Home / Tips

Back to

Published: 17.11.2019

Reading time: 5 min

0

1608

Do not forget to carry out timely maintenance of gas boilers.

The operation of heating equipment leads to wear of parts, so it can break. Maintenance of wall-hung boilers helps to identify the source of the problem in a timely manner and eliminate it.

- 1 Types of procedure

- 2 Service objectives

- 3 What is included in the list of services

- 4 Performing the process 4.1 Inspection of important components

- 4.2 Cleaning from contamination

- 4.3 Functionality check

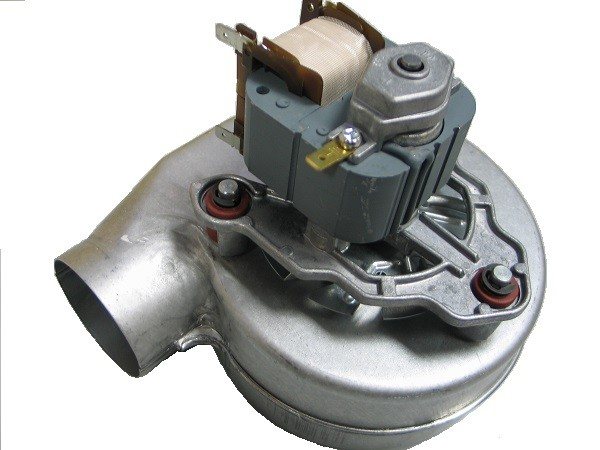

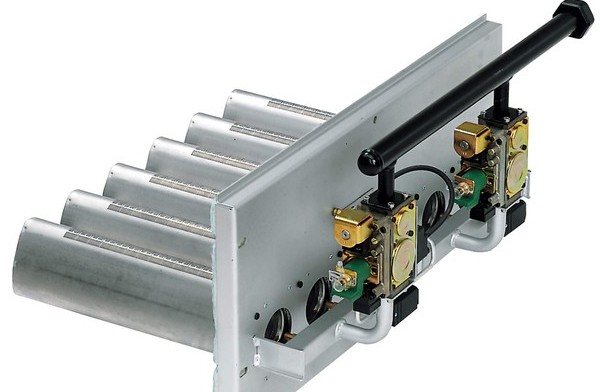

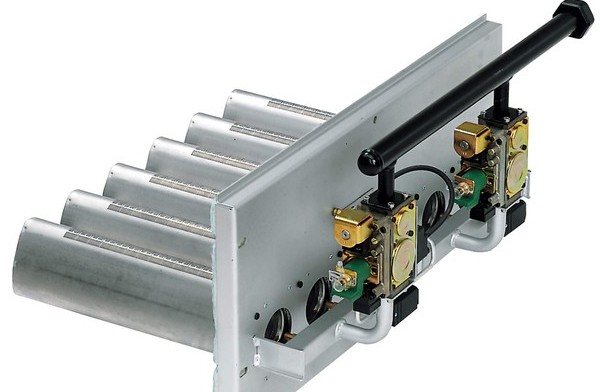

Turbine service

Gas boiler turbine

The smoke exhauster ensures proper removal of carbon dioxide, soot and smoke after the combustion of the gas mixture. After dismantling the fan, it is worth checking the chimney outlet leading to the street for clogging. The fan must be cleaned of dust and lubricated by the shafts. The condensate collector leading to the turbine must be sealed.

Before entering into a service contract

It is impossible to provide gas boiler service on your own - this is a fact. To do this, you need to have a special education, admission to perform such work, professional tools and devices. Naturally, all these requirements will be met by a representative of the service company. But before signing a service agreement with such an organization for a specific boiler model, it is worth finding out what is included in the list of services. Then this list with a list of those works that are recommended by the manufacturer of heating equipment.

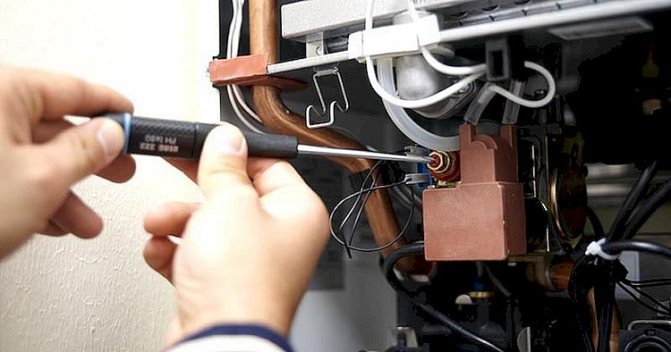

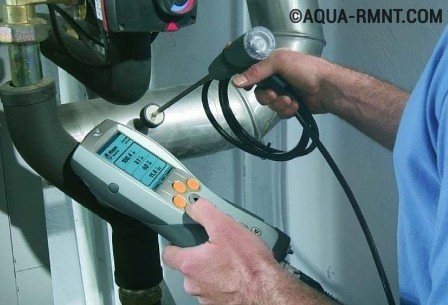

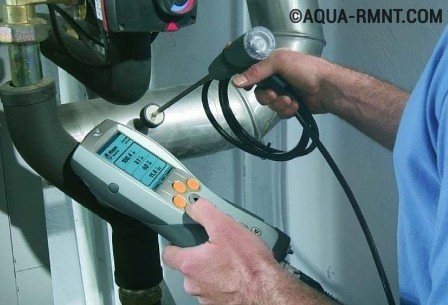

Determination of the technical condition of a gas boiler is impossible without special equipment

The detailed operating manual included with the boiler always contains all the necessary information regarding its maintenance. Moreover, the features of the maintenance are scheduled according to the frequency and type of work for various units and parts.

That is, even a non-professional can understand what work should be carried out annually - the minimum amount, and what will be done as additional manipulations and should be paid separately.

Cleaning the gas burner chamber and heat exchanger

gas boiler burner

After removing the cover, we clean the outer fins of the heat exchanger from combustion products with a coarse brush. A well-cleaned heat exchanger ensures uniform heating of water or other heat carrier and prevents local overheating.

Using a soft copper brush, remove soot residues from the ignition electrodes and the ionization sensor, which are in the chamber, and wipe them with isopropyl alcohol. Finally, you need to check the gap from the electrode to the burner, which should be about 4 mm.

The most common breakdowns and how to fix them

The most common failure is a misconfigured system. This is perhaps the only problem that can be solved by ourselves. In this case, it will be enough to check the correctness of the settings or find the absence of contacts.

The situation is much more complicated when repair of the circular pump is required. It can stop functioning as a result of salt deposition. This leads to braking of the wheel and rotor. In this case, the issue is resolved by cleaning the clogged elements and rinsing them with a special solution. As a preventive measure, polishing and grinding of the wheel and shaft is carried out.When the pump stops turning on and all phases are connected correctly, the fuse or cable may need to be replaced. If the motor winding burns out, you will have to purchase a new pump.

In some cases, it may be necessary to clean the gas boiler flue. By eliminating debris, high-quality exhaust and efficiency are ensured.

Quite often, such a boiler element as a heat exchanger is repaired. If it is not promptly cleaned of soot, problems with the pipe arise. When water begins to drip from it, it may be necessary to change the gaskets. In the event of damage or damage, soldering of problem areas will be necessary.

It is advisable to repair double-circuit gas boilers only after high-quality diagnostics of the equipment. It is also recommended to contact gas service specialists in a timely manner in order to carry out maintenance.

Chemical descaling

gas boiler heat exchanger

There are operating conditions (they are indicated at the end of the article), under which it is necessary to service the gas boiler in the form of cleaning the heat exchanger from scale. In this case, the supply pipes are unscrewed and the entire heat exchanger is dismantled. For chemical cleaning, it must be filled with a solution of hydrochloric acid, which dissolves blockages. After 10-15 minutes, drain and rinse with running water. If during flushing there are still difficulties with the passage of water, the cleaning process should be repeated.

Choosing a gas boiler

In order for the gas boiler to work in optimal mode, you need to choose the right choice when buying and carry out maintenance after connecting. There are many selection criteria, but the main ones should be highlighted:

- the power that the device gives out;

- one or two circuits, type of body, heat exchanger material;

- installation site;

- operational safety.

How to choose a gas boiler: Beautiful appearance and promoted advertising do not speak about the quality of the product. It is necessary to focus not only on design, but also to take into account the functionality of the equipment. Inside the body of each boiler there is a gas burner and a combustion chamber with a heat exchanger. But there are models with pumps and other modules. For hot water supply, it is worth choosing a double-circuit unit or connecting a boiler separately. If you approach the choice according to certain criteria, then you should pay attention to:

- Heat exchanger material and device. The material must be durable and conduct heat well. The more it transfers heat to the carrier, the higher the boiler efficiency will be. Heat exchangers are usually made from steel, cast iron and copper. If we compare these materials in terms of their susceptibility to corrosion, then the cast iron option can be considered the most reliable. However, it weighs a lot, and if used incorrectly, it can burst at the point of contact between high and low temperatures. This can be avoided by rinsing it frequently. Steel heat exchangers are more common. Steel is cheaper and more ductile, but it can corrode in the heating circuit. Copper is more resistant to corrosion, in addition, it transfers heat well. A copper heat exchanger will be light and compact, but it costs much more.

The presence of a huge variety of gas boilers will help you choose the most suitable one for you

- Place of installation. Boilers are placed on the floor or attached to the wall, which is why they are called floor-standing and wall-mounted. The floor-standing models have good power and the best performance in all respects. Their only drawback is their heavy weight.

- The number of contours. Single-circuit are suitable for summer cottages and small houses. For a private house with several floors with a pool and underfloor heating, it is worth buying a double-circuit boiler.

- Combustion chamber type. There are open chambers, when oxygen is supplied from the room, and closed ones, when air is supplied from the street through the chimney.Heaters with an open chamber are installed outside the home (in the basement or annex).

- Automatic regulation of the process. To ensure safety, boilers have various sensors, valves, filters and thermostats, as well as a self-locking system.

Gas boiler service:

All automation is needed for the safety of heating equipment. The gas boiler can be configured so that it will work in the absence of owners with a minimum power and turn on before they arrive. The main thing you need to know is that you should not buy a boiler without the heat engineering calculations of a specialist for a particular house.

Choosing a gas boiler for home:

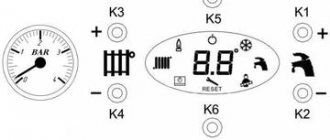

Expansion vessel pressure adjustment

During the production of a gas boiler, nitrogen is pumped into the expansion tank, but during operation, manufacturers are allowed to pump with ordinary air. An expansion tank is necessary to compensate for excess pressure that occurs as a result of heating and cooling of the coolant. In addition, it has the function of protection against water hammer in the heat supply system.

For the complete prevention of a gas boiler, using a pressure gauge, you need to measure the pressure in the expansion tank. For most wall-hung boilers, the pressure required for operation is 1 bar. The exact numbers must be clarified in the documentation for the boiler. In the event that the pressure is insufficient, it is required to pump nitrogen or atmospheric air there with the help of a compressor. In case of excessive pressure, it is necessary to bleed the excess through the valve.

Choosing a boiler maintenance organization: the main rules

Not all boiler manufacturers have service centers. Special organizations receive a license for this, having the necessary equipment and specialists. Such a company receives a certificate for the performance of a certain type of work.

The service center technicians must be trained at the boiler manufacturer's factory. This gives them the knowledge they need to work.

To find out the qualifications of specialists, you should familiarize yourself with all the company's documentation. At the same time, there are a number of recommendations that should be followed when choosing an organization. These rules will protect you from fraudsters.

Recommendations for choosing a service organization:

- The location of the company should be as close as possible. Ideally, this is the same city or at least a region. Thus, the time for the arrival of specialists will be reduced.

- The organization must provide a certificate from the manufacturer.

- It is required to draw up an agreement with a detailed description of all services and obligations of the parties.

You can find out about service centers on the website of the manufacturer of gas boilers. There should be a list of all organizations. This allows you to get a certain guarantee about the certification of organizations.

Cleaning the filters

Inbound filtering is required. If water is used as a heat carrier, then often the stream contains fine sand, silt, scale, rust or metal shavings. Dirt entering the system can disrupt the inlet flow sensor, clog the heat exchanger, etc.

The filter and flow sensor are cleaned with ordinary running water and a hard-bristled brush. Further, before reassembling, to soften the O-rings that prevent leakage, they must be treated with silicone grease to achieve a tight connection.

Gas pressure adjustment

Measuring and adjusting the minimum and maximum gas pressure will allow not only to achieve the correct operation of the boiler, but also to save money. The exact pressure range is indicated in the instructions. For wall-hung boilers, it is at least 2 mbar. The maximum pressure is 13 minibars.

If there are no errors, we start the gas boiler and open the gas valve. Using a differential pressure gauge, we measure the minimum gas pressure in the system.To measure the maximum possible pressure, turn on the boiler in the "chimney sweep" mode and check the pressure in this mode. If necessary, we adjust the pressure to the rated values.

The Importance of Correct Gas Pressure Setting

When the pressure drops below the permissible values, the boiler automation is not able to accurately regulate the heating temperature and operates at maximum values. The electronics opens the maximum pressure and heats the boiler to the required temperature, but due to insufficient pressure, it is impossible to maintain the required temperature. The automation shuts off the gas and, after reaching the minimum allowed temperature, again heats the boiler to the maximum in the maximum possible mode.

If the gas pressure exceeds the rated values, the flame height is too high. This can lead to premature burnout of the heat exchanger, which is not designed to operate in this mode.

Compare this with normal operation, in which the temperature is gradually brought to the required values, after which it is maintained at a minimum gas flow. In this case, there is a decrease in gas consumption due to the smooth dynamics of heating and cooling.

Why does a heat generator need service

When purchasing a boiler for operation in closed heating systems, we all often think exclusively about its rational use and the advantages of the chosen model. Most homeowners have been using this equipment for ten years, until, suddenly, in the middle of the heating season, the boiler unit was not able to normally heat the room.

And the reason for this may be the usual corrosion of the heat exchanger: for many years without maintenance, scale has formed in the heat exchanger coil, which has led to a gradual decrease in efficiency. Boiler power at normal settings began to be insufficient, which led to an increase in the temperature of the coolant and, as a result, in the gas consumption. A simple procedure for flushing the heat exchanger of a gas boiler during maintenance solves this problem even at the stage of scale formation. And this is not the worst scenario of what can happen to the boiler unit without maintenance.

Recall that a gas boiler is a set of equipment that uses gas and electricity to operate. In the event of a malfunction of the electrical system or gas pipeline, not only the property and inhabitants of the apartment in which the equipment is installed, but also the residents of the entire apartment building are at risk. Regular inspection and maintenance will allow the specialist to identify only the emerging problems at the initial stage, without bringing them to the point where the operation of the equipment poses a threat to life and health.

Gas consumption depends on the quality of the heat generator, as well as the comfort and safety of your household.

Is it necessary to chemically clean the inside of the heat exchanger?

Under normal operating conditions, no. The service life of the heat exchanger is about 6-7 years and it is easier after this time to make a preventive replacement. Disassembling and reinstalling annually will only increase the risks associated with possible breakage of connections and the risk of subsequent fluid leakage.

However, there are reasons why it is worth performing an annual chemical cleaning. It is very hard water and contains too many mineral impurities. Scale builds up in the heat exchanger too quickly. Because of this, difficulties arise associated with insufficient water heating. With prolonged operation under such conditions, the heat exchanger generally ceases to pass enough liquid, overheats, burns out and the boiler fails.

How often should the boiler be serviced? Regularity of prevention

The gas boiler must be audited at least once a year, before the start of the heating season.Why is regular maintenance of gas boilers necessary? The answer is simple, it is necessary for a reliable and uninterrupted supply of hot water. Let's try to figure out what can happen if you do not conduct an annual audit of the gas boiler.

- Over time, the joints become more and more fragile, insulating materials use up their resource and cannot provide a sufficient degree of sealing. This applies to both the coolant and the gas.

- Excess dust and burning on the turbine impeller leads to its wear and tear and premature failure.

- Insufficient or excessive pressure in the expansion tank leads to sudden pressure surges, which leads to the destruction of joints, oil seals and hydraulic systems.

- If the filter is dirty, the water supply can be cut off. Also, poor filtration leads to clogging of thin tubes in the heat exchanger. If dirt gets into the water flow sensor, the boiler will not turn on when the hot water tap is opened.

- Incorrect gas adjustment leads to burnout of the heat exchanger, failure of the Venturi nozzle or excessive gas consumption. Over time, the pressure in the gas pipe changes and only the annual pressure setting can ensure that the pressure meets the rating.

Pay attention to the gas boiler, do its maintenance and prevention, and then it will serve you for a long time

What is included in the maintenance of a gas boiler

There are three types of maintenance work on the gas unit:

- Annual work carried out before turning on the heating and after turning it off.

- Maintenance - carried out once every few years. Parts with a long service life are subject to maintenance. This type of work involves: flushing the heat exchanger, replacing oil seals and valves, checking the fans.

- Repair in the event of a boiler failure provides for a list of actions in the event of unexpected problems, for example, breakdowns.

The types of repair work differ from each other. Let's take a closer look at what each of them includes.

Seasonal service

Before the start of the heating season, the serviceability of the gas unit components must be checked. Only then is the device put into operation.

If the manufacturer allows maintenance to be performed only once a year before switching on, then in addition to commissioning measures, the main components of the unit must be cleaned: the components of the burner device, filters. Optional in this case is the cleaning of the heat exchanger and a complete inspection of the parts.

…

If maintenance is carried out after the heating season, then all working units are subjected to flushing. The device must be disconnected from electricity and gas before disassembling and cleaning. The general list of works is as follows:

- visual inspection of the boiler, removal of dirt from the body and internal surfaces;

- cleaning filters or replacing them;

- removal of dirt and sample of the burner;

- cleaning the combustion chamber;

- check for tightness of gas pipes;

- test of ignition electrodes;

- testing of the electrical control unit;

- testing the operation of sensors and automation responsible for safety;

- regulation of the unit settings, adjustment of the combustion process - the action involves the analysis of flue gases;

- checking the condition of the valve;

- setting the pressure in the expanded tank.

Periodic maintenance allows you to identify the "weak" points of the gas boiler and prevent breakdowns. Often, during a seasonal inspection of the device, it is revealed: violations of the tightness of water or gas pipes, problems with the membrane of the water unit, clogging of burner elements with soot, etc.

Major overhaul

In addition to the works that are carried out annually, during the overhaul of the gas unit, the following is carried out:

- replacement of parts with an expired warranty period for new ones;

- thorough flushing of the device circuits;

- replacement of valves, filters and oil seals.

The main task of a major overhaul is to replace parts that have expired.

…

Breakdown repair

If a breakdown occurs during use of the boiler, it is necessary to quickly correct the situation and return the device to work. Breakdowns in most cases occur during the heating season, especially if the unit has been operating at maximum capacity for a long time. During this period, it is imperative that the device is repaired in a short period of time. But finding a specialist who would quickly fix the problem is not always possible. Therefore, it is recommended to conclude a service contract. Then, for the prompt implementation of the repair, you just need to leave a request, and the service team will arrive as soon as possible. In addition, the service center keeps records of all models of gas units, so the master comes with a set of necessary tools and spare parts for a specific boiler model.