Service repairs air conditioners from the following manufacturers:

- Toshiba (Toshiba)

- LG (Alji)

- Mitsubishi electric

- Samsung (Samsung)

- Panasonic (Panasonic)

- General

- Carrier

- Electra

- Fujitsu (Fujitsu)

- Ballu

- Gree (gri)

- BEKO (BEKO)

- Sanyo

- Mitsubishi Heavy

- AEG (Aeg)

- Hitachi

- AFE (AFE)

- Dantex (Dantex)

- Daikin

- Midea

- Haier

- Funai

- Electrolux

The service center produces:

- Ventilation service

- Ventilation systems design

- Installation of ventilation systems

- Installation of supply ventilation

- Exhaust ventilation installation

- Repair of chillers and fan coil units

- Repair of air conditioning systems

- Pool ventilation

- Refrigeration equipment repair

- Maintenance of precision air conditioners

Authorized Certified Center

Help Center

- Library

- Photo

- Video

- FAQ

- Articles

- Testimonials

Order air conditioner repair

Sale of air conditioners

Installation discount

Discount for installation on air conditioners purchased from us! Get Discount Air Conditioner Parts

Did you know:

Why is the air conditioner making noise? Discover

All articles Reliable supplier:

- the main

- >

- Refueling car air conditioners

Mobile air conditioner

First of all, it is worth understanding the very concept - a mobile air conditioner, and how it differs from the usual split - systems.

This is a device for ventilating air flows in a compact room. Installed in rooms where split-system installation is impossible.

His work has a number of features:

- Mobility

- Compactness

- Convenience during transportation

- High power guarantees good working results (high efficiency of room temperature cooling)

- Carries out work in several modes

- It can not only ventilate and change the temperature of air streams, but also clean them of harmful impurities and microbes.

By their design, floor-standing air conditioners can be single-component monoblocks or split-systems of a mobile type. Both monoblocks and split systems require timely refueling of a mobile air conditioner.

The most popular type of floor standing air conditioner is a single unit. It includes a main body and an air vent pipe. The peculiarity of the device is the intake of air flows from the room and the exit of the processed air to the street through the air pipe.

A floor air conditioner is usually purchased in premises where it is impossible to install a split - system, with the possibility of frequent change of residence. The device is often used as a seasonal room cooler in summer cottages. It is also used when renting a home.

Its main advantages (compactness, portability, ease of use) make this type of device so popular. The device is in the middle price category, therefore it is available for most consumers.

The most common causes of air conditioner leaks.

Periodically refueling car air conditioners is a common operation for this equipment. After all, an automobile air conditioning system practically does not differ from any household air conditioner. There is also an evaporator, condenser and compressor connected by aluminum tubes and rubber hoses through which freon flows.

Even with the ideal state of the climate system, there is a "natural leak", which is considered the norm for certain of its values. But circumstances such as:

- contamination of the condenser;

- temperature drops outside;

- constant vibrations and shocks when driving a car;

- corrosion of materials;

- formed leaks and cracks at the junction of the elements of the freon circuit

- increase the rate of refrigerant leaving the vehicle air conditioning system.

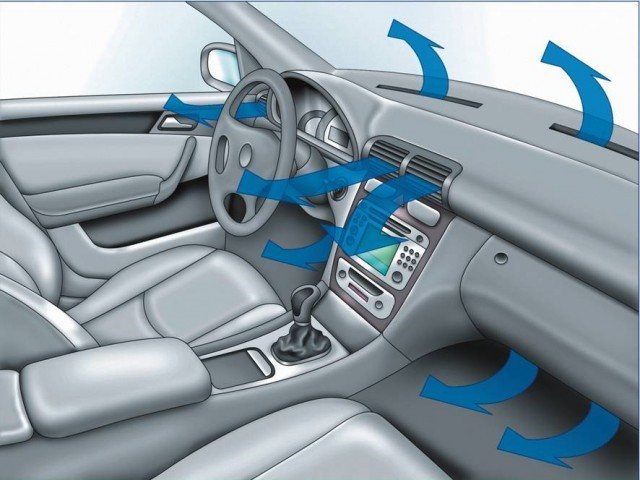

Car air conditioning system in action

Exploitation

The design of the device assumes ease of assembly and installation. Caring for the system also does not require certain knowledge and skills. Each consumer is able to independently refuel a mobile air conditioner in the event of a refrigerant leak.

For proper operation of the device, you must follow the basic rules for its installation:

- The vent pipe should be installed in a window opening or a special hole in the wall should be installed.

- Place the floor-standing air conditioner close to the air duct opening.

- Make sure that there are no obstacles in the path of the air flow of the device.

- For long lasting work, you must work in accordance with the instructions.

- The operation of the device can be started after 2 hours from the moment of installation.

Refueling

The main reason for the breakdown of floor-standing air conditioners is untimely refueling or its absence at all. The fact is that freon gas is used as the refrigerant of the device, which is subject to evaporation. Thus, a refrigerant usually loses 10% of its mass within a year. Also, during operation, there is a natural leak of freon. Therefore, each consumer needs to be able to refuel the mobile air conditioner himself and periodically carry out this procedure.

Symptoms of a lack of refrigerant:

- Slow work speed

- Poor quality of work

- The presence of extraneous noise

- Increase in electricity consumption

- The appearance of a coating of frost on the body of the device

- Air pipe icing

The appearance of one or more signs during operation indicates the need for a refueling procedure.

Before filling a mobile air conditioner with freon, you should know the main features of filling floor air conditioners:

- The device design implies the use of components in a single housing. The manufacturers provide for complete tightness of the system, therefore the device body is subjected to a soldering procedure. The manufacturer refills the device with freon, after which refueling is not provided. However, any air conditioner is susceptible to refrigerant leakage, therefore, it needs to be filled with freon. Refueling is carried out using a special Schroeder valve mounted in the device, through which freon is supplied.

- The peculiarities of the manufacture of floor-standing air conditioners imply only the procedure for fully filling the device, i.e. partial filling is not suitable in this case.

- Freon types R22 and R407C are used in mobile air conditioners - in more modern devices. R407C is a three-component gas of complex composition. In the event of a leak, only a part of its components is lost, therefore it is impossible to refill this type of refrigerant. A full refueling procedure is required.

The refueling procedure for the mobile air conditioner can be done by yourself. For this, it is recommended to follow the basic rules. It is necessary to read the instructions for refueling mobile air conditioners.

At the moment, this service is not available.

A car air conditioner works in difficult conditions: constant vibrations, dust and gas pollution on the roads, temperature drops and other factors negatively affect its working condition. Timely service and refueling of the car air conditioner will help the owner to provide a comfortable microclimate inside the car during the entire hot season.

Automated filling station

It is recommended to carry out diagnostics and maintenance of the car's climate system at least once every 1-2 years before the beginning of summer. So you can fully use the car air conditioner all season and reduce the likelihood of breakdown at the wrong time.

Also, a situation may arise when the service period has not yet arrived, but the car air conditioner needs refueling. You can independently determine this by the following features:

- the air does not cool or is slowly cooled;

- frost or ice build-up appeared in the joints of the freon circuit with the outdoor unit

It is required to turn off the air conditioner and urgently contact a car service or service station where specialists work, and there is specialized equipment. The refueling procedure itself will take a little time, but first you need to determine the cause of the leak and eliminate it.

Indoor unit of car air conditioner

Instructions

Step-by-step instructions for refueling mobile air conditioners:

- Clean the device before refueling. Remove the accumulated dirt in the housing with a vacuum cleaner. Flush the device with detergents. Dry. Apply antibacterial liquid to the housing. Turn on the device so that the disinfectant liquid gets inside.

- Disconnect the device from the network.

- Solder the filling cord into the device.

- Calculate the amount of refrigerant to be charged. Because mobile air conditioner requires a full refueling, the amount of the required device can be found in the technical documentation for the device.

- Connect an empty bottle to the air conditioner. Pump out the accumulation of excess freon.

- Connect a refrigerant bottle to the device. Fill the conditioner with freon.

- Disconnect the filling cord.

- Seal the device.

After the end of the procedure, it is necessary to check the quality of the work performed. To do this, turn on the device. Set the "cooling" mode with minimum parameters and monitor the operation of the device. If the room temperature corresponds to the declared one, the cooling will occur quickly, there will be no extraneous noise from the device, which means that the refueling procedure was carried out correctly and in compliance with the basic standards.

Refueling of air conditioners: when and how?

Refueling of air conditioners should be understood as pumping freon into the system. The presence of a sufficient amount of freon is a guarantee of stable operation of the system and protection against overheating of the main elements. How to determine the moment when you can no longer hesitate with refueling? Usually, such situations develop when dismantling and transferring the air conditioner from place to place. Or if the length of the interconnect trunk exceeds the standard. These are already risk factors. But the need for refueling may arise for an air conditioner that has been operating stably for many years. So how do you determine when you need to refuel?

How do I know if the air conditioner needs to be refilled?

In fact, the need for refueling is visible to the naked eye. It is possible to assume that there is something “wrong” with freon at the stage when the air conditioner stops cooling or does not cool as efficiently as before. Another sign is ice on the indoor unit. It shouldn't be like that. Finally, take the time to look at the valve elements while the air conditioner is on. If frost is visible there, the air conditioner needs to be refilled!

By the way, this is also a reason to find out where such an amount of freon has gone. Let us clarify that a winter / summer air conditioner operating all year round loses no more than eight percent of its initial volume in 12 months. If there is ice and frost, then there are more losses. The location of the leak can also usually be found by visual inspection of the system. Since the freon contains oil, oily stains are observed in the places of leakage.It would be logical to restore the tightness first. And only then proceed to the injection of a new portion of freon.

What needs to be done before refueling?

Please note that each type of air conditioner needs its own type of freon. If you pour the wrong freon into your mechanism, the air conditioner may break down. You can find the right type of freon for your model in the instructions or on the Internet at specialized sites.

It is also worth inquiring about pressure standards there. The data will be useful when pumping freon "by pressure", that is, when the achievement of the required indicators will serve as a guideline. You also need to weigh the freon bottle in advance in order to navigate when refueling "by weight". The weight of the cylinder will decrease just by the weight of the freon that has "passed" into the system.

Next, you should "dry" the air conditioner by purging with nitrogen or freon. This is usually done with freon in an external unit. And then remove the air from the communications by means of evacuation. This applies to cases when refueling will be carried out "by weight". Now you can go to the gas station.

How to pump freon into the system?

Before refueling, you need to turn on the air conditioner "for cooling". The recommended temperature is + 18 degrees. To pump, close the three-way valve clockwise, connect the pressure gauge to the fitting on the side with low pressure, and connect the freon bottle. Then you need to open the valve so as to supply freon in small portions, constantly monitoring the pressure gauge. As soon as the indicators reach those indicated in the instructions, refueling can be stopped - there is enough freon in the system.

When refueling "by weight" it is necessary either to carry out control weighing of the cylinder and refuel until the required amount of freon comes out, or to use the refueling cylinder. The cylinder is filled to the level required. And then they use it to fill the system. As you already know, in this case it is imperative to "remove" all the refrigerant before charging, and also to evacuate the circuit.

A sight glass can also be used for control if it is possible to see the refrigerant through it. Charge should be continued until visible bubbles disappear and the refrigerant returns to normal. This moment is perfectly visible when you pump freon in small portions.

At the end of the work, close the valve again, disconnect everything that you connected to the block, and reopen the valve. Next, you need to wait a little so that the refrigerant is evenly distributed throughout the system, after which you can turn on the air conditioner. If the system works as it should, and neither ice nor frost forms anywhere, then everything has been done correctly.

If all of the above is difficult for you, then you should contact a certified specialist dedicated to all the intricacies of refueling air conditioners and pumping freon into the system.

Freon selection

Before refueling a mobile air conditioner, the consumer should decide on the type of refrigerant for the device. First of all, you need to read the instructions for the device. It indicates which type of refrigerant is recommended to be used and whether the unit can be charged with another type of refrigerant.

Freon is an inert chemical. It has no characteristic color or smell. It can use both liquid and gaseous states. The use of freon does not harm human health.

The most common type of refrigerant is R22. Freon of this type was one of the very first used in air conditioning systems. This type of refrigerant has an affordable price, but its destructive effect on the ozone layer has been proven. Due to its harmful qualities, manufacturers do not recommend using this type.

For mobile air conditioners, manufacturers recommend using new types of refrigerant, such as R407C or R410. These types of refrigerant are safe for the environment. They contain several gases.Due to the safety of use, the presence of useful properties, the use of such types is recommended to all consumers. However, the cost of this type of refrigerant is an order of magnitude higher than that of the previous generation devices. Also, this type of refrigerant is capable of very strongly absorbing humid vapors. This leads to additional dehumidification of the air in the room and an increase in the load on the operation of the device.

It should be remembered that untimely refueling of the device will lead to subsequent breakdown of the compressor - the main part of the device. In this case, an expensive replacement will be required. The cost of a new compressor can be 60-70% of the cost of the air conditioner itself. Therefore, it is advisable to carry out regular diagnostics and timely replenishment of the refrigerant level.