Here you will find out:

- What is a water circuit oven

- Making a stove with your own hands

- We make a coil

- How to make a brick oven

- Making a metal furnace

- Some Recommendations

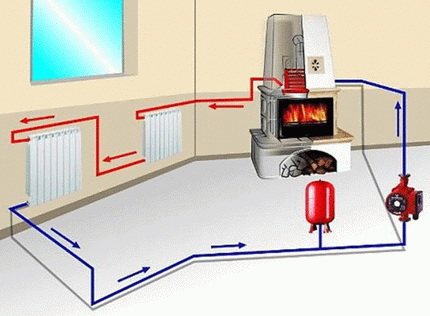

Hot water heating systems continue to hold the leading position. Despite some difficulty in installation, they ensure uninterrupted delivery of heat to heated rooms, taking heat energy from gas boilers... If there is no gas in the house, the systems are powered from alternative heat sources. IN In this review, we will look at how to organize water heating in a private house from a wood-burning stove - in some cases, such stoves become the cheapest heating option.

Why choose steam heating?

It must be admitted that steam heating systems cannot be classified as very popular. Such heating is rather rare. Let's take a closer look at its advantages and disadvantages.

The first, undoubtedly, include:

- Heating system efficiency. It is so high that a small number of radiators are enough to heat the premises, and in some cases you can do without them: there will be enough pipes.

- Low system inertia, due to which the heating circuit heats up very quickly. Literally a few minutes after starting the boiler, warmth begins to be felt in the rooms.

- There is practically no heat loss in the system, which makes it very economical in comparison with others.

- Possibility of rare use, since due to the small amount of water in the pipes, the system does not defrost. Alternatively, it can be installed in country houses, where they come from time to time.

The main advantage of steam heating is considered to be its efficiency. The initial costs for its arrangement are quite modest; in the process of operation, it requires relatively small investments.

However, even with so many advantages, the disadvantages of the system are very significant. They are associated primarily with the fact that water vapor is used as a heat carrier, the temperature of which is very high.

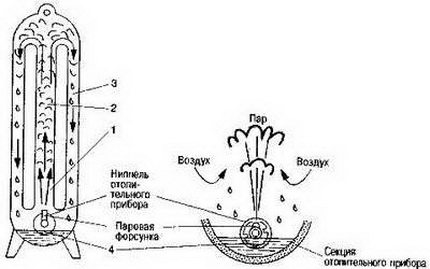

Condensation of water vapor occurs inside the steam heating radiator. During this process, a large amount of thermal energy is released, which explains the high efficiency of the system.

Thanks to this, all elements of the system are heated to 100 ° C and even higher. It is clear that any accidental contact with them will cause burns. Therefore, all radiators, pipes and other structural parts must be closed. Especially if there are children in the house.

The high temperature of radiators and pipes provokes active air circulation in the room, which is quite uncomfortable and sometimes dangerous, for example, in case of an allergic reaction to dust.

When using steam heating, the air in the rooms becomes too dry. It is overdried by hot pipes and radiators. This requires additional use of humidifiers.

Not all finishing materials used to decorate rooms heated in this way can withstand the proximity of hot radiators and pipes. Therefore, their choice is very limited.

The most acceptable option in this case is cement plaster painted with heat-resistant paint. Everything else is questionable. Steam heating has another disadvantage that affects the comfort of those living in the house: the noise that steam passing through the pipes produces.

The more significant disadvantages include poor controllability of the system.The heat transfer of the structure is almost impossible to control, which leads to overheating of the premises.

Steam heating is a potentially hazardous system, so the choice of equipment must be treated very responsibly. The pipes for the system must be made of metal only.

There are solutions. The first is the installation of automation, which will turn on the boiler when the premises cool. In this case, those living in the house will be quite uncomfortable from the constant fluctuations in temperature.

A more "sparing", but time-consuming method is the arrangement of several parallel branches that will need to be launched as needed.

The main disadvantage of steam heating, due to which it is little used, is its increased emergency danger. You need to understand that when a gust occurs from a pipe or radiator, hot steam will beat out under pressure, which is extremely dangerous.

That is why such systems are now prohibited in apartment buildings and are less commonly used in production. In private houses, however, they can be arranged under the personal responsibility of the owner.

What is a water circuit oven

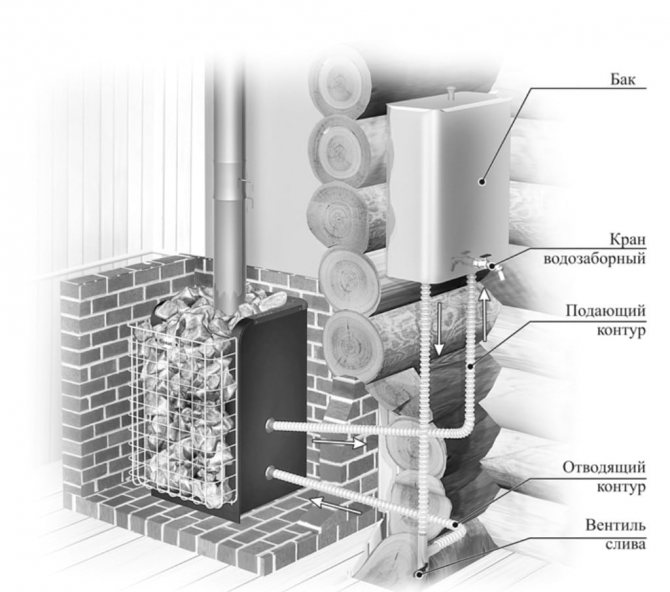

A traditional wood-burning stove has an extremely simple design - it contains a combustion chamber with a loading door, an ash pan with a blower and a chimney. It turns out a kind of potbelly stove, distinguished by its simplicity. But this simplicity deprives the stove of the ability to heat several rooms at once. This disadvantage is eliminated by means of a water circuit. As a result, we get an assembly consisting of the following parts:

- Firebox - firewood, coal and other types of solid fuel are loaded here;

- Ash pan - ash formed during combustion is poured into it;

- Chimney - through it, combustion products are sent into the atmosphere;

- A stove heating coil is a heat exchanger through which a coolant circulates.

It is the coil that is the most important link here, because it is responsible for transferring heat to the heating system.

Consider the main advantages of water heating with a wood-burning stove:

The choice of firewood should be approached very carefully, because the efficiency of the stove depends on it.

- The possibility of self-assembly of the stove - nothing prevents you from assembling it with your own hands, focusing on the drawings and orders;

- Low costs for maintaining the system in working order - the cheapness of firewood affects;

- Fuel availability - firewood can be purchased or chopped by yourself.

In the latter case, we get almost free water heating with free firewood. But there are also disadvantages:

- The need for regular cleaning of the stove for water heating - it needs ash removal;

- The need to store a large amount of firewood - for this you will have to build a woodpile;

- Low efficiency - it rarely exceeds 80%, although some factory models have good efficiency, reaching or even exceeding 90%.

In addition, to maintain the operability of water heating, the stove will have to be constantly fed with wood. It is the frequent approaches to loading the next portion of logs that are the main disadvantage. But this disadvantage is neutralized by the pyrolysis combustion scheme.

The ash formed during the combustion of firewood is recommended to be used as fertilizer for feeding flowers and crops.

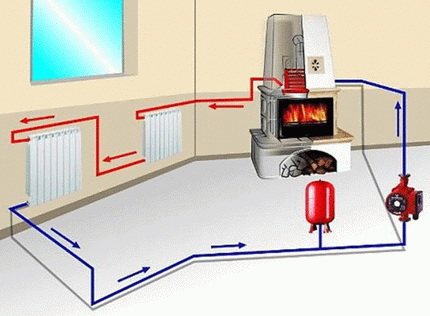

The principle of operation of a water heating system with a wood-burning stove is ugly simple - burning wood gives off thermal energy absorbed by the heat exchanger. From there, the heat is sent to the radiators installed in the rooms. A thermometer is placed in the system to control the temperature. The circulation of the coolant can be natural or forced (using a circulation pump).

Natural circulation water heating is suitable for heating small households.It is distinguished by its simplicity and the absence of unnecessary installation costs. If the house is large, a scheme with forced circulation is implemented - after the wood-burning stove, a circulation pump is installed in the system, which drives water through the system. Stove water heating can be open or closed - in the latter case, the circuit is hermetically sealed, to compensate for the expansion of the coolant, a special membrane tank is built into it.

The main elements of the steam system

The steam system includes several essential elements. Let's consider each of them in more detail.

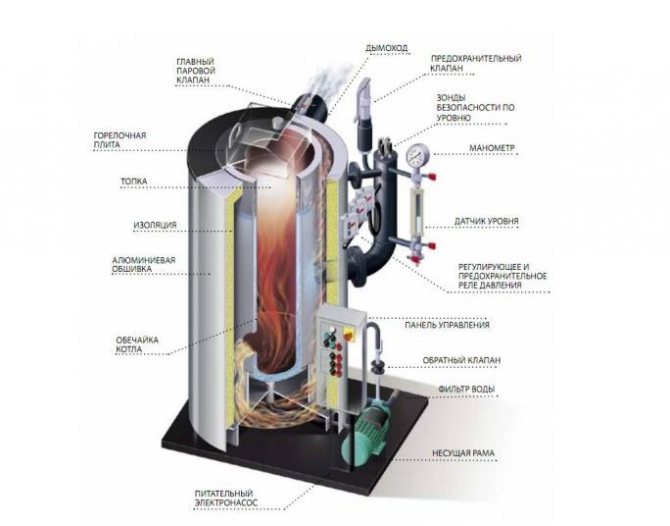

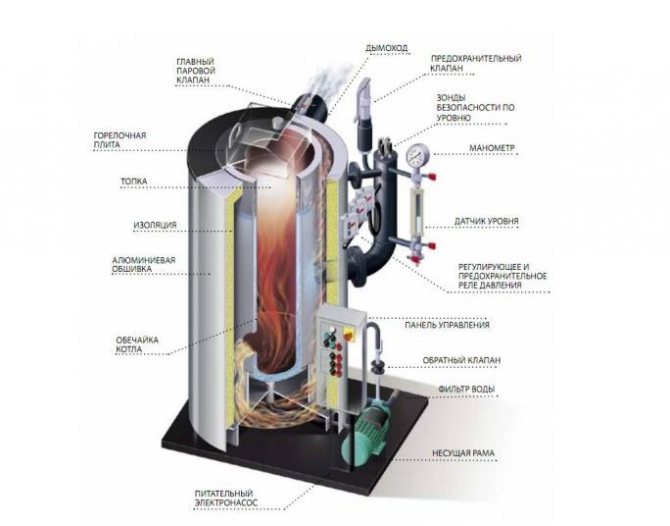

The steam boiler is the heart of the system

The main function of the heater is to convert water into steam, which subsequently enters the pipeline. The main structural elements of the device are manifolds, drum and pipelines.

In addition, there is a container with water, which is called a water space. A steam space is formed above it during the operation of the device. They are separated by the so-called evaporation mirror.

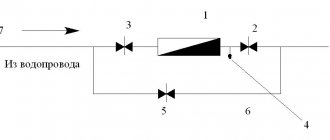

The figure schematically shows one of the varieties of a household steam boiler

Inside the steam space, additional equipment can be installed to separate the steam. The operation of the boiler is based on the principle of heat exchange of flue gases, water and steam.

There are two types of steam heating devices: fire-tube and water-tube. In the first case, heated gases move inside the pipeline laid inside the container with water.

They give off heat to the liquid, which reaches a boiling state. Water-tube varieties work a little differently. Here, water flows through pipes laid inside the flue gas chamber. It warms up and boils.

Water and steam inside the boiler can move either forcedly or naturally. In the first case, a pump is included in the design, in the second, the density difference between water and steam is used.

All types of steam boilers use approximately the same principle of converting water into steam:

- The prepared liquid is supplied to a reservoir located in the upper part of the boiler.

- From here, the water flows through pipes into the collector.

- The liquid from the collector rises into the upper drum, while passing through the heating zone.

- As a result of heating, steam is formed inside the pipe with water, which rises upward.

- The steam, if necessary, is passed through a separator, where it is separated from the water. After which it enters the steam line.

A steam boiler can use a wide variety of fuels. Depending on this, certain changes are made to its design. They touch the combustion chamber. For solid fuel, a grate is set up, on which coal, firewood, etc. are placed.

For liquid and gaseous fuels, special burners are used. There are also practical combined options.

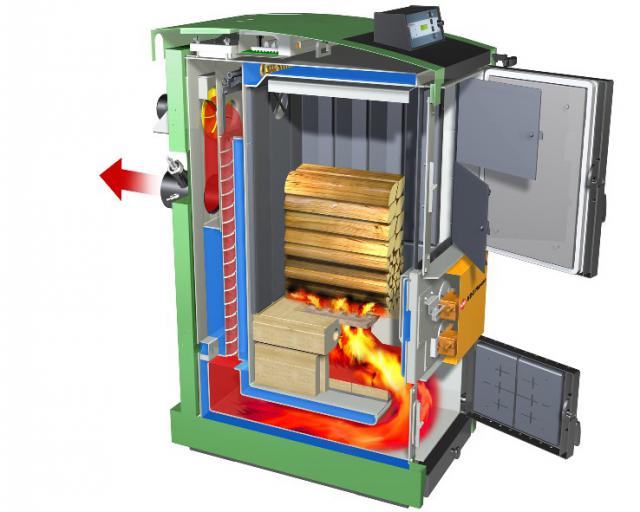

Among home craftsmen, the arrangement of steam heating using a stove is especially popular. The photo shows one of the possible options for reworking the furnace.

The power of the boiler is selected depending on the area to be heated.

This can be done based on the average values:

- 25 kW for buildings up to 200 sq. m;

- 30 kW for houses ranging from 200 to 300 sq. m;

- 35-60 kW for buildings from 300 to 600 sq. m.

If more accurate data is needed, they use the standard calculation method, where for every 10 sq. meters account for 1 kW of equipment power. Remember that the formula is used for houses with a ceiling height of 2.7 m or less.

For higher buildings, you need to take more power. When choosing a boiler, special attention should be paid to its certification. Any steam heating system is potentially dangerous, therefore equipment testing is imperative.

Heating pipes and radiators

The coolant temperature in steam systems ranges from 100 to 130 ° C, which is much higher than in liquid systems, where it ranges from 70 to 90 ° C. Therefore, it is strongly discouraged to use similar equipment for arranging systems.

First of all, this applies to metal-plastic and polypropylene pipes. The maximum operating temperatures for these materials vary between 90-100 ° C, so their use is strictly prohibited.

Ideal for arranging a steam heating system copper pipes. They do not corrode, withstand high temperatures, but are very expensive

For main pipelines of steam systems, three types of pipes are usually used. The most inexpensive option is steel. They can easily withstand temperatures of 130 ° C, which is more than enough, and are quite durable.

However, the condensate formed inside the parts quickly destroys the pipes, since the steel is susceptible to corrosion, and the aggressive medium formed by the steam only enhances this disadvantage.

Another disadvantage of steel elements is the need for joining by welding, which takes a lot of time and effort. Galvanized steel pipes are much more resistant to corrosion. They also withstand high temperatures well.

To connect them, the threaded method is usually used, which greatly simplifies the process. The main disadvantage of galvanized pipes is their high cost.

Copper pipes are considered ideal. The material can withstand high temperatures, is sufficiently plastic and at the same time durable, does not corrode. Soldering is used to connect copper parts.

Copper piping is very durable and strong, but the cost is very high. Thus, the most acceptable option in terms of quality and price ratio is steel pipes with an anti-corrosion coating or galvanized.

The best choice for steam heating is cast iron radiators. They will be able to withstand the severe stress caused by the presence of hot steam inside the batteries.

Radiators for steam systems are selected on the basis of durability. It is important that they can withstand high temperatures and are corrosion resistant. Based on this, massive cast-iron batteries can be considered the best option, steel panel batteries are the worst.

Given the high efficiency of the system, in some cases, the use of ribbed steel pipes is quite acceptable.

Control and measuring equipment block

The steam heating system is characterized by an increased emergency hazard, therefore, the presence of control devices is mandatory. The pressure in the system is monitored, if necessary, it is normalized. For these purposes, a gearbox is usually used.

The device is equipped with a valve through which excess steam is removed from the system. For powerful installations, you may need not one, but several such valves.

Making a stove with your own hands

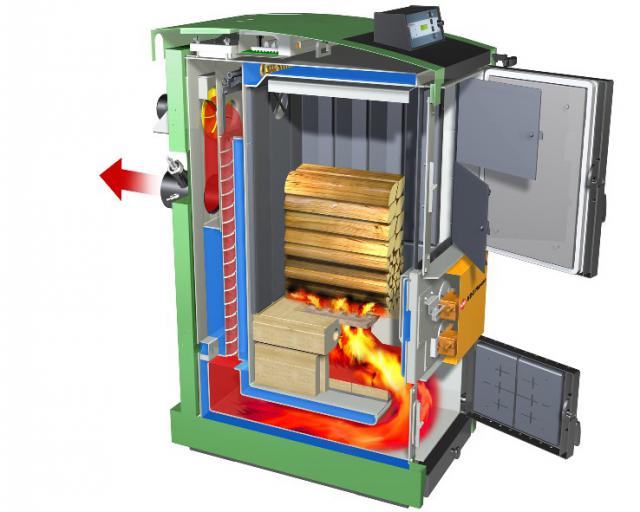

The purchase of a pyrolysis unit will be a big plus - it is distinguished by long burning of firewood and increased efficiency.

Stove heating with a water circuit can heat large buildings - it all depends on the capacity of the stove used. If there is an opportunity to purchase a factory wood-fired stove, then this is a plus. Factory units are more accurate and efficient, but they need money to purchase them.

With a lack of funds, stove heating with a water circuit is implemented on the basis of self-assembled wood-fired stoves. They are assembled from sheet metal and bricks. Metal stoves are simple - you need a welding machine to assemble them. They are also extremely compact and do not take up much space. Their brick versions are more voluminous, but they keep heat longer and have a more aesthetic appearance.

Wood-fired brick stoves have always been an attribute of home comfort.And being supplemented with heat exchangers for organizing hot water heating, they will give warmth to the whole house, and not to a single room.

Assembling a simple stove with a water circuit for heating a house with your own hands is not difficult for those who know how to handle tools. In this review, we will consider two schemes - one of them will help to assemble a stove from metal, and the other from brick. But first you need to talk about making a coil, which is the heart of any heating unit that runs on wood.

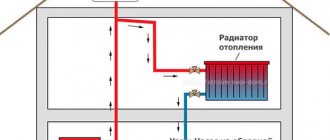

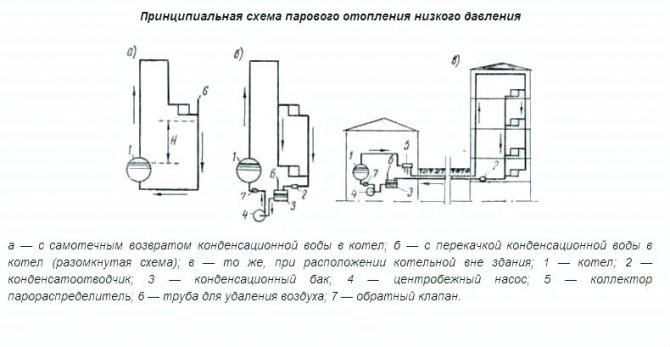

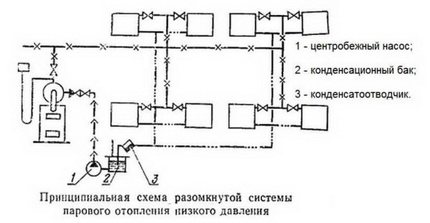

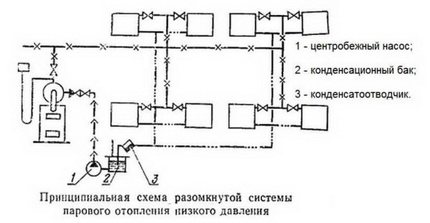

Varieties of the heating system

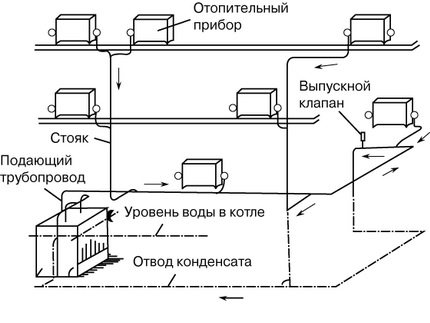

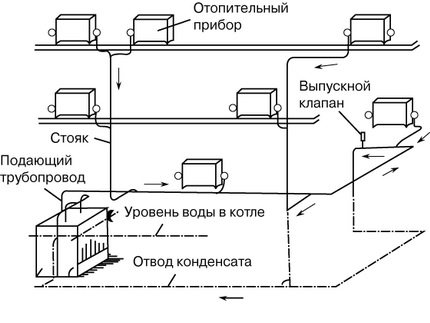

In practice, you can find a fairly large number of variations in steam heating. By the number of pipes, one and two-pipe types of steam systems are distinguished. In the first case, steam moves continuously through the pipe.

In the first part of its journey, it gives off heat to the batteries and gradually turns into a liquid state. Then it moves like condensation. To avoid obstacles in the path of the coolant, the pipe diameter must be large enough.

It happens that the steam does not partially condense and breaks into the condensate pipeline. In order to exclude its penetration into the branch intended for condensate drainage, it is recommended to install condensate drains after each radiator or group of heating devices.

A significant disadvantage of the one-pipe system is the difference in the heating of the radiators. Those located closer to the boiler heat up more. Those further down are smaller. But this difference will be noticeable only in buildings that are large in area. In two-pipe systems, steam moves through one pipe, condensate leaves through the other. Thus, it is possible to make the temperature equal in all radiators.

But this significantly increases the consumption of pipes. Like water, steam heating can be single or double-circuit. In the first case, the system is used only for space heating, in the second - also for heating water for domestic needs. Heating wiring also differs.

Three options are practiced:

- With top wiring. The main steam line is laid above the heating devices, pipes are lowered from it to the radiators. Even lower, a condensate line is laid near the floor. The system is the most stable and easiest to implement.

- With bottom wiring. The line is located below the steam heating devices. As a result, steam moves along the same pipe, which should be slightly larger than the usual diameter, and condensate moves in the opposite direction. This provokes water hammer and depressurization of the structure.

- Mixed wiring. The steam pipe is mounted slightly above the level of the radiators. Everything else is the same as in a top-wired system, thus maintaining all its advantages. The main disadvantage is the high risk of injury due to easy access to the hot pipes.

When arranging a circuit with natural compulsion, it must be remembered that the steam line is mounted with a slight slope in the direction of steam movement, and the condensate line is for condensate.

The slope should be 0.01 - 0.005, i.e. for each linear meter of the horizontal branch, there should be 1.0 - 0.5 cm of the slope. The inclined position of the steam and condensate lines will eliminate the noise of steam passing through the pipes and ensure free drainage of condensate.

Steam heating systems are built according to a one-pipe and two-pipe scheme. Among the one-pipe, options with horizontal connection to heating devices prevail. In the case of constructing a circuit with vertical connection of devices, it is better to choose a two-pipe version

By the level of internal pressure of the system, two main types are distinguished:

- Vacuum. It is assumed that the system is completely tight, inside which a special pump is installed to create a vacuum.As a result, steam condenses at lower temperatures, making the system relatively safe.

- Atmospheric. The pressure inside the circuit is several times higher than atmospheric pressure. In the event of an accident, this is extremely dangerous. In addition, radiators operating in such a system heat up to very high temperatures.

There are many options for arranging steam heating, so everyone can choose the best option for their home, taking into account all the features of the building.

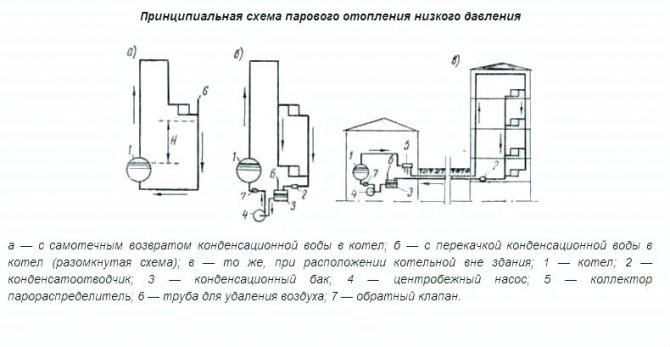

The figure shows a diagram of an open-loop steam heating system

How to equip a boiler room?

A steam boiler operating on any fuel must only be installed in a specially equipped room.

The standards developed for standard steam appliances with pressures up to 0.07 MPa, generating steam with a temperature of 120-130 ° C, provide for a number of requirements for such boiler rooms:

- the distance from the walls to the heater cannot be less than 100 cm;

- the height of the room must be at least 220 cm;

- the minimum level of fire resistance of doors - 30 minutes, walls - 75 minutes;

- the presence of high-quality ventilation;

- the presence of doors and windows facing the street.

It is best to equip the boiler room in a separate room, but partitioning of a suitable room is also allowed. Inside, it must be finished with non-combustible materials. Ceramic tiles are best suited for these purposes.

The walls in the boiler room should be finished with non-combustible materials, for example, ceramic tiles.

Preparing to install the steam system

To make steam heating correctly, you need to start with the preparation of the project. Its development is a complex task, which is best solved by specialists. In the finished project, many points must be taken into account.

First of all, the calculation of thermal loads for each of the premises and for the building as a whole is carried out. The source of steam is selected, and the mechanism and degree of automation of the system is determined.

In addition, the steam consumption is necessarily determined, based on this, the equipment and the scheme of its use are selected. After the project is ready, you can start drawing up an installation plan.

To complete it, you will need a building plan, on which the locations of the equipment are applied. They usually start with a boiler. Its location is determined. If the system has natural circulation, the boiler must be below the level of the batteries.

In this case, it is usually lowered into the basement or into the basement, so the condensate can drain independently to the device. Then the layout of the entire heating system is applied to the plan of the house. Moreover, all the necessary equipment is noted.

Experts advise to perform this operation directly "on site", being in the room where the equipment will be located. This is the only way to notice and take into account all the protrusions and obstacles that will have to be skirted.

Before starting the installation, a plan diagram of the future system must be carried out, on which all equipment and radiator mounting points are marked

All transitions and corners must be marked on the diagram. After it is completed, you can proceed to calculating the amount of material required for its implementation. Once again, it is worth paying attention to the importance of choosing the right equipment.

The steam system is potentially hazardous, so you shouldn't skimp on materials and appliances. Everything must be of high quality and certified, otherwise serious problems cannot be avoided.

Steam heating installation technology

Work begins with the installation of a heating boiler. It is mounted in a pre-prepared room on a concrete base. In some cases, a separate small foundation is prepared for the equipment.

The device is installed on the base strictly horizontally, the correctness is checked by the building level. Any errors noticed are eliminated immediately.

The boiler placed on the base is connected to the flue gas system. The connection must be solid and completely sealed.

The next step is to hang the radiators. To do this, in the places indicated on the installation diagram, special hooks are driven into the wall, onto which the batteries are attached. If the use of finned tubes is supposed, then they are fixed.

Finned pipes can be used in steam heating systems instead of radiators. The high heat transfer parameters of the system will be significantly enhanced due to the increased area of the heat-conducting surface

The strength of fastening of the heat emitters is checked. Next, you can start arranging the expansion tank. It is fixed at the highest point at a short distance from the heating boiler, it is best to keep this distance as small as possible.

You can now set up a group of control devices. They are installed at the outlet of the boiler. A pressure gauge and a relief valve should at least be located here.

All installed equipment is connected to each other by pipes. The connection method depends on the material from which they are made. In any case, the correctness and reliability of the connections should be carefully checked.

For open systems, a condensate collection tank is installed at the end of the line and a pump is installed. The branch pipe that goes from it to the heating device must have a smaller diameter than the rest of the pipes.

The steam boiler is connected to the heating circuit. In this case, all the necessary shut-off valves and filters must be installed, which will retain large particles of dirt that may be contained in the water.

If the equipment runs on gas, the fuel line is connected. In this case, it is forbidden to use flexible hoses - only rigid liners.

All connections are made exactly according to the standards in order to avoid an emergency later

Then you can carry out a test run. For this, water is poured into the circuit, after which the equipment is put into operation. At first at the minimum operating temperature, then it is gradually increased, while monitoring the correct operation and integrity of the system.

When the slightest shortcomings are revealed, the equipment is stopped and all malfunctions in its operation are eliminated.

Pros and cons of stove heating

Stove heating is different:

- reliability;

- financial availability;

- economy, which is expressed in the possibility of relatively cheap purchase of solid fuels;

- ease of operation and maintenance. That is, even if small problems arise, you can solve them yourself, without involving specialists.

In addition, stove heating can be installed in a house located in any area, since such a heating device does not require special communications.

Although heating is also characterized by some negative points:

- long heating time of the furnace, heat carrier, and, at the same time, the room;

- low efficiency of brick construction;

- the building occupies a large area;

- during the functioning of the structure, it is necessary to keep an eye on it all the time, since it is necessary to add fuel to the furnace.

Advice! In order to increase the efficiency, it is recommended that the ducts be long, which will allow the heat to stay inside the furnace for a longer time, and the chimney itself should be high.