Oddly enough, some are still heated with wood and coal. And this is not exotic, not a desire to see a real "live" fire, but the most commonplace necessity. Natural gas is far from being installed in all regions of Russia, and for most summer residents this is a pipe dream. This is why the question of finding solid fuel equipment is acute, with a minimum of means giving out maximum efficiency.

Photo 1 Butakov's boiler in the house

One of such examples is Professor Butakov's stove, based on the principle of gas generation (pyrolysis), which makes it possible to significantly reduce fuel consumption. So, for example, a house of 100 sq.m. you can warm up a day with only three tabs of firewood. In this article we will tell you how to make a Butakov oven with your own hands and what is needed for this, because compared to the same Buleryan, this oven looks much more presentable. And the glass door with dancing tongues of flame gives a special charm.

High heat transfer, economical fuel consumption and external design are three comparisons that show how the Butakov's stove is more efficient and in demand among consumers.

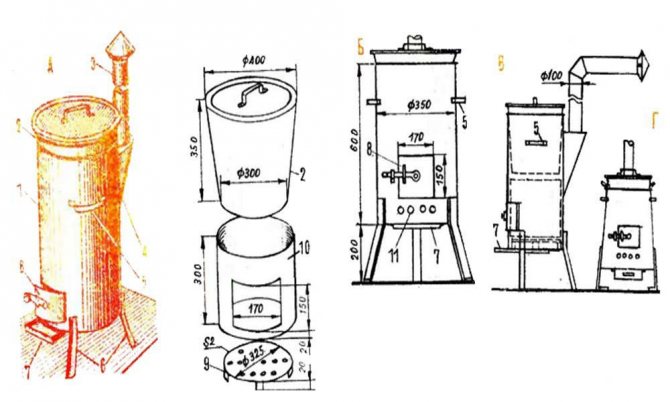

Potbelly stove from a bottle or eggplant.

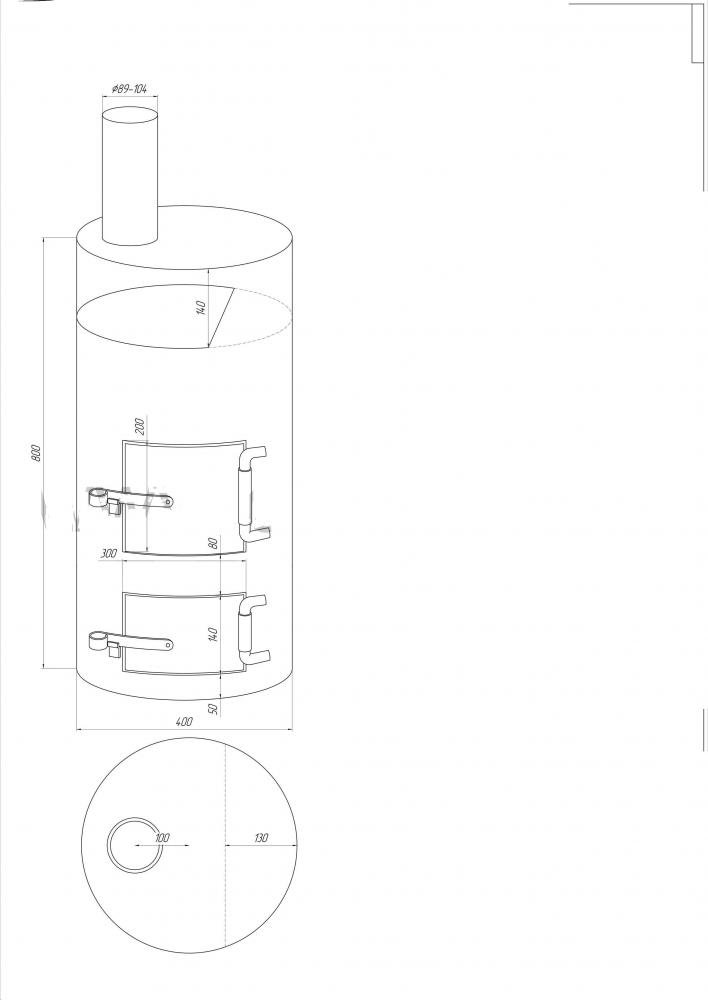

This type of furnace can be made directly, both from a solid metal sheet, but also from any heat-resistant device, for example, a barrel, flask, pipe or propane gas cylinder.

Long burning gas cylinder furnace can be made in different ways and have different positions - horizontal or vertical. In some cases, two cylinders can be used at once, one cylinder is vertically placed on the other in a horizontal position.

There are more than enough models of such an application of gas cylinders, and after considering all the options, you can choose exactly the one that turns out to be the most acceptable for you.

Of course, in order to complete this device, you need to have the necessary materials and tools at hand, and it is also a good idea to acquire at least a little experience in this segment.

Choice of design

The barrel shape is very versatile. On its basis, you can collect:

- simple wood-burning boilers, potbelly stoves;

- long burning, Bubafon, for example;

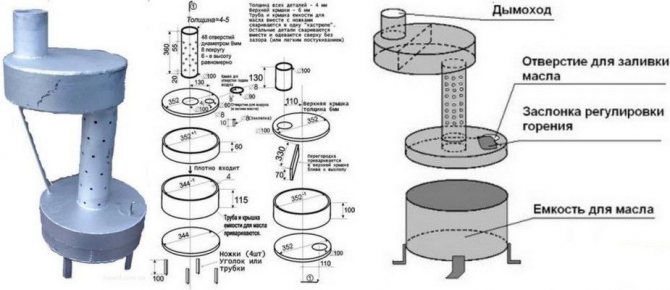

- liquid fuel oven;

- sauna stove with a stove.

It is clear that if you need a special sauna stove, the choice of model is not worth it.

But if it is supposed to make a stove for a summer residence or a technical room, it is worth deciding which structure is best to do.

Potbelly stove is easy to manufacture, easy to use and maintain. But one cannot count on high efficiency.

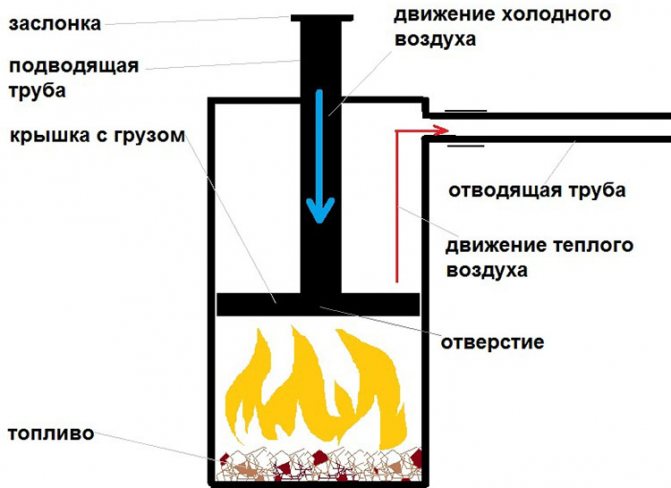

Bubafonya is an analogue of Stropuv's long-burning boilers. They are efficient, they need to be refilled with fuel less often than a conventional boiler. But the design requires careful calculation, the slightest violation of the technology - and the combustion process will not go smoothly (attenuation, smoke, rapid overgrowth with soot are just some of the problems).

Even a good unit needs to learn how to properly heat and adapt to the "character" of a particular specimen. But it is difficult to clean any long burning stove, especially its lower compartments. In addition, you cannot throw fuel into the combustion chamber until the combustion cycle is completed, and by connecting the Bubafon to the water jacket, we will get unstable combustion and a decrease in efficiency.

It is not recommended to make a full-fledged gas generating or pyrolysis oven from a cylinder. In their production, structural steel is used, which does not have sufficient heat resistance.

Materials and tools

Materials for this work:

- A sheet of metal with an approximate thickness of 3 millimeters, it is used in making a place for cooking and an ash pan;

- Smoke exhaust pipe;

- A cast-iron door, already made in advance, or you can make it yourself, using a sheet of metal or a piece of a cylinder;

- A corner or strong rods of reinforcement for making legs and, in the absence of a finished one, for making a grate.

- One or two cylinders are also needed, for this purpose, both gas cylinder containers and small ones can be suitable.

- Tools for making a potbelly stove:

- Welding machine 200 A;

- Grinder or grinder with discs of the required diameter, about 180 millimeters;

- Electrodes;

- Cutting and grinding wheels for metal;

- Hammer for cleaning slag from welding;

- A brush for performing metal work;

- Meter or tape measure, chalk or marker for marking;

- Drill with drills of the appropriate diameter;

- Hammer, chisel, pliers.

In order for the stove to be comfortable and accessible to use, as already mentioned, it can be positioned horizontally and vertically, to determine which is better, the size of the room must also be taken into account.

How to make a stove from a gas cylinder with your own hands

Consider two of the most popular homemade oven options:

- Stove-Potbelly stove.

- Long burning, Bubafon.

You need to prepare a grinder and several removable discs in advance.

And also a welding machine and other tool will definitely come in handy.

All work is best done outdoors, and the initial cut must be done outdoors.

The design of a potbelly stove from a cylinder is the simplest. Even grates are not needed. You just need to make a door, weld the chimney pipe and install this miracle on the legs.

The door can be inserted ready-made, store, after cutting a hole for it to size.

On the legs, trims of reinforcement, or a corner, will go. It is important that the stove is stable. Moreover, it is not at all necessary to make it vertical. A horizontally oriented Potbelly stove can be made from a smaller container (12 or 27 liters).

A pipe in a low-power heater also plays the role of a heat exchanger. The larger its segment passes through the room, the more heat will have time to get into it. Sometimes they make an inclined chimney of 2 - 2.5 m, and then take the rest of the pipe out into the street.

The diameter of the chimney pipe matters. Optimum dimensions are calculated: 10 - 12 cm for a 50 liter stove. For 12 liters. 6 cm is enough, and for 27 cm - 8 cm.

Balloon preparation

At the beginning of all work, it is necessary to carry out the correct processing of the cylinder for further use, especially if it is a gas cylinder. Because if the gas was recently present, then its particles could remain and when cutting metal due to a spark, the container may explode.

To this end, you first need to do a procedure that requires time and attention: open the valve and release excess gas. For this purpose, it is better to put the container overnight on the street or in a room with high ventilation, and it is even easier to fill the balloon to the brim with water.

Further, the container is freed from condensation in an inverted form, which also smells unpleasant, which means that such actions are carried out outside the living quarters.

The washed container becomes safe and can be safely attached to processing.

Preparatory work before assembling the oven

The preparatory work includes a very important stage - the removal of gas residues from the cylinder. This stage should be considered in detail, since without its correct implementation, further work is extremely dangerous.

First of all, it is necessary to unscrew the cylinder valve to remove the gas under residual pressure in the cylinder. The valve is completely dismantled from the body. After removing the gas, the cylinder is inverted to remove the condensate.

The gas contained in the cylinder contains a certain percentage of moisture. Moisture accumulates inside it in the form of condensate (liquid).

Turning the balloon over, we eliminate moisture in a natural way. It is better to collect condensate in a disposable container. Condensate often has a specific unpleasant odor. Therefore, it is better to immediately discard the container with the collected condensate.

Then the balloon is turned over again - set in a vertical position. For complete cleaning of gas residues, water must be drawn into it. The water drawn up to the edges of the cylinder will completely displace the remaining gas from it. After that, the balloon is emptied of water and it is considered suitable for cutting.

Related article: Painting plaster - what paints do plaster like? (+ 4 videos)

For greater clarity, a video of the preparation of the cylinder for cutting is shown.

The video is taken from Youtube. Used for informational purposes only and does not constitute advertising.

Preparing a gas cylinder for safe handling with a power tool: video

Preparation of the tool (power tool) includes its inspection for damage, establishing the degree of its suitability for safe work.

Potbelly stove of vertical type

When making a potbelly stove with this type of position, the cylinder is placed in the standard placement for it, everything is removed from the neck and the markings are made using chalk and a meter. Next, an entrance for the furnace and blower is cut out, for this purpose a grinder is used or, if available, gas, plasma cutters are used.

The next step is the grate, since it is practically not available in the finished form of the required dimensions, then the reinforcement of the required length is cut and welded between the firebox and the blower at a previously marked place.

Doors - for this purpose, for do-it-yourself manufacturing, the required sash size is cut out of metal pieces and attached to the hinges previously welded to the furnace blank.

In order to securely fix them when using the oven, latches or latch are welded onto the door.

If necessary, you can equip a hob in the upper part of the stove, on which hot drinks are heated or a light lunch is prepared; sheets of metal are also used for this purpose.

You can build not only a cooking surface, but a device similar to a samovar for heating water, where the pipe coming from the firebox will pass through a special reservoir with water.

All seams of joints must be sealed.

The chimney is installed either at the top of the stove, or in the side and leaves the room through the roof or wall of the room. This type of stove placement is very economical, as the result is a compactly placed heating device that is ideal for a small room in the country or for heating a garage and does not take up much space.

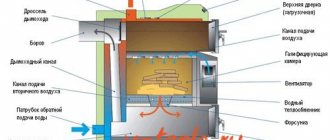

We increase the efficiency of the furnace

The potbelly stove is able to heat the room in just a matter of minutes. Moreover, everything that comes to hand can be thrown into the firebox: since there is no branched network of chimneys in it, and the smoke comes out “directly” in it, there is no need to fear that they will clog up.

But if an ordinary heating stove, installed in premises for permanent residence, has an extensive network of chimneys that trap heat, in a stove it goes directly into the pipe, so its efficiency is not too high. That is why it is too "gluttonous" and requires a lot of fuel.

To reduce fuel consumption, you can use the following tips from experienced stove-makers: • door to the firebox and blew

in such a furnace should be as tight as possible; otherwise, the air supply to the stove will increase, and the fuel will burn out too quickly; • to regulate the release of warm smoke in the chimney

it is desirable to provide a damper

; • next to the stove can be provided

side metal screens

at a distance of 5-6 cm from the stove, in this case, it will heat the room not only by radiating heat, but also by convection (circulation of warm air);

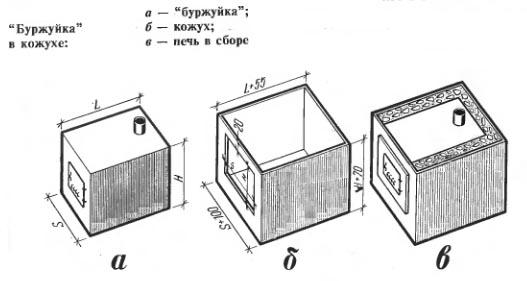

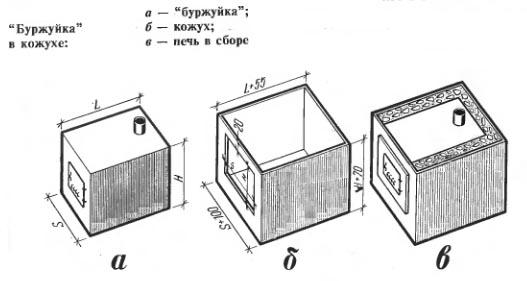

Potbelly stove in a casing

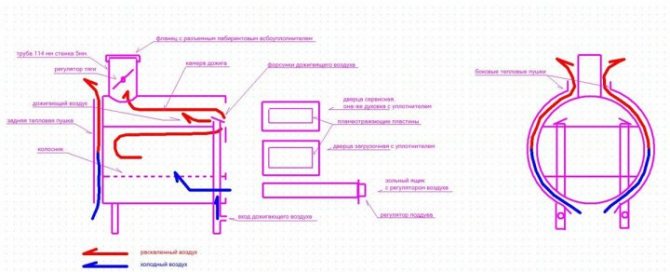

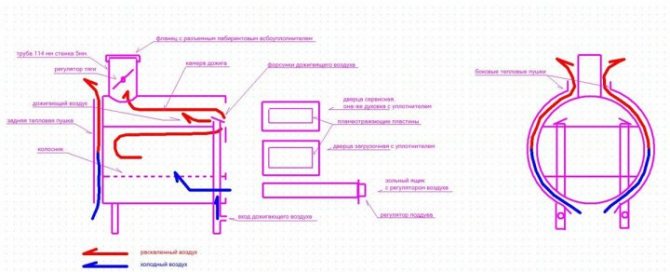

Round furnace with afterburner and casing with heat gun

• to retain heat in the room, bends should be built up in the pipe; however, soot will linger in them, so it is advisable to create a collapsible structure; • the pipe can also be given a stepped shape: arrange the elbows in stages, with each step turning by 30 °; in addition, each of the knees must be securely attached to the wall with rods;

Stove with chimney elbows

• chimney throughput

should be less than the capacity of the furnace itself, in which case the hot gases will not go into the pipe immediately; its diameter should be only 2.7 times larger than the volume of the furnace, for example, with a volume of the furnace of 40 liters, the diameter should be equal to 110 mm;

chimney blowing with a fan

- this will turn the stove into a kind of smoke cannon; • to reduce air circulation

firewood in the oven

should fit as tightly as possible; if it is heated with coal, stir up the resulting ash as rarely as possible;

slots and latch

... which will cover these slots; • to increase the heating area, it can be ribbed, that is, welded onto its body perpendicular to the furnace

metal stripes

; • if you put steam on the stove

buckets or metal box with sand

... then they will accumulate heat and store it even after the oven goes out;

sand filling or heat accumulator made of stones

can be sewn up inside the metal body of the furnace;

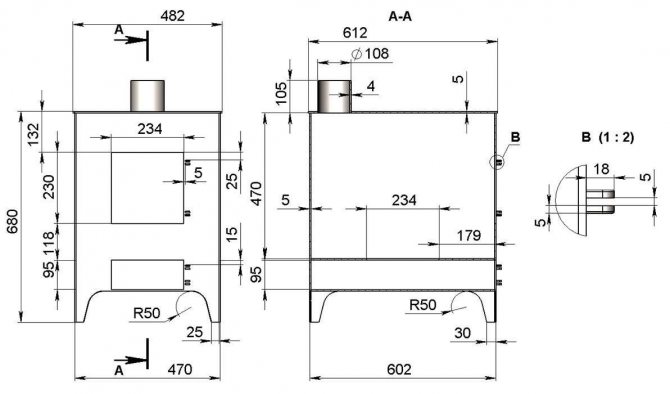

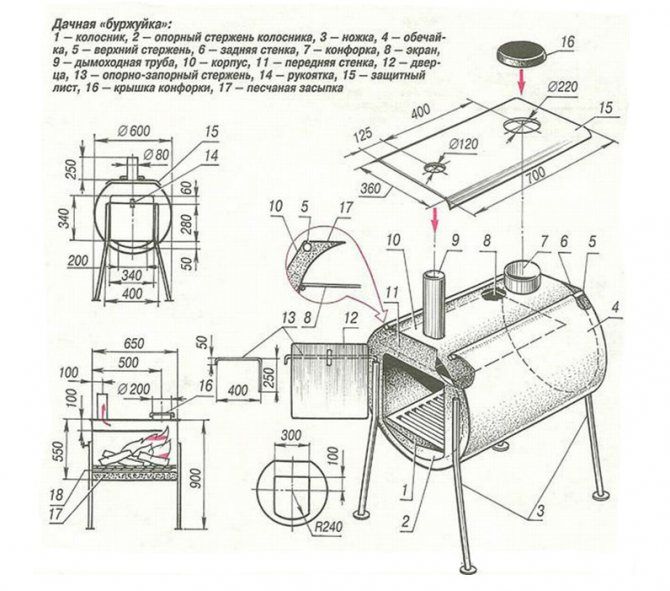

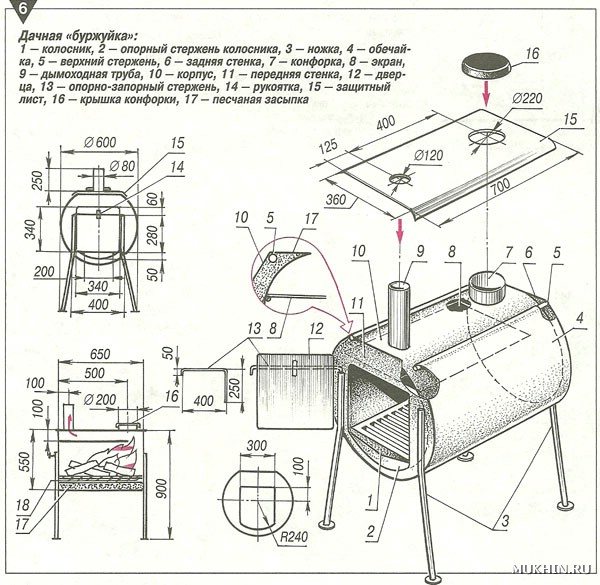

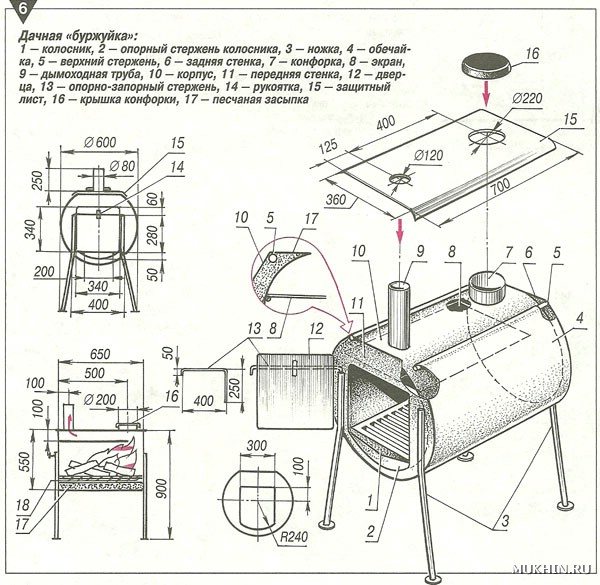

The scheme of a potbelly stove with a sand backfill, the furnace is made of a pipe with a diameter of 500 mm, its length is 650 mm

• bake, lined with 1-2 layers of brick

... will keep warm for much longer;

• the volume of the furnace also matters: the more the area of its walls

... the more heat they will give into the room; •

bricks or sheet metal

... on which the stove is installed, will help not only to protect the room from fire, but also to keep warm.

Related video: Do-it-yourself stove stove

8f772c3fed439782b7a382d3001fa981.jpe

Horizontally equipped oven

The next option for placing the oven is horizontal and it also has its advantages as a large hob where you can cook a full meal.

For the stability of the horizontal stove, after the completion of all work on the manufacture of the stove, it is fixed on a securely standing stand, welded from the corners, using spot welding.

In this case, all activities begin with marking, after which a square hole is cut for the door and a round one for the chimney. Cutting a round hole can be tedious in the absence of a cutter, since the grinder is not an assistant here. First, you need to cut holes in a circle, then a chisel and a hammer are used, and in the end everything is brought to the desired result with a file.

The role of the grate will be played by a hole cut in the bottom of the furnace, and the box welded under it will become a container for ash. The same box plays the role of a blower, and therefore a door is welded onto it in order to regulate the inflow and outflow of air in order to achieve the necessary traction.

The door can be made independently using part of the cylinder, or you can purchase a ready-made one with a frame and a ready-made latch, and this option, of course, is much easier.

After fixing the door on the hinges of the oven, the device is fixed on a stand while fixing it securely, or you can weld legs of the required length to it.

Next, a branch pipe is fixed, to which a chimney pipe is attached, which in turn will come out through the holes in the wall or roof of the room.

The design of the stove-stove: features, principle of operation, arrangement of heat exchangers

A potbelly stove with a water circuit works as follows:

- Firewood is loaded into the firebox.

- Fire is kindled, heat is transferred directly to the water tank or to the recuperator coil.

- Hot water is supplied to the heating or water supply system.

- Residual heat and combustible gases are removed from the room through the chimney.

- Ashes fall through the grate into the ash pan.

In the design of the unit with a water circuit, two principles of energy collection are used:

- Direct collection of heat energy. The heat exchanger circuit is located inside the stove. Heat transfer begins immediately from the contact of the open flame and the boiler tubes. The water in the radiator boils and flows into the heating system. From there, it is sent to the water supply pipes. The heat exchanger experiences large temperature differences (contrast between the temperature of the water and the heat inside the oven).

- Collection of secondary radiation from the heater. The boiler circuit is located outside the heater. Being outside, it collects the secondary thermal radiation from the heated metal surface. The degree of heating of the heat exchanger is lower than in the previous case, the temperature differences are not so significant. The water in the circuit of the device begins to heat up after the stove warms up.

Photo gallery: common types of heat exchangers

Mineral salts are formed inside the boiler. Therefore, instead of water, it is more advisable to use antifreeze or antifreeze, which contain additives that prevent the formation of mineral deposits. The most common heat exchanger designs:

- a water tank built into the stove - a capacitive boiler;

- a pipe boiler - a tank in the form of a water jacket around a stove or chimney - a capacitive heat exchanger;

- main boilers - a coil spiral or a water conduit passing in the active zone of heat transfer.

The principle of operation of such a stove

A stove of this type is a practical solution for all kinds of unheated rooms that need to be heated occasionally. Due to its design features, the potbelly stove heats up very quickly, which makes it possible to achieve a comfortable temperature with a minimum amount of time. However, it cools down just as quickly and this is its big drawback. You can cope with it by overlapping the stove with a brick, but at the same time it is imperative to leave a small gap between the masonry and the metal. Only in this case, the device will maintain a high heating rate, but it will take longer to cool.

There must be two rectangular holes on the body of the heater. One for fuel supply, the second - blew

The main structural element is the body, on which the doors are located, through which fuel is put into the system. The system also includes a chimney and a blower. This is the name of the special hole for the combustion air. Quite often it is combined with a compartment where ash is collected. It is best to equip another door here, this will make it easier to clean the oven. The principle of the system is simple. Fuel is put into the furnace. When it burns, heat is generated, which heats up the metal of the case. That, in turn, gives off heat to the air and heats up the room very quickly. The chimney removes combustion products harmful to humans from the premises.

A small nuance. If the chimney is made along the shortest path, then most of the heat will go outside along with the smoke. This is very irrational, so you should equip a broken pipe. This will significantly improve the efficiency of the furnace. Almost anything that can burn can be used as fuel for the system. This can be firewood, coal, carpentry waste, old clothes, household waste, etc. The attractiveness of the potbelly stove lies in the simplicity of its design and versatility, since the device can be used not only for heating, but also for cooking.