Maintenance of circulation pumps

Pump malfunctions and remedies

The design of a circulation pump with a wet rotor is based on a modular principle. Modules can be assembled in different configurations. It all depends on the power and size of the pump.

Circulation pump device

Any repair work can only be carried out if the power is completely disconnected and the area is drained.

- The pump turns on, sounds are heard, but the shaft does not rotate. Why is the heating pump noisy and why did the other "symptoms" appear? The reason may be shaft oxidation after prolonged inactivity of the device. If the pump is blocked, the device must not be left on. It is necessary to drain the water and all screws that tighten the pump casing to the electric motor must be unscrewed. Next, we remove the engine itself, and its impeller turns manually. If the pump is of low power, the shaft can be unlocked by turning it with a screwdriver. For this, there is a special notch in the end of the shaft.

- A foreign object has blocked the wheel. How to disassemble a heating circulation pump? We dismantle the pump motor using the above method. To prevent repeated blocking, a mesh filter must be installed in front of the pump.

Circulation pumps for heating wilo

For high-quality debugging of ventilation, heating, air conditioning, underfloor heating and water supply systems, it is necessary to use reliable equipment. For private and industrial arrangement of heating, ventilation and water supply systems, circulating pumps are used. This type of equipment allows you to run water in pipes under the required pressure and head. A breakdown of the pump can lead to the failure of the entire system, and therefore, even at the stage of creating a heating system, water supply and underfloor heating, it is better to choose the highest quality equipment.

Wilo circulation pumps have long been in great demand in the domestic market. The popularity of the products of the mentioned company is due to their durability, simplicity, versatility and a large assortment of models for various technical needs.

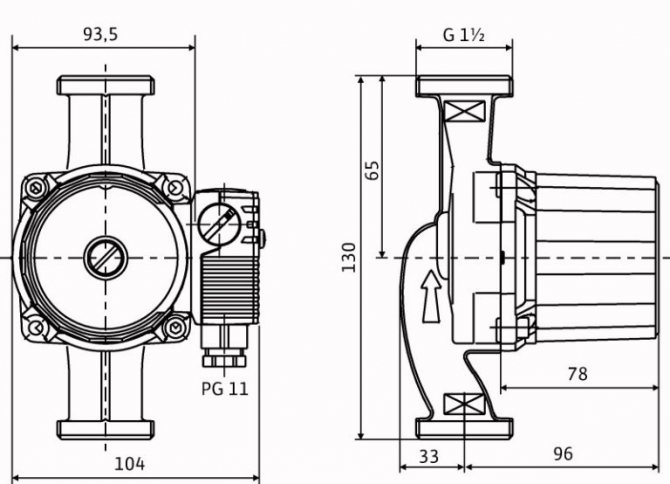

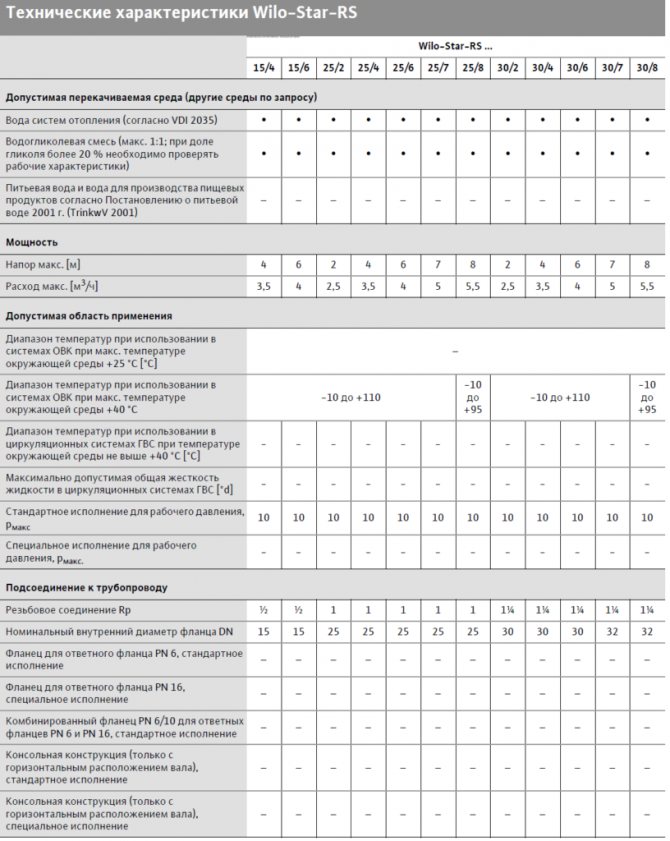

The most widely used circulation pumps from Wilo of the STAR-RS series. This series is represented by equipment of various power and capacity, it is characterized by the presence in all models of pumps of the so-called "wet" rotor and threaded transition to pipes. The "wet" rotor protects the motor from overheating, thereby making the STAR-RS series circulation pumps resistant to continuous loads and high temperatures.

All Wilo products are created in such a way that the installation of the pumps is as simple and convenient as possible, depending on the purpose of the equipment. Threaded pipe connections allow easy installation of water supply, air conditioning, ventilation and heating equipment, and also easy to remove for maintenance or repair. Spring terminals are designed for quick connection of pumps to the mains (almost all models of Wilo circulation equipment operate from an ordinary 220 V socket). The terminals can be positioned at different angles on the floor for easy connection to the network.

It is quite simple to buy Wilo circulating pumps in Kiev. Turning to a specialized store of climatic technology and equipment for water supply systems, heating and underfloor heating, the buyer will definitely find the necessary circulating model at a reasonable price. The equipment of the above company is widely known not only in the domestic, but also in the European market, therefore it has all the necessary international quality certificates.

Circulation pump for heating Wilo

The company exists a century and a half... During this time, its name has become a symbol of quality and reliability. Since 2008, the name Wilo SE has been approved.

If you need to complete the heating system, then the Wilo pump will be the best choice.

Specifications

- performance 2.2-6 cubic meters per hour;

- power depends on the set frequency and is within 39-176 W;

- rotation frequency 0.1-4.8 thousand rpm;

- pumps cold water with temperatures below zero (up to -10 ° С);

- pumps hot water up to 110 ° С;

- weight - 2-8 kg.

Installing a pump will extend the life of the heating boiler and will economically use fuel or electricity.

Important! A circulation pump is a means of increasing the pressure in the piping of the system, regardless of the configuration. Even a simple low-power unit able to improve heating efficiency.

The benefits of Wilo products

The device is designed for comfortable use:

- reliability, simple design, compactness;

- cataphoretic coating protects against rusting;

- manufactured made of quality materials;

- manual speed control pumping;

- engine does not react to blocking currents and does not need a relay;

- dry running protection;

- tolerates hot environments up to 40 ° Сinstalled in boiler rooms;

- available self-assembly.

Judging by the feedback from users of the products, there are no shortcomings.

Wilo pumps are suitable for customers with all income levels. The cost of a simple device starts from 2500-3000 rubles, powerful models for multi-storey buildings can be bought for 150-230 thousand rubles.

Component devices

A circulation pump consists of several elements:

- body;

- working chamber;

- engine;

- rotor;

- impeller;

- automation.

Wilo engines are presented in a large assortment for any system configuration. There are products with powerful motors that create excellent head.

The lineup

The concern is famous for a fairly wide range of products. The Wilo CAD catalog contains 142 series, among which the most common are:

- Wilo-Economy-CO - multi-pump and single-pump pressure boosting stations. They are assembled on the basis of vertical pumps MVI, Helix V, MVIS, MHI. In the station, 2-4 units are installed in parallel, which increases operational reliability and productivity. Supplied with collecting collection tank and solids separation system and control panel. The head varies from 60 to 160 m. The flow rate, depending on the pump, can be 14, 75, 80, 135 cubic meters / h.

- The Wilo-Multivert MVI family is a vertical outdoor centrifugal device. They provide water for irrigation installations, are component parts of boiler rooms, fire extinguishing installations. The design and dimensions of the MVI during installation save space. The MVI 2 series consumes 5 cubic meters / h, the head - 220 m, the fourth series - 8 cubic meters / h, the head - 210 m, the eighth - 14 cubic meters / h with a head of 225 m.

- Star is a line of models with a wet rotor and a threaded connection. There are 3 speed modes. The devices are used for cold water supply, in heating systems. Head - up to 8 m. Flow rate reaches 6 m3 / h.

- TOP are compact circulating pumps with the ability to connect it to a pipe. They work quietly, are ideal for pumping liquids through a pipeline in private houses, they are thermally insulated. Head - 9 m, flow rate - 65 m3 / h.

- The Wilo Helix pump family is multistage equipment belonging to the subtype of non-self-priming pumps with a flow rate of up to 93 m3 / h and a max. heads up to 240 m. The units are equipped with a dry rotor, each unit has a frequency converter and air cooling.

- Stratos are highly energy efficient circulation devices. Applicable in heating systems, cooling circuits, air conditioning. The company also creates various control devices.For example, Wilo SK 702 is a device for control, protection and monitoring of pumps against overcurrent, dry running.

- The line of Wilo Comfort Vario pumps has 3 series, differing in design features. The regulator can combine up to 4 products in parallel.

Wilo Comfort Vario pumps

Popular models, their technical characteristics

The most popular models are:

- WJ 203 EM is a self-priming water supply station with a 50-liter tank and a power of 0.75 kW. Max. head - 41 m, flow rate - 5 cubic meters / h;

- Star-RS 25/4 is a circulation model of balanced design used in heating and hot water supply systems. Head - 4 m. Connected to the power supply, the unit operates in one of three stages of rotation. Vit has a 2-sided cable drive, stamps;

- Wilo Hisewlift 3-35 sewage cutter unit with a power consumption of 0.4 kW and a direct start-up type. Rated speed - 2900 rpm. Tank volume - 17 liters;

- Wilo JET HWJ 204 is a horizontal, single-stage portable self-priming jet device. It pumps water in the supply / suction modes. Delivers water to a depth of 8 m thanks to the hydraulic power of the system. Power consumption - 1.3 kW;

- device HWJ 202 EM Wilo for water supply, irrigation, pumping rainfall, is used mainly in garden areas, a 20-liter membrane tank helps to reduce the frequency of starts. Suction head is 8 m, head is 37 m. Max. the water supply is 4.5 cubic meters / h.

- Wilo Hisewlift 3-15 - automatic installations that drain wastewater from the sink, wastewater with feces from the toilet bowl. The volume of the tank is 17 liters. Power - 0.4 kW. Liquid temperature - from +5 to +35 degrees;

- in the model range of circulating Star RS, a special place is occupied by the Wilo RS 30/6. This is a standard glandless pump with a threaded connection. Has 3 stages of rotation frequency, manual control. The head is 6 m, the flow rate is 4 cubic meters / h.

The principle of operation of the circulation pump Wilo MTSL 155 HE 2

The main part of the pump is an electric motor, consisting of a stator with several inductors for adjusting the speed of rotation, and a rotor, which is integrated on the shaft with bearings.

When power is applied to one of the stator windings, an electric field is created that drives the rotor with the turbine. The turbine blades capture liquid from the suction pipe and move it along the outlet pipe. In this way, the coolant circulates throughout the entire heating circuit.

Let's consider the main reasons leading to the breakdown of the Wilo MTSL 15/5 HE - 2 pump.

Unstable voltage in the network

With a reduced power supply, the pump motor slows down until it comes to a complete stop. With an increased voltage, the inductor coils are heated, due to which an interturn short circuit or burnout of the winding wire may occur.

Contamination of pump mechanisms

At a liquid temperature of more than 60 ° C, scale can form on the turbine and shaft, which will slow down the rotation of the motor armature. The reasons for the pump jamming can also be increased oxidation of the driving mechanisms or the ingress of foreign objects.

Poor quality material of components

If the pump uses parts made of low-quality materials, its resource is sharply reduced. For example, the shaft starts to seize due to the formation of a layer of rust on the surface of the bearings, because they are made of bronze, which contains iron. Such symptoms are typical for a non-original model.

Incorrect use of the device

Water through a running pump must constantly circulate at a certain rate. If the movement of the coolant is disturbed (the valve of the return or supply line is closed, the system filter is clogged, etc.), the bearings and inductance coils will overheat in the device - this will lead to jamming of the rotor, breakage or short circuit of the stator winding.

The circulation pump Wilo MTSL 15/5 HE - 2 must not be used when there is no water in the pipeline.But since Ariston's two-circuit automatic units are equipped with fluid pressure sensors, the boiler will not turn on if there is no water in the system or if its pressure is low.

Application and purpose

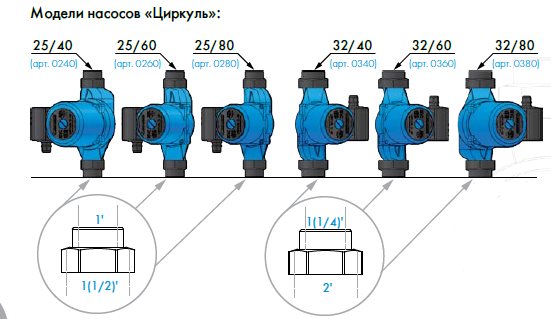

Jileks Compasses are circulation devices designed for heating and cooling, air-conditioned, ventilation systems. The purpose of the units is to circulate the working fluid in closed systems. When operating the devices, pipes of a smaller diameter are used than with natural circulation. Provides an even distribution of temperatures in systems. The unit series features a wet rotor and a three-speed motor. The engine is equipped with a block for manual adjustment of the speed of the working fluid in a closed system.

Dzhileks Compass provides warming up of the heated room and uniform distribution over all parts of the working fluid circuit.

Standard complete set of the Jileks pump Compasses

The presence of a wet rotor allows the system to be adjusted. It features high performance, energy efficiency and low operating noise.

The lineup

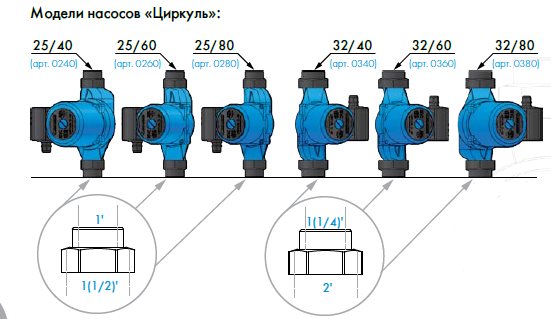

Jileks Compasses series consists of six models with different characteristics.

Description of models Compasses:

- 25 40. Circulating pumps Jileks Compass 25 40 operate with a temperature range from ten to one hundred and ten degrees Celsius. Creates a head of four meters. The throughput is three cubic meters per hour. Has three speeds. Operated at indoor temperatures up to fifty degrees. Weighs three kilograms;

- 25 60. The difference between the model and the previous one in the generated head of six meters and a throughput of 3.8 cubic meters per hour. Creates a noise of 65 dB;

- 25 80. The model creates a maximum head of eight meters. The throughput is eight cubic meters per hour. Pumps Dzhileks Zirkul 25 80 emit noise 45dB;

- 32 40. Model of circulation pumps Dzhileks Compasses 32 40 are made of cast iron. Works with liquid temperatures up to one hundred and ten degrees Celsius. Circulating pumps Compass 32 40 have a rated power of 32 W, a head of four meters, a weight of 3600 grams, a hole diameter of 1.25 inches;

- 32 60. The power of the model is 55 W, it creates a head of six meters, a throughput of 3.8 cubic meters per hour. Emits noise 45 dB;

- 32 80. Pump model 32 80 The compass weighs six kilograms. The rated power of the device is 135 W. Circulating pumps Dzhileks Zirkul 32 80 operate at three speeds. The maximum head and flow capacity is eight meters.

Design and application features

Compass devices have a number of features that distinguish them from other models and manufacturers.

Model range of pumps Jileks Compass

Features of the devices:

- devices are distinguished by high performance;

- used for domestic hot water supply and heating systems;

- it is forbidden to use in systems for drinking water;

- wet rotor for all models;

- three-speed manual control motor;

- works with water and liquids with ethylene glycol;

- cast iron body, not subject to corrosion;

- mounted horizontally and vertically;

- a decrease in the rotation speed reduces the energy consumption and the volume of the device;

- the complete set includes nuts for mounting;

- low vibration.

Distinctive features

When Wilo pumps are connected to heating systems, their design allows you to significantly increase heating efficiency due to high heat transfer efficiency.

After examining the factory description, you can find out that:

- when installing a water supply system, it is possible to use pipes of a smaller diameter, which can significantly save on materials and energy carriers for heating;

- in normal operating mode, the pump consumes no more than 250 W of electricity per day, therefore it is very beneficial for installation in home water supply and heating systems;

- the design of the device is reliable and durable even when working in difficult conditions and allows you to work with high pressure and any temperature of the working fluid;

- the original mechanism for connecting to the pipeline using spring clips allows you to carry out the installation yourself, without the involvement of specialists;

- the pumps have a wet rotor, so they practically do not make noise during operation.

Wilo circulation pump in retail areas

There are several models for use in heating systems, which are selected depending on the total heated area. It can be from 200 to 1000 square meters for one device.

The main indicators - power, head height, pumped volume of liquid per unit of time, the recommended area of the heated room - are indicated by the manufacturer.

Advantages in application

All materials used in the manufacture of Wilo pumps are reliable and durable and do not corrode. Parts and assemblies are made of cast iron, stainless steel, metallographite, high-strength polymers.

The advantages of such devices include the following:

- there are no heat losses arising from liquid evaporation;

- work is carried out in fully automatic mode, the parameters of which are displayed on LCD screens;

- there is a possibility of manual adjustment of the rotation speed;

- stable operation of the device and prevention of failure is ensured by a multi-stage protection system against voltage surges in the stationary network;

- all models, even the most powerful ones, have small overall dimensions, therefore they do not require a specially designated place for installation;

- the absence of noise during operation makes it possible to install the pump directly in the living room.

Wilo circulation pump in the heating system

Overall dimensions of the Wilo TOP S pump range

Pump sizes

| Wilo TOP S ... | Piping connection / nominal diameter | Thread | Pump dimensions | Weight approx. | Outline drawing | ||||||

| [Rp / DN] | G | I | a1 | a2 | l1 | b1 | b2 | b3 | PN 6/10 | – | |

| – | – | – | |||||||||

| 25/5 | Rp 1 | G 11/2 | 180 | 40 | 70 | 150 | 50 | 87,5 | 92 | 4,5 | A |

| 25/7 | Rp 1 | G 11/2 | 180 | 34 | 56 | 165 | 66 | 80 | 92 | 5,0 | A |

| 25/10 | Rp 1 | G 11/2 | 180 | 52 | 72,5 | 171,5 | 68,5 | 92 | 102 | 6,3 | A |

| 30/4 | Rp 11/4 | G 2 | 180 | 50 | 70 | 156 | 53 | 87,5 | 92 | 5,0 | A |

| 30/5 | Rp 11/4 | G 2 | 180 | 40 | 70 | 150 | 50 | 87,5 | 92 | 4,5 | A |

| 30/7 | Rp 11/4 | G 2 | 180 | 34 | 64 | 172 | 66 | 88 | 92 | 5,0 | A |

| 30/10 | Rp 11/4 | G 2 | 180 | 52 | 72,5 | 171,5 | 68,5 | 92 | 102 | 6,3 | B |

| 40/4 | 40 | – | 220 | 54 | 76 | 178 | 83 | 103 | 92 | 9,5 | C |

| 40/7 | 40 | – | 250 | 46 | 72 | 193 | 78 | 97 | 102 | 11 | D |

| 40/10 | 40 | – | 250 | 58,5 | 88 | 217 | 90 | 121 | 110 | 14,5 | D / E |

| 40/15 | 40 | – | 250 | 55 | 83 | 258 | 99 | 135 | 119 | 20,6 | D / E |

| 50/4 | 50 | – | 240 | 53 | 80 | 200 | 93 | 112 | 104 | 13 | D |

| 50/7 | 50 | – | 280 | 63 | 82 | 225 | 91 | 119 | 110 | 16,5 | D / E |

| 50/10 | 50 | – | 280 | 67 | 91 | 223 | 101 | 123 | 110 | 17 | D / E |

| 50/15 | 50 | – | 340 | 81 | 112,5 | 242 | 105 | 137 | 119 | 25,5 | D / E |

| 65/7 | 65 | – | 280 | 72 | 97 | 234 | 111 | 124 | 110 | 18,5 | D / E |

| 65/10 | 65 | – | 340 | 79 | 100 | 256 | 118 | 136 | 119 | 23,5 | D / E |

| 65/13 | 65 | – | 340 | 79 | 100 | 256 | 118 | 136 | 119 | 25,5 | D |

| 65/15 | 65 | – | 340 | 79 | 100 | 283 | 118 | 136 | 119 | 29 | D |

| 80/7 (1~) | 80 | – | 360 | 95 | 130 | 258 | 135 | 159 | 119 | 28 | E |

| 80/7 (3~) | 80 | – | 360 | 96 | 130 | 227 | 111 | 149 | 110 | 25,5 | D |

| 80/10 | 80 | – | 360 | 95 | 130 | 258 | 135 | 159 | 119 | 28/30 | D |

| 100/10 | 100 | – | 360 | 95 | 130 | 258 | 135 | 159 | 119 | 28,5/30,5 | D |

Flange dimensions

| Wilo-TOP-S ... | Flange | Nominal inner diameter | Pump flange dimensions | Outline drawing | |||

| – | DN | Ø D | Ø d | Ø k, Ø kL1 / kL2 | n x ØdL, n x ØdL1 / dL2 | – | |

| – | – | – | |||||

| 40/4 | Combination flange PN 6/10 (flange PN 16, according to DIN 2533) | 40 | 150 | 88 | 100/110 | 4 x 14/19 | F |

| 40/7 | |||||||

| 40/10 | |||||||

| 40/15 | Combination flange PN 6/10 (flange PN 16, according to EN 1092-2) | 40 | 150 | 84 | 100/110 | 4 x 14/19 | F |

| 50/4 | Combination flange PN 6/10 (flange PN 16, according to DIN 2533) | 50 | 165 | 102 | 110/125 | 4 x 14/19 | F |

| 50/7 | |||||||

| 50/10 | |||||||

| 50/15 | Combination flange PN 6/10 (flange PN 16, according to EN 1092-2) | 50 | 165 | 99 | 110/125 | 4 x 14/19 | F |

| 65/7 | Combination flange PN 6/10 (flange PN 16, according to DIN 2533) | 65 | 185 | 122 | 130/145 | 4 x 14/19 | F |

| 65/10 | |||||||

| 65/13 | |||||||

| 65/15 | |||||||

| 80/7 (3~) | Flange PN 6 (designed for PN 16, according to EN 1092-2) | 80 | 200 | 132 | 150 | 4 x 19 | G |

| Flange PN 16 (according to EN 1092-2) | 80 | 200 | 132 | 160 | 8 x 19 | G | |

| 80/7 (1~) 80/10 | Flange PN 6 (according to DIN 2531, holes according to EN 1092-2) | 80 | 190 | 128 | 150 | 4 x 19 | G |

| Flange PN 16 (according to DIN 2533, holes according to EN 1092-2) | 80 | 200 | 138 | 160 | 8 x 19 | G | |

| 100/10 | Flange PN 6 (according to DIN 2531, holes according to EN 1092-2) | 100 | 210 | 148 | 170 | 4 x 19 | G |

| Flange PN 16 (according to DIN 2533, holes according to EN 1092-2) | 100 | 220 | 158 | 180 | 8 x 19 | G |

What do the designations of the name of Wilo pumps mean?

After the word "Wilo", the pump names contain a word or several letters indicating the type of product:

- Drain - drainage;

- TWU or Sub TWU - downhole;

- Drainlift - sewerage installations;

- PB, EMHIL - increasing pressure;

- KH - sewer installation;

- Star-RS or RSD - circulating, etc.

Further there may be letters and numbers, meaning various characteristics.

This is the inner diameter of the connection to the pipeline (in mm) and the delivery head, that is, the head (in meters). Example: star-RS 25/7.

The installation length of the product can also be indicated with a hyphen (example: Star-RS 15 / 6-130). For drainage:

- STS - submersible, fecal;

- TS - submersible, working in dirty water;

- LP - self-priming;

- LPC is a self-priming cast version.

Next comes the diameter of the nozzle and the head. A hyphen is either the letter A, which means a float switch, or CEE - there is no float switch.

The most popular models of Vilo drainage pumps

- Wilo-DrainTMT 32H102 / 7,5Ci pump Submersible unit for vertical installation. It can be used for pumping hot water and aggressive liquid media.

- Drainage pump Wilo-Drain TMW 32/11. Used for pumping waste water. Prevents the accumulation of precipitated substances, destroys them together with the pumped out liquid. The temperature environment is not more than 35 degrees.

- DrinVC model. The vertical positioner can handle contaminated environments that contain a 5mm particle.The VC30 / 10 type pumps water at a speed of 7m³ per hour with a head of ten meters.

- The EMU KS unit is used for pumping wastewater from flooded basements or pits, ingress of grains with a diameter of 5-45 millimeters is allowed.

Wilo manufactures versatile equipment that can be used in different areas of life. Each drainage pump of this brand will delight you with excellent quality and optimal technical characteristics.

TOP-S series

The models in this series are designed for use in buildings up to 1400 m². These pumps, with one or three-phase connection, guarantee faster pumping of hot water through pipes and radiators.

In their manufacture, materials similar to the previous line from the German company Wilo were used.

Working and installation conditions

The equipment operates at a temperature of +20 + 130 ° C, and for two hours the units can operate without interruption if the maximum temperature rises by 10 ° C. The admissible pressure is 6, 10 or 16 bar (special version). As in the previous case, the rpm is regulated by a three-stage switch.

Vilo TOP-S series is produced with increased motor protection and thermal insulating casing. The versatility of Wilo equipment is due to the double-sided cable connection and the configuration with a combined flange 6/10 bar (for models with an inner diameter of 40 - 65 mm).

Design and principle of operation of Wilo pumps

- Noise characteristics - the operation of the module is absolutely noiseless, which allows installation directly in living quarters, in the kitchen and in the bathroom.

- Air removal - a valve is installed in the structure through which air is removed from the heating system.

- Reduced energy consumption - all models consume the minimum amount of electricity. At the same time, high productivity is maintained.

- Long service life. Wilo pumps for heating systems have a cast iron casing. All important parts of the structure have anti-corrosion properties. All models are subject to mandatory testing and certification.

- Convenient control - a mechanical or electronic switch is provided. The power and speed of movement of the coolant is regulated.

- Electronically controlled models are equipped with a built-in thermostat.

- Protection of the electric motor and rotor against voltage surges is provided.

- Operating parameters - head of water column from 1 to 7.5 m, heated area from 100 to 2200 m², throughput from 1 to 12 m³ / hour. The working temperature range of the coolant is from -10 ° С to + 110 ° С.

The Wilo pump device is distinguished by thoughtfulness, high performance and efficiency. The models are ideal for radiator heating, multi-circuit systems as well as DHW and air conditioning.

Heating pump Wilo Star

- Wilo Star RS - 12 equipment models are produced in the series, with markings from 15-4 to 30-8. The body is made of heat-resistant cast iron, the rotor, bearings and other elements in contact with the coolant are made of stainless steel. Star RS is a manually controlled circulating pump with the ability to generate pressures up to 10 bar. Maximum throughput up to 6 m³ / hour.

- Wilo Star RSD are dual circulation pumps that perform several tasks at once: they increase the pressure in the heating system, increase the service life of the devices and make it possible to simultaneously connect the module to two independent circuits. The set includes a switch that controls the operation of two electric motors.

Heating pumps Wilo Top

- Wilo TOP-RL and TOP-S are the most efficient pumps in the series. Models are equipped with 1-2 motors, wet rotor. One-two-phase connection to the mains is possible. The Wilo three-speed pump uses a mechanical switch.

- Wilo TOP-Z is a model of the Tor series, for which the quality of the heat carrier used is insignificant.The module has found wide application in systems with possible deposition of calcium and magnesium deposits. The pumping equipment is located in any places, the most unsuitable for this.

- Wilo TOP - basic configuration. The circulation pump for heating Wilo Top is offered in more than 50 items. The difference lies solely in the mounting size of the flange, as well as performance parameters: pressure from 6-10 bar, temperature of the heating medium from -20 ° C to + 130 ° C.

Mounting equipment of the TOP series is optimally suited for industrial use, in conditions of an aggressive heat carrier environment.

Heating pumps Wilo Stratos

- The power consumption of the Wilo pump is from 2 to 48 W.

- The night mode is set when the power consumption drops to a minimum.

- Automatic adjustment of operating parameters - the controller is connected to a room thermostat, which allows it to select the optimal speed, performance, depending on actual needs.

Wilo Stratos are suitable for energy-efficient heating systems. Compared to ordinary pumping equipment, the energy savings are at least 80%.

Types of pumping devices

Allocate two main varieties circulation pumps for heating systems.

Dry rotor

Devices of this type differ in increased power.

The main parts of the pump do not come into contact with the pumped mediumbecause they are located in a sealed chamber.

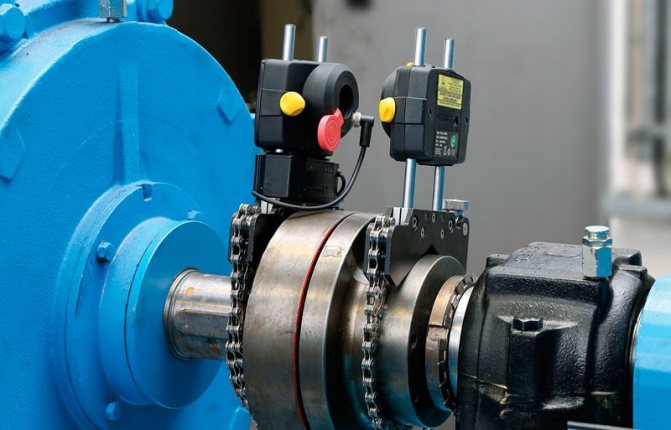

Photo 1. Circulation pump from the manufacturer Wilo with a dry rotor. There is a fan at the back for cooling parts of the device

Such a device is capable of creating a pressure column up to 15 meters, but a dry rotor means some problems:

- requires regular maintenance;

- there is noise when the engine is running;

- dry running means periodic wear and tear, which will require action.

In the event of a breakdown, you will have to replace spare parts, which are made from expensive materials and have a tangible cost.

Wet rotor

This variety is more unpretentious and does not require attention from the owner.

Maintenance-free because the device does not need to be cleaned or lubricated. The role of the lubricant is played by the coolant, which is in contact with the moving parts of the equipment.

Thereby the pump does not make noise, does not wear out and consumes little energy.

Photo 2. Circulation pump from the manufacturer Wilo with a wet rotor. It is less whimsical than the dry type of the device.

Comparison tables of the main parameters of WILO pumps of the Drainlift family.

All installations of this group are used for pumping untreated wastewater in the sewer mains, in cases where it is impossible to drain them by gravity, i.e. due to the natural height difference.

| Series (varieties) | Max. delivery height, m | The total volume of the tank, l | Max. diameter of solid particles, mm | Max. inflow at S3 mode, l / h | Max. level (volume) of inclusion, l | Pumped liquid temperature range | Features of the |

| (S 1/5) | 5 | 45 | 40 | 600 | 20 | from +3 to + 40 ° C, short-term up to + 60 ° C | One built-in pump. Single or three phase motors. The motor unit is located outside the tank. |

| (M 1/8, M 2/8) | 8 | 62 or 115 | 45 | 1080 or 3600 | 24 or 40 | from +3 to + 40 ° C, short-term up to + 60 ° C | One or two built-in pumps. Single or three phase motors. The motor unit is located outside the tank. |

| (L1 /…, L2 /…) | 25 | 115 or 140 | 40 | 1050 or 3000 | 35 or 50 | from +3 to + 40 ° C, short-term up to + 60 ° C | One or two built-in pumps. Three-phase motors only. The motor unit is located outside the tank. |

| RexaLift FIT L | 115 or 140 | 40 | 1050 or 3000 | 35 or 50 | from +3 to + 40 ° C, short-term up to + 60 ° C | One or two built-in pumps. Three-phase motors only | |

| (XL2 / ...) | 25 | 380 | 40 | 15600 | 260 | from +3 to + 40 ° C, short-term up to + 60 ° C | Two built-in pumps. Three-phase motors only. The motor unit is located outside the tank. |

| (XXL 840, XXL 880, XXL 1040, XXL 1080) | 400 or 800 | 78 or 95 | 26400, 27600, 52800 or 55200 | 305, 315, 610 or 630 | from +3 to + 40 ° C, short-term up to + 65 ° C | Two pumps - Drain TP 80 or Drain TP 100 - dry (not in tank). Three-phase motors only. |

Mine sewage pressure pumping stations for installation both inside buildings and outside (in the ground).

Shaft pumping stations of this group are used for collection and pressure discharge of wastewater into main sewer networks, in cases where their drainage by gravity is impossible, i.e. due to the natural height difference under the influence of gravity.

| Series (varieties) | The total volume of the tank, l | Max. diameter of solid particles, mm | Max. inflow at S3 mode, l / h | Max. level (volume) of inclusion, l | Pumped liquid temperature range | Features of the |

| (WC 40 D, WC 40 E) | 255 or 400 | 40 | 1950, 3000 or 9600 | 65, 100 or 160 | from +3 to + 40 ° C | Installed in a building or in the ground. One or two Drain TC 40 pumps. Single or three phase motors. The pumps are included in the scope of delivery. |

| Mine installations-tanks for waste water. The pumps are not included in the scope of delivery. | ||||||

| (WS 40, WS 50) | 255 or 400 | 44 | depends on the pump | depends on the pump | from +3 to + 35 ° C or + 40 ° C, depending on the pump | Installed in a building or in the ground. One or two Drain TP 50 / TP 65 or MTS 40 pumps. Single or three phase motors. The pumps are not included in the scope of delivery! |

| (WS 625 E /…) | 368, 460, 552, 664 | 10 or 40 | depends on the pump | depends on the pump | +3 to + 35 ° C, + 40 ° C or + 90 ° C, depending on the pump | Installed only in the ground (outside buildings). Only one pump is used - TMW 32/11, TC 40, STS 40 or MTS 40. Motors can be single or three phase. The pumps are not included in the scope of delivery! |

| (WS 830 E) | 929 or 1261 | depends on the pump | depends on the pump | from +3 to + 40 ° C | Installed only in the ground (outside buildings). Only one pump is used - MTC 32 or MTS 40. Motors can be single or three phase. The pumps are not included in the scope of delivery! | |

| (WS 900, WS 1100) | 880, 900, 1215, 1220 or 1240 | 10, 44, 50, 65 or 80 | depends on the pump | depends on the pump | from +3 to + 35 ° C or + 40 ° C, depending on the pump | Installed only in the ground (outside buildings). One or two pumps are used - TS 40, TP 50 / TP 65, Rexa FIT V05, Rexa PRO V05, TP 80, MTC 32 or MTS 40. Motors can be single or three phase. The pumps are not included in the scope of delivery! |

Pumping station and its types

A pumping station is a complex system of pumping equipment that is used for pumping liquid and consists of a main pump and an additional pump, a tank or water tank, a hose, a pressure gauge for pressure control, a pressure switch and a union. Simple and common pumping stations in this design: diaphragm tank, self-priming pump and pressure control switches.

Modern equipment has reached a high level and a dozen types of pumping stations have appeared. Stations that are capable of pumping liquid are divided into two types:

- household;

- industrial.

Self-priming station Wilo HWJ 201 25L

Household pumping units are necessary for water supply of private houses and summer cottages, cottages, farms and agricultural holdings, automatic and manual irrigation of gardens, personal plots and greenhouses. Such Wilo pumping equipment is widely used in the sewage mains of water supply and wastewater disposal, where they collect and discharge wastewater into special treatment facilities.

Industrial pumping stations:

- Boost station. Such a station is used to increase the pressure or to maintain it at a given level in the hydraulic line.

- Fire station. In fire extinguishing, high pressure and pressure stations are used.

- Hydraulic. With the help of such stations, hydraulic tools are supplied with working fluid and tools under constant pressure.

- Modular. Used for collecting and discharging waste water. Most often, modular equipment is supplied ready-made and assembled. This increases reliability, quality and saves time during further assembly.

- Pumping and filtering. Such installations are necessary when it is required to provide cities and villages with drinking water. Modern filtration systems cope with the elimination of impurities and bacteria in the water. Filtration takes place using ultraviolet cleaning technology without the use of chemicals.

Wilo pumps

Among the pumping equipment, the products of the Wilo company have proven themselves. Vilo pumping equipment of high quality and reliability.

About Wilo

Wilo SE is a world famous manufacturer of pumping equipment in various directions: air conditioning systems, ventilated systems, water supply systems, heating and fire extinguishing, founded in 1872. The main office of the company is located in Dortmund, Germany and has 60 representative offices in the world. Wilo was founded in 2002. The company uses innovative and highly efficient technologies for production.

The advantages of Vilo products

- low consumption of electrical energy by equipment;

- high level of assembly quality, mechanisms and components are carefully selected;

- pumping equipment of this manufacturer is convenient to use and repair;

- low noise level of equipment during operation, which is appreciated by owners of houses and estates;

- availability of specialized Wilo service centers in large cities. This allows for quick service and repair of equipment.

Use of Vilo pumps and stations:

- Vilo pumps for houses with a small number of apartments and low buildings;

- Vilo pumps for houses, summer cottages, cottages;

- Vilo pumps for business buildings;

- Vilo pumps for industrial use;

- Vilo pumps for use by public utilities and enterprises.

Pump increasing the pressure in the water supply

A variety of species, their features

Consider some types of pumps for heating and their characteristics:

Circulation pumps Wilo

They work in a closed-loop heating system. There are:

- Wet rotor.

- And with dry.

Different capacities of "wet" devices allow heating rooms from 100 to 750 m2. The coolant can be heated up to 120 °, or it can be cooled down to -10 - the unit will remain operational. Head - from 2.2 to 12 m. Rotational speed 0.95 - 4.8 thousand per minute.

The units have three operating speeds that can be switched, depending on the load and temperature outside the window. The equipment weighs from 2.2 kg. up to 8 kg. The working parts of the engine are placed in a coolant, as a result of which it is lubricated and runs silently.

For rooms exceeding 1000 m2, as well as for boiler rooms serving several buildings, the use of "dry" models is provided. The frequency of rotation of such devices is up to 2.85 thousand per minute. The work is accompanied by a lot of noise, but the power of such a device is higher than the previous version.

Well fork

Submersible downhole tools work at a depth of 350 m, in sandy and artesian wells. Diameters 74 mm or 98 mm.

Drainage pumps

The peculiarity of drainers is that they can distill large volumes of liquid, but at the same time the height, or the length to which the device can deliver this liquid, is limited (as a rule, it is about 10 meters).

Another important feature is the filter system and the reliability of the blades, which allows the pump to work with contaminated water (particles from 2 to 15 mm).

Fecal Wilo

Place of work - sewer pits, old silted wells, mines, septic tanks and any stagnant water. Most often they are equipped with a cutting device that grinds viscous and semi-solid elements contained in a liquid. Different models can pass solid particles up to several centimeters!

Sewerage installations

They can automatically drain water from showers, washing machines and dishwashers, and work with rainwater. The effluent must be free from fats, fibers, faeces and solids. Equipped with a check valve to prevent backflow of sewage and a charcoal filter.

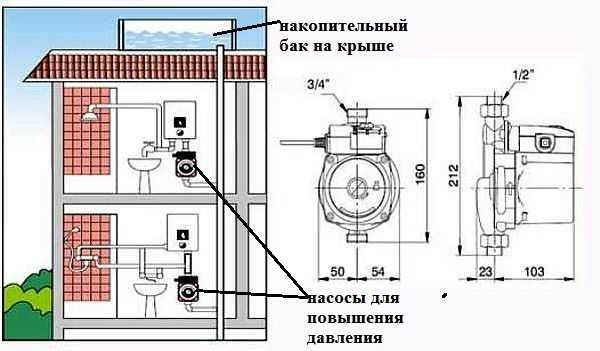

Pressure boosting pumps

They are used in cold water supply to increase the pressure.

It is a centrifugal automatic unit of the "wet" type.

Differs in quiet operation and low weight. The pump is switched on and off using the flow sensor.

Afraid of frost, long downtime and air ingress into the structure.

How to correctly install a Wilo pump in a heating system

- Only vertical installation is allowed. Do not install a Wilo pump horizontally in the system. The only exceptions are models specially designed for horizontal connection. The installation position of the pump can be found in the operating instructions.

- Connecting underfloor heating - the pump is installed in a special mixing unit. The correct location of the Vilo heating pump is indicated by arrows on the body and on the hydraulic wiring.

- Connection to a radiator-type heating system - installed in the heating return, directly in front of the boiler. To prevent a complete stop of the circulation of the coolant, they are mounted in a bypass. The rules for installing Vilo pumps allow the use of equipment for heating systems with natural and forced circulation.

- Installation and maintenance - the pump is installed in a vertical position, observing the direction of the coolant indicated by the arrows on the body and mixing unit. It is recommended that the installation be carried out by qualified personnel. The installation methods of the pump depend on the selected model and are described in detail in the technical documentation. Provided that it is correctly connected, no special maintenance of the Wilo pump is required.

- On the bypass frame, it is necessary to install a coarse filter in front of the pump.

- You can leave the pump on at all times. It is recommended to turn on the device for a few minutes after the end of the heating season.

- Hum when the pump is running - indicates several possible malfunctions. The air vent is clogged, as a result of which no air is removed from the system. Another malfunction lies in the incorrectly selected operating mode. Reducing the operating speed usually stops the hum. If not, pump service will be required.

- It is possible to turn on the pumping equipment only when the heating system is full. Wet rotor models use heat transfer fluid for lubrication. When turned on, if there is no lubricant, the bearings burn out quickly.

Only a qualified technician can take into account all the details of the installation of a Wilo circulation heating pump. Equipment installation is completed in just a few hours. When installing a bypass, it will take 3-6 hours.

How to choose a pump for heating a private house

Wilo, as a pump for heating a private house, is used by owners everywhere. The selection of a pump is actually quite a delicate matter and of course all the little things must be taken into account. It is necessary to calculate the length of the line, take into account the number of radiators, do not forget about the heat loss, and much more. In general, as a rule, a heating system project is calculated at the stage of building a house and it is better to entrust such a calculation to a competent specialist. In addition, on the official website of the manufacturer Wilo, you can be helped by the online pump selection program - vilo select.

Calculation of the Wilo pump

Nevertheless, we can of course give some indicative recommendations. For initial calculations, it is necessary to calculate the heated area, and decide on the purchase of a boiler of sufficient power. Roughly enough, "by eye", the required boiler power is calculated on the basis of 1 kW per 100 square meters.

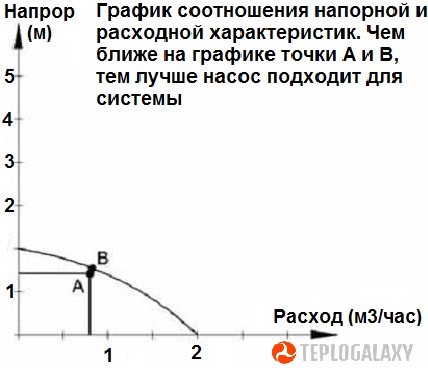

Having calculated the power of the boiler, it will not be difficult to find out the flow rate of our pump by the formula: Q = N / (t2-t1), where Q is the flow rate we need to select the pump in cubic meters / h; N is the power of our selected boiler in watts; t2 is the temperature of the water at the outlet from the boiler; t1 - water temperature at the boiler inlet.

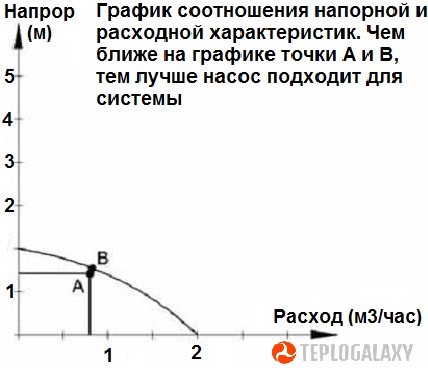

Next, we need to determine the head we need from the hydraulic curve (which is attached to all pumps). If you did everything correctly, then with a high degree of confidence we can say that your system will work properly. Do not forget that the Vilo pumps are supplied with three speeds, so that it will be possible to slightly adjust its operation on site. With frequency regulation, this will be even easier.