Do-it-yourself oven from a 200 liter barrel for various purposes in the garden

Consider how you can make a stove from a 200 liter barrel with your own hands for various purposes in a summer cottage or garden plot.

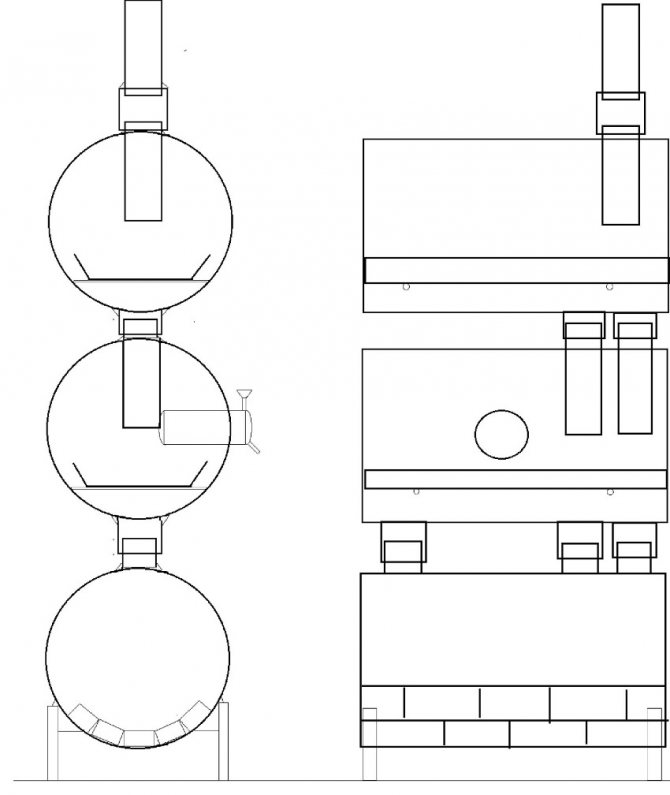

Bubafonya is a long burning barrel stove. It is an upper combustion stove, where the loaded solid fuel burns gradually from top to bottom, pressed down by a piston with a descending pipe for air supply. Due to the restriction of air access, combustion occurs for a long time. Pyrolysis gases, burning out above the surface of the piston, heat the body and go outside through the chimney.

Bubafon long burning stove

A stove is made from a barrel of 200 liters, which is usually used for storing fuels and lubricants or paint. An empty iron barrel can be bought from warehouses, metal warehouses, or found in a landfill. In addition to it, you will need:

- a metal circle for a piston with a diameter of several centimeters less than the inner diameter of the barrel;

- metal corner 5-6 cm wide on the base of the piston and legs;

- an iron pipe with a diameter of 10 cm, a length of 5 cm higher than the height of the barrel, which serves to supply air and is at the same time a guiding piston rod;

- 5-meter metal chimney pipe and tee with a diameter of 15 cm.

The furnace is kindled as follows:

- Dry solid fuel is tightly packed into an empty cylinder to such a height that the upper plane of the piston is below the lower boundary of the chimney hole. Do not allow the laying of wet firewood, which can slow down the movement of the piston during combustion.

- On top, put chips, a rag or paper poured with diesel fuel or kerosene, close the lid with a piston.

- Open the damper fully, light the curled paper and throw it into the pipe. When the wood is well lit, close the damper, setting the minimum clearance for air intake.

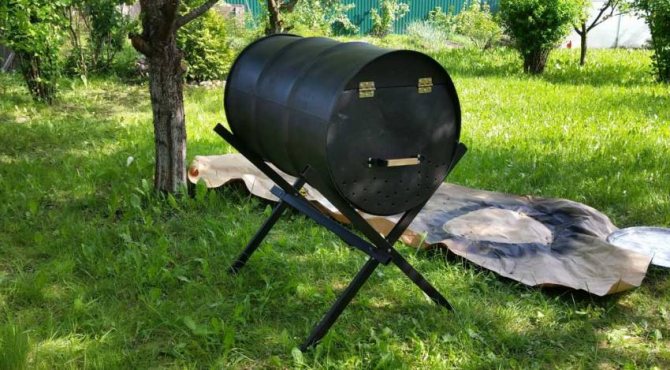

Cooking kebab on a homemade stove

On a home farm, a 200l barrel stove can be used to heat greenhouses, kindle a bath or incinerate garbage.

The progress of work on the manufacture of a furnace from a barrel

1

... The door for the stove The cast-iron doors were cleaned of rust with an angle grinder.

2

... A barrel for a stove A barrel from fuels and lubricants, which is reinforced around the perimeter with steel rings, is better suited. Typically this is a 200 liter barrel.

3

... Recyclable materials When creating the oven, we used a sealing cord, old handles and brackets.

4

... Door position Measure and use a sharp hairpin or nail to mark the position of the door.

5

... Opening for the door Drill a hole in the barrel in the corners for the future opening for the doors. This is necessary so that the angles are exactly 90 degrees.

6

... Opening processing We have cut openings on the door for attaching and removing ash. Sharp edges are sanded.

7

... Protecting the Doors Feeding the door install a protective piece of metal that prevents them from being burned.

8

... Assembling the door We use nuts and bolts of large diameter, and, if possible, refractory metals.

9

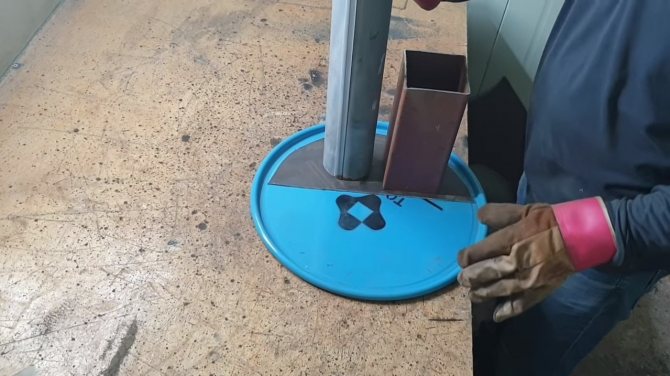

... Chimney Cut a hole along the diameter of the chimney. We make sun-shaped cuts in the hole.

10

... Chimney adapter To the chimney opening, we attach a piece of pipe. The wall thickness of the pipe section is 1.5-2 mm.

11

... Fastening the pipe segment Insert the cut "rays" into the hole in such a way that they alternate: one inside the furnace, the second on the outside.

12

... Hermetic connection We weave paronite thread hermetically into the connection between the stove and the pipe section.

13

... Adapter Then we attach a piece of pipe.It should be well pressed and clamped, and evenly tightened with thread.

14

... Chimney collar We use an additional galvanized steel collar. To make a cuff, we make a template. We will use cardboard to make a template.

15

... Mineral wool To the cuff, add a seal - mineral wool. Any non-flammable sealing material can also be used.

16

... We fix the cuff We tighten the cuffs with clamps in order to bend the most tightly around the pipe. Use a hammer to bend the cuffs.

17

... The cuff is ready We are completing the strengthening of the cuff and sealing the transition section.

18

... We strengthen the walls of the stove. We fasten metal plates with rivets to any holes or places with rust.

For the happy owners of summer cottages, a stove from a 200 liter barrel is a panacea for many troubles that await them in managing a household in the difficult climatic conditions of Russia. It can be used to heat greenhouses and utility rooms, burn leaves and other debris, fumigate trees in case of frost, and kindle a bath.

The main advantage is that such a stove is made from a barrel with your own hands. This does not require special knowledge and large financial costs. Its other advantages are:

- the use of an improvised solid fuel - firewood, wood chips, sawdust, brushwood, etc.;

- small size and weight, mobility;

- simplicity and reliability of work.

The oven from a 200 l barrel has disadvantages that you need to know for safe operation:

- the need for periodic ash and ash removal, cleaning the boiler from soot;

- low heat accumulation;

- a non-combustible base or pedestal is required, distance from the walls at a safe distance;

- the need for a high chimney pipe to provide traction;

- periodic monitoring of the combustion process due to the possibility of reverse draft and smoke in the room.

The advantages of a barrel stove

When assembling homemade stoves, artisanal craftsmen often use old gas cylinders or sheet metal. It is problematic to get both, and even almost free of charge. This applies to the greatest extent to sheet metal, which is most often simply bought. Barrels of 200 liters are a more affordable raw material for the construction of heating equipment.

200 liters is quite a decent volume. A firebox organized in a barrel will fit a large amount of firewood, which is necessary for the implementation of long burning. Also, there will be a place for a spacious ash pan. In other words, an old metal barrel will still serve for the benefit of a person, providing him with warmth and comfort.

A barrel stove is an excellent solution for heating non-residential premises of any type. It will fit in the garage, give warmth to a small workshop, and heat the basement. Its assembly does not take much time, but you need to pay attention to the choice of source material. The selected barrel should not be rusted through - the thicker the metal, the longer the stove itself will last. Therefore, you do not need to save on assembly materials.

Other advantages of a barrel stove:

- The volume of 200 liters is enough for normal combustion of a flame in the furnace.

- Possibility to organize a spacious and easy-to-clean ash pan.

- Unpretentiousness to fuel - the stove will be able to work on anything that burns.

- Easy to operate.

A potbelly stove from a 200-liter barrel is in certain demand among those who need inexpensive and easy-to-assemble heating equipment.

There are also disadvantages:

- High case temperature.

- Low efficiency - some of the heat simply flies into the chimney.

- Thin Walls - Durable furnaces require 3-4mm metal.

You should not try to heat the stove from a barrel with coal - it has a high combustion temperature and can thin the metal.

Assembly sequence

A barrel stove is easy to assemble and requires an equally sophisticated tool. We will need:

- angle grinder (grinder);

- welding machine;

- a hacksaw for metal for working with small parts (it's more convenient this way);

- grinder machine.

We suggest that you familiarize yourself with Do-it-yourself repair of the blind area around the house

You will also need auxiliary materials:

- pieces of sheet metal - for scalding doors;

- door hinges;

- chimney metal;

- metal for the legs;

- brick and cement for organizing the base for the stove;

- fittings for creating a grate.

Prepare cutting wheels for the grinder and electrodes for the welding machine (if electric welding is used).

Making a potbelly stove from a barrel is not the most difficult task, the main thing is to follow our instructions exactly and observe safety precautions.

Making a stove from a barrel with your own hands is as easy as shelling pears. The first step is preparing our "source". A barrel with a volume of 200 liters must be cleaned of paint (if it has been painted). Those who neglect this step will have to inhale the aromas from the burning paint. Our goal is to make the barrel shiny, and at the same time get rid of rusty stains. Use a grinder to grind metal.

In the next step, arm yourself with a grinder and carefully cut out two rectangular windows in the barrel. Work with the tool carefully, as the sawn out rectangles will be useful to us as doors. We process the edges with the same grinder or file so that they are not so sharp. The door for the firebox should be larger than the door for the ash pan. In addition, the ash pan door will serve as a blower.

Cut off the top of the barrel completely. We will need to collect and place a grate inside the 200 liter barrel. Therefore, the absence of a top cover will ensure the convenience of its installation.

For the manufacture of a grate, use fittings. The diameter of a standard 200 liter barrel is 571.5 mm. Therefore, the lattice must be smaller in diameter in order to pass through the internal volume. At the level between the firebox door and the ash pan door, we make arbitrary projections - the grate itself will rest on them. For example, you can make them from sheet iron and weld them to the inner walls.

A potbelly stove from a barrel will generate quite a lot of ash that falls into the ash pan. Therefore, it must be large - the recommended height is 100-130 mm. Do not make the door too narrow, otherwise there will be problems with the ease of cleaning.

The doors of our stove will be clearly smaller than the loading and ash windows. Therefore, they must be scalded around the perimeter with pieces of sheet iron about 20 mm wide. We also cut out handles from sheet iron, rivet or screw them to the doors. At the next stage, we carefully weld the hinges, after which we weld the doors to the stove itself - now our 200 liter barrel is almost ready to serve a second life.

Making the foundation

For our 200 liter barrel, it is desirable to make legs. Adapt pieces of thick reinforcement for this or make them from metal corners with a thickness of 2-3 mm. The optimum distance from the bottom of the barrel to the base is 100 mm.

Intending to make a potbelly stove from a barrel, think about the place of its installation. You will need a reliable, non-flammable base. It is best to make it out of bricks or pour in a concrete screed. The space in front of the stove is made of non-combustible material - for example, sheet iron laid here. If the floor in the heated room is concrete, just lay a sheet of iron on it and place a barrel on it.

The design of the stove from a 200 liter barrel implies the obligatory presence of a chimney. It would be nice if it was removable - a pipe-in-pipe system is suitable for this. That is, we weld a pipe of a smaller diameter with a height of 100-150 mm to the stove, and already we put on the main chimney of a larger diameter on it.

We take our 200 liter barrel with legs welded to it, install it on a previously prepared base. We lower the grate inside. In the next step, we weld the top cover with a short chimney. Next, we put on the main chimney on it and go for firewood.

We offer you to familiarize yourself with the ceiling in the bath inside with your own hands

Put some paper and small chips on the grate, light a fire, achieve a steady flame. Now start laying the main firewood - it is best if it is dry. Wet logs burn worse, and even smoke, clogging the chimney. Close the door of the firebox and adjust the intensity of combustion with the blower. Do not forget to periodically add new portions of fuel until the set temperature is reached.

Oven collection sequence

So, let's look at how to make a stove from a barrel. The self-assembly technology is quite simple, but it requires strict adherence to the entire sequence:

- Remove paint or rust from the inside and outside of the barrel, then cut the top off. Cut the metal carefully to minimize the risk of deforming the metal.

- Cut a circle out of metal that will be smaller than the diameter of the inside of the barrel, and then make a hole in it for a pipe.

- Make a lid from the cut off top of the barrel or sheet steel of sufficient thickness, then cut a hole for the pipe.

- Cut a neat hole in the barrel for the fuel supply, as well as a hole slightly below for cleaning the ash.

- Create a chimney based on a metal pipe, but at the same time the angle of any bend of the smoke outlet should not be more than 45 °.

A mandatory stage of assembly is the manufacture of a capital non-combustible base in one brick, followed by pouring with cement mortar... It is allowed to replace the main base with a metal sheet, the dimensions of which exceed the dimensions of the furnace by half a meter.

When assembling the heating structure, it must be borne in mind that a prerequisite is the installation of a straight section of the chimney, which must be longer than the diameter of the barrel used.

Another option for a barrel stove

In this case, the stove will be manufactured in this way: 1. The firebox is equipped in the same way as in the first version of the furnace equipment. Only the upper part of the structure needs to be changed. 2. The firebox should be covered with a "dull" steel tile to which the flue gas tile must be welded. The distance between the walls of the barrel and the pipe should be laid with stones.

It is possible to make an oven in which there will be a liquid tank. 1. A grate should be installed above the firebox. you can also use a plate with holes. Flue gases will penetrate through them. They will go between stones and out through a pipe. 2. Above the chamber in which the stones are located, you need to install a tank in which the water will be heated.

It is possible to make this tank from the lower half of another barrel. To do this, you just need to attach a chimney to it, as well as a cover. 3. It is also worth welding a pipe to the tank, through which cold water will be supplied and hot water will be taken. 4. In the upper side of the chamber, in which the stones are located, you need to install a steam door.

You can find out more about how to make a sauna stove from two barrels yourself here.

How to order a bath from us? - Elementary!

| Make an application on the website It will take less than 1 minute | Consultation Our manager will contact you by phone and clarify all the details | Conclusion of an agreement Signing of all necessary documents | Production Your bath will be manufactured at our factory | Delivery and assembly The bath kit will be delivered and installed on your site |

5 reasons why there are already 873 people

entrusted the construction of baths to us!

| Bani.rf is a brand that is trusted by millions of people! | No pitfalls We discuss in advance all possible additional expenses | We comply with the terms We clearly outline the stages and terms of construction, then we comply with them | Quality of materials Only tested and proven construction products | A team of professionals Experienced specialists and responsible foremen |

A feature of heating greenhouses is the need for uniform heat supply over a large area. This is usually accomplished in the following ways:

- Natural convection method

A garden oven from a barrel is installed at the entrance to the greenhouse, and a chimney at the opposite end. A pipe with a slight upward slope runs along the entire greenhouse, connecting the stove to the chimney. Hot gases passing through the pipe heat it along the entire length, and the greenhouse is heated more evenly over the entire area due to the natural convection of warm air.

- In a 200 liter drum, the top cap must be removed.

- In the side part, cut three holes for standard oven doors for the ash pan, firebox and heater. The hole in the ash pan should be located above the bottom at the height of one layer of brick, above it there is a hole in the firebox, and the hole in the stove should be closer to the top cover of the barrel on the opposite side.

- Lay out the bottom and bottom of the barrel up to 60 cm with a thick layer of refractory bricks, forming the volumes of the ash pan and combustion chamber, dividing them with grate bars.

- Weld the doors, sealing all the cracks with cement mortar.

- Install a grating made of metal profiles with a gap of 5-8mm, separating the stove from the firebox, and line the walls with a thin layer of refractory bricks up to the top.

- Lay granite stones on the grate in several layers, starting with large ones and ending with small ones. The smoke should pass freely between them. The upper border of the stones should end at the level of the beginning of the door.

- Weld the door into the stove, sealing the cracks with cement mortar.

- Drill a hole for the chimney in the top cover of the barrel and weld a branch pipe there.

- Close and seal the barrel lid tightly. On the side surface of the barrel or on the lid, you can attach a hot water tank connected to the water supply system.

Diagram of a horizontal furnace from

The stove is installed in the bath so that the door of the firebox looks into the dressing room, and the door of the heater looks into the steam room in compliance with all fire safety measures. It should be heated like a regular potbelly stove, using wood, pellets, coal, etc.

We offer you to familiarize yourself with Choosing and building a foundation for a bath from foam blocks depth views How not to bring down a building

Instructions

At a certain moment of construction, the question arises of how to properly design a stove on your own. A 200 liter barrel is just becoming one of the most suitable frames. The oven can be distinguished by shape and size, it can be round, square, located horizontally or vertically. It all depends on the imagination and on the premises.

To understand the principle of operation of the device, it is enough to understand the diagrams and assembly stages.

Vertical model

Vertical stoves are made in the following sequence:

- Preparation of an opening on the side of the barrel in order to ensure the possibility of loading fuel.

- The door can be purchased in advance, or you can try to adapt the cut part from the wall of the container instead of it - by welding a handle to it, hinges for the convenience of opening and closing the firebox.

- Just below the door, cut an additional hole for installing the blower door. To create a blower, a thick-walled pipe is used, which could move along the metal slats, but not be pulled out completely.

- Grates are mounted 20 cm above the bottom of the barrel - this is a metal plate with holes, it can be replaced with a cellular piece made of reinforcement. Fixation is done by means of a steel angle.

- At the bottom of the barrel, metal legs are welded or the structure is simply installed on bricks.

- Steel wire plays the role of the cooking panel; it is welded to the top cover of the furnace.

- To protect the walls from burning inside, the firebox can be finished with refractory bricks, giving it the shape of a semicircle with a grinder. The masonry is done with a special oven mortar, which contains a part of oily clay and two parts of sand. Such a mixture is diluted with the minimum possible volume of water, it should turn out to be very thick.

- Then the chimney is formed. The hole for the pipe is at least 15 cm in diameter, usually made on the side or top of the barrel. The height of the chimney is more than 4 m. To reduce the load on the body, the chimney should be additionally fixed against the wall.

- On the chimney, you can make a rotary or moving valve. It will help you quickly adjust the removal of heated smoke, completely blocking the chimney when the stove is not working.

Vertical oven

Horizontal model

From a barrel with a volume of 200 ml, you can also make a device for heating the room, which would have a horizontal arrangement. First, it is important to prepare the structure for supporting the frame. The height is calculated taking into account the features of operation. When choosing this indicator, you should first pay attention to the area of the room where it is planned to mount a homemade potbelly stove.

The drawing always takes into account the features of the placement of the furnace. The assembly of the horizontal unit is almost identical to the vertical one. In more detail, the process includes the following steps:

- A hole must be formed in the bottom of the prepared barrel, which will be used to remove ash. It is important to understand that its size should not be too large.

- Now you need to build an ash pan. Its dimensions should not be more than a third of the canister's height. The height of a 200 liter barrel is 85 cm - according to this parameter, the calculation is carried out. As a material, you need to pick up an ordinary sheet of metal that would fit in thickness. It is joined to the bottom of the heater. For this, welding equipment is used.

- For arranging the ash pan, it is required to provide another viewing window, through which the compartment must be cleaned. Then the installation of the chimney structure is carried out. The two most popular pipe locations are at the back or top.

Horizontal oven

A long-burning potbelly stove, which is placed horizontally, can be used not only for heating garages, basements, various buildings, but also for cooking and heating food. For this purpose, it is complemented by an arched panel. The device turns out to be mobile, so they even take it with them to nature.

Modernization of the structure

These steps will help you make your barrel stove more efficient. If you do not find a sample for 200 liters, you can take 150 liters - there will be a little less space in it, so you will have to throw up the firewood more often.

- To the right, to the left and to the back of the barrel, brick walls are being built - they will work as a kind of heat accumulators.

- The stove is scalded with round pipes of a small diameter (for example, ¾ inch) - a convector is formed, which will cause air circulation in the room and effectively remove heat from the stove.

- By lengthening the horizontal part of the chimney - lead it through the entire room in order to take maximum thermal energy from the combustion products.

We will offer you a few more ideas for modernizing the stove from a 200 liter barrel. For example, you can lay out the inside of it with refractory bricks. To organize the hob, use the cast iron insert in the top cover. Try to make a stove with increased heat dissipation - weld two barrels together in height. There are also modifications with horizontal barrels.

Interesting potbelly stove with stone masonry

A 200 liter barrel can serve as the basis for another interesting stove - with a masonry inside. To build it you will need:

- the barrel itself;

- thick metal wire or reinforcement;

- large rounded river stones;

- chimney pipes.

There is no ash pan in such a stove, so there will be some difficulties with cleaning. We immediately recommend making the door of the firebox at the level with the bottom of the barrel - this way it is more convenient to rake out the ash. From reinforcement or thick metal wire we make a kind of grate. Only here it will fulfill a different role - it will support the masonry.

To assemble the stove, it is necessary to cut off the top cover from a barrel with a volume of 200 liters and equip it with a pipe for connecting the chimney. In the lower part, we cut out a door for laying firewood with a height of 150-200 mm. We fix a grate at a height of 250 mm, on which we pile stones to the top. Please note that it is precisely large stones that are needed so that combustion products pass through the space between them.

The stove will need a solid non-combustible base with a metal sheet in front of the firebox - it will be quite weighty, so the legs must be strong or absent altogether. The barrel is placed on the base before the stones are placed in it. Otherwise, you won't budge it later. After installing the stove in its original place, weld the lid and connect the chimney - you can start kindling. To improve traction, it is recommended to drill several holes with a drill with a diameter of 4-5 mm - air will be sucked in through them.

The optimal chimney height for both stoves described in the review is at least 3-4 meters - this will provide an acceptable draft.