Features of heating from gas cylinders

Used as a heat source butane or propane. After the gas is liquefied, it is distilled into cylinders. Then they are connected to the heating system through reducer - pressure reducing device.

In the process of passing through it, the gas again assumes its natural state. Then it is burned in a boiler, giving off a large amount of heat.

Reasons for choosing

- Low cost;

- low fuel consumption gives a large amount of heat;

- connection of such a heating system is permissible at any time and after the operation of other types of boilers;

- the use of this type of fuel acceptable in any area and building.

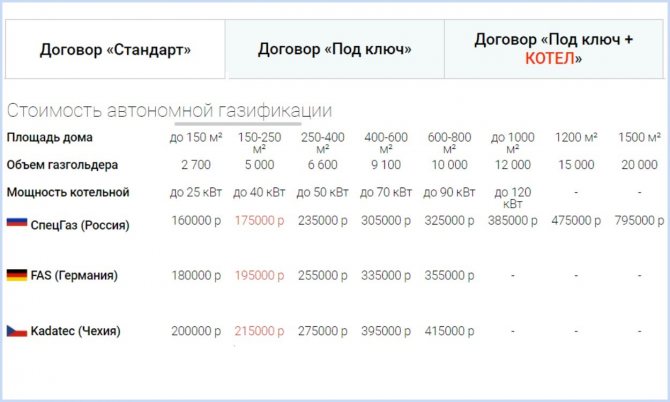

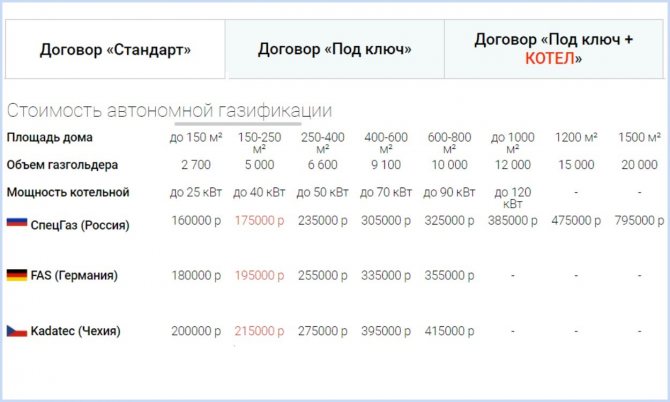

The cost of autonomous gasification of a private house

To calculate the potential costs for autonomous gasification of the site, you need to know the heated area and calculate the degree of intensity of use of the gas system.

The price of a 1000 liter gas tank is about 230 thousand rubles, a 1650 liter tank will cost 260 thousand rubles, and a 5000 liter tank will cost 520 thousand rubles.

Some residents unite to install an autonomous gas supply system in several neighboring areas.

Of course, the costs of purchasing a gas tank are not the only costs for autonomous gasification of a private house.

However, the connection to the main gas pipelines may require substantial expenditures.

Obviously, in this case, the main requirement is the availability of low-pressure gas networks for connection to centralized networks. If they are not there, then the possibility of connecting natural gas can be expected for years.

In this case, the only alternative option is autonomous gasification, which is carried out quickly and relatively hassle-free, and at the same time may cost less.

The average cost of connecting to the centralized gas supply networks in the Moscow Region to the natural gas network is 400 thousand rubles. (provided that the low-pressure gas pipeline runs nearby). Medium or high pressure gas lines are not suitable.

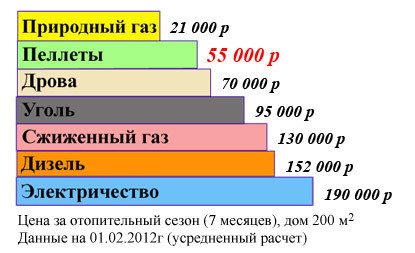

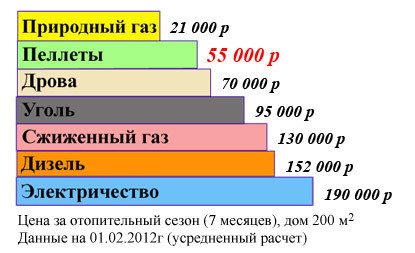

Comparison of different heating cost options

In this table, we analyzed the costs of various types of fuel for heating a residential building with an area of 100 sq. M.

For more information on the possibility of connecting gas in a private house (to the main gas pipeline), see this article.

Still have questions? Want to get answers to them?

Here you can ask it for free to experts or lawyers of the gkh-konsultant.ru portal.

Gas or electricity

This question is faced by everyone who considers various analogs sources of heating. To make a decision, it is important to compare them in terms of key indicators.

Gas

By cost 1.5–2 times cheaper than electricity. The financial side of the issue will be especially noticeable if the building is of a large area.

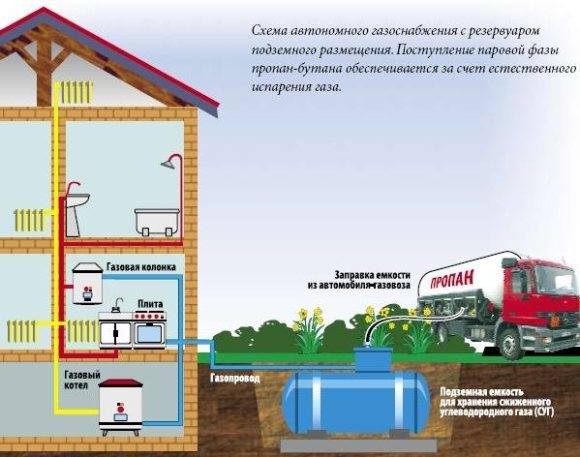

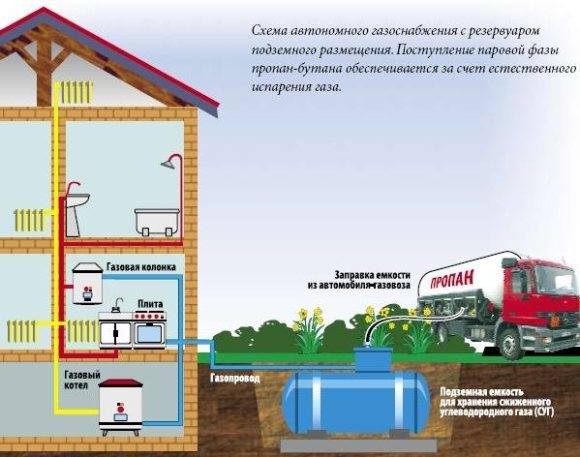

Autonomous heating works by means of tank-gasholderlocated underground. It can hold thousands of liters of gas. The gas tank is refueled by specialists twice a year.

The underground reservoir does not interfere with the full-fledged exploitation of the territory and does not emit an attention-grabbing smell.

Electricity

The costs are high since this energy source is considered one of the most expensive.

Sometimes the power consumed by the heating system is overestimated for the suburban electrical network, there is not enough energy to heat the whole house.

In bad weather, it often happens power surgeswhat leads to a failure in the heating system.

It follows from this that liquefied gas is a more profitable, economical and reliable option.

Autonomous gasification of a private house using a gas tank and cylinders

Despite the emergence of numerous new technologies for the organization of autonomous heating, a gas boiler still remains the most optimal and cheapest way to heat the coolant. But what if the highway runs far from the house and gasification from it is impossible? In this case, you need to carefully approach the solution of the issue. The costs of using electricity will be high, and a traditional solid fuel boiler is not very convenient to use. In this case, there is only one option left - the organization of an autonomous gas supply.

Currently, there are two methods of gasification of a house, which differ from each other in a number of parameters:

- Bulk storage of gas (described here).

- Installation and operation of gas tanks - large special containers.

The choice of one of them directly depends on the following parameters:

- House area and the number of gas consumption points.

- Estimated amount of estimated fuel consumption.

- Land area. Will it be possible to install a gas tank in principle?

Let's take a look at both of them, starting with the cheapest, but not entirely effective.

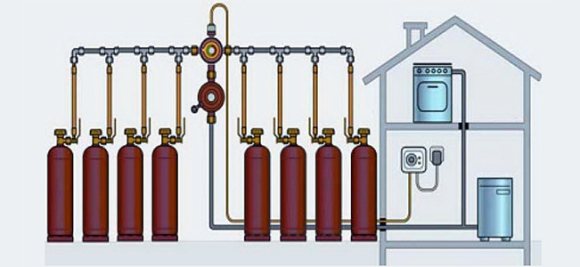

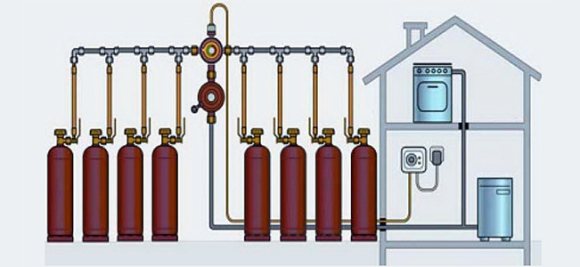

Cylinder gas supply

This option is the installation of several special gas cylinders and connecting them to the gas supply system in the house. It is advisable to use it only for relatively low consumption.

The organization of this method involves performing a number of actions.

Premises preparation

According to the provisions of the current SNiP, the place for storing and operating gas equipment must comply with the following standards:

- Free-standing or adjacent to the house. There must be a separate entrance and a forced ventilation system.

- A heat-resistant material for decoration and construction is used.

- The area of the room directly depends on the number of cylinders and must exceed this value by at least 8 times.

- The operation of any heating equipment or the use of devices with an open source of fire in the storage room is prohibited.

- The cylinders should be placed along the wall, on a special pallet. At the same time, any misalignment is prohibited - they must be strictly vertical.

After all these conditions are met, you can start organizing the connection. To do this, it is necessary to calculate the average gas consumption in order to determine the number of cylinders. One standard container can store up to 50 liters of gas.

This system must be checked by the relevant gas authorities. They will also write out permits for its operation.

Benefits:

- Small initial expenses for the purchase of equipment and components.

- Possibility of placing cylinders outside the house, but in a special steel box with a lock.

Disadvantages:

- A small supply of fuel requires constant replenishment.

- Laboriousness when replacing a used container and installing a new one.

This option will be convenient for country houses and buildings with seasonal residence.

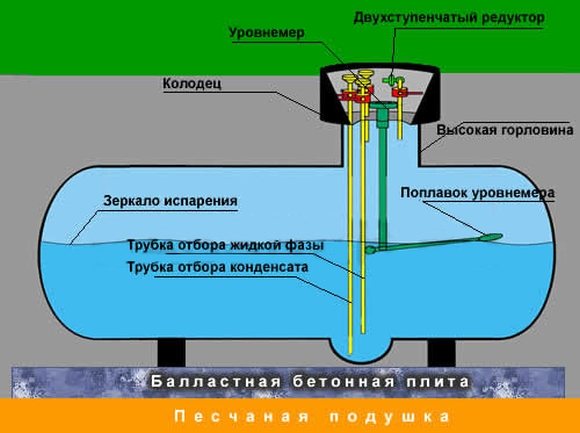

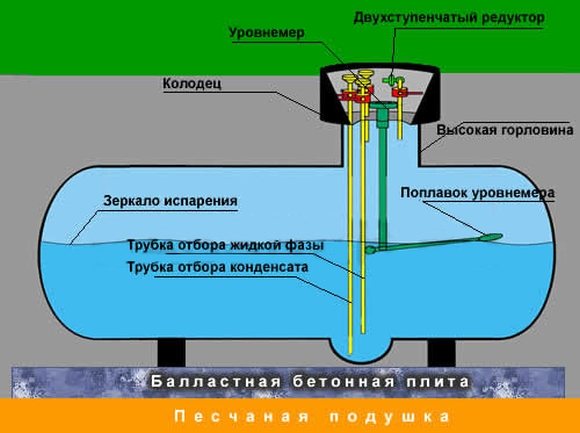

Installing a gas tank

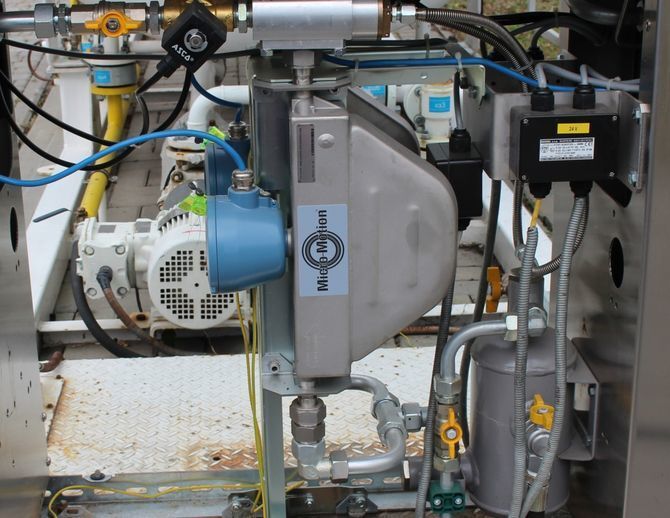

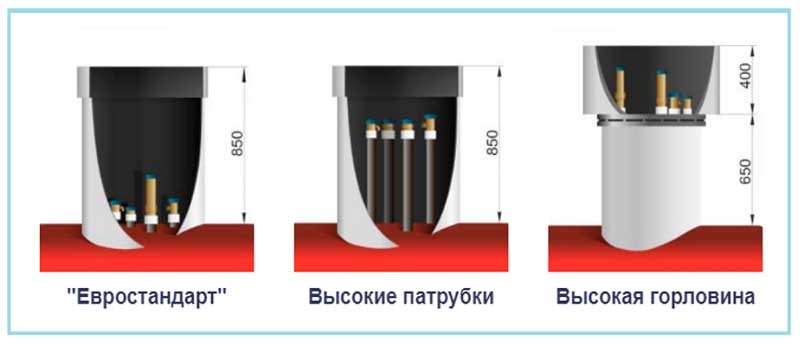

A typical example of a gas tank design is shown in the figure.

At the end of its installation, a gas pipeline is laid to the house. This method is convenient because a large storage volume allows you to work offline without refueling for up to 1 year.

Gas tank installation rules:

- The minimum distance from the house to the structure is at least 10 m.

- Providing free passage for vehicles for refueling and maintenance work.

- All installation and preventive measures are carried out by representatives of a special service company, which has the appropriate certificates and permits.

Typical wiring is underground piping to the building foundation.

To ensure safety, special shut-off valves and alarm sensors are installed on the structure of the gas tank and at the point of connection with the home gas pipeline.

Benefits:

- Economic benefit compared to the balloon version.

- Almost complete autonomy of the entire system.

- The monitoring equipment allows you to remotely monitor the gas level in the tank.

- The ability to connect multiple homes to one storage facility.

Disadvantages:

- Possible problems with the registration of permits, rather stringent requirements for the condition of the site and the house.

- Gas tank filling and maintenance can only be performed by certified companies.

Storage of liquefied fuels

Gas is contained in gasholders or special containers with spherical or cylindrical surface or underground installation type.

Such reservoirs necessarily welded.

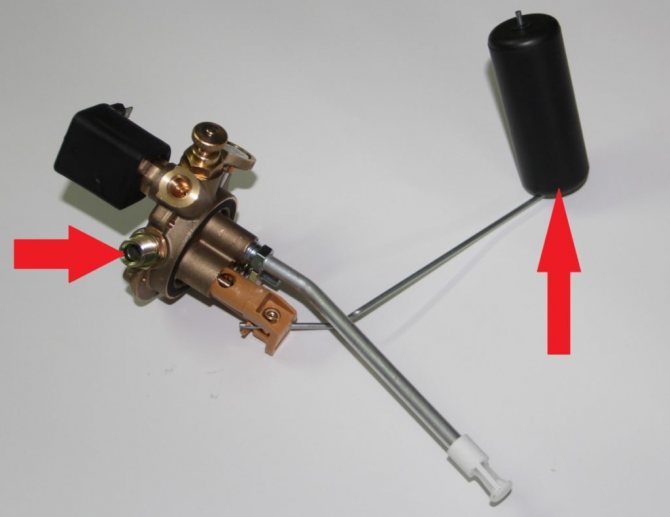

LPG storage cylinders are manufactured sheet steel... They consist of a neck, two bottoms, a shut-off valve, a plug, a cap, a shoe, and a shell.

Photo 1. Gas cylinder for storage of liquefied fuel with a neck, shut-off valve, plug.

Each cylinder is marked with its type, weight and capacity, permissible pressure, stamp of OTK of the company and Gosgortekhnadzor, test pressure obtained during the hydraulic test, the date of the completed and subsequent surveys, the name of the manufacturer.

The balloon has red coloring and white signature "Propane - butane".

Reference! Before shipment, cylinders are stored in specialized one-story warehouses in the form of premises or open areas under a canopy.

Documentation and design

An owner organizing an autonomous gas supply to a country house often has a question - whether it is necessary to register a gas holder installed on an individual site in state organizations.

In accordance with Federal Rules and Regulations (clause 215), the following pressure vessels are not subject to registration:

- Tanks of gas carriers, designed to move liquid gas.

- Automobile gas cylinders.

- Other containers, the volume of which does not exceed 100 liters.

If the owner enters into an agreement with an organization that has the right to install, service the equipment with an appropriate license, its authorized representatives are engaged in registration issues, and all that a homeowner needs to know about LPG is to conclude an agreement.

When drawing up the contract, one should take into account the list of obligations that the contractor takes, there are usually items there:

- Submission of an application by the contractor to the supervisory authorities indicating data on the company, the location of the gas tank and the specifics of its operation, if any.

- Submission of an act to the supervisory authority on the readiness of the gas supply system for operation and a copy of the order for commissioning.

- Submission of information about the tank with an indication of its technical characteristics, the gas mixture used, the date of the last check.

Fig. 5 The cost of installing gas tanks - an example

The autonomous gasification system does not require complex design solutions and is quite simple to install, when an underground reservoir with a volume of up to 10 cubic meters is located. the following standards must be observed (SNiP 42-01-2002):

- Distance from public buildings - at least 15 m, from residential 10 m.

- From garages and playgrounds - 10 m.

- From sewerage, heating routes, communications and ground structures, underground wells, trees - 5 m.

- From the water supply and channelless communications, fences - 2 m.

- In the presence of near power lines - at least half the height of the support.

When designing, take into account the convenience of access roads, the volume of gas tanks, soil features (electrochemical activity, the value of stray currents), based on the information obtained, the type of tank protection is selected.

Advantages and disadvantages of balloon heating

Pros:

constant pressure level in pipes;- minimum fuel consumption;

- autonomy work;

- ease of use and management;

- clean natural fuel;

- the possibility of heating water for private needs.

Minuses:

- freezing of condensate at low temperatures;

- placement of cylinders is strictly provided in ventilated areas;

- in the event of a leak, the gas is lowered into the basement or subfloorleading to serious consequences.

Is there an alternative

To date, the following methods of heating private housing are known:

- natural gas supplied through the main pipeline;

- electric boiler;

- solid fuels: firewood, coal;

- pellet boiler;

- liquefied gas in cylinders.

Each option has its own advantages and disadvantages. Considering that the gas pipeline is not even in all urban-type settlements, it is unlikely that it is connected to the dacha settlement. And if they promise to let her down, then not as soon as we would like.

House heating costs 200 m2.

The most commonplace solid fuel today is also not cheap, but the main drawback of this type is far from the price. If you heat the dacha with wood or coal, then you must definitely be there every day.

Electricity is considered one of the most expensive ways to heat a home. Therefore, many use it in addition to solid fuel, to maintain the temperature during periods of absence from the country. The electric boiler itself is much cheaper than a gas boiler, but the price of electricity is growing every year.

Wood pellets (pellets) are widespread in Europe, Denmark, Sweden. For Russia, this is still a rare phenomenon, but it also takes place in homes where the owners take care of the ecological cleanliness of the fuel. It is convenient that the pellets are poured into a special hopper and automatically fed into the pellet boiler, without any physical effort. In comparison with pipeline gas, they will cost 3 times more, unless all stages of gas installation are included in the estimate, starting with the project.

A device with a boiler for heating with your own hands

To form a heating system with your own hands of this type you will need:

- Gas boiler with liquefied gas burner. Models with low pressure and highest efficiency are suitable.

- Gas cylinders with a volume of 50 liters.

- Shut-off valves.

- Reducers.

- Ramp (used to connect several tanks).

- Gas pipeline, formed from hoses and pipes and designed to connect elements to the heating system.

Boilers are floor and wall, single and double-circuit. The latter allow not only to increase the temperature in the room, but also to heat the water.

The cylinders are connected to the system by means of a reducer with a capacity 2 cubic meters m / hour. The reducer can be one or separate for each tank.

Connecting several cylinders to a gas boiler increases the period of their necessary refueling. For such a connection is used ramp - a device that divides tanks into main and reserve. First, gas is taken from the first group, and as it ends, from the second. The moment of transition is sounded by a signal.

To fix a gas boiler with a gas pipeline, use flexible eyeliner, and for the reducer - a durite hose. The wall thickness of a gas pipe made of metal is not less than 0.2 cm... In the wall, such pipes are brought into a case and foamed.

The boiler fuel consumption is about 9 kg of gas per day. A large amount of resource will go away at the very beginning to warm up the heating system, and later - will decrease by 4 times.

Photo 2. A red gas cylinder and a flexible hose that is used to connect to the boiler.

Refueling cylinders produced weekly specialists. Before this process, condensation is removed from the tanks.You can independently take the tanks out into the open, ground and remove the reducer. 2 hours laterwhen the remaining gas has disappeared, and the water has dropped into the ground, the cylinders can be taken to the refueling station.

Important! Not allowed for simultaneous refueling more than three cylinders.

Frequency of draining condensate from the cylinder

But when should the condensate drain? This question is very individual and depends on the quality of the filled gas and operating conditions.

Many users of gas cylinders did not encounter such a need at all, while others do it before every refueling. Both of these extremes are normal behavior under certain conditions, and to determine which is closer to you, let's look at these conditions in more detail.

Option # 1 - refueling at a specialized substation

If you fill a cylinder at a specialized substation, you may not encounter condensate at all, for several reasons at once. Firstly, they fill up the "right" gas, with a high content of propane, and not just cheap butane, as at car gas stations.

Secondly, their gas quality control is much stricter, so the degree of gas purification is higher, and there are practically no impurities.

Thirdly, at most of such substations, cylinders are taken for exchange, and before refueling they are inspected and serviced, discarding excessively worn ones, and after refueling - safety and tightness control. In particular, the substation workers drain the condensate if it has accumulated in the cylinder.

Even if you insist on refueling your particular cylinder, it will not be performed without first making sure that the unit is in good working order and safety. The fact is that specialized substations work officially, observing the norms and technical requirements for refueling cylinders, and are responsible for the safety of each client.

Features of use

In different rooms there are own rules operation of gas cylinders.

In the apartment

The installation of a gas boiler is only permitted if the following conditions are met:

- obtaining a number of approvals on this process from specialized services;

- purchase of the necessary equipment;

- preparation of the apartment;

- heating system change - its disconnection from centralized communications;

- chimney and ventilation installation.

In this case, the room itself must meet the requirements:

- area of at least 4 sq. m;

- the presence of good natural lighting, vents;

- ceiling height not less than 2.5 m;

- entrance door with a width of at least 0.8 m;

- cold water pipeline;

- smooth walls.

Gas cylinders are allowed to be placed in the apartment, but no more than one... In this case, the building itself should not exceed 2 floors. Such containers fix 50 cm from the gas stove and 100 cm from heaters... The limiting temperature of the room in which the installation process is carried out - not higher than 45 ° C.

Attention! Independently carry out the process of installing a gas heating system Absolutely forbidden, this is done by employees of special services.

In a private house

Along with the installation of a gas heating system, in some rooms, fixation of convectors - devices that allow you to warm up the room in a few minutes.

Used as a storage for cylinders gas tank... Its volume is determined in the course of calculations LPG consumption level... In this case, it is important to take into account both the fireplace and the hot water boiler and the gas stove. The higher this indicator, the larger the volume of the selected container.

In the garage

This structure is considered fire hazardous, therefore the gas boiler must be taken out to a separate room with an area of at least 4 sq. m. with walls made of non-combustible materials.

Gas cylinders have in a special metal cabinet, at a safe distance from flammable objects, above the floor mark.This will quickly detect and prevent gas leaks.

Gas workers portal

General Provisions

This instruction has been developed in accordance with the Methodological Recommendations, taking into account the requirements of legislative and other regulatory legal acts containing state labor protection requirements, intersectoral labor protection rules (safety rules).

Knowledge of this instruction on labor protection for workers of all categories and groups of qualifications, as well as their immediate supervisors when bleeding gas from a gas pipeline is mandatory

General labor protection requirements

- The personnel of the Branch who have reached the age of 18, who have been admitted to independent work and who have undergone special training in techniques and methods of work, targeted instruction, testing the knowledge of labor protection requirements, having the skills to apply the appropriate PPE and actions on PLA, which has no medical contraindications for this type of work.

- When performing work when venting gas, the personnel may be affected by hazardous and harmful production factors:

Table 1

| Dangerous and harmful production factors affecting the employee | Possible undesirable events during the implementation of production factors (hazards) |

| 1 | 2 |

| Explosion and fire hazard | Getting an employee of injuries and bruises when flying apart equipment items, pipelines. Wounds by shrapnel, parts, particles. Lack of oxygen, choking. Getting burns of four degrees: I - skin redness; II - the formation of bubbles; III - necrosis of the entire thickness of the skin |

| Crumbling structures | The employee receives injuries and bruises when elements of structures of buildings, walls, structures, scaffolding, stairs, stored materials fall, impacts by falling objects and parts (including their fragments and particles). Fractures, wounds, dislocations, bleeding. |

| Increased or decreased surface temperature of equipment and materials | Overheating of the body, heatstroke, burns and frostbite of the limbs or parts of the employee's body |

| Increased pressure of equipment, pipelines, high pressure in the working area and (or) its sharp change | The employee receives injuries and bruises when elements of equipment, pipelines are scattered, wounded by shrapnel, parts, particles. Wounds, bleeding. Lack of oxygen, choking |

| Increased dust and gas content in the air in the working area | Lung disease, acute or chronic poisoning, shortness of breath, decreased body resistance to infectious diseases, lack of oxygen, suffocation |

| Increased air pollution of the working area with vapors of flammable and poisonous liquids | Acute or chronic poisoning, intoxication, nervous system disorders, allergic diseases, the development of cancer In case of mild poisoning - headache, dizziness, palpitations, weakness, mental agitation, causeless lethargy, slight muscle twitching, trembling of outstretched arms, muscle cramps |

| High or low air temperature in the working area | Heat or sunstroke, thermal imbalance, overheating and cooling of the body, impaired activity of the cardiovascular system, impaired water-salt metabolism, colds |

| Increased noise levels in the workplace | Damage to the hearing organs, partial or complete hearing loss. Neurosis, impaired activity of the central nervous system, changes in metabolic processes |

Work on bleeding gas from the gas pipeline of the linear part of the main gas pipeline refers to gas hazardous work and is carried out according to a permit.

- When carrying out work, it is prohibited to install and use pressure gauges:

- if there is no seal or stamp on the pressure gauge with a mark on the inspection;

- if the verification period has expired;

- if the glass is broken or there is other damage to the pressure gauge that may affect the correctness of its readings;

- if the arrow of the manometer, when it is turned off, does not return to the zero mark of the scale by an amount exceeding half of the permissible error for this manometer.

- Pressure gauges should be selected with such a scale that the working pressure measurement limit is in the second third of the scale. The dial of the pressure gauges must have a red line or a red plate attached to the glass of the pressure gauge through the division of the scale corresponding to the permitted working pressure.

- It is forbidden to perform bleeding without an uninterrupted connection of the place of work of the responsible work manager with the dispatch service of the Branch.

- Do not vent gas through candles during a thunderstorm.

Labor protection requirements before starting work

Before starting work, personnel:

- If the maximum permissible concentration in the air of the working area is exceeded, the work must be stopped and go to a safe place, report to the responsible work manager, and, upon his instructions, identify and eliminate the cause. The work should be resumed at the direction of the responsible work manager after the malfunction has been eliminated and satisfactory results of the air analysis are obtained.

The responsible work manager acquaints the personnel involved in the work with the plan and nature of the upcoming work.

Labor protection requirements during work

They report to the person in charge of the work on cases of violation of the requirements of safety signs and, on his instructions, take measures to remove unauthorized people and vehicles from the security zone.

- The posts are removed with full bleeding, upon completion of work on the bleed-off section of the gas pipeline at the command of the responsible work manager and the transfer of the functions of observers over the state of the section to the shift personnel of the Branch facility.

Labor protection requirements in emergency situations

- In the event of an emergency, personnel must:

- stop working;

- ensure your own safety using protective equipment;

- report the incident to the responsible work manager and dispatch service of the Branch.

- In the event of an emergency, the responsible work manager is obliged to:

- to notify the personnel about the accident;

- to provide priority measures for the rescue and evacuation of people, the provision of first aid to the injured;

- ensure the implementation of measures to localize and eliminate the accident in accordance with the operational part of the submarine

- Before investigating the causes of the accident (accident), it is necessary to keep the working environment and the state as it was at the time of the accident, if it does not threaten the life and health of the surrounding workers, does not interfere with the provision of assistance to the injured person, does not cause accidents and does not disrupt the production process.

- If it is impossible to preserve it, the current situation is recorded with a diagram, photograph, etc.

Labor protection requirements upon completion of work

- Upon completion of work, personnel must:

- tidy up the workplace, clean the equipment from contamination;

- collect used cleaning material, other waste in a special container and hand it over for disposal in the prescribed manner;

- hand over the workplace, devices, tools and protective equipment to the work manager;

- clean and put the overalls in the designated place;

- take the necessary personal hygiene measures (wash your hands thoroughly, take a shower, etc.);

- proceed to the place of gathering and dispatch of personnel and follow the requirements of the instructions on the procedure for transporting employees of the Branch by road.

- The responsible work manager must report to the dispatch service of the Branch about the work done.