When building a garage, some make minor mistakes that negatively affect the thermal insulation properties of this room. One of the main sources of heat loss is gates. Therefore, during their manufacture and installation, it is extremely important to properly insulate them. At the same time, the insulation should be complex, otherwise it will not give any result.

In this article, we suggest that you familiarize yourself with all the details of which seal is best to choose. After reading this article, you will be convinced of the truth of the statement, the sealing of a garage door "do it yourself" is quite possible and without the involvement of a specialist.

What is the seal used for

The need to insulate the walls, ceiling and flooring in the garage is clear to everyone. However, some doubt that the gate should also be insulated.

Each type of gate has small slots through which cold air gets inside. This leads to a decrease in the temperature inside and an increase in humidity. To reduce heat loss, builders are advised to do the insulation of the sashes. In this case, it is necessary to sheathe not only metal structures with thermal insulation material, but also wooden ones.

Some car garage owners do not know at what stage they are engaged in insulation. All thermal insulation works are carried out during the installation of the gate.

Classification of rubber seals and their characteristics

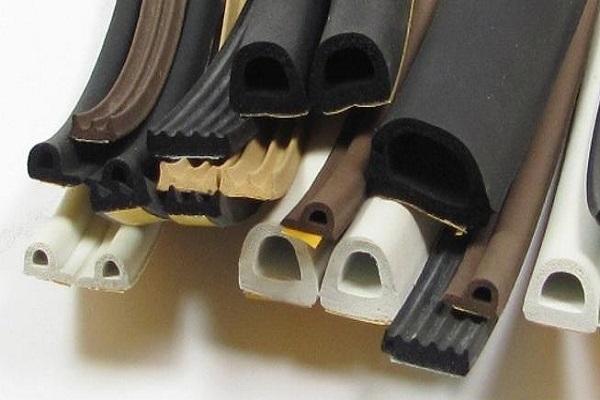

Today, there are many effective and interesting solutions for the processing of cracks on the market, which are also used for garage doors. The most popular are:

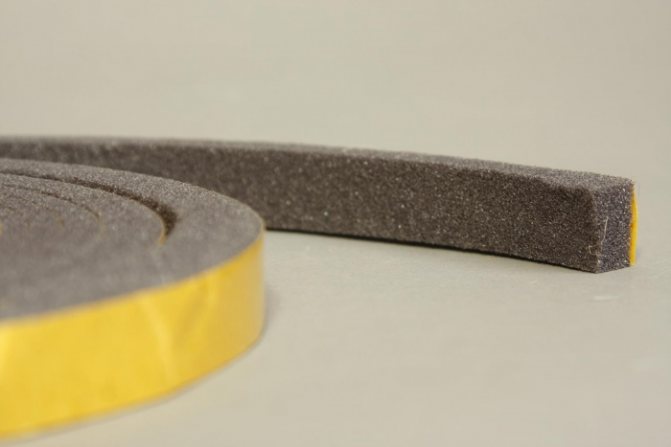

- Rubber compressor. It is considered one of the most popular materials for this type of work. Used for sealing doors in many garages. Sealing with it will relieve the garage of uneven gaps. By design, rubber seals are flat, tape and tubular. Rubber seals are most suitable for stationary structural elements.

- Silicone seal on the gate. Suitable for thermal insulation of various types of surfaces. Can be produced in tape form, which is softer than conventional silicone material. Silicone gasket has special properties, thanks to which it can be used to easily fill all gaps and crevices.

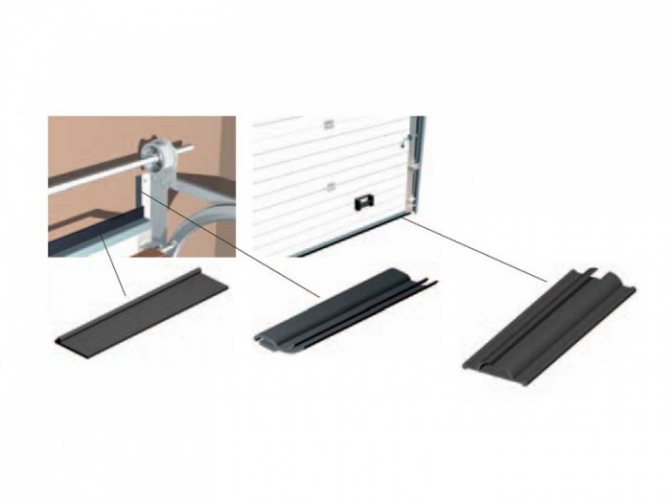

- Brush seal. Typically, the brush seal is used for sectional doors. Being impregnated with special compounds, the brush seals will last long enough, moreover, they are well cleaned. In general, strip brushes have a very simple design, which is why insulation with brushes is possible even for beginners in this business.

- Gaskets for gates made of polyurethane foam. After laying in the slot, the material takes up the entire space provided, acquiring the desired shape.

In addition, a very interesting option is a seal made by hand from improvised means. In this case, the result will depend only on skills. You can make a product from an old waste tire or from a garden hose. With proper manufacturing, the resulting product will have almost all the necessary properties and characteristics that have "store" counterparts. This will not only allow you to enjoy the work and the result, but also save a little.

If you are going to make a seal yourself, you need to choose the right material.This is due to the fact that the "factory" options have good antiwear properties and resistance to low temperatures during use. Of course, it will be difficult to achieve ideal quality in the conditions of "garage production", so you need to carefully monitor the condition of the material during operation.

The specificity of seals using a rubber material is such that all of these materials will cope with this task without any problems and can differ only in the method of installation and its complexity. Before starting the workflow, you need to prepare.

First of all, be sure to measure all the places where the material will be laid. It is best to purchase a sealant with a small margin, which in any case will not hurt.

What criteria should be met

The quality of thermal insulation is influenced by the characteristics of the selected seal. Therefore, it is recommended that you familiarize yourself with the criteria that such materials must meet. These include:

- Reliability. The selected building materials must meet all approved quality standards and have a long service life.

- Tightness. The main criterion that is paid attention to when choosing thermal insulation products. Hermetic insulation has a high level of thermal insulation.

- Wear resistance. Seals made of quality material must cope with mechanical damage, high humidity and sudden changes in temperature.

- Waterproofing. Reliable heaters must have not only thermal insulation, but also waterproofing properties.

How to choose a gate seal?

Experts recommend choosing a seal depending on what type of construction the garage door has. If they are made in the presence of swinging parts, then the best option would be a brush-type seal. It is impregnated with wax or other compounds and has a long service life of up to 8 years.

The presence of fixed elements in the construction of garage doors involves the use of silicone or rubber bands.

The material can be tubular or double-sided.

The rest of the gaps are sealed with any materials, which depends on the preferences of the garage owner. These can be not only factory-made materials, but also hand-made products that have elasticity and the necessary strength.

When choosing products, it is necessary to take into account their main disadvantages, since in most cases the available varieties of materials can cope well with the tasks assigned to them. They differ in the method and degree of complexity of the device. If the safety of the material is most important to the garage owner, then it must be moisture-resistant and heat-resistant.

Various types of seals that allow you to insulate garage doors with your own hands are the main types of products. In fact, they are produced in the largest quantities and have certain advantages and disadvantages.

Classification of sealing material

To insulate the garage space, they use various insulation materials and therefore it is necessary to familiarize yourself in more detail with each of them. Among the common seals, the following are distinguished:

- Rubber materials. This variety is popular with car owners due to its affordable cost. Ready-made rubber plates will close the gaps through which cold air penetrates and even out the unevenness of the gate. Building materials stores sell various forms of sealant. For insulation of garage doors, a tubular or flat tape is used.

- Alkaline. Such heaters are used to cover sectional door models.Thermal insulation products of the alkaline type are impregnated with special agents that protect them from low temperature and humidity. The advantages of alkaline seals include the fact that their surface is quickly cleaned of contamination.

- Silicone. Builders consider these seals to be universal, as they are suitable for all surfaces. Silicone material is often used because it is elastic and soft. This allows you to get rid of even the smallest gaps in the gate.

- Polyurethane foam. Such heaters, like silicone, are very elastic. However, polyurethane materials are not cheap and therefore are used much less often than others.

What material should you give preference to?

The range of heaters used in a garage is quite extensive. And each of them has its own characteristics, advantages and disadvantages. For example:

- Mineral wool is durable, non-combustible, but requires the highest quality waterproofing. Otherwise, moisture will accumulate with the cotton wool, which will subsequently lead to the formation of fungus and mold.

- Available foam is available in a wide range of thicknesses to insulate a garage located in all climates. The material is not afraid of fungus, mold and rodents, does not sag over time and does not lose its insulating properties during the entire period of operation. Among the minuses is the need for crate and additional door trim.

- Reliable sprayed polyurethane is the most effective solution. For insulation, in addition to the main material, you only need a linoleum substrate and polyurethane foam. It has an increased coefficient of thermal conductivity, which favorably distinguishes the material from other methods of insulation. Among the disadvantages is the need to glue parts on which it is undesirable to apply polyurethane foam. It is best if the garage is insulated by specialists with experience in this type of work.

- Thermal insulating paint is a relatively new and expensive solution, which, nevertheless, is gaining more and more popularity. Its secret is simple. The paint is not afraid of either water or ultraviolet radiation, does not make the structure heavier, which is important both for sectional doors and for sliding mechanisms. The coating is vapor-permeable, has anti-corrosion properties, does not allow warm air to seep through the door sections to the outside.

How to do it yourself

Some refuse to buy finished products, as they prefer to make seals on their own. However, before you carry out the insulation, you need to familiarize yourself with the recommendations for creating thermal insulation products with your own hands.

For self-production of sealing materials, they use improvised means. For example, some are made from high-strength car tires. Also, sealing strips are made from hoses that are used to water vegetables and fruits in the garden. To create a seal, it is enough to cut a few meters of the hose with a knife and align.

If you do everything right, the quality of the resulting material will be in no way inferior to the products that are sold in building materials stores.

Insulation of garage doors

It is not at all difficult to insulate garage doors using materials available on the market. The sheet insulation is placed close to each other and fixed with a special adhesive or foam. Mineral wool slabs are fixed in place with a lathing; it is recommended to provide the structure with a vapor barrier film.

Now we put the seal in place. They need to carefully glue the gate around the perimeter, if desired, you can use it to close the gaps obtained during installation, if there is no more suitable material for this. Choose the adhesive base carefully - it must correspond to the climatic conditions of the region. The manufacturer indicates all the characteristics you require on the packaging.You should familiarize yourself with them before starting work on installing the seal in place.

The adhesive must have characteristics that allow it to fix the sealing material to the one of which the gate is made (in most cases it is metal). As the best option, it is proposed to stick plastic strips on the metal parts, then fix the seal on them.

Step-by-step installation instructions

Before insulating sectional garage doors, you need to familiarize yourself with how to do it correctly.

First, the surface of the gate is prepared. Preparatory work is carried out in several stages:

- Cleaning the surface from dirt and corrosion. In order for the thermal insulation material to tightly cover the surface, you will have to clean off all dirt and rust from it to the floor. To do this, it is better to use a grinder with a special attachment in the form of a metal brush.

- Degreasing. Finishing is carried out after preliminary degreasing of the surface with special solvents.

- Primer. Priming works are needed to protect the gate from rust. Gates made of wood are primed with linseed oil, which will prevent the appearance of mold and mildew.

After preliminary preparation of the surface, a sealant is applied at the joints of the flaps. Then the inner surface of the gate is covered with the selected seal.

To protect the seal from mechanical damage, it is covered with thick plywood or clapboard on top.

Sealing material options

Building material on the market for closing problem areas can be divided into the following categories:

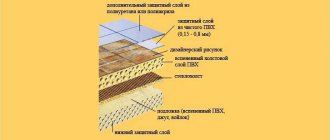

- rubber seal for garage doors, produced in the form of a tape, it can be of different shapes and colors and is sold in rolls of different lengths;

- tubular rubber - it can be of different shapes and sizes, so it is great for hiding any cracks and irregularities;

- silicone tape - in terms of its working properties, the material is close to the rubber variety, but it differs markedly in softness, more of it is needed for work;

- silicone material in the form of profiles with different shapes, is the best option for reliable filling of various gaps;

- brush seal - suitable for lazy or inexperienced craftsmen who are not able to carry out the calculations correctly or do not know how to do the job at a good level;

- a universal material with the ability to expand itself if necessary, made of polyurethane foam impregnated with acrylic.