Characteristic

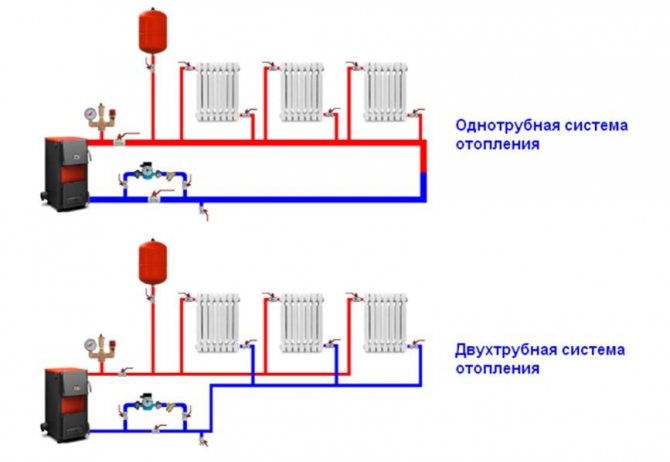

The most common is precisely the two-pipe heating organization, despite some of the advantages of single-pipe structures. No matter how complex such a line with two pipes (separately for the supply of water and its return), the majority prefers it.

Such systems are installed in multi-storey and apartment buildings.

Device

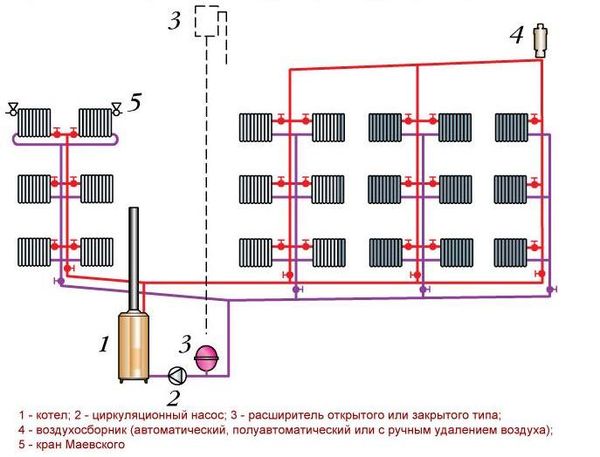

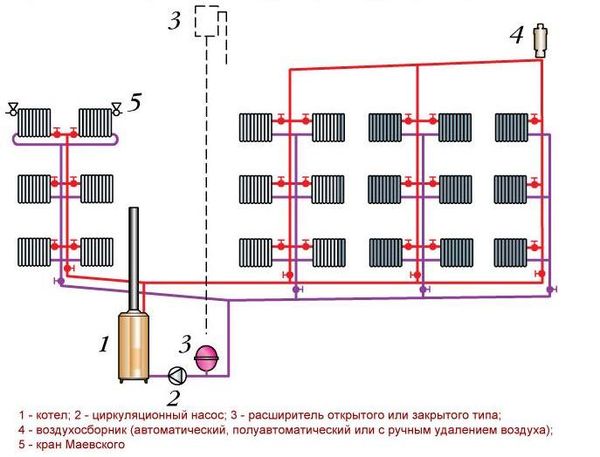

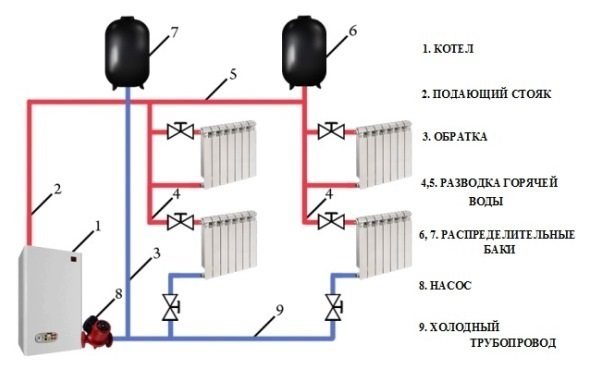

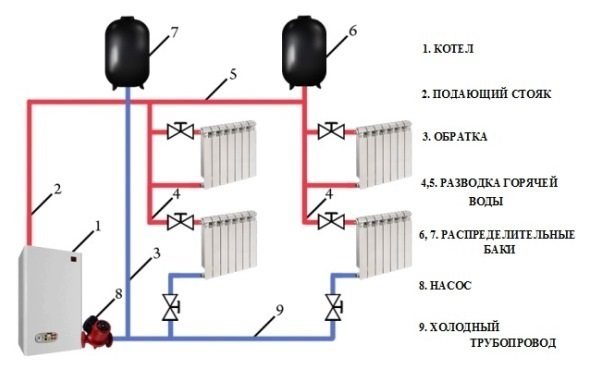

The elements of two-line heating with a bottom pipe cut are as follows:

- boiler and pump;

- auto air vent, thermostatic and safety valves, valves;

- batteries and expansion tank;

- filters, regulating devices, temperature and pressure sensors;

- bypasses can be used, but not required.

Advantages and disadvantages

The considered two-pipe connection scheme, when used, reveals many advantages. Firstly, the uniformity of heat distribution along the entire line and the individual supply of the coolant to the radiators.

Therefore, it is possible to regulate the heating devices separately: turn on / off (you only need to close the riser), change the pressure.

Different rooms can be set to different temperatures.

Secondly, such systems do not require shutting down or draining the entire coolant in the event of a breakdown of one heating device. Thirdly, the system can be installed after the construction of the lower floor and not wait until the whole house is ready. In addition, the piping has a smaller diameter than a single pipe system.

There are also some disadvantages:

- more materials are required than for a single-pipe line;

- the low pressure in the supply riser makes it necessary to frequently bleed air by connecting additional valves.

With bottom polypropylene routing

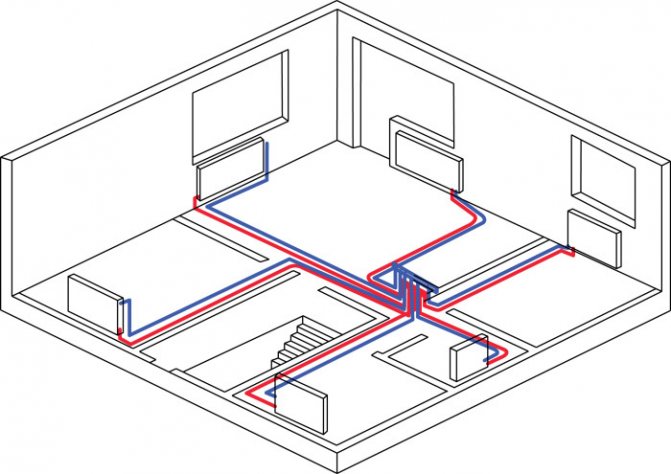

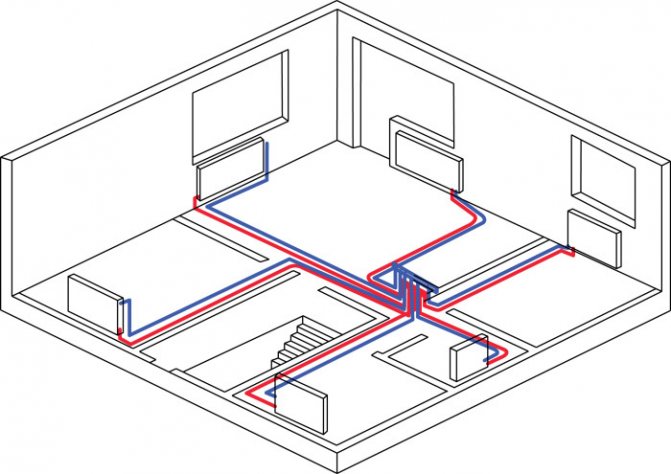

Bottom wiring diagram

Pipes from the boiler to the radiators are laid at the floor level, below the radiators. A distribution pipe is laid from the boiler along the perimeter of the building, passing along all radiators. The return pipe is laid in the same way. Radiators are connected from below, from the side or diagonally, cutting into common pipes with the help of tees.

The coolant along the heating circuit with a lower wiring cannot circulate independently under the influence of gravity. Therefore, this scheme is chosen specifically for a circuit with forced circulation. A booster manifold can be used as a fallback in the event of a power outage, but its efficiency is too low for continuous operation.

The main advantages of the bottom wiring scheme are:

- The pipes are laid at the floor level, are unobtrusive and, if desired, they can be sewn into a box or even hidden in a screed.

- Only one hole is required for the passage of the walls.

- Any third-party heat loss on the pipes is reduced.

- Lowest material costs among two-pipe connection schemes.

It is best to separate the pipes from the boiler to the radiators with polypropylene. It is enough to choose the optimal diameter for the common pipe and lay it along the entire route, soldering tees under each radiator.

Polypropylene at the joints forms reliable welded joints with the fittings, so that they can be hidden from view even in the concrete screed.

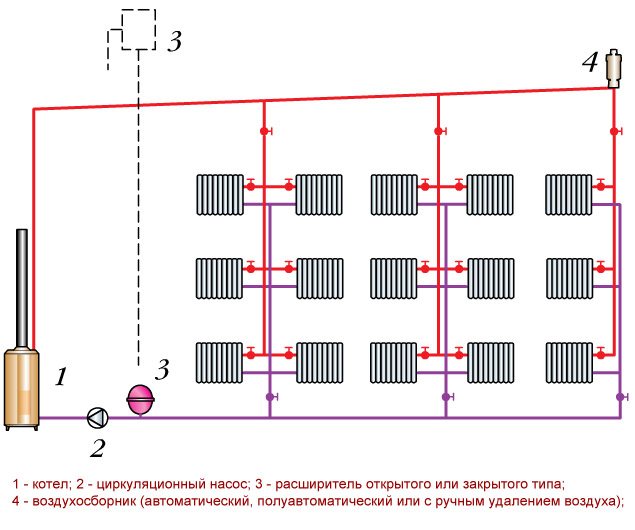

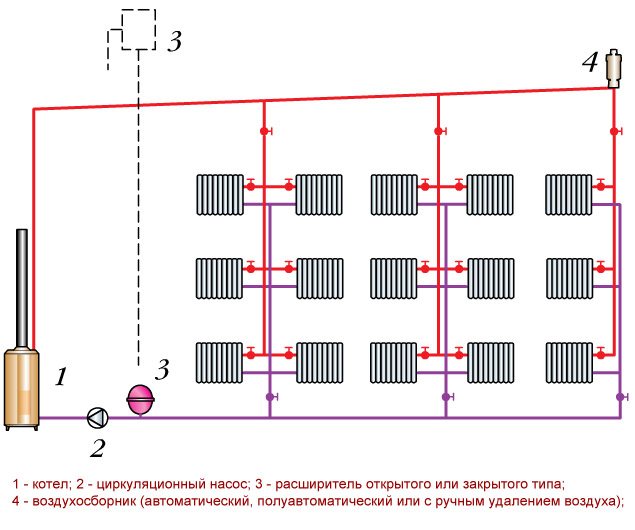

Forced circulation

Forced circulation circuit

It is better to connect the circulation pump to the cold inlet in front of the boiler with a direct-flow bypass. He will set the speed of movement of the coolant in the heating circuit and the effectiveness of the entire heating.

The loop resistance must be lower than the head set by the circulation pump.The greater the difference, the less effort the pump will have to spend to swing the coolant. Considering the cost of the pump and its consumption, it is always better to minimize the loop resistance than to increase the performance of the equipment.

To determine the hydrodynamic parameters of the wiring diagram and calculate the diameter of the pipes, the longest contour is selected with the inclusion of one radiator. It is divided into sections:

- boiler with piping;

- common distribution line;

- return line from the radiator to the boiler;

- radiator connection.

For each section, the diameter of the pipe and the composition of the equipment are calculated. When calculating the distribution and return lines, the total volume of the heating system is taken as a basis, in order not to lose sight of the required volume of the heat carrier passing through.

Radiators are connected with a pipe with a diameter equal to the inlet pipe of the heat exchanger. The thermostat is installed on each heater separately. It is not necessary to use a bypass, the load associated with the increased resistance of one circuit will be distributed evenly over the others. To decouple the circuit with radiators from the boiler, it is enough to use a bypass or a storage tank installed after the boiler piping.

Comparison with other types

In the lower inset, the supply line is laid from the bottom, next to the return, because the coolant is directed from the bottom up along the supply risers. Both types of wiring can be designed with one or more circuits, dead-end and associated water flow in the supply pipe and return.

Natural circulation systems with a bottom line are very rarely used, since they require a large number of risers, and the point of such a pipe tie is to reduce their number to a minimum. With this in mind, such designs most often have forced circulation.

Roof and floors - meaning

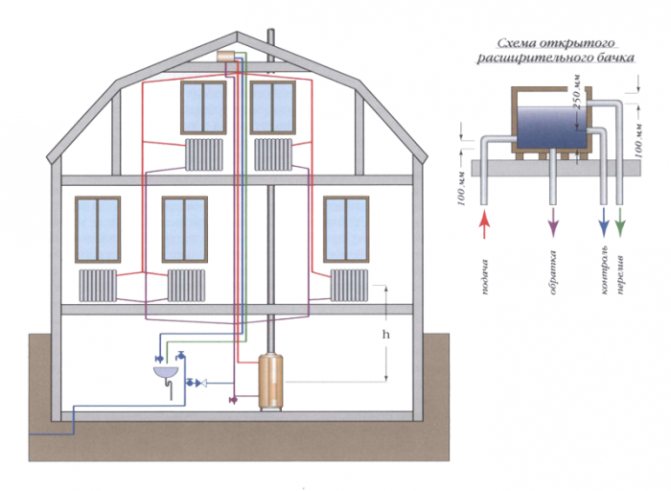

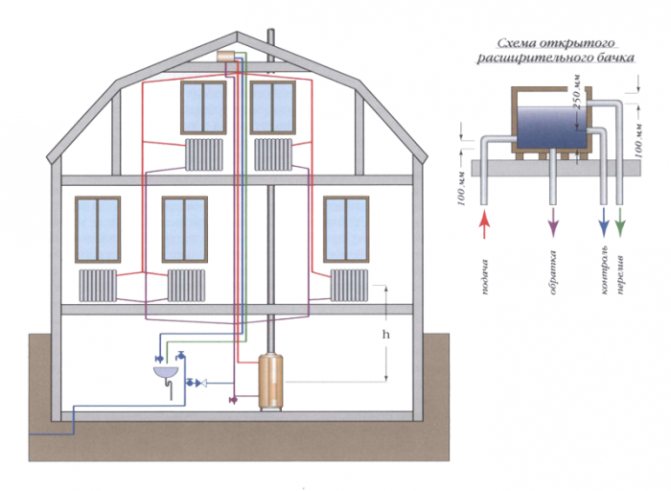

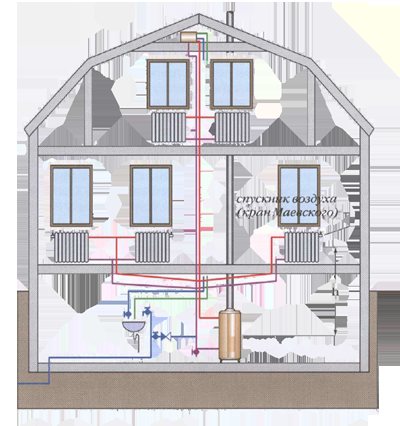

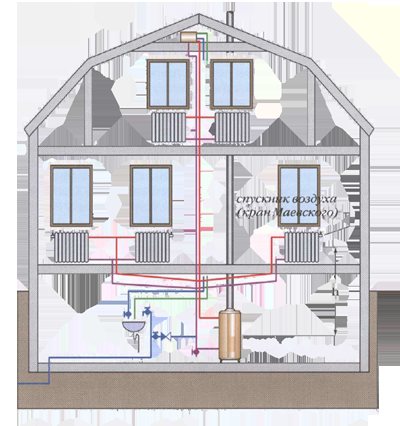

In the upper connection, the supply line is above the radiator level. It is installed in the attic, in the ceiling. The heated water enters the top, then - through the supply risers, it evenly spreads over the batteries. Radiators should be located above the return line. To exclude air accumulation, a compensating tank is mounted at the very top point (in the attic). Therefore, it is not suitable for flat roof houses without an attic.

The bottom wiring has two pipes - supply and outlet, - the radiators must be higher than them. It is very convenient for removing air locks with Mayevsky taps. The supply line is located in the basement, in the plinth, under the floor. The supply line must be higher than the return. The additional slope of the line towards the boiler minimizes air pockets.

Both wiring is most effective in a vertical configuration where the batteries are mounted on different floors or levels.

Principle of operation

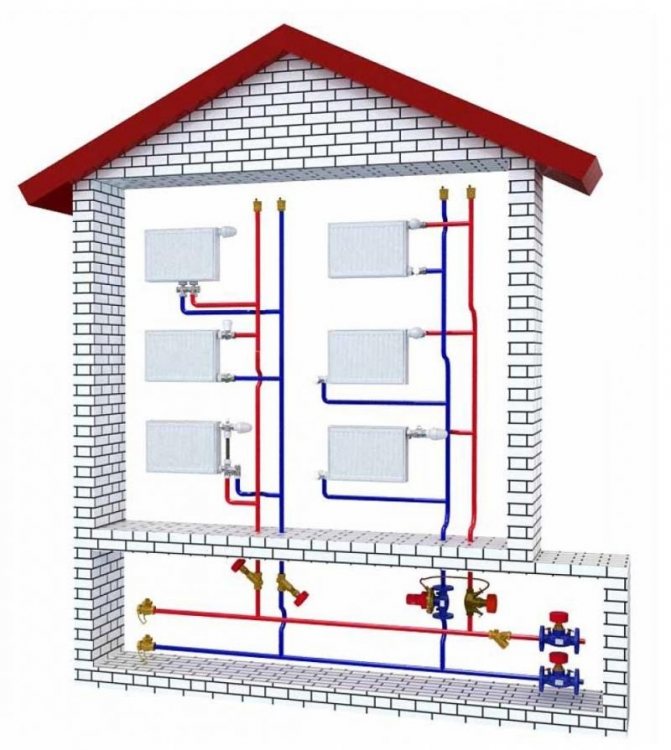

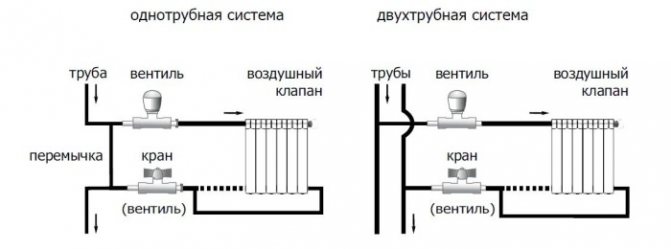

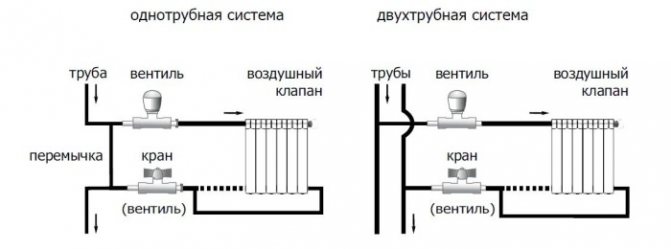

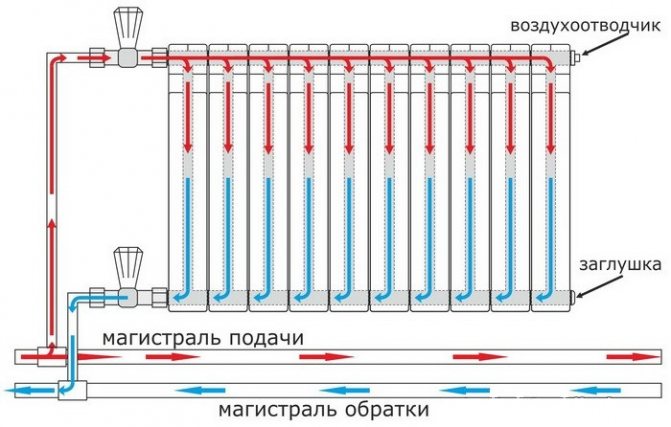

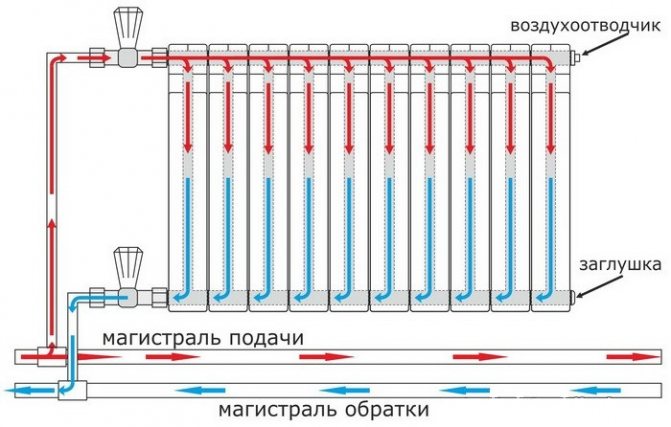

The main characteristic of a two-pipe system is the presence of an individual water supply line to each radiator. In this scheme, each of the batteries is equipped with two separate pipes: water supply and outlet. The coolant flows to the batteries from the bottom up. The cooled water returns through the return risers to the return line, and through it to the boiler.

In a multi-storey room, it is appropriate to install precisely a two-pipe structure with a vertical line and lower wiring. In this case, the temperature difference between the heating medium in the supply pipe and the return pipe creates a strong pressure, which increases as the floor rises. The pressure helps the water move through the pipeline.

In the considered lower pipe connection, the boiler must be in a recess, since the batteries and heating devices must be higher to ensure uniform delivery of water to them.

The air that accumulates is removed by Mayevsky taps or drains, they are mounted on all heating devices. Automatic dumpers are also used, which are fixed on risers or special air vent lines.

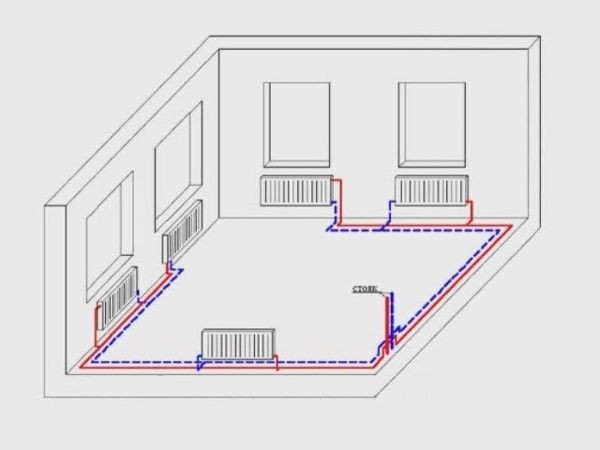

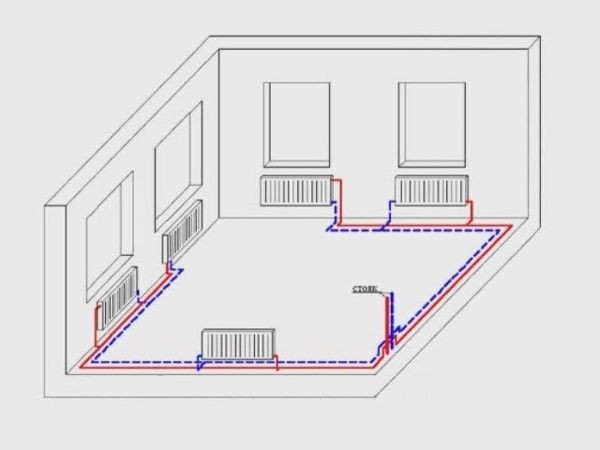

The principle of operation of the two-pipe system

With a two-pipe heating system, a return pipe is provided along with the heating agent supply line. Hot water is supplied to the radiators through the supply risers. The spent coolant goes through the return risers into the return pipeline, through which it returns to the heating unit.

Due to the fact that each radiator receives the hot coolant individually for a two-pipe system, it is possible to turn off individual devices if necessary.

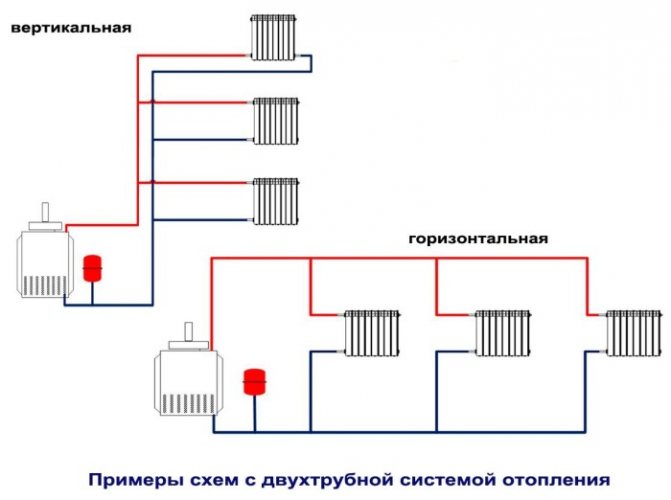

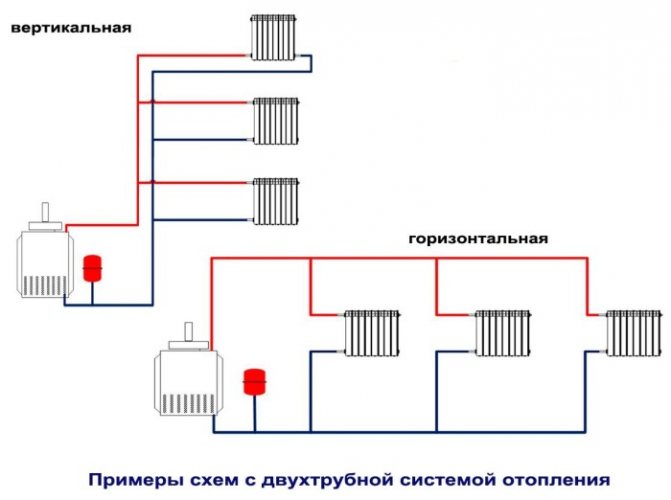

The scheme of a two-pipe heating system has two varieties, which differ from each other in the position of the supply line relative to the installation level of the radiators.

A two-pipe heating system with top wiring is characterized by the upper position of the supply pipe relative to the level of the radiators. With this scheme, the straight (supply) pipe is mounted, as a rule, in the attic or in the ceiling. From the heating unit, the hot coolant rises up the main pipe, and then, through the supply risers, is evenly distributed over the radiators.

The return pipe, through which the spent heat carrier returns to the boiler or other heating device, is located below the level of the radiators. The expansion tank is installed at the highest point of the system, mainly in the insulated attic. This heating scheme is not suitable for cottages with a flat roof.

The main feature of a two-pipe heating system with a bottom wiring is the laying of the supply line in the basement, under the floor, in the plinth. The return pipe, through which the coolant returns to the boiler, must be installed even lower.

If a two-pipe heating system is selected for heating the room, the lower wiring provides for the deepening of the boiler, since the radiators should be located higher to ensure uniform delivery of the coolant to the batteries.

Air locks from radiators are removed using Mayevsky taps.

Bottom piped heating system

Both types of wiring are applicable for both vertical and horizontal arrangement of the coolant supply pipes. In a multi-storey building, a two-pipe system with a vertical position of the main pipeline, as a rule, has a lower wiring. This is due to the fact that the thermal difference between the coolant in the flow and return pipelines creates a significant pressure, which increases with an increase in the floor.

The lower distribution of heating pipes, thanks to this pressure, helps the coolant move through the pipeline. In this case, the upper wiring is used if it is impossible to arrange the lower one due to the architectural features of the building.

Basic characteristics of two-pipe heating with bottom wiring

Despite its higher material consumption, in comparison with a one-pipe system, a two-pipe heating scheme with a lower wiring has a number of significant advantages:

- This type of heating allows you to avoid heat loss as much as possible, since the main main pipe runs in the basement or under the floor.

- This heating system can be put into operation immediately after the construction of the lower floor, without waiting for the construction of the whole house.

- The shut-off and control valves of the direct and return risers are located in the basement, which greatly facilitates its maintenance and makes it possible not to occupy the useful area of the building with engineering support systems.

- No need to turn off the heating of the lower floor when carrying out repair work on the upper floors.

- An important advantage of all types of two-pipe heating systems is the possibility of installing thermostats on each radiator, which allow for heat regulation, thereby saving heating costs.

- The pipeline of a two-pipe system has a smaller diameter compared to a single-pipe system, therefore it does not spoil the appearance of the interior and, if desired, it can be easily hidden in wall or other building structures.

Views

A two-pipe heating system can be of the following types:

- horizontal and vertical;

- straight-through - the coolant flows in one direction through both pipes;

- dead-end - hot and cooled water moves in different directions;

- with forced or natural circulation: for the first, a pump is needed, for the second, the slope of the pipes towards the boiler.

The horizontal scheme can be with dead ends, with passing water movement, with a collector. It is suitable for single-storey buildings with a considerable length, when it is advisable to connect the batteries to a horizontally located main pipe. Such a system is also convenient for buildings without walls, in panel-frame houses, where it is convenient to place the risers on the staircase or corridor.

According to experts, the most effective was the vertical circuit with forced water flow. It needs a pump, which is located on the return line in front of the boiler. An expansion tank is also mounted on it. Due to the pump, the pipes can be smaller than in a design with natural movement: with its help, water will be guaranteed to move along the entire line.

All heaters are connected to a vertical riser. This is the best option for high-rise buildings. Each floor is connected to the riser pipe separately. The advantage is the absence of air pockets.

Installation

Conventionally, several stages of work can be distinguished. First, the type of heating is determined. If gas is supplied to the house, then the most ideal option would be to install two boilers: one - gas, the second - spare, solid fuel or electricity.

Next, you should agree on the installation of the heating system in the project documentation and proceed with the purchase of the necessary materials, devices, and preparation of tools.

Stages

Briefly, the installation consists of the following points:

- the supply pipe is brought up from the boiler and connected to the expansion tank;

- a pipe of the upper line is taken out of the tank, which goes to all radiators;

- a bypass (if provided) and a pump are installed;

- a return line is drawn parallel to the supply line, it is also connected to the radiators and cut into the boiler.

Boiler

For a two-pipe system, the boiler is installed first, for which a mini-boiler room is created. In most cases, this is a basement (ideally a separate room). The main requirement is good ventilation. The boiler must have free access and be located at some distance from the walls.

The floor and walls around it are lined with refractory material, and the chimney is led out into the street. If necessary, install a pump for circulation, a manifold for distribution, regulating, measuring instruments near the boiler.

Radiators

They are installed last. They are located under the windows and are fixed with brackets. The recommended height from the floor is 10–12 cm, from the walls - 2-5 cm, from the windowsills - 10 cm. The inlet and outlet of the battery is fixed by locking and regulating devices.

It is advisable to install temperature sensors - they can be used to monitor temperature indicators and regulate them.

If the heating boiler is gas, then it is necessary to have the appropriate documentation and the presence of a representative of the gas industry at the first start.

The final stage of work

At the last stage, the radiators are connected, while their inner diameter and the volume of the sections are calculated taking into account the type of supply and the cooling rate of the coolant. Since centralized heating is a complex system of interconnected components, it is quite difficult to replace radiators or repair jumpers in a particular apartment, because the dismantling of any element can cause interruptions in the heat supply of the entire house.

Therefore, apartment owners who use central heating for heating are not recommended to independently carry out any manipulations with radiators and the piping system, since the slightest intervention can turn into a serious problem.

In general, a well-designed, productive heating scheme for a residential apartment building allows you to achieve good performance in matters of heat supply and heating.

Advice

The expansion vessel is located at or above the highest peak point of the line. If there is an autonomous water supply, then it can be integrated with a supply tank. The slope of the supply and return pipes should be no more than 10 cm by 20 or more linear meters.

If the pipeline is at the front door, it is appropriate to divide it into two elbows. The routing is then created from the top point of the system. The lower line of the two-pipe design must be symmetrical and parallel to the upper one.

All technological units must be equipped with taps, and it is advisable to insulate the supply pipe. It is also advisable to place the distribution tank in an insulated room. At the same time, there should be no right angles, sharp fractures, which will subsequently create resistance and air locks. Finally, we must not forget about the pipe supports - they must be made of steel and cut in every 1.2 meters.

One-pipe heating system with top piping

In what cases is it relevant to install a two-pipe vertical heating system with top wiring? Most often, this scheme is applicable for small houses up to 100 m². Consider an example of organization for the most common system with natural circulation of the coolant.

Depending on the method of connecting the radiators, the heating scheme with the upper filling of natural circulation is divided into two types - with a passing and counter movement of the coolant.

Counter scheme

It is characterized by a series connection of radiators and a different direction of water flow in the main and return pipes. In this case, the heating system is one-pipe with top wiring, the scheme of which has a number of features, differs in the following parameters:

- Inability to adjust the degree of heating in each radiator;

- The dependence of heating the coolant on the length of the line. The further the radiator is installed from the boiler, the lower the temperature of the water entering it. To normalize the temperature regime in all rooms, batteries with a different number of sections should be installed;

- Compliance with the angle of inclination of the upper supply line. On average, 1 lm the slope in the direction of fluid movement should be 5-7 mm.

An expansion tank must be provided for the top filling in the heating system. It is located at the highest point and performs several functions. The main one is pressure stabilization when heating water in pipes. If an open-type tank is installed, the coolant can be topped up through it.

It is possible to increase the water pressure with the help of a booster manifold - a vertical pipe installed immediately after the boiler. However, the minimum height of this element must be 3 m, which makes it impossible to install it in apartments.