Pros and cons of metal

The characteristics of pipes are determined by the technological nuances of their production. Metallurgical plants use processes to give the finished product certain properties. Products can be solid-drawn or welded. The former are formed using sophisticated equipment, while the others are sewn from sheet metal.

The main advantages of the products:

- Strength. Metal pipes are indispensable in the construction of high pressure lines.

- Low thermal expansion. This eliminates the need for thick-walled products.

- Almost one hundred percent gas tightness. This is a very important condition for creating a complete closed heating circuit.

- High thermal conductivity. A very important point for the organization of heating systems in residential buildings. The surface of the metal transfers heat to the surrounding air, partially performing the functions of heating devices.

- Availability. The cost of the metal is low, which is of great importance when arranging budget options for heat supply.

Disadvantages:

- Corrosion susceptibility. Metal poorly resists oxidative processes and aggressive environments.

- Electrical conductivity. Although very conditional, but still a negative factor. It is of particular importance when arranging a heating system with an electric boiler.

- Rigidity. It is possible to bend the line only when exposed to heat. For installation, a lot of connecting and shaped elements are required.

- Large mass. During installation, you have to make a lot of physical efforts in order to correctly position the section of the highway.

The choice between plastic and metal for the arrangement of heating circuits

The choice between plastic and metal for the arrangement of heating circuits

Between plastic and metal, metal pipes are more often preferred for heating, although the popularity of plastic pipes in recent decades is so great that new materials have almost displaced metal from the pipe market, but metal is still the preferred option for heating circuits.

It is enough to compare the technical features of metal and plastic to make sure that it is more reliable when used as a material for heating systems.

Plastic in the heating system

Plastic pipes have the following performance characteristics:

- the value of the permissible operating water temperature is 95 degrees,

- the value of the working pressure is not more than twenty-five atmospheres.

At first glance, this is quite acceptable for use in heating, where the operating temperature and pressure usually do not exceed these values.

However, the maximum pressure data corresponds to the declared one only at water temperatures up to 20 degrees. With an increase to the limit of 95 degrees, the working pressure in the plastic pipes will drop to eight atmospheres.

Note! When plastic pipes are used at the maximum permissible level, their service life is reduced to about ten years.

In winter, in case of frost, the management company may decide to increase the water temperature. In this case, the incoming liquid may not be 95 degrees, but all 150.

We recommend that you familiarize yourself with: Types of saddles for a polyethylene pipe and features of their application

Do not forget that heating mains are inspected about once a year. During these checks, the ultimate pressure is increased by three times the values during normal operation. Therefore, plastic often fails these tests.

Metal pipes

The main condition is that the pipes for heating are strong and reliable. Metal products are able to withstand even extreme loads, and in this plastic counterparts cannot be compared with them, despite the susceptibility to corrosion, which reduces their service life, and their large weight, which makes installation and transportation difficult.

Reliability for heating mains is the most important quality, especially since manufacturers use various alloys for anti-corrosion resistance, which do not have these disadvantages.

Types of pipes

Cast iron

The composition is a complex iron-based alloy. The molten mass is excellently molded and differs from pure steel in its increased carbon content.

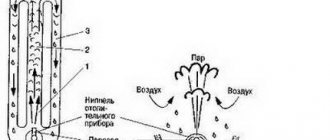

Pipes made of cast iron for heating systems are rarely used. When their use is fundamental, then operations are performed to improve the insulating characteristics:

- joints are sealed with cuffs and special couplings

- the inner and outer walls are treated with a protective film

Manufacturers supply the market with products with a diameter of 50 to 300 millimeters. Compared with plastic counterparts, cast iron has an advantage in mechanical strength.

Copper

Copper pipe

The material has exceptional thermal conductivity. Along with sufficient mechanical strength, it is characterized by a long service life.

Copper pipes are used in places where welding work is categorically unacceptable. These highways did not receive mass distribution due to their high cost.

For heating systems, there are two types of these pipes:

- Made of pre-work-hardened material. Products gain increased mechanical strength. Deliveries, as a rule, are carried out with purlins cut to the required dimensions. Their diameter ranges from 22-54 mm.

- Made from welded copper. Products are distinguished by high malleability and manufacturability. They are supplied to the market in coils with a diameter of 6-22 mm.

Separate sections of the highways are joined together by welding.

Black steel

It is the most common material for domestic heating systems in the 70-90s of the last century. This steel grade is not resistant to corrosion and is unlikely to leave behind positive memories for homeowners. Although the service life was declared at 25 years, the problems started much earlier.

Namely:

- Depressurization of the system. This was partly due to the incorrect operation of the pipelines. They could serve for a long time, provided that the system was filled with water all year round, which was absolutely not observed.

- Deposits. The inner walls are a great place to collect salt, sand and other impurities. As a result of the decrease in the diameter of the mains, the efficiency of their work also decreased.

Cink Steel

Galvanized pipe DN 32

The protective top layer has dramatically changed the performance characteristics of conventional steel. The pipes began to serve several times longer. In many "Stalinkas" these highways serve to this day. However, the quality of modern products raises many questions from both installers and consumers.

In fairness, it should be noted that there are enough high-quality products on the market. Heating made of zinc-coated metal pipes is durable. The material itself remains strong and resistant to aggressive environments.

Separate sections are mounted on threaded joints, since welding destroys the insulating layer.

Of the shortcomings, two can be noted:

- Higher cost than traditional steel.

- Threaded joints are much more time consuming than welding or brazing.

Stainless steel

In theory, stainless steel pipes can be used to equip heating.Moreover, the installation can be performed both by welding and by means of threaded connections. Such highways are practically not limited by any terms of operation. The building itself will become unusable faster.

However, the extremely high cost of anti-corrosion steel precludes widespread use of the material. Corrugated counterparts, on the contrary, are successfully used and become more and more popular every year. Their price is quite acceptable, and consumer demand is growing due to the many advantages of the material:

- You don't need a lot of tools to complete the installation work. The most primitive pipe cutter and two gas switches are enough.

- High performance parameters. The metal can withstand the boiling point of water and the pressure of 12 kgf / sq. Cm.

- Pipes are connected using compression fittings and silicone seals. They are easily joined by means of fittings and are clamped with threaded connections.

- The pipes are easy to mold. No thermal action or great force is required to obtain the desired bend.

Add to bookmarks

DIY installation rules for heating pipes

Installing a copper heating system using special press fittings can be done by hand. Detachable connections are formed that can be disassembled and reassembled if necessary.

Required tools and materials

For wiring the heating system you will need:

- A hacksaw for metal, or even better - a pipe cutter.

- File, sandpaper.

- Calibrator.

- Two wrenches.

- Pipe bender.

Drawings and diagrams

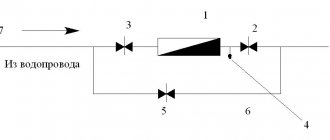

First of all, you need to draw a diagram or drawing. This will help determine the number of fittings and correctly purchase materials.

Installation technology

The installation technology with compression fittings is simple. Copper pipe fittings are made of brass. They differ from fittings for plastic - the inner thrust ring is made without a cut (see photo). No special equipment required.

Work progress

- First it is cut and deburred. Then the cut is calibrated by the calibrator so that it has a round shape (copper is soft and the workpiece is crumpled during cutting).

- Then a crimp nut is twisted from the fitting, put on the workpiece, the branch pipe is inserted into the fitting, the nut is tightened by hand with little effort.

- Then they grip the fitting with a wrench, tighten the nut by 1-1.5 turns with the second wrench.

- On the other side of the workpiece, the work is repeated. The entire workpiece is then assembled into the system. Corner fittings are used for turns, but you can bend the pipe using a pipe bender.

- After about 80 centimeters, the brackets are installed.

- After assembly, the system is filled with water and tested. If necessary, tighten the nuts with wrenches.

Installation features

Do not use the installation of pipelines on compression fittings for the underfloor heating system.

It is not worth increasing and decreasing the diameters of the pipelines - this will not improve heating and lead to an imbalance in the system.

Classification and characteristics

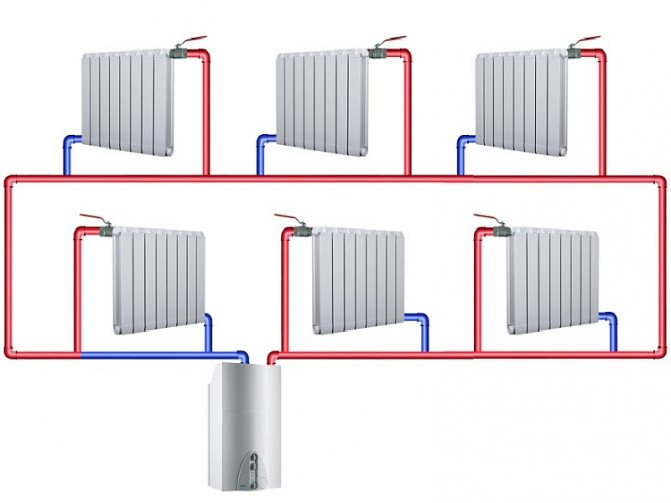

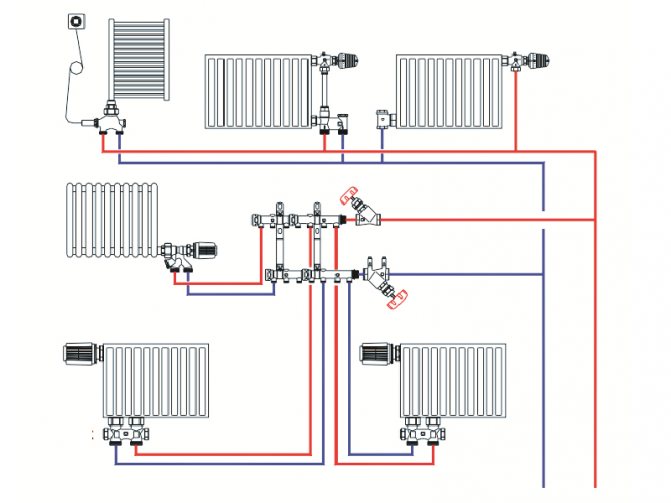

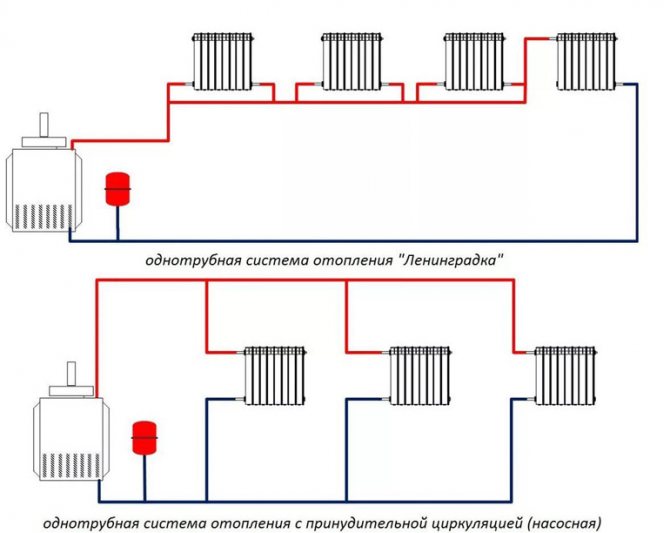

Two-pipe heating circuit with forced circulation of the heat carrier

According to the manufacturing method, iron pipes can be seamless, hot or cold drawn and electrically welded. Seamless rolled steel is more reliable and designed for higher pressure. The choice of such pipes entails an increase in the cost of installing a heating system, since their cost is much higher than that of electrowelded ones.

The main characteristics are:

- Size and weight. The size of the product is determined by the inner and outer diameters, nominal bore diameter, wall thickness and pipe length. All these physical quantities, including the mass of 1 linear meter. m pipes, regulated by GOST and TU. Using them, you will easily make a choice in favor of one or another type of rolled metal.Diameters and wall thicknesses are measured in millimeters, length in meters, and mass in kilograms or tons.

- Strength. Strength characteristics include the ability of the pipeline to withstand a certain pressure (operating, nominal, test, excess) and the temperature of the environment. Pressure is measured in pascals and temperature in degrees Celsius or Kelvin. These are the main characteristics that guide the design of heating systems.

- Material. It can be carbon steel, stainless steel, carbon iron, alloy and non-ferrous metal.

Bimetallic contour elements

Bimetallic pipes

Bimetallic heating pipes function as batteries. They can be mounted in a hidden way, or open. Convenient to use for heating office premises. In apartments, this is rare, except as a baseboard heating. Steel and non-ferrous metals are used for manufacturing. The combination of cheap and expensive materials significantly improves the price-quality ratio of products. In this case, you can select the metals with the most suitable characteristics.

The reinforcement tape is fixed by welding or pressing. Basically, ribbing is carried out in a spiral welding method. Such products are not only resistant to heat, the maximum temperature is 350 degrees, but also have excellent heat dissipation. Strengths:

- can work with a coolant of any quality;

- long service life;

- relatively small diameter. In the domestic market it is ½ and ¾;

- good heat dissipation - both have about 300 watts per meter.

In addition to heating, bimetallic products are used in many industries. This is the petrochemical industry and mechanical engineering. They are also used for air conditioning systems and even at nuclear power plants.

Steel pipes of the heating system: installation

Gravity (gravity) heating circuit diagram

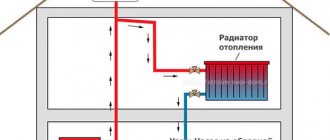

For indoor heating systems, as a rule, ½- and ¾-inch pipes with a nominal diameter of 15 cm and 20 cm are used, respectively. The heating scheme is a system of series-connected sections of metal pipes of various lengths. The main requirements for this are the tightness and tightness of the entire circuit, regardless of temperature movements.

Installation of iron pipes is carried out in three ways:

- Using gas flame or electric arc welding;

- With flanges;

- With a threaded connection.

Installation and connection of pipelines using welding guarantees a strong and reliable connection. There are many types of welding, but when installing heating systems, installers often opt for gas or electric arc welding. Before starting welding, all joints and edges are thoroughly washed and degreased, and also treated with an abrasive tool (file, special chamfering machine, grinder, etc.).

In gas welding, under the influence of flame and high temperatures, the filler material (wire) melts, which forms the weld. Electric arc welding is performed using electrodes using direct or alternating current. In this case, the positive phase is connected to the workpiece, and the negative phase is connected to the electrode. Welding with alternating current is more cost effective, and the equipment for it does not require additional maintenance and testing.

Connecting pipes with a thread makes it possible to further dismantle and install individual sections of the heating circuit

Connecting pipes using a thread makes it possible to subsequently dismantle and install individual sections of the circuit for repair or replacement. When making such a connection, additional fittings are used:

- transitions,

- bends,

- traffic jams,

- stubs,

- connecting nuts,

- tees,

- couplings, etc.

And the question immediately arises, what quality characteristics should the fittings have? The answer is simple: all geometric dimensions of the connecting elements must comply with GOST, the thread must have a clear axial direction, be free from contamination and breaks.

All threaded connections are made using sealing materials. It can be impregnated linen tow, asbestos cord, paronite, rubber or FUM tape. Thoroughly clean the threads and sealing surfaces before carrying out the operations. All connections must be made to the end to ensure complete tightness. Pipe wrenches are used to screw pipes and fittings. Pipes are connected in special devices or directly at the installation site

Installation of pipes using flanges consists in bolting and sealing the sealing surfaces of the welded flanges. The sealing material can be asbestos cardboard, paronite, rubber, etc. The installation of the system must be carried out sequentially, excluding possible misalignment and distortions.

The gasket should be cut precisely to the size of the flange sealing surfaces, should not rest against the bolts and overlap. The bolts, in turn, should not be too long, and their heads should be marked on one side of the connection. It is necessary to tighten diametrically opposite nuts alternately for the entire connection. Use wrenches for this.

Summing up, I would like to say that, having complete information about steel pipes, you can easily determine which pipes are better and which type of their connection is more suitable for you. As practice shows, a high-quality metal pipe will last for decades and will not disappoint you.

In modern conditions, to create a heating system, you can use a wide variety of types of pipes: plastic, metal and metal-plastic. All of them can be used. Of course, each material is special, it differs not only in characteristics, cost, but also in installation requirements.

Heating pipes serve to supply and remove the required amount of heat. And at the moment, metal products are most often used for this.

Services for the installation of heating water supply

DESIGN PRESTIGE LLC 8 (495) 744-67-74

In addition to fast and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our page by topic heating > resant.ru/otoplenie-doma.html For communication, use the contact phone number of DESIGN PRESTIGE LLC 8(495) 744-67-74, which you can call around the clock. note Our company DESIGN PRESTIGE LLC is a part of the non-profit organization ANO INTERREGIONAL COLLEGE OF JUDICIAL EXPERTS. We also provide services for an independent construction technical expertise. Calculating the cost of heating Heating system repair cost Water supply installation cost Previous post Plastic heating pipes for your home Next post Custom roller shutters It is quite difficult to choose this material for heating. It must be resistant to environmental influences, must serve for a long time, be reliable and durable. Each metal has its own characteristics, which are worth considering further. This is almost an ideal option, if you do not take into account the rather high price for them and for installation. The products look great, have a high level of strength, are resistant to corrosion, and can be used for a hundred years. Such pipes have high strength, serve for a long time, and weld well. Also, such products are characterized by increased thermal conductivity. And this is very good just for the heating system. In addition, such material is inexpensive. However, steel pipes are not without drawbacks. For example, they are susceptible to corrosion, so contact with water is not good for them. As a result, the inside of the pipe can become covered with rust, as a result of which it can overgrow. Therefore, the throughput will be degraded. As a result, replacement may often be required, which is not beneficial for heating. Galvanizing is needed just to protect steel from corrosion. However, this does not mean that the zinc coating will completely avoid this disadvantage. It will only slow down the process. Recommendation: galvanizing of the connecting fittings is optional. Also, in the process of welding such material, substances hazardous to health are released. Therefore, it is better to make threaded or alternative connections. Thermal insulation is installed on pipes running on the territory unprotected from the cold, for example, down the street. Regardless of the material, the devices freeze, which can completely deprive the heating system. Insulation serves to keep pipes warmas well as for sound insulation. As a heat insulator, various materials are used that differ in price and composition. Mineral wool is most often used for heating pipes. The properties of the substance allow it to be used in any conditions. Mineral wool keeps high temperatures, durable, versatile, while having a low price. Together, these factors make the substance one of the best for thermal insulation. Synthetic material. Thermal insulation is performed in the form of pipe halves. The assembly takes place accordingly: the strapping is “put on” in an insulating material, which is then fastened. Polyurethane foam promotes protection against low temperatures, increases mechanical strength, some of its types reduce the possibility of leakage. In addition to polyurethane foam, they also use 4 substances: Photo 4. Thermal insulation of a plastic pipe with foam, which can serve for more than a dozen years. It can be made simpler than any other type. Enough paint the heating systemby applying a small layer. When the liquid dries up, the pipe is considered to be thermally insulated and ceases to release heat. Such products have many advantages: For all its ideality, copper pipes also have disadvantages. Mechanical impurities, as well as acidic water, are terrible for them. It should also be remembered that steel or galvanized products cannot be present in the same system with copper. Otherwise, corrosion may occur. Such products can be welded or seamless. The latter are the most reliable material. This is one product, no components involved. The result is high strength. If necessary, the surface can be zinc plated to prevent rust formation. In general, such a product does not require a protective coating such as a primer or paint. It is worth applying such compositions with your own hands only in places where the zinc coating is damaged - at the joints. Pipes can be connected with fittings.At the same time, we note that their material must be identical with the material of the pipes. Therefore, everything should be, say, copper or steel - depending on the material used. As for welded pipes, they are very widespread. At the same time, modern technologies make it possible to obtain high strength of the welded seam. Therefore, such products are applicable where seamless ones are also used. Moreover, such products have less deviations in thickness, and the wall can be thin. Hence the classification by thickness: In addition, registers are made of metal pipes. A heating register made of a smooth steel pipe is a kind of battery, which consists of several parallel pipes connected to each other in such a way that the coolant can circulate freely through it. Steel pipe heating registers are used in non-residential premises, in production, in agriculture, schools and kindergartens, etc. Also, an air vent can be installed in them, thanks to which the formed air locks can be vented. The fastening of steel heating pipes is carried out according to the following recommendations: After the system is ready for commissioning, it should be checked, which is called a pressure test. This is a test of the circuit for strength and tightness at a pressure exceeding the operating pressure. Installing metal pipes for heating is not an easy task. Even small flaws can affect the service life or even render the system unusable. First, a project is drawn up. The material, dimensions, scope of work are selected and the locations of the system elements are determined. And only after that, direct installation is possible, taking into account, of course, the requirements of SNiP. Making a heating system with your own hands is a pleasant, but painstaking and costly task, especially if metal products are used. Therefore, the priority will be the option of inviting the master to perform all installation work. If you have enough confidence, experience and knowledge, you can try it yourself. We make a choice, and go! Today, many types of pipes are offered for heating systems: metal-plastic, plastic, metal. All of them are suitable for use in heat supply. They differ from each other only in the methods of installation, the material of which they are composed, the price and the service life. Central heating pipes are designed to supply the quantity and remove the coolant from heating devices. For this, pipes from different materials are used, but in this article we will talk about metal pipes. The first step is to change the valves. It is necessary to turn off and discard the risers, unscrew the old valves. To ensure proper patency of the water pipe in its direction, it is necessary to clean it with a cable. Then we protect the thread with a metal brush, we wind it up with linen using drying oil or enamel. Of course, FUM tape can also be used. However, there is danger in this option. If there is the slightest backtracking, the connection will leak. The above method is proven and does not have such a disadvantage. FUM tape Next, we turn on the valve and tighten it with an adjustable wrench very carefully. If the plumbing is carried out over several rooms, make sure that the diameter of the holes in the wall is sufficient. If necessary, it is better to expand them immediately. If the laying of the water supply system will be carried out under the tiles, you need to make grooves. In order for all devices connected to the water supply to work for a long time and reliably, it is recommended to install coarse filters. This is especially important if your home has a water heater. This is a mandatory requirement of manufacturers. Coarse and fine filter It is better to cut polypropylene or metal-plastic in place. Prepare galvanized steel in advance: cut and cut threads. You can connect through a conventional tee or through a manifold - wiring to individual devices with shut-off valves. You can connect, as already noted, with your own hands using welding or threaded connections. For welding, it is still better to turn to a welder, and the threads can be cut by hand or using a lathe (if available). It is very difficult to select pipes for heating, they are divorced around the entire perimeter of the house, and therefore must be resistant to corrosion, strong, reliable and last a long time. There are certain types of pipes, consider some of them, their advantages and disadvantages: Metal pipes for heating from stainless steel. They can be called ideal for a number of reasons: Unfortunately, with all these high-class properties, there is a significant drawback - the high price of not only pipes, but also their installation will also cost you dearly. Very often this is the reason for favoring other types of pipes. They are made of high quality steel, which has high strength, excellent weldability and a relatively long service life. Steel pipes have a high thermal conductivity, but this advantage applies only to the heating system. The main disadvantage is that steel pipes are not covered with anything and, in contact with water, this leads to metal corrosion. Corrosion is the cause of rusty water, the inner diameter of the pipe gradually overgrows, and this entails a decrease in water flow. That is why steel pipes have a low price, but still need relatively frequent replacement. To avoid corrosion of steel pipes, a layer of zinc is applied to them, but this does not completely protect, but only slows down the corrosion process. Tip: The connecting fittings must also be galvanized. Important: In certain cases, the zinc coating of pipes is very harmful to the welder's health, since harmful substances are released during the welding process. Therefore, it is recommended to connect such pipes with threads. The advantages of these pipes are similar to those of copper itself: Metal pipes are manufactured using various technologies, for example, they can be seamless (seamless) or welded. Solid-drawn metal heating pipes are perhaps the most reliable and high-quality material among all existing ones. They represent a single product (which is why they are called seamless) and are not assembled from component parts. This makes them durable. They can be coated with zinc, which protects the pipes, and there is no need to take action to prevent rust formation. Such pipes do not require painting or priming, only at the joints (they have threads, and with such a manipulation, the galvanized steel is damaged).Solid pipes, as well as welded pipes (galvanized or not galvanized), are connected to each other by special devices - couplings, and they are also called fittings. Please note: If you have chosen metal pipes for heating, for example, stainless steel, then the fittings for them must be of the same material. That is, from what metal the pipes are the fittings. Welded pipes are widely used in many industries. New and improved welding techniques guarantee a high seam strength that matches the strength of the pipe itself. All these technologies allow the use of welded pipes in those industries where it was possible to use only seamless pipes. A welded metal pipe for heating, in comparison with a seamless one, is produced with less deviations in thickness and with a thinner wall. This technological feature is an advantage. According to their thickness, pipes are of the following types: The large thickness of the metal has both a plus (high anti-corrosion performance) and a minus - they are very difficult to bend during installation and repair work. Installing pipes for heating is a rather difficult and painstaking task when building or renovating a house. Minor errors can lead to a short service life or disable the entire system. Attempts to minimize damage from these properties have been accepted by mankind from the very beginning of the industrial use of iron. The emergence of new materials and methods of protection is bearing fruit, but it does not completely eliminate the disadvantages. The fight against deposits inside the pipes is carried out using special fluids as an energy carrier. In addition, steel pipes for heating are regularly cleaned with chemicals added to the water. This method has a significant drawback - the aggressiveness of the environment increases significantly, which also leads to undesirable results. For the laying of trunk networks, steel pipes for heating with PPU coating have been increasingly used. The process of applying polyurethane foam in the factory is carried out, in addition, an additional surface coating with polyethylene is applied, which reduces the effect of aggressive environments, and also reduces the intensity of the corrosion process. To reduce the effect of rust, many means are used, these include various synthetic coatings, treatment with other metals that are more resistant to corrosion. Let us consider separately zinc coatings, the use of which is most widespread due to the relatively low cost of the process. The ability of zinc to protect steel from oxidants has been known for a long time. This technology is used in various sectors of the production of building materials, it is not only galvanized heating pipes, take the same metal profile or metal tile. This coating is used not only for steel, it can be used for various other alloys, as well as cast iron. The principle of operation is based on the greater activity of zinc atoms, therefore oxygen, in the first Two main coating technologies: It should be noted that in this way the electrochemical protection of pipes is significantly increased. Such processing naturally influenced the fact that galvanized pipes for heating are much more expensive. Important: When installing the heating system, it is imperative to comply with the requirements of SNiP 41 - 01 - 2003. Equipping your home on your own is pleasant and commendable, but it requires a lot of effort and certain financial costs, but even a small error can create everyday problems not only for you, but also for your neighbors. Heating from metal pipes must be carried out by a master who will ensure an uninterrupted heating system. For this, you can use a pipe cutter or reciprocating saw. Pipe cutters divide the product into sections by means of cutting discs, which need to be changed from time to time. For stainless steel, there are special discs that are sharpened in a special way, which allows them to work with more viscous materials. The use of a hand tool is not always possible, for example, when it is necessary to cut off a part of an already established contour. Therefore, a reciprocating saw is used for these purposes. It is fixed on the contour to get an even cut; It is not recommended to use a grinder to cut off a part of an already installed contour. In addition to sparks, there is a risk of short circuit or electric shock if water from the system gets on the instrument. Use a reciprocating saw.Heating from DESIGN PRESTIGE LLC Type: hot water here> /otoplenie-dachi.html

Engineering systems: heating water supply:

Types of metal pipes

Stainless steel

Steel

Cink Steel

Types of thermal insulation

Mineral wool

Polyurethane foam

Synthetics

Liquid

Copper

Hydraulic pipe bender

Installation

Installation steps

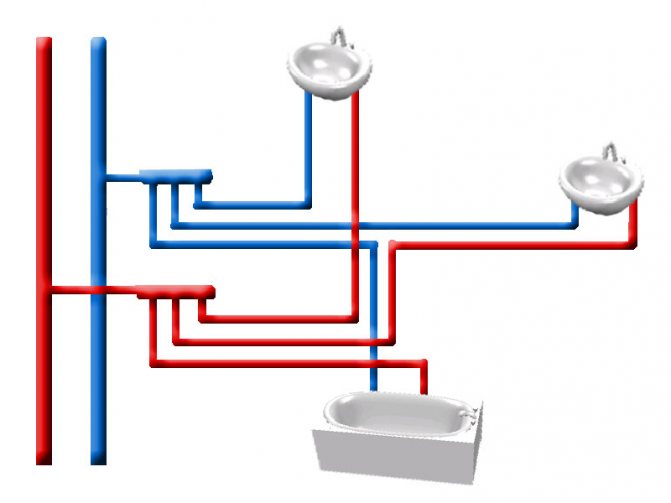

Installation of water pipes

Filters

Pipe preparation and assembly

Installation options

Varieties of metal pipes

Stainless steel pipes

Steel tubes

Galvanized Steel Pipes

Copper pipes

Methods for dealing with negative properties

The fight against energy losses and frost protection is carried out only in one reliable way - insulation. In addition, active protection systems using an electric heating cable are becoming more and more popular.Galvanized Steel Pipes

turn, reacts with it, and steel remains intact for a longer time. The use of galvanizing increases the service life of the systems by 10-15 years.The main stages of installing pipes for the heating system

All about installation

Installation highlights: