if you screw drywall, and paste over with ceramic tiles on top? Is this insulation suitable?

There is one more old "GREAT" way.

Flat slate sheet…. As a technologist .. I can say the following. Asbestos is DANGEROUS only in its free state, namely in fibers (raw materials). The "asbestos" canvas in its pure form does not exist. This is a "canvas" departure from the production of slate (installed on a sheet-forming machine). After some "run" - it is changed, and after being taken to a landfill .. it is taken away by enthusiasts for their needs ... In this form, it is also not harmless, asbestos particles in it are with an incredible density per 1 sq. M. When heated, asbestos is dangerous! But the finished product - slate (wavy or flat) is not subject to the release of asbestos, because in slate, it is bonded with cement. And it is completely admitted to installation as a non-combustible material.

BUT! Yet even slate is not entirely shown for installation in residential premises. It is good either as a roofing material or as a fence….

And what prevents you from attaching a metal sheet-3mm to the wall, and already on it place your boiler as you like!

Gas heating remains the best option for organizing heat supply for apartments and houses. To install the equipment, you need to know the current standards, get a permit in the appropriate service. Of particular difficulty is the installation of a wall-mounted gas boiler in a wooden house with your own hands. The requirements for such buildings are much stricter than for reinforced concrete or brick buildings.

Requirements for the premises

The first task is to choose the place of installation. Basic norms are set out in SNiP on February 31, 2001. Installation in living quarters, bathroom or toilet is prohibited. Installation in a basement room is possible, but not in a basement. Also cannot be mounted in the attic. For powerful equipment over 36 kW, you need to equip a separate boiler room.

It is necessary to take into account the basic requirements - a gas boiler in a wooden house with a capacity of up to 60 kW can be installed in a room with the following parameters:

- The minimum volume is 15 m3. For each kilowatt of energy above the norm, you need to add 1 m?.

- Ceiling height - from 2.5 m and above.

- The presence of forced and natural ventilation.

- Artificial lighting should be complemented by natural lighting.

The installation site is isolated from the living quarters by a door, if the installation is carried out in a separate boiler room, there must be an exit directly to the street.

Installation of a wall-mounted gas boiler in a wooden house in a separate boiler room is carried out according to the following rules:

- standard requirements for the volume and height of ceilings - 15 m? and 2.5 m;

- interior wall decoration with fire-resistant material with a fire resistance limit of 0.75 hours;

- normal room lighting - artificial and natural;

- the presence of ventilation systems.

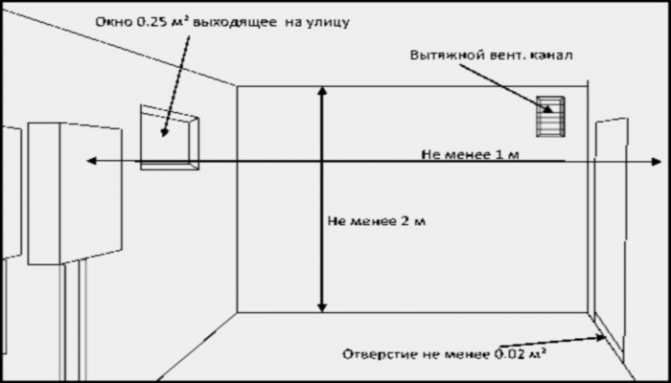

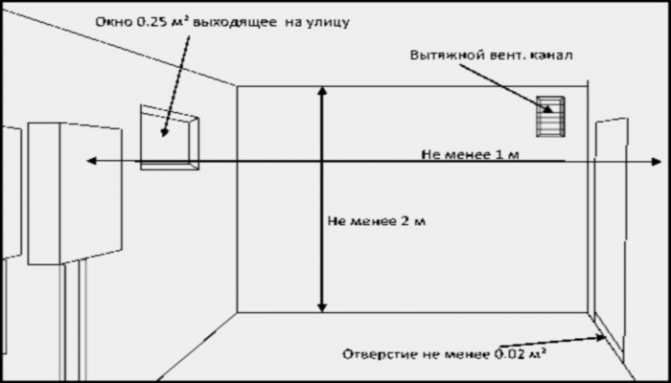

In addition to the door to the street, there may be an additional doorway to the house. It is important that tightness is ensured - combustion products must not enter the building. Ventilation parameters depend on the type of combustion chamber - closed or atmospheric. For the second, the value of air exchange should not be less than 3 volumes of the boiler room per hour. Combustion air consumption is additionally taken into account. This parameter is indicated in the boiler passport. The distance from the heating equipment to the ventilation hole is at least 2 meters. The glazing area depends on the volume of the boiler room. At 1 m? requires 0.03 m? light opening. It is important - this is an indicator of the net inflow of light, excluding the width of the frames and imposts.

How to make a boiler room correctly

In this article, we will consider how to properly make a boiler room in a private house (cottage) and what are the requirements for such boiler rooms.

We are talking about boiler houses, whose capacity does not exceed 350 kW.

Important! It is imperative to observe the standards listed below for boiler rooms! This is necessary so that there are no problems with gas workers and firefighters, and to avoid breakdowns of boiler equipment, which, as you understand, is very expensive, and for your own safety.

Types of autonomous boiler rooms

Autonomous boiler rooms are of the following types:

- Built-in: located on any floor of the building.

- Attached: added to an existing house.

- Roof: located on the roof, as its name suggests.

- Detached: the boiler room is located at some distance from the house.

Permits documentation

Unlike installing a solid fuel boiler in a wooden house, gas equipment requires a permit. To do this, you need to contact the local organization responsible for gas supply - Oblgaz or Gorgaz. The connection to the gas main should only be carried out by certified specialists, but the installation of boiler equipment can be done independently.

Stages of obtaining a permit:

- Obtaining a technical specification. It indicates the requirements for connecting to the gas main. It is necessary to provide a plan of the house with its characteristics.

- Drawing up a gasification project. This work is carried out by specialized organizations licensed.

- On the basis of the project, a permit is issued to install a parapet boiler in a wooden house. The same applies to wall-mounted or floor-standing models.

- After installation, gas service representatives must check the building and the pipeline for compliance with the technical conditions and the agreed design. They also connect the equipment to the pipeline.

To optimize time and financial costs, it is recommended to use the services of subsidiaries of Gorgaz. Their representatives know the nuances of design and the latest changes in the requirements for premises and equipment.

Gas boiler installation diagram

Connect your equipment responsibly. It is necessary to study the SNiP documents, take into account the layout of the premises. Take into account the power of the boiler and how far from the walls it should be placed. The gas equipment connection diagram will be issued together with a permit, only after that the owner of a private house can start installation work. Experts will connect the central pipeline to the line, the pipe from it will go to the house.

Installation diagrams

After preparing the premises and issuing permits, you can proceed with the installation of the boiler. The equipment installation site is finished with refractory materials. For wall models, it is imperative to use reliable fasteners.

How to hang a gas boiler on a wooden wall, and what standards must be observed? To do this, you need to familiarize yourself with the general rules:

- Drawing up a diagram. The location of the nozzles for connecting to the pipeline, the location of the gas pipeline are taken into account. Before installing a gas boiler in a wooden house, the diagram indicates the location of auxiliary equipment - indirect heating tanks for hot water supply, a circulation pump, an expansion tank and a protection group.

- The minimum permissible distance to the surface of the wall on which the equipment is installed is 4.5 cm. To the side slabs this value is at least 20 cm. The distance to the floor is from 30 cm, to the ceiling is 45 cm.

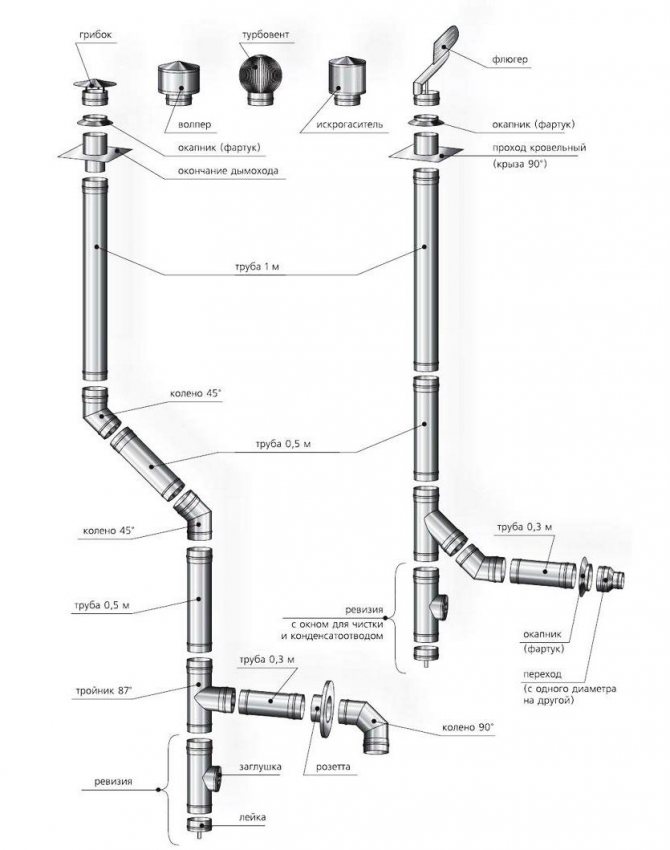

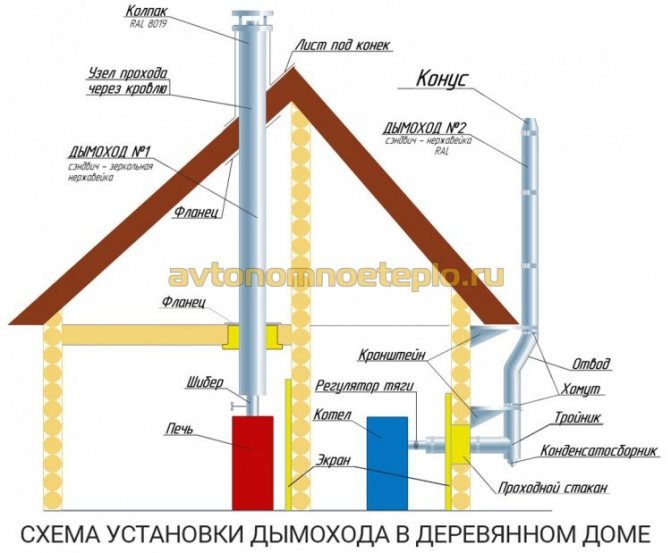

- The opening in the floor or wall for the chimney is protected by a special fireproof sleeve. Its function is to prevent direct contact of the tree with the heated surface of the chimney.

- The use of plastic pipes for heating.To protect the line surface from overheating, it is recommended to install a steel pipe up to 0.5 m long at the hot water outlet from the boiler.

In practice, the same installation of a wood-fired boiler in a wooden house will be easier. But in the future, the cost of heating and maintenance will be higher than for gas heating.

Wall materials when attaching a hinged gas boiler

The most common installation errors are associated with insufficient fixation of the heat generator to the wall of the house. Existing standards indicate the need for rigid installation of boiler equipment. The boiler must be firmly fixed to the wall, with strict observance of the vertical and horizontal level.

The requirements for fasteners when installing a wall-mounted gas boiler largely depend on the material of the walls. Separately, the installation standards for wooden, plasterboard, reinforced concrete, brick, and also hollow walls are stipulated.

How to hang a boiler on a wooden wall

According to SP 41-108-2004 "Apartment heat supply of residential buildings with gas-fired heat generators", it is possible to hang a boiler on a wooden wall, subject to the following conditions:

- Material with a high degree of flammability, at the place of installation of the boiler, is treated with antipyrine.

- The wall is faced with plaster mixes with a minimum thickness of 15 mm, or roofing steel over an asbestos sheet.

An alternative to the above is cladding a section of the wall with a gypsum fiber board, followed by cladding with ceramic tiles.

Correctly hang the gas boiler on a wooden wall, with the installation of an additional reinforcing bar placed under the facing material (lining) to ensure a reliable fixation of the heat generator.

How to install a boiler on a plasterboard wall

A plasterboard wall is made by attaching sheets to a metal structure and implies the presence of voids. Fixing the heat generator firmly on drywall is problematic, but possible. At the stage of manufacturing the metal frame, a place is provided for the installation of the boiler. The mounting point is reinforced with a wooden beam and a metal profile.

There are special fasteners for gas boilers to a plasterboard wall, which are plastic plugs screwed directly into the facing material itself. Installation anchors are screwed directly into the plug. As practice shows, ready-made fasteners loosen over time and lose the strength of fixation to the wall.

How to fix to a reinforced concrete wall

Reinforced concrete is the optimal wall material for installing a gas heating boiler. Reinforced concrete structures, differ in strength, belong to the group of NG (non-combustible) materials. To install the boiler, no additional conditions are required.

Work is carried out using metal anchors, by means of which, strictly according to the level, the mounting plate is fixed. The boiler is hung on a prepared site. The reinforced concrete wall is suitable for the installation of any type of heater: high power, with a built-in storage tank, etc.

How to hang on a brick wall

In the norms, the conditions for installing the boiler on a brick wall are separately stipulated. Brick belongs to non-combustible materials, therefore, the heat generator can be installed directly on the wall. But, sometimes, when commissioning a boiler installed in this way, certain difficulties arise.

Wall backing material

The main requirement in the decoration of walls, floors and ceilings is fire protection. For this, a special substrate is used for a gas boiler in a wooden house. It should not support the combustion process, protect the walls from temperature effects.

Recommended backing material:

- Basalt wool.A layer with a thickness of 50 mm or more is installed on a rigid base (metal sheet). The density of the cotton wool is maximum.

- Basalt refractory sheets. In the event of an open flame, they will protect the wooden surface of the walls from thermal effects.

It is forbidden to use polymeric materials - polypropylene, foam. For floor models, special attention is paid to the preparation of the floor surface. It is leveled, fire-resistant material is mounted. In this case, basalt wool is not recommended, as it will be compressed by the mass of the boiler. The way out is to install basalt sheets.

Installing a gas boiler has always been considered a rather difficult task, which must be performed by a specialist with special skills and certificates.

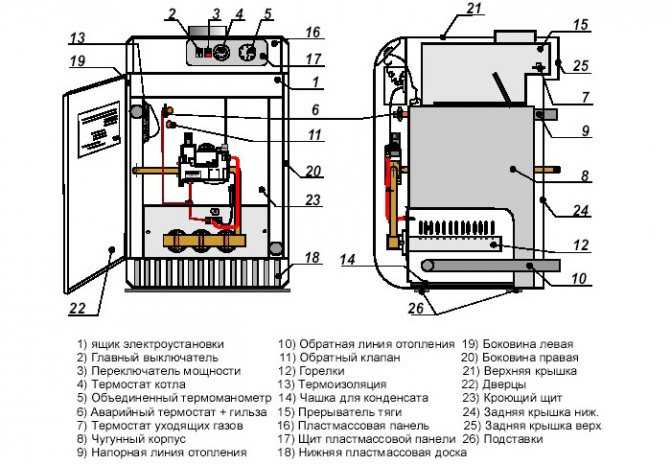

Diagram of the device of a gas floor boiler.

But it should be noted that it is better to entrust the work directly on the gas pipeline to a professional gasman, and you can supply the coolant, water and electricity necessary to connect gas heating yourself.

This will significantly save the family budget.

What you need to know about the placement of a gas boiler

As SNIP says, there are some rules that must be followed if you purchased a gas boiler and want to equip heating in your house with it.

- The area of the room in which the equipment will be located, depending on its capacity, should not be less than 4 sq. M.

- The permissible ceiling height is from 2.5 m.

- The room for heating equipment must necessarily have a free exit, while the width of the doorway cannot be less than 80 cm.

- If you plan to install a suspended boiler, then the wall on which it will be located must be sheathed with refractory materials.

- The floor-standing gas boiler is installed on a special stand, which has a base depth of 30 to 50 cm and is made of cement mortar. Otherwise, the stand must have a sheet steel backing.

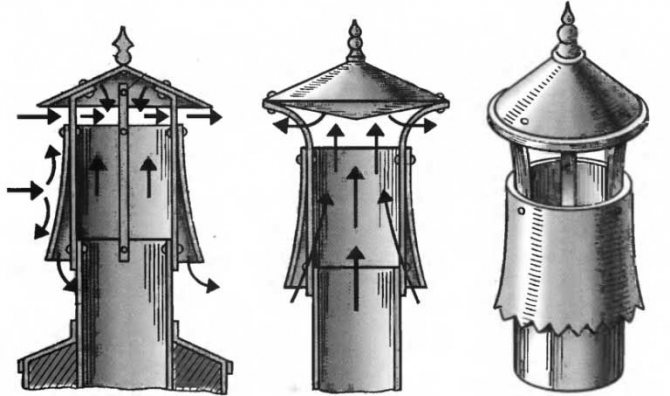

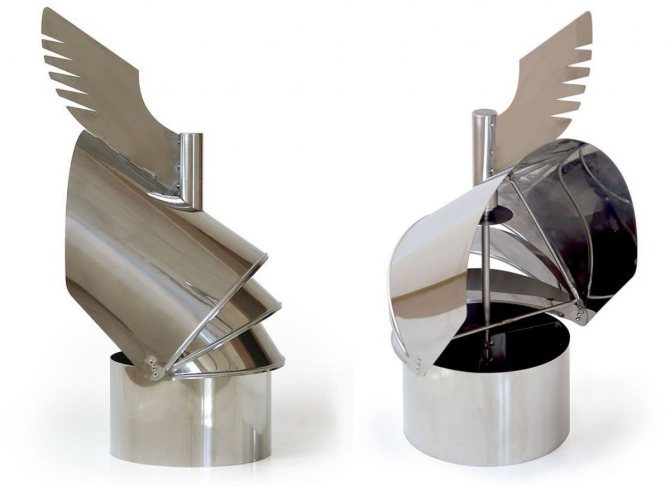

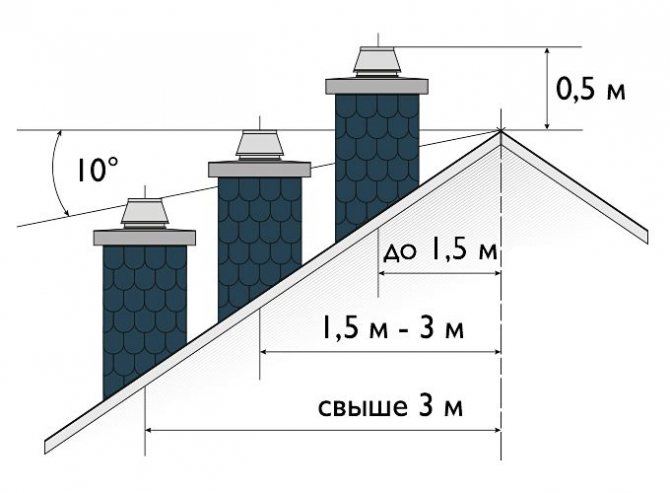

- If the boiler is not equipped with a system for removing combustion products, a special chimney must be installed. For equipment with a system, a small hole is sufficient to install the outlet pipe.

- Any electrical or gas appliances must not be placed at a distance of less than 30 cm from the boiler.

- All places of contact between the chimney and the building must be sheathed with refractory materials.

Back to the table of contents

Wall-hung boiler installation

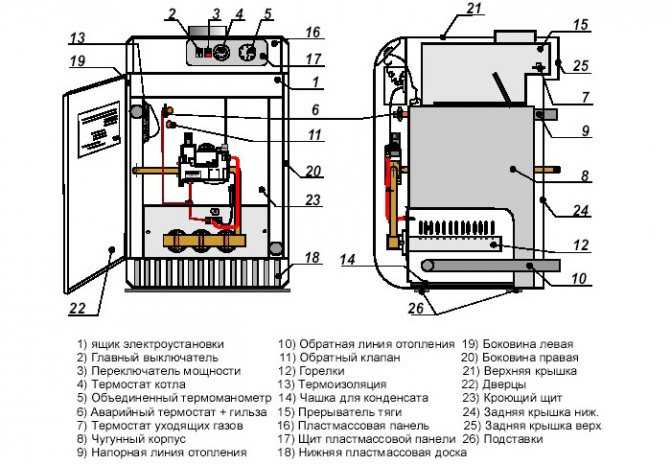

Installation diagram of a wall-mounted gas boiler.

In order to properly install gas heating equipment, which will be located on the wall, upon purchase, you must carefully check the kit for the presence of all major fasteners. You should also check the quality certificates certifying the fact that the gas boiler meets all existing standards. In the absence of a certificate, the heating equipment will not be registered by the gas service specialists, and you will not be able to use it. In addition, it is necessary to check the compliance of the number printed on the inner surface of the equipment with the number indicated in the documents.

Before starting the installation of the device, it should be thoroughly rinsed. To do this, remove the plugs and pump a large amount of water under high pressure through the equipment. Then you should check the tubes, which may have gotten debris during manufacture and assembly. After that, you can proceed with the installation.

In order to install heating equipment correctly, you need to stock up on the following tools:

- building level;

- screwdrivers;

- screwdriver;

- pliers;

- filter for the water supply pipe.

The wall on which the boiler will be placed must be sheathed with any fire-resistant material. This is especially true for wood or paper surfaces. The heat-resistant coating layer should not be less than 0.3 cm.Heating equipment must be installed 4.5 cm away from the wall.

First of all, the mounting strips are mounted. They should be located 0.8 to 1.6 m above the floor. The verticality of the planks is checked using a building level. Then a boiler for heating is attached to the strips, the verticality of which is also checked by the level.

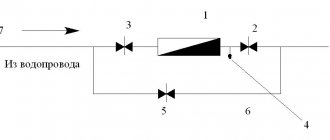

Diagram of a wall-mounted boiler.

In order for the boiler to work correctly, a pre-purchased filter is installed on the water supply pipe, which will help to avoid clogging of the equipment. Stop valves are attached around the filter. With its help, it will be possible to clean or replace the filter without draining the water from the boiler. If the boiler is equipped with a combustion products exhaust system, check the operation of the fan and pass the exhaust pipe through a hole specially prepared for this.

The next step in installing gas heating is connecting the gas. To date, this manipulation is carried out only with the use of a special metal pipe and a squeegee, therefore, the help of a qualified gasman will be required to complete it. Only he has the right to check the quality of the installation, compliance with all rules and regulations and authorize the operation of the equipment.

After connecting the gas, the boiler must be connected to the mains. Modern non-volatile boilers for heating are equipped with an automatic protection against short circuits and overheating.

Back to the table of contents

Installation rules for floor-standing boilers

Floor-mounted gas boilers usually have a much higher power than wall-mounted ones and are capable of heating large rooms. Such boilers have a fairly large weight, therefore, the base under them must be reliable and strong.

Floor standing boiler installation diagram.

If the room in which the boiler will be installed for heating has a wooden but solid floor, it is not necessary to pour a concrete screed. It is allowed to lay steel or galvanized iron sheet, the size of which is slightly larger than the size of the boiler base. To position the boiler on the sheet correctly, you need to be guided by the following - the dimensions of the boiler on the sides may coincide with the dimensions of the sheet, but in the back they should be 30 cm or more less.

If the floor is not reliable, a base must be prepared for the boiler. To do this, you need to make a concrete screed and cover it with an iron sheet or build a special support from a cement mortar. In order for the boiler to work correctly and not to malfunction, after installation, check its verticality using a level. If there are deviations, pieces of hard, non-combustible material can be placed under one of the legs, thereby giving the boiler the desired position.

Then, you should perform all the actions that are performed in order to connect the wall-mounted boiler - lay the pipe for the outlet of combustion products into the hole and connect the boiler to the heating system. The gas boiler must be installed in such a way that it can be removed at any necessary time. To achieve this, it will be correct to place valves on each pipe leaving the boiler. Using the valves, it will be possible to dismantle the boiler without draining the water from the building heating system.

The last stage is connecting to a gas pipe. Here we connect the equipment only in the presence of a gas service specialist. He will check the quality of the installation and sign the commissioning permit for the equipment.

Using this instruction and having certain skills, you can install and connect a gas boiler within a few hours. And when the gasman you have called will sign all the necessary documents and permit the start-up of the equipment, you will fully enjoy not only the warmth in your home, but also the savings in the family budget.

Underfloor heating device from a gas boiler

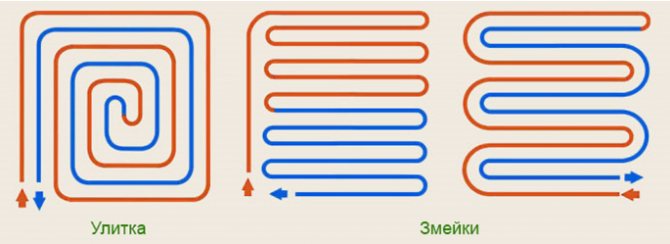

The main elements of the underfloor heating system in a wooden house from gas heating are as follows:

- A gas boiler.

- Discharge pump.

- Connecting fittings and valves.

- The main pipeline that distributes warm water to the premises.

- Floor piping mounted on a sub-floor.

- Automation.

- Collector.

Choosing a gas boiler

If the installation of a warm floor is planned in a house with a large number of rooms of a large area, a double-circuit boiler with a high power will be the best choice. Such equipment performs two tasks at once: it provides hot water supply and home heating. Double-circuit floor-standing boilers should be installed in a separate room - a boiler room, the area of which ranges from 4 m2 for devices with a capacity of up to 30 kW.

Advice. For a warm floor, you can also use a single-circuit boiler, but in this case you will have to install an additional indirect heating boiler for hot water supply, which can be placed in the same room.

Single-circuit and double-circuit gas boilers.

If the house is small, or there is no opportunity to equip a separate room for a boiler room, you can choose a wall-mounted boiler with more compact dimensions. If you correctly calculate its power (for this equipment it fluctuates within 7-30 kW), then it will be able to ensure the efficient operation of the underfloor heating system. The placement of such boilers is allowed in any premises, including kitchens and bathrooms, it is only necessary to equip a chimney that goes to the central or to the street.

Pipes for underfloor heating system

Copper pipes are considered ideal for creating warm floors, which have a huge service life. Due to the high quality, their cost is quite high and not everyone can afford it. Therefore, metal-plastic, polypropylene and PEX pipes are more often used in houses.

Polypropylene products are of quite high quality, but they are not very suitable for a warm floor, since they have insufficient flexibility, and therefore the turns have to be done at a sufficiently large distance from each other.

Metal-plastic pipes are very popular, which are resistant to damage, and the aluminum inside provides good thermal conductivity. Moreover, the products are characterized by an affordable cost.

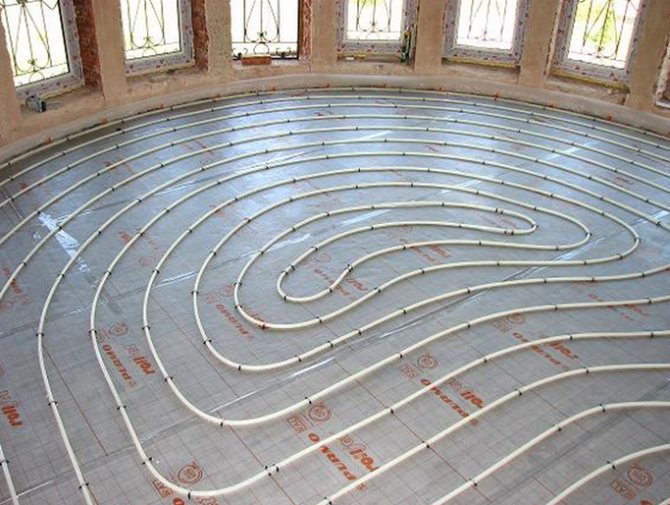

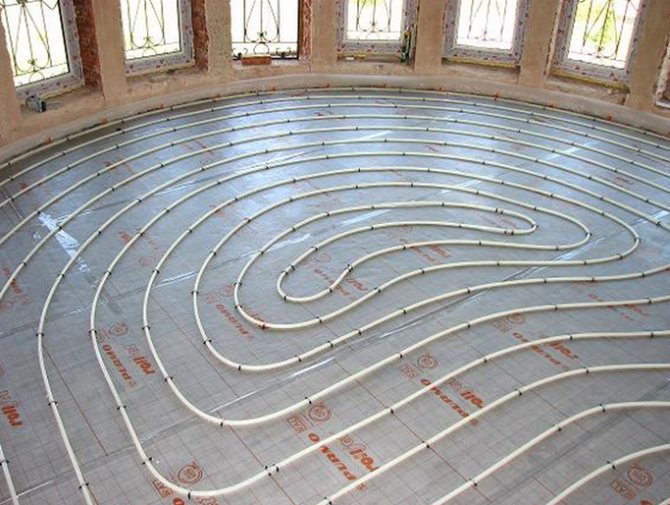

Underfloor heating made of metal-plastic pipes.

PEX pipes are inexpensive products made of specially modified polyethylene, characterized by high strength and durability. It should be borne in mind that these products must be rigidly fixed in the screed, since, when heated, they tend to straighten and take their original shape.

Advice. Purchase pipes that are specifically designed for use in water systems and are labeled accordingly. Such products can easily withstand heating up to 95 C and pressure up to 10 bar.

Implementation options

How can you realize gas heating of a wooden house with your own hands?

Actually, there are two options.

A gas boiler

A centralized boiler (see how to choose a gas heating boiler) heats the coolant by burning gas. It circulates through the pipes, giving off heat to the radiators located under the windows, which have a completely safe temperature (no higher than 80C). They, in turn, warm the air in the rooms.

The layout will look something like this.

This solution is optimal if you have main gas. In this case, it will only be brought into a well-ventilated boiler room, which is clearly safer than distributing gas throughout the house.

Are there any nuances that are useful to know when designing?

- Willy-nilly, you will have to prefer a gas boiler for heating a convection-type private house. More economical condensing ones require a very low return pipe temperature, which, when using radiators, is problematic to maintain while maintaining heat in the house.And a warm floor with its lower water temperature, as we remember, is difficult to mount in a wooden house.

- The optimal layout of the heating system, resulting from the type of boiler (the convection boiler uses a return temperature of at least 60C) - one-pipe, barrack type. A thick (at least 1 1/4 inch) pipe surrounds the perimeter of the house; radiators do not break it, but cut in parallel. It is she who is shown in the diagram above.

- Electronic fired boilers are more economical. The fact that they do not need a constant pilot flame also means a little more safety. If you have frequent power outages, just get an uninterruptible power supply.

The circulation pump is also perfectly powered from the same UPS. True, then it is better to attend to the purchase of additional batteries.

Important: for the normal operation of electronic ignition, wiring is needed not only for zero and phase, but also for grounding.

Gas convector

If you have only imported gas in cylinders at your disposal, gas convectors will be a very convenient solution. They do not need to distribute the coolant around the house: the convector is mounted directly under the window, the cylinder is placed in this or an adjacent room.

The air intake goes from the street, and combustion products are discharged through a coaxial pipe there.

The only nuance associated with this type of heaters is that they will provide heating only for the room in which they are located. If there are many separate rooms in the house, the convector will have to be installed in each one. Accordingly, the number of cylinders that will have to be transported to the gas station will grow.

The convector in the photo, however, perfectly heats the halls on the first and second floors. If the premises are not insulated, the possibility of heating rests only on its heat output.

The main advantage of gas convectors against the background of a boiler with wiring to rooms is the price of the project. One convector is not much more expensive than a high-quality bimetallic radiator. Moreover, he does not need a boiler or pipes.