of work.

Eco Four 24F

The surest way to determine a suitable stabilizer model is to calculate power from consumption indicators. This will allow you to choose a device that is capable of performing its tasks with high quality, without overpaying for extra power or other unnecessary features.

The power consumption of the model is 80 watts. Multiplying it by the reliability factor (1.3), we obtain the minimum allowable power of the stabilizer.

The resulting value is 104 W, but you should choose from slightly higher values in order to take into account the inevitable drop in indicators over time.

Eco 4s 24 F

The power consumption of the boilers of this model is 130 W. Accordingly, the minimum power of the stabilizer will be 169 watts.

It is recommended to choose a suitable stabilizer starting from 200 W models, as their performance decreases slightly over time.

Baxi fourtech

Baxi Fourtech boilers have different power consumption values - 130 and 80 watts. This means that different types of stabilizers are suitable for different models, corresponding in terms of power.

Choose from 140 W or 200 W samples to obtain reliable and economical voltage regulation.

Main 24Fi

The electrical power consumption of this model is 170 W. Accordingly, the minimum power of the stabilizer should be 221 W. INThe choice should be made from installations from 300 W of power, which will allow to compensate with a margin for all possible distortions of the input voltage parameters.

NOTE!

The recommendations given are only for the power of the stabilizers. When buying, you must also be guided by the magnitude of the error and the type of device. The best option is thyristor stabilizers, which work quickly and quietly.

It is necessary to take into account that the best choice will be devices of domestic production. They are designed by engineers who understand the specifics of the equipment, represent the range and parameters of possible failures.

The devices of the following companies were highly appreciated by users.:

- Energy.

- Calm.

- Teplokom.

- Resant.

- Caliber.

- Bastion.

- ERA.

Among foreign companies that produce voltage stabilizers for gas boilers, one can note:

- Daewoo.

- Elitech.

- Powerman.

- Lenz Technic etc.

It should be borne in mind that one should be guided by the characteristics and parameters of the device, and not by the name of the company.

The best voltage stabilizers for gas boilers

Not all companies manufacture devices of several varieties at the same time. Usually companies focus on one type of development. The choice of protection for the boiler unit is significantly determined by the parameters of the regional network and the load of the switched on boiler units.

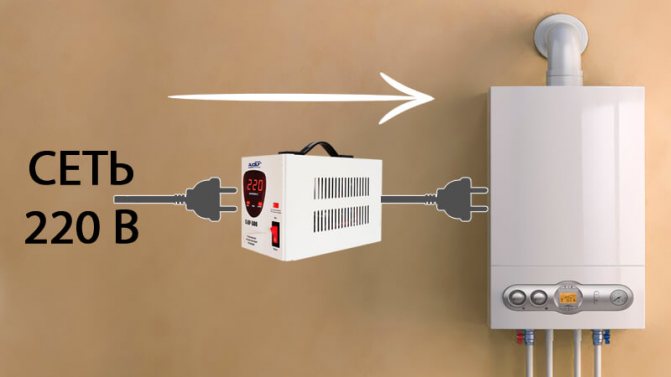

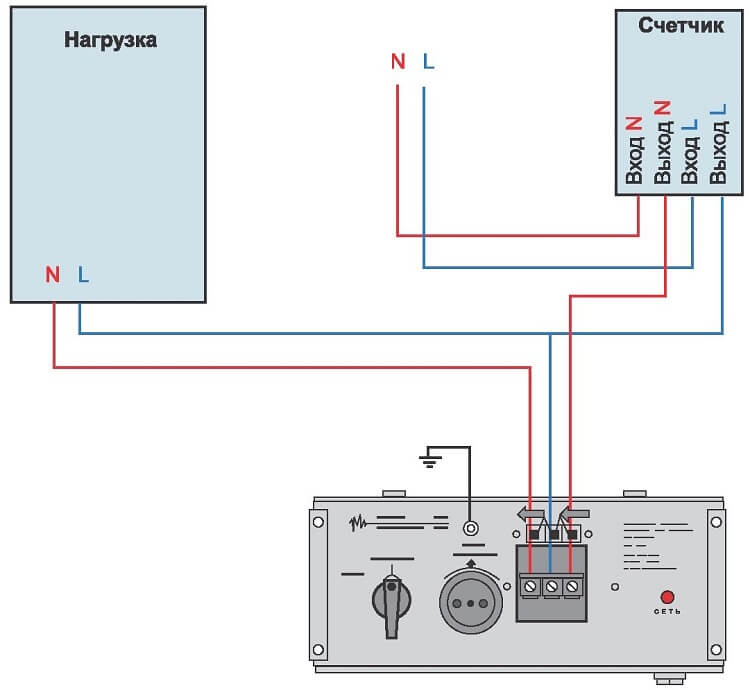

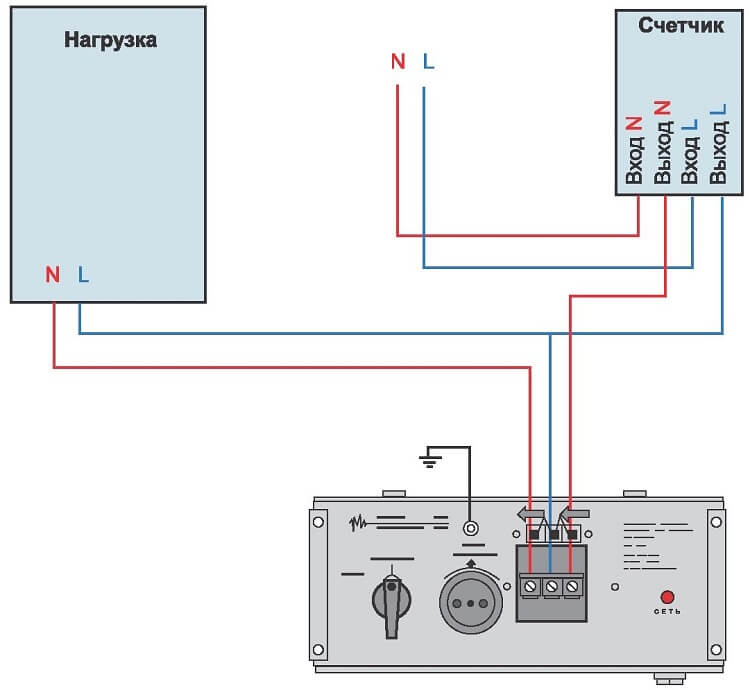

Installing the stabilizer in the circuit: Photo source: fenixled.ru

You can make up the characteristics of a decent device:

- The smallest power is 1000 VA.

- Built-in protection against overheating of contacts and short circuit.

- Input voltage range 90-290 V, absolutely non-critical to the load.

- Output perfect sine wave.

- The low voltage pickup level is higher than the normal value on the district power grid.

- Autostart with the suspension of the process, upon completion of the protection operation.

- The presence of a grounding terminal.

- The speed of voltage regulation is no more than 20 ms, with a processing accuracy of 2-3%.

According to this list of parameters, the rating of voltage stabilizers:

- Cool stabilizer 220v relay type for gas boiler Baxi - LogicPower LPT-1000RV, the price as of December 1, 2019 - 2180 rubles.

- Relay stabilizer Warm unit TEPLOCOM ST-222/500, price as of 1.12.2019 - 2970 rubles.

- Best Servo Motor Stabilizer - Resanta ACH1000 / 1-EM, price as of 1.12.2019 - 3120 rubles.

- Excellent thyristor device - voltage stabilizer Calm for gas boilers R 1200SPT, price as of December 1, 2019 - 13,070 rubles.

Popular models rating

Review based on customer feedback.

"Resanta ASN-500 N / 1-Ts"

Relay-type single-phase stabilizer. The compact body fits well on the wall. Provides protection of equipment in case of voltage surges in the 220/380 V network. The built-in filter eliminates interference, the current frequency is automatically regulated. "Resanta" operates in a wide range of temperatures, but does not tolerate high humidity in the room.

| Rated power (W / A) | 500 W (0.5 kW) |

| Frequency Hz) | 50 |

| Input voltage (V) | 220 |

| Deviation percentage | 8 % |

| Response time (ms) | Up to 7 |

| Ambient temperature | 0 ° C to 40 ° C |

| Connection | Wire and plug |

| Display availability | Digital |

| Dimensions (LxWxH) | 260 × 200 × 110 mm |

| Weight, kg) | 3 Kg |

Price from 2,000 rubles.

Pavel

I bought a "Resantu" for a boiler with a circulation pump. I conducted a test, tried to connect a TV and a microwave to it - suitable for any technique. After connecting to heating equipment, it has been working stably for a year, without shutdowns. There were no problems with the instruction, I connected everything myself. Now I do not worry that the electronics will fail, because repairs are expensive. I advise all my friends.

"Spire InStab IS3500"

Model of the inverter converter "InStab" from the Russian. A single-phase device is perfect for protecting gas double-circuit boilers, refrigeration, and household appliances. Available in wall and floor versions. LCD and LEDs help keep track of the current mode.

- Reacts instantly to changes in the network.

- Does not distort the voltage in the primary network.

- Performs double conversion.

- Built-in protection against short circuit (short circuit), overheating, overload.

- Forced cooling by a fan.

- Noise filter installed.

| Rated power (W / A) | 3500 (2.5 kW) |

| Frequency Hz) | 50 |

| Input voltage (V) | 220 |

| Deviation percentage | ± 2% |

| Response time (ms) | 0 |

| Ambient temperature | + 5-40 ° С |

| Connection | Terminal block |

| Display availability | LCD display |

| Dimensions (LxWxH) | 203х359х106 mm |

| Weight, kg) | 5 |

The cost is from 22,000 rubles.

Alexander

Initially looking for an inverter option. It is more reliable and produces a high-quality sinusoid in contrast to relay switches. While it functions normally, it is on the floor in a horizontal position. True, it makes noise during work, which is annoying. Probably due to forced cooling by fans. It is better to secure the equipment once than to call the foreman and overpay later. While happy with the purchase, the main thing is that everything is protected.

How to connect

The stabilizer manufacturers clearly state in the instructions how to turn on the device. First of all, you need to prepare the workplace, which must be dry. Further, the installation is carried out in such a way that there is an unobstructed approach to the apparatus.

At the same time, it must be taken into account that the regulator is air-cooled. For this reason, a lot of free space in front of it will be required. Therefore, it is forbidden to place it in a sideboard or drawer. And the last limitation, the installation is placed away from fire hazardous building materials.

The monophase device is connected via a standard socket. The plug with the adjusted mains values is connected to the socket on the boiler body.

Based on the above, it can be argued that the stabilizer is needed for the gas boiler to function correctly and not be damaged from failures in the power grids.

The specific conditions of power supply and the power of the protected equipment will determine which voltage stabilizer will better cope with its tasks.

Advantages of inverter stabilizers "Calm" for heating systems

Let us list the main advantages of Shtil inverter stabilizers and consider their effect on the operation of a gas boiler:

- instantaneous speed - eliminates the transmission of the disturbing effect from the input of the stabilizer to its output and, as a result, protects the electronic components of the boiler from damage during a sharp network drop;

- wide range of stabilization (90 - 310 V) - allows you to operate the stabilizer, and therefore the boiler connected to it with extremely strong fluctuations in the input voltage;

- high stabilization accuracy (± 2%) - guarantees the boiler supply with voltage with a nominal (extremely close to nominal) value;

- smooth regulation - excludes step voltage surges typical for relay and electronic stabilizers;

- ideal ("pure") sinusoid at the output - ensures the correct and correct operation of all volatile boiler units;

- the presence of a "through zero" for the correct operation of phase-dependent boilers;

- filtering of input and output noise - eliminates noise coming from the network and prevents "load" noise from entering the network. This function contributes to the "comfortable" operation of both sensitive boiler automation and other electricity consumers included in the same network;

- multilevel protection system - will turn off the boiler in the event of an emergency network situation, as well as in the event of failure (overheating) of the stabilizer itself. After the normalization of the network parameters (condition of the stabilizer), the power supply to the heater will be automatically restored;

- small dimensions - make it possible to save space and place the stabilizer in the immediate vicinity of the protected boiler. In addition, some models of stabilizers have several installation options, which allows you to place the device in the most convenient way;

- ease of connection - handling the network cable and load outlets is elementary and does not require any additional skills;

- modern design - allows you to integrate the stabilizer into the interior of the room without violating its style.

Attention! The non-sinusoidality of the output voltage, inherent in many stabilizers with a principle of operation different from the inverter one, has an extremely negative effect on the functioning of a modern gas boiler (up to the breakdown of the device)!